Do-it-yourself barn ventilation: types of systems, air exchange rates + procedure for arranging the system

Have you ever had a situation on a farm when, with a balanced diet and warm conditions, cows suddenly began to produce less milk or the quality of such milk yield significantly deteriorated? Agree, this is not a very pleasant situation. Especially if animals begin to get sick for no apparent reason.

For productive cattle keeping, the room must have a stable microclimate with proper air circulation. Increased humidity and temperature changes are most often the causes of decreased milk production and loss of live weight. This situation can be corrected if the exhaust system is properly designed and installed.

In this article we will tell you how to do barn ventilation with your own hands. Let's look at the existing types of exhaust systems and talk about how to select equipment for them.

The content of the article:

Functions of ventilation in a barn

Typically, barns are built from reinforced concrete slabs. Such structures are quickly erected, they are strong and durable. Along with the advantages, concrete buildings also have a number of disadvantages: lack of air circulation, which is why it is stuffy inside the building in summer and cold in winter.

Cow waste causes the formation and accumulation of ammonia.If there is no circulation of air masses, the gas accumulates, and its high concentration can harm animals. In such an environment, bacteria multiply faster. Acrid fumes corrode the mucous membranes, causing dry mouth and stinging in the eyes.

Poor living conditions lead to a decrease in the immunity of cattle and losses to the farmer. Therefore, for any barn, as well as for chicken coop or other premises for keeping animals and birds, a ventilation system is required. It removes carbon dioxide and provides fresh air without creating drafts.

Types of ventilation systems for cattle

There are several variations of ventilation: forced, natural, and mixed. The choice of exhaust system depends on the size of the building, the number of livestock, climate conditions and other factors.

Cows can live comfortably if the area in the room per individual is at least 6 m² and the ceiling height is at least 2.5 m. There should also be an area for females with calves and a place for placing equipment.

Requirements for ventilation of barns are given in SNiP 2.10.03-84. The document specifies the basic requirements and calculation formulas for selecting equipment.By complying with the requirements of SNiP, the farmer will create comfortable conditions for keeping animals. The better the cows feel, the more milk they produce.

All types of ventilation systems have their own operating and installation characteristics. Incorrectly selected ventilation or incorrect placement of equipment can cause microclimate disturbances. Exhaust equipment should not cause drafts.

Next, we will consider in more detail the features of various types of ventilation.

Type #1 - natural system

The flow of fresh air is carried out through windows, cracks and door structures. Exhaust humid air is discharged through the ceiling.

The advantages of natural ventilation include low cost of construction and simple installation. Despite the absence of additional energy costs, such an exhaust system also has a number of disadvantages.

Disadvantages of natural ventilation:

- difficult to calculate power;

- it is impossible to adjust the humidity level;

- presence of stagnant zones;

- drawing in dust and bacteria through open windows;

- dependence of the indoor microclimate on the weather.

It is permissible to use this type of ventilation only in private farms and farms with a small number of cows. At the same time, the waste products of cows must be removed in a timely manner, or the natural ventilation system will be of little use.

The operation of the natural exhaust system can be improved using special equipment: ventilation curtains, light skate. Additional devices will improve the process of air inflow and outflow.

Ventilation curtains for barns

The product can have a rigid, semi-rigid or soft structure. Control of the curtain fabric can be automatic, manual, or mixed. Such structures are installed on various areas of the barn: windows, doors, roof, and walls.

Curtains can be made from various materials. The most commonly used variations are made of synthetic plastic. Some types of curtains are designed to completely shade the barn. There are also products that allow sunlight to pass through when closed.

Advantages of ventilation curtains:

- protection of the barn from the influence of the external environment;

- the ability to adjust the opening width of the canvas and create the required air flow;

- allow you to create climatic zones inside large rooms;

- can be used to create a thermal barrier.

Ventilation curtains are optimally suited for large livestock farms. Small barns can also be equipped with the device. This will allow you to quickly create comfortable conditions for keeping animals and significantly reduce energy costs.

Light skate in the barn

The equipment is made from translucent cellular polycarbonate. Mount the light ridge on the roof. It improves air exchange and lighting in the room.

The device of a light ventilation ridge will protect the barn from the penetration of strong wind, rain or snow into the room. The product facilitates the natural outflow of exhaust moist air.

Advantages of a light skate:

- Can be manufactured for any type of roof;

- improves the microclimate in the barn;

- protects equipment and structures from fungus formation;

- saves energy due to natural lighting;

- ensures the penetration of fresh air without drafts.

Polycarbonate sheets have good insulating properties. The material is resistant to friction and scratches. He is not afraid of temperature changes. These properties allow the light skate to be used for a long time.

Type #2 - forced ventilation

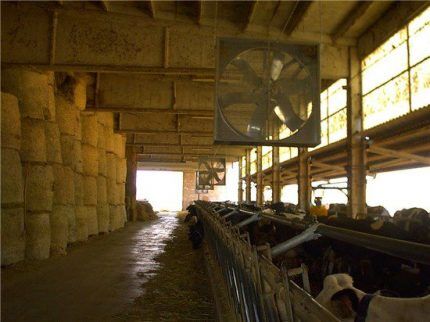

To ensure forced ventilation in the barn, install fans, as well as special valves. The system allows you to effectively remove excess moisture and unpleasant odors from the room. It is able to fully provide cows with fresh air.

The forced ventilation equipment operates from a 220 V network. Additional costs of the system include periodic lubrication of fans and other devices, replacement of spare parts, as well as energy costs.

The advantages of the exhaust system include:

- fast air exchange process;

- elimination of unpleasant odor;

- absence of stagnant zones;

- automation of the ventilation process;

- possibility of temperature control.

It is difficult to install forced ventilation on your own.You need to prepare the project in advance, choose the right type and power of the fan. Therefore, many farmers order the installation of an exhaust system from specialists.

Type #3 - mixed ventilation system

A mixed type of ventilation is used in large barns. It combines the use of automatic equipment and natural ventilation (the design of the room has many opening windows).

This type, in comparison with forced ventilation, can significantly reduce energy costs for air conditioning the barn. Since the artificial exhaust system is connected only when the temperature drops.

Types of fans for barns

For air circulation in large barns, forced or mixed ventilation is installed. Such structures are equipped with various types of fans.

Fan types:

- horizontal ceiling;

- vertical accelerating

In order for exhaust systems to work for a long time, barn fans must be made of durable and high-quality materials.

Booster fans for barns

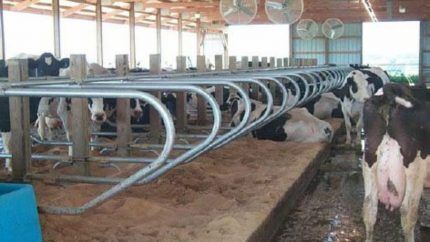

These types of fans are most often used in barns. They are affordable and capable of creating air flow throughout the entire room. Products are hung at a certain angle on guy wires.

Typically the devices are placed above stalls or aisles.The height above the floor should be 2.5 m. Fans are hung in increments of 20 meters.

Fan blades are made of stainless or galvanized steel. Stainless steel has greater wear resistance due to its anti-corrosion properties and high strength.

The accelerating fans have a belt drive, which is hidden under a special cover. The engine is quite powerful, it can operate for a long time and continuously, which is especially important for regions with hot summers.

Speed adjustment and control of the device is carried out using a special panel. The most expensive fan models have a mesh design or automatic blinds (designed for installation in shafts and openings).

Horizontal ceiling fans

Ceiling fans are installed in barns with 50 or more heads. The design of the devices is quite large; the blades are capable of moving large flows of air masses and evenly distributing fresh air inside the structure.

The products are often used to organize mixed type ventilation in barns. They can be mounted together with curtains or a light skate. These fans provide a constant flow of air, which contributes to the well-being of cows and calves. The lying areas and stalls always remain dry. The number of germs in the room is reduced.

The blades of exhaust products are made of lightweight and durable aluminum profile. The length of the blades depends on the blowing area.A fan with a diameter of about 7 m is capable of providing normal airflow to an area of 22-25 m.

The control panel of the device allows you to turn the ventilation on or off, as well as change the speed of rotation of the blades. One ceiling fan can easily replace several vertical fans.

Air exchange rates in a barn

Regardless of climatic conditions, ventilation in the barn structure must be carried out constantly. In summer you should refresh the air more often than in autumn-winter.

When temperatures are too low, cows begin to eat a lot. But the energy received is not used to increase milk production, but to maintain body temperature.

The air humidity in the barn should also be monitored. Dry air provokes rapid breathing and has a bad effect on the general condition of animals. High humidity promotes the proliferation of microbes and viruses, which contributes to various diseases.

The permissible humidity level for keeping cows is 50-85%. The optimal humidity for animal life is 70% (for all ages).

When determining optimal air exchange in a room, a special formula is used (the joint release of heat and the level of evaporation adjusted for animal respiration must be taken into account):

L= Q x K + a / q1 – q2,

Where:

- L – the amount of air required, the volume indicator in cubic meters is calculated. m/hour;

- Q — level of evaporation;

- K – moisture that is released during the breathing process of cows;

- a – rate of moisture evaporation in the barn;

- q1 – indicator of humidity of air flows indoors;

- q2 – humidity of the incoming flow.

The air exchange rate is given great importance. Especially in conditions of keeping large livestock. Because the quality and quantity of milk production depends on this.

DIY ventilation device

You should only build an exhaust system yourself if you have the skills and appropriate tools. Typically, owners of small barns arrange natural or mixed ventilation.

First of all, the barn needs to be equipped with supply openings to allow fresh air to come in from the street. They should be placed evenly along the wall at a height of 20 cm from the floor (above the foundation). Before installation, the wind rose of the area is analyzed. The equipment should be installed on the leeward side of the barn and equipped with dampers, which will allow you to regulate the intensity of the air flow.

Then install ventilation ducts in the upper part of the room (at least 2 m from the floor) to remove exhaust air. For these purposes, boxes and pipes are used. Parts are made of plastic, metal or wood.

We also recommend that you familiarize yourself with the features insulation of air ducts.

To improve the flow of air masses over the entire area of the barn, a ventilation shaft is installed - a box with a diameter of 50x50 cm, in which holes are made in 60 cm increments. It is better to make the shaft itself from stainless steel, so it will last longer.

If ceiling fans are used, then they are mounted at an angle of 15 degrees at a height of 2.5 m from the floor covering. The distance between units is 20 meters.

When arranging mixed ventilation, care should be taken to ensure that the fans are automatically turned on/off. Because temperature as well as air humidity changes, devices will not always operate at constant power.

Special sensors will help ensure gradual switching on and off of fans. When the temperature changes by 0.5-5 °C, they will operate and start ventilation. In large rooms where more than 10 fans are installed, a step of 0.5 °C can be set. Then, when the set temperature is reached, the units will operate alternately. This operation of the devices will allow you to avoid sudden changes in microclimate.

The power of the fans is calculated for the specific conditions of keeping cattle. Formulas and calculation parameters are given in special regulatory documents: SNiP 2.10.03-84, Designer’s Handbook (section “Ventilation and air conditioning”), as well as NTP-APK 1.10.01.001-00.

But specialists are invited to design and install a forced ventilation system - installation and connection of complex equipment requires skills and special tools.

Conclusions and useful video on the topic

You can see how the equipment is placed in the barn for supply and exhaust ventilation in the video below:

In the video you can also see an example of ventilation of a small barn (up to 100 heads):

In the article we talked about comfortable conditions for keeping animals, air exchange standards, and also looked at existing types of ventilation equipment. We analyzed the features of creating an exhaust system in a barn with your own hands.

Thus, the productivity of cows directly depends on housing conditions: ambient temperature, humidity and the presence of fresh air in the room. The ventilation system allows you to create an optimal microclimate. For small barns, the natural type is suitable. It is advisable to equip farms with a livestock of 20 or more animals with ceiling or booster fans.

Would you like to supplement the above information with useful information? Or would you like to talk about your personal experience in arranging ventilation in a barn? Write your additions, share information, participate in discussions - the feedback form is located below.