Toilet installation repair: possible malfunctions and ways to eliminate them

Installing a wall-hung toilet has many undeniable advantages.However, strong practical and aesthetic priorities are occasionally overshadowed by breakdowns that require correction. Agree, you shouldn’t even try to restore plumbing if you don’t know how to repair a toilet installation.

We are ready to help you deal with the problem that has arisen. The article we have proposed describes all the ways to eliminate minor problems and serious problems in the operation of hanging plumbing. Valuable recommendations for operating the equipment and preventing negative situations are given.

For you, we have collected and scrupulously systematized all the options for breakdowns, and thoroughly analyzed the methods of dealing with them using examples. The information is confirmed by photos and video guidance.

The content of the article:

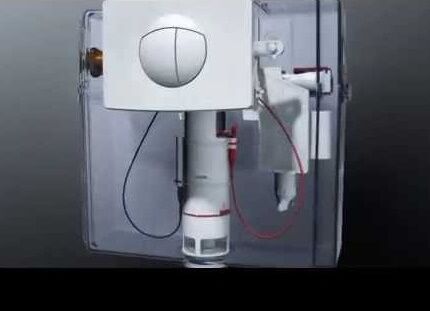

Operating principle and design of the toilet

The installation system has a similar operating principle compared to the usual tanks. When you press the water release lever or button, the valve in the lower hole of the tank rises, after which the bowl is washed with water. When the tank is empty and the button is released, the valve returns to its original position under its own weight.

Then the automatic tank filling mechanism comes into operation. It consists of shut-off valve, which is connected to the water supply.The shut-off valve operates synchronously with the float.

When the tank is empty, the float moves down and opens the valve to fill the tank. Water arrives in the container and the float floats up in parallel. When it reaches a certain upper point, the water supply stops and the shut-off valve closes.

Today you can often find tanks with economical flushing, where there are two buttons, one of which allows you to use any part of the tank’s volume.

Types of problems with wall hung toilets

All breakdowns can be divided into several categories, each of which is tied to a specific unit of a given type of plumbing:

- violation of the integrity of the drain tank;

- a lot of water flows out (the bottom valve cannot cope due to wear or clogging);

- malfunctions in the drain mechanism (the tank does not fill or fills continuously);

- violation of tightness when supplying water to the tank (connections of flexible hoses/fittings are not sealed sufficiently).

Direct repair of the toilet installation may concern smaller elements in the structure. The main labor intensity of the work is associated with replacing components or the entire mechanism in the drain system.

Malfunctions can also be caused by a violation of the shape of the frame on which the installation system is located. This applies to low-cost models from dubious manufacturers or fakes.In such products, the frame is made of thin profiles that can simply bend under the influence of the weight of the water tank.

Instructions for DIYers

Most of problems in systems with installation or traditional models is associated with the appearance of malfunctions in the tank mechanism. The reason for this may be poor water quality, which over time causes corrosion of metal elements and also contributes to the deposition of sediment.

If you discover that water has stopped filling and draining correctly, you will probably have to perform several actions.

#1: Water slowly fills into the tank

We clean the mesh filter at the entrance to the tank (if there is one). You need to disassemble the unit and remove the filter to rinse and clean it with a soft toothbrush. The fractions that water carries with it could clog the mesh cells.

If little water enters the tank, then it is necessary to adjust the position of the valve and float. This can be done by bending the metal arm, ensuring that the float takes the correct position when filling the tank.

We repair the float valve. In some cases, it could simply be skewed and need to be straightened. In other cases, you need to check the lever that connects the float and the valve. If there is a communication failure, the valve will constantly shut off the flow of water even when the float is lowered. You also need to flush the inlet valve.

#2: Outlet valve clogged

After flushing, the tank begins to fill, but after the float reaches the top position, water still continues to flow into the tank. The issue is most likely a clogged valve due to the fact that there are many inclusions in the water and they are deposited on surfaces.

There is no need to completely dismantle the valve - just loosen the fasteners a little to remove the rubber gasket.

It must be rinsed under strong water pressure, and the valve cover must also be rinsed. After this, you can assemble.

#3: The drain button does not work

When you press the drain button, nothing happens. Flushing problems are associated with faults in drain fittings, in particular, with a violation of the connection between the valve and the button. In this case, it is best to replace the drain fittings.

If you still want to pick up spare parts and make repairs yourself, we recommend contacting the equipment supplier. A repair kit from another brand will not work.

#4: Water leaks regularly

Water constantly flows into the bowl in a thin stream. To eliminate additional water consumption, you need to replace the rubber gasket that serves to seal the drain hole. The resulting gap or decrease in sealing density can serve as cause of leakage.

Sometimes the exhaust valve may become deformed after prolonged use. In this case, replacing the rubber gasket will not help and you will have to change the entire mechanism.

Another reason water leaks An emergency tube may be lowered into the bowl, which serves to remove excess water. This happens as follows: if the inlet valve and float system breaks down, a continuous flow of water will drain directly into the toilet, preventing the bathroom or toilet from flooding.

The solution to this problem can be done in two ways. The first is to raise the emergency tube higher. If there is simply nowhere to raise the tube higher, then the second method is suitable - lower the float lower, doing this with screws. This will slightly reduce the amount of water in the tank and help stop the leak.

We carry out repairs float valve. In some cases, it could simply be skewed and need to be straightened.In other cases, you need to check the lever that connects the float and the valve. If there is a communication failure, the valve will constantly shut off the flow of water even when the float is lowered.

Replacing the rubber gasket should solve most problems associated with poor water line shutoff. Many modern models are deprived of the usual polymer gasket, having a one-piece plastic inlet valve. In this case, you will have to completely change the valve.

#5: Replacement of installation required

The extent of dismantling depends on the design. Some manufacturers produce models with an inspection window through which you can repair the drain tank. For models from popular manufacturers, the drain button is simply dismantled, after which the technician gains full access to the mechanism.

Unfortunately, not every model has such amenities, so you often have to dismantle the partition or tile. The possibility of revision must be laid down at the stage of installation of the system with installation.

Once access to the tank is gained, the following operations must be performed:

- Remove the flush button. As a rule, it just needs to be squeezed out from the reverse side so that it falls out of the cordon.

- Remove frame. We unscrew the screws that serve to fix the frame, and then remove the pusher clamps. Now the frame can be removed.

- Remove the partition. Tighten the latches and remove the partition.

- Turn off the water and press the drain button. We must not allow the renovation to turn into a flood.

- Blot the inner surface tank with a rag, since working with wet parts is inconvenient.

- Remove reinforcement block and remove the inlet valve.

- Remove the drain valve retainer.

Now you can replace any components by reassembling in reverse order. Before changing spare parts, the installation sites must be completely cleaned of rust and sediment. To do this, you can use WD-40 and similar products.

#6: Dealing with bowl defects

The toilet needs to be repaired in the following cases:

- crack/chip formation;

- wear of the cuff, which serves to connect to the sewer;

- clogging.

Damage to the bowl could occur after draining hot liquid, as well as due to mechanical impact. If a crack appears at the bottom of the toilet bowl, you will have to completely replace the bowl.

If the damage is located at the top or where the screws are attached, then the following set of consumables and tools will fix the crack:

- sandpaper;

- sander;

- drill with small diameter drills;

- epoxy resin and solvent.

The edges of the crack need to be drilled out to stop further cracking. Clean the crack along its entire length and degrease the surface. The space inside the crack must be filled with resin or glue with similar properties.

After this, you need to leave the toilet for a day until the adhesive composition completely crystallizes. The next day, sand the seam area.

If a puddle begins to appear under the toilet, then it’s time to change the cuff.This seal is used to seal the connection between the sewer pipe and the toilet flush. Replacement begins with removing the worn gasket. Using a knife, you need to clean the surfaces of the pipes from dirt. Everything should be thoroughly degreased.

Then the joint is treated with sealant. A new cuff is inserted into the sewer hole and placed on the toilet flush. You can additionally take silicone sealant from above and apply it to the contacting surfaces.

The toilet may become clogged after prolonged use. To clean hard-to-reach surfaces, you will need a plunger, plumbing cable and chemicals.

First you need clean the drain using a cable and a plunger. Then add the “chemistry” and wait a certain time. When working with chemicals, you should use safety glasses, a mask and clothing that completely covers your skin. After the chemical reactions, rinse and treat the bowl again with a plunger and cable.

#7: The microlift on the lid is broken

With ordinary lids, owners don’t “bother” by buying a new one after wear, since it is inexpensive, and the market offers models for every taste. Products with a microlift are significantly more expensive. The slow lowering mechanism may have broken due to forced closure.

To restore the microlift, tightening the side mounting screws often helps. If this does not help, then the entire mechanism needs to be changed.

Correct operation of the installation system

The premises where it is produced installation of a wall hung toilet, acquires a special charm. It is for the sake of improving the interior that many choose systems with installation. This facilitates faster cleaning of the room, since all engineering parts are hidden behind the wall, including valves and pipework.

When installing such a product, it is necessary to leave space for the inspection compartment, through which inspection and dismantling can be done.

The main enemy of any plumbing is water and the impurities it carries. Its aggressive composition can lead to clogging and rust within a year. Therefore, it is recommended to use filters at the entrance to the tank.

The presence of at least a coarse filter will significantly reduce the accumulation of dirt inside the tank, which will certainly increase its service life.

Do not forget to purchase a repair kit along with the purchase of the system. In the future, the search for compatible components may become more difficult, especially for products from foreign manufacturers that use non-standard and unique drain designs in the tank.

Conclusions and useful video on the topic

The video will help you avoid mistakes when installing the installation and improve your understanding of the repair process.

Advice from experienced engineers will allow you to quickly find the cause of a malfunction in your toilet installation and promptly eliminate it.Study the principle of operation of the drain system, and you will be able to find the cause of the breakdown yourself.

What kind of breakdowns have you encountered while using your toilet installation? Tell us about your personal experience and ask questions in the comments to the article.

How timely I came across this article. Now I will solve the problem with the tank. At first the flush didn't work. The valve did not seem to be clogged, I washed it myself. It's too early for wear and tear, it has a one-year warranty. Now the water is constantly running, but the gasket was changed not so long ago. Most likely, the system will have to be completely changed. I’m not sure that I can handle it, although everything is written out step by step. I think it's better to trust a specialist.

Repairing such a system cannot be difficult. The simplest thing is to replace the parts with new ones; they are not that expensive. In our case, a simple adjustment of the valve helped, or rather, adjusting the position of the float. We noticed something was wrong only by the appearance of rusty deposits in the toilet due to a constant, barely noticeable stream. There are probably reliable mechanisms made of hard materials, but this is clearly not the case here, since the correct position of the parts changes over time.

Several years ago (about 2 years), we installed a wall-mounted toilet with a flush barrel hidden in the wall from Geberit. We noticed a damp smell in the room—a moldy smell that was difficult to breathe. The smell came from the box with the water drain buttons. We opened it and found drops of water collecting on the top of the drain barrel box.

I can’t find any information on how to solve the problem of condensation inside the tank. The tank is insulated with foam plastic. We would be grateful to receive advice on how to resolve the problem.

I took out the drain valve, and the gasket remained inside the drain barrel. How to get it? oli system