Setting up toilet fittings: how to properly adjust the drainage device

The internal filling of the tank is not a very complicated device, but its breakdown can significantly reduce the comfortable feeling for the residents of the house.It happens that everything looks normal, but the operation of the drain mechanism leaves much to be desired.

To eliminate problems, you will need to properly configure the toilet fittings. This procedure must be performed when installing plumbing fixtures, and later the drain operation must be periodically adjusted.

If you encounter such a problem, our material will help you quickly solve it, without even resorting to the help of specialists. We will tell you how to get your toilet flush working properly. For clarity, the material contains thematic photos and videos.

The content of the article:

Types of fittings for flush cisterns

The principle of operation of a conventional tank is not complicated: it has a hole through which water flows and a place where water is discharged into the toilet. The first is closed with a special valve, the second with a flap. When you press a lever or button, the flapper rises and the water, in whole or in part, flows into the toilet, and then into the sewer.

After this, the valve returns to its place and closes the drain point. It works immediately afterwards drain valve mechanism, which opens a hole for water to enter. The tank is filled to a certain level, after which the inlet is closed. Water supply and shut-off are adjusted using special valve.

There are separate and combined designs of fittings that collect the volume of water required for flushing and drain it after activating the flushing device.

Separate and combined options

Separate option has been used for many decades. It is considered cheaper and easier to repair and configure. With this design, the fill valve and damper are installed separately, they are not connected to each other.

To control the flow and shutdown of water use float sensor, in the role of which even a piece of ordinary foam is sometimes used. In addition to a mechanical damper, an air valve can be used for the drain hole.

A rope or chain can be used as a lever to lift the damper or open the valve. This is a typical option for retro-style models, when the tank is placed quite high.

In compact toilet models, control is most often carried out using a button that needs to be pressed. For those with special needs, a foot pedal may be installed, but this is a rare option.

In recent years, models with double buttons have been very popular, which allow you to empty the tank not only completely, but also halfway, in order to save some water.

Separate option fittings is convenient in that you can repair and configure individual parts of the system separately.

Combined type fittings are used in high-class plumbing; here the drain and water supply are connected into a common system. This option is considered more reliable, convenient and expensive.If this mechanism breaks down, repairs will require completely dismantling the system. Setup can also be a bit tricky.

Materials for making devices

More often toilet fittings made of polymer materials. Typically, the more expensive such a system is, the more reliable it is, but this method does not provide clear guarantees. There are also counterfeits of well-known brands, as well as quite reliable and inexpensive domestically produced products. The average buyer can only try to find a good seller and hope for luck.

Bronze and brass fittings alloys It is considered much more reliable, and such devices are much more difficult to counterfeit. But the cost of these mechanisms will be significantly higher than that of plastic products.

Metal filling usually used in high-end plumbing fixtures. With proper configuration and installation, such a mechanism functions smoothly for many years.

Water supply point

An important point is where water enters the toilet. It can be done from the side or from below. When water is poured from the side hole, it produces a certain amount of noise, which is not always pleasant to others.

If water comes from below, it happens almost silently. Bottom feed water in the tank is more typical for new models produced abroad.

But traditional domestically produced tanks usually have side feed water.The advantage of this option is its relatively low price. Installation also differs. Bottom water supply elements can be installed in the tank before it is installed. But the side supply is installed only after the tank is installed on the toilet bowl.

Typical problems with the tank

Problems with the tank most often arise for three reasons:

- due to improper installation;

- after incorrect setting of the fittings;

- as a result of wear or breakdown of individual components and elements.

If There is too much or not enough water in the tankFirst of all, it is recommended to check the condition of the float. If it is held by a thick wire lever, adjustment will be easy.

It is enough to slightly bend the metal so that the float changes its position. If more water is needed, the float must be moved higher. To do this, the wire is bent in an arc downwards.

If There is too much water in the tank, the float should be lowered slightly. To do this, the wire holding this element is bent upward in an arc. But in the new models, all elements are made of plastic that cannot be bent. Here, a special screw is provided to change the position of the float. By rotating it, you can move the float to the desired level.

Sometimes lack of water in the tank is not due to the incorrect position of the float, but to contamination of the flow holes through which water flows. In this case, you need to remove the float from the mechanism, then remove the membrane covering the hole and wash the mechanism.

In order to adjust the level of water entering a tank with a simple float tap, you need to do a few simple steps:

Of course, before starting any manipulations with the tank, it is necessary to turn off the water in the riser.

If water flows into the tank continuously, which means you need to check the condition of the membrane or valve with which the float valve is equipped, for this:

Prudent owners, even when installing a toilet, install a shut-off valve directly in front of it. In this case, there is no need to shut off the entire riser; it is enough to turn off only the tank and start repairing and setting up.

Sometimes the following unpleasant situation occurs: water constantly flows out of the tank, and the tank is either only partially filled or remains practically empty. Most likely, the culprit is a locking mechanism that is installed incorrectly or worn out.

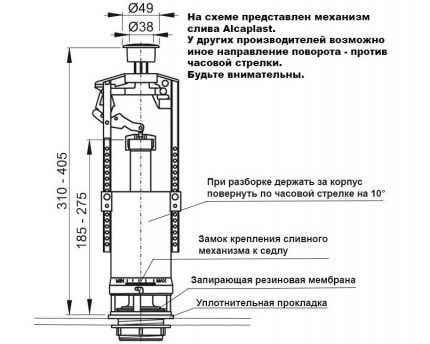

We replace the water drainage mechanism as follows:

Most often, it is enough to simply tighten the mounting bolts that secure the locking device in the correct position.

If this does not help, you need to check the valve for wear and clogging. To do this, the valve is removed, disassembled and washed, and if necessary, the worn membrane is replaced.

Sometimes rubber gasket fails, which is installed between the tank and the toilet. In this case, water will flow out of the tank and accumulate on the floor near the toilet.

To fix this problem, you will need to completely dismantle the tank, replace the leaky gasket and install the tank in place.

Construction and adjustment of the compact

Compact toilet models have recently become widespread. It makes sense to consider their design in order to understand the main features of adjusting and repairing the locking mechanism.

The compact toilet consists of the following elements:

- cistern container with lid;

- system for filling water into a container;

- shut-off device or water drainage system;

- control button or lever;

- toilet.

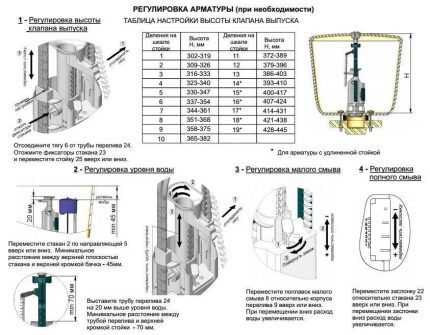

The tank in the compact is installed on a special shelf, which is located behind the bowl. Typically, adjustment of the fittings of such a toilet is carried out after the cistern bowl is installed, but before its lid is installed. Before starting work, it is recommended to carefully study the manufacturer's instructions. Usually there is detailed information about the procedure for performing the work.

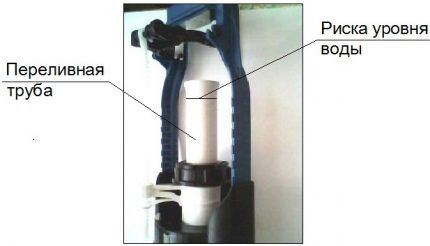

The overflow pipe of the device usually indicates the water level that is considered normal for that particular model. You need to find this designation, which is often made in the form of a strip or bead. Usually, if, when filling the tank, the maximum water level is below this mark, poor-quality flushing of sewage is observed.

To change the situation, you need to move the “glass” on the intake valve to a higher position. To do this, loosen the clamps holding this element located under the float. After the required level has been set, you need to check the result of the work, i.e. fill the tank and drain the water.

When installing tank fittings, it should be remembered that all moving parts of the valves must be separated by a distance, at least small. If the valves come into contact during operation, this can disrupt the normal operation of the system, leading to its imbalance and breakdown. It is also unacceptable for the moving elements of the fittings to come into contact with the walls of the tank.

To prevent water from splashing when filling the tank, you most often have to cut or change the filling tube:

An important step in installing the tank is installing the lid with a push-button regulator. Before screwing it in, there should be a distance of no more than seven millimeters and no less than three between the cover and this unit. If these conditions are met, the cover will be fastened securely enough.

Before you start screwing the flush button, the instructions recommend making a couple of turns in the opposite direction, i.e. counterclock-wise.

This will center the thread position.After this, screwing the button assembly is carried out clockwise. You need to rotate it by hand until it stops; additional tools are usually not needed. Upon completion of installation, you should drain the water again to make sure that the button and all fittings are configured correctly and installed correctly.

Compacts are produced with both bottom and side water supply. With fittings designed for bottom water supply, a problem such as clogging of the filter installed at the water supply to the container may arise. After flushing, i.e. During the process of filling the tank, a characteristic, rather loud and unpleasant whistle is heard.

This situation most often indicates that the filter is clogged and needs to be washed. The debris accumulated inside reduces the clearance for water, which enters the tank with high pressure and accompanied by sound effects. In addition, due to this malfunction, the tank fills much more slowly than usual.

To correct this plumbing problem, you need to flush this filter. To do this, turn off the water supply to the tank and press the flush button/lever. After this, remove the hose through which water flows to free access to the device. Now the filter just needs to be removed from the intake valve body, washed and installed back. The system is then reassembled in reverse order.

It looks simple in theory, but in reality there can be some complications. For example, you need to unscrew the plastic nut that secures the inlet valve. If this element does not have edges, the task may seem difficult.

You should not use an adjustable wrench in this situation, as excessive force may damage the fastener. It’s not always possible to just do it with your hands, especially if the plastic has become “burnt” as a result of prolonged use.

Experts recommend using other means; pliers with a large space between the “lips” may be a suitable option. Pliers can also be useful when removing the filter from the housing, since it usually fits tightly and will require additional effort for removal.

Where the quality of tap water remains consistently low (that is, almost everywhere), not only the filter, but also other elements can become clogged. The membrane bushing is at risk, as well as all the holes through which water enters.

If washing only the filter was not effective enough, it makes sense to rinse the entire device and clean all the channels. In this case, you will have to completely dismantle the inlet valve to provide access to the holes.

Unfortunately, washing the filter, and even the entire valve and ducts, does not always help. Low quality intake valves can completely fail within one and a half to two years after the start of operation. In this case, you will have to completely replace the valve with a new model. In such a situation, it is recommended to choose a higher quality filter.

The additional costs will pay off, since there will be several times fewer problems with setup, flushing and repairs. Another way to prolong the operation of the tank fittings and prevent problems: install an additional mechanical filter on the water pipe in front of the toilet or even at the entrance of the system to the apartment.

If the compact has problems with the shut-off valve, i.e. water constantly leaks into the toilet, then the easiest way to fix the problem is to completely replace the device with a new one, exactly the same. To do this, you need to turn off the water and simply remove the valve from the tank.

The new one is installed in its place, fixing it in the holders of the receiving part. It is recommended to adjust the length of the valve in advance so that there are no problems with installing the flush button.

Conclusions and useful video on the topic

The process of adjusting and repairing the shut-off valves of the toilet cistern can be viewed in detail here:

Setting up the tank fittings is not difficult. It is important to study the instructions and understand the general principles of operation of the inlet and locking mechanisms. Attention to detail and accuracy will help to complete all the work correctly.

Have you already encountered setting up drain fittings and were able to cope with this task yourself? Or maybe you know other ways to configure the drain? Please share your experience in the box below.

This information is right on topic for me. The tank began to behave strangely: it would not fill. It’s expensive to call a plumber every time; it’s better to learn how to fix it yourself. I read it and realized that the problem was with the float.It turns out that all you have to do is bend the wire a little and everything will work out. If that doesn't help, I'll clean the membrane. The main thing is that these are all elementary actions that anyone can handle.

A case from my practice. A neighbor came to me with her problem: water was constantly leaking from under the tank of her compact. I came, looked, touched the tank, it was a little wobbly. I tightened the nuts on the bottom and it seemed to have stopped. A few days later (I was on duty for a day) he comes and says that it’s leaking. The reason turned out to be the gasket, which between the tank and the toilet appears to be intact, only with a scratch on the bottom. With excessive compression, it somehow miraculously turned into a banal crack (modeled in a vice). Replaced it and everything went away. And the design of the shut-off valves is so transparent that setting it up is not particularly difficult.

For any repair, in general for any disassembly, it is better to replace all gaskets. They are inexpensive, but you will be insured against troubles.

It's not the same! My compact is not here, I can’t catch it and adjust it so that it works normally and correctly: either there is no pressure, or the lever slightly raises the overflow tube...

Can you be a little more specific? What fittings are installed in your toilet cistern? Here you can even attach photos so that you get a constructive answer to your question. If you cannot adjust the current fittings in the cistern, then they need to be replaced. It is possible that defects have appeared in it that are not compatible with normal operation.

If you have a faucet with a float, then it will not be difficult for you to adjust and set the required water level.And if you have fittings without a float, then you need to adjust a special adjusting screw (there is a lock nut), loosen it and move the regulator closer to the tank valve, this will reduce the water level in the tank.

Check for debris between the valve seat and the gasket; this may cause the valve to malfunction.

This blue fittings are bullshit! I recently bought one with 2 flush modes. I puffed for more than 3 hours to set 2 drain modes. But I couldn’t (this is the first time). Maybe marriage!?

The difference between pressing the small and large flush buttons is small. You can only set 1 mode. Either a small drain (then it is not fixed on the larger one) or a large drain (then the small button is fixed on the large drain). There is no limit to my indignation! what the... did I buy!?

The fittings on the santek tank will fill the tank 60%, a short solid overflow tube, not height adjustable, how is that? Why?

Grohe floor-standing toilet. When installed, the tank lid with buttons immediately puts pressure on the drain and does not allow the valve to close. I also cannot set up a double drain. Please tell me how to get rid of this problem.

In what position should the rod be secured? I now have it in the lowest position and it slams a lot when closing

What kind of traction are we talking about? And where does she clap?