Types of insulation for the walls of a house from the inside: materials for insulation and their characteristics

From year to year, energy prices are rising inexorably, while the level of income of the population remains almost unchanged. Looking at the unaffordable bills for heating a house or apartment, you come to the understanding that the problem needs to be solved on your own - by insulating residential premises.

For this purpose, various types of insulation can be used for the walls of the house from the inside and outside.

Let's take a closer look at the possible options for insulation materials, their advantages and disadvantages.

The content of the article:

Choosing a method of insulation

Wall insulation can be external and internal: the option with external insulation is more preferable and more effective. But there are situations when it is not possible to insulate the walls from the outside.

For example, a ban by the architectural commission: the building is an architectural monument, the appearance of which is not recommended to be changed. Or when an unheated workroom is discovered behind the wall, in which it is impossible to insulate the walls.

In such cases, internal wall insulation with various types of insulation will be the ideal way out.

It is necessary to approach the issue of choosing insulation with great responsibility, study the characteristics of each type, and select them taking into account the building materials from which the walls of your house are made.

Incorrectly selected material will not help achieve the desired goal and can only make the situation worse. For example, after improper installation of insulation, the wall not only does not retain heat, but in winter it freezes even more than before.

In most cases, if the wall is not properly sealed, after a certain period of time condensation becomes dangerous for the insulation material and for the wall itself.

The material and the wall are saturated with moisture, as a result the insulation effect is reduced to zero, and the walls of the building begin to gradually collapse from infection with fungus.

In order not to encounter these problems for many years after repair and insulation of the surface, you must strictly adhere to the technical installation recommendations.

Equally important is the correct sealing of the seams of the internal walls of the house, the joints between the insulation boards and the wall surface when it is attached.

Types of materials for internal thermal insulation

Among the many types of insulation that can be used to insulate the interior walls of a house, we will tell you about the most popular and most in demand options. These include fiberboard, glass wool, polystyrene foam, cork wallpaper, etc.

Let's look at each of them in more detail.

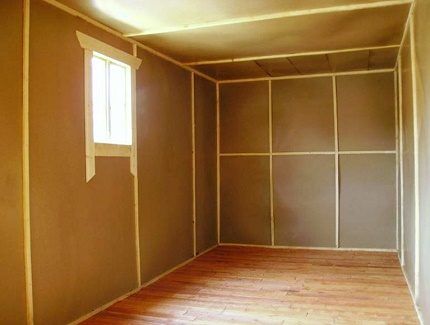

Option #1 - fiberboard slabs

Fiberboard The slab is an excellent material for insulating walls from the inside, quite cheap, one might say economy class.

Plates Fiberboard produced from waste wood-processing industry, are glued together with glue made from natural resins when exposed to high temperatures and pressure.

The material is treated with antiseptic elements, not susceptible exposure to high temperatures and high humidity.

Option #2 - withglass wool

Glass wool is the most common, budget material for wall insulation. As practice shows, there is a big drawback due to which experts do not recommend using it on the inside of walls.

It absorbs moisture very well, which reduces its thermal insulation properties - the material decreases in volume and size, which leads to significant heat loss.

For external insulation, glass wool is laid end-to-end between wooden beams so that it tightly covers the required space.

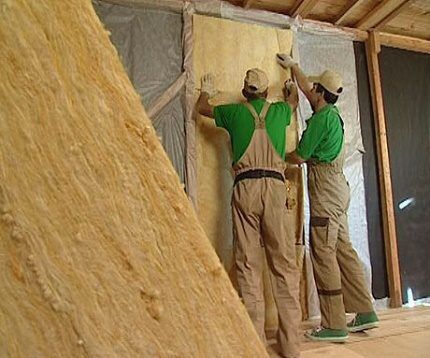

Option #3 - mineral wool

A material made from certain types of igneous rocks is popularly called mineral wool, although in fact we are talking about stone wool. The term “mineral” includes not only stone, but also glass wool and slag wool.

Today this material is most in demand; it has many positive characteristics:

- high level of thermal insulation;

- does not react to high temperatures and combustion;

- sound insulation at the highest level;

- strength, practicality and durability.

Mineral wool is used as insulation not only for the internal walls of a house, but also for attic ceilings and external walls of buildings.

Mineral wool slabs come in different hardnesses - the stiffer the slab, the higher its cost.

The thermal insulation properties of more rigid and less rigid slabs are almost the same. For interior work, less rigid types are used.

More rigid types are relevant for external insulation of facades. This material comes in thicknesses of 50 mm and 100 mm. Less thick - 50 mm. It is used for internal insulation. Thicker - 100 mm - for external insulation of facades.

The only drawback of mineral wool is that it needs to be covered with an additional partition made of drywall, plastic, plates OSB or other materials. This significantly reduces the living space of the room.

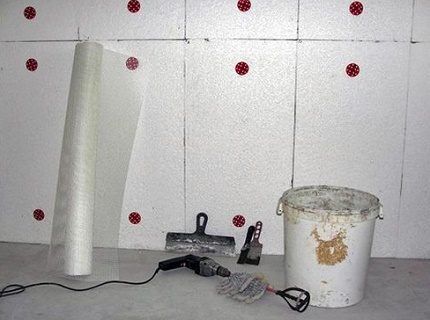

Option #4 - penoplast

Polystyrene foam has long been used in the construction industry as a cheap material for sound and waterproofing of premises.

Compared to mineral wool, it has better thermal insulation properties, so a thinner slab can be installed indoors. As a result, the living space will practically not decrease.

Along with positive qualities, polystyrene foam has a number of disadvantages:

- The structure of the material is very fragile, so work with it should be carried out very carefully.

- At the slightest violation of the integrity of the sheet heat loss increase significantly.

- Rodents are a threat to foam boards, they simply adore it. If there is access, the slightest hole, after a certain period of time, the sheets will look like Dutch cheese.

- A very flammable material - when burned, it emits caustic, poisonous smoke.

Lay the foam on the surface, using construction adhesive for fastening, and apply it generously over the entire area of the sheet.

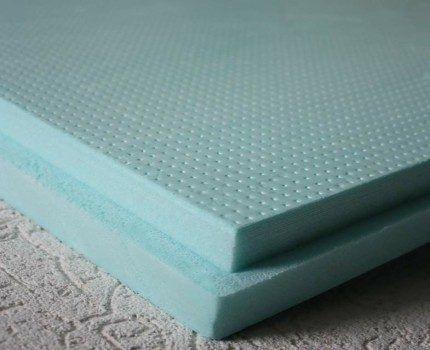

Option #5 - ppolystyrene

Polystyrene is a more innovative insulation for walls. Its density is much higher than the density of foam, which makes its installation much easier.

On the other hand, polystyrene slabs do not fit well together, forming many uneven joints that need to be coated with high-quality sealant.

For dense fit sheets and fixing them on the wall, it is recommended to use a solution of a waterproof mixture for bathrooms and bathrooms.

When insulating rooms with polystyrene, it is recommended to carefully consider sealing the seams between the slabs. This will prevent warm air from leaking between them and prevent condensation from forming.

We also recommend reading about thermal insulation of premises using types of expanded polystyrene:

Option #6 - ptimid wallpaper

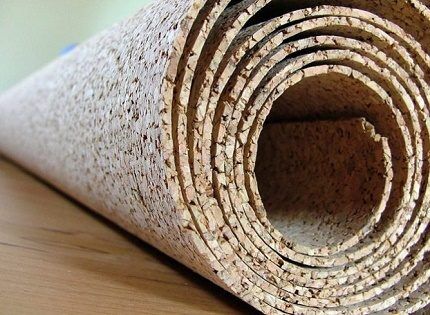

One of the most modern environmentally friendly thermal insulation materials that are used to insulate a house from the inside is cork wallpaper. They are made from natural ingredients: processed, crushed and compressed cork bark.

Cork wallpaper is not only a type of insulation, but also a material that is perfect for finishing and decorating walls. A room decorated with this material, which is warm even in appearance, radiates an aura of comfort and coziness.

Characteristics of cork material:

- has antibactericidal properties;

- excellent sound insulation;

- heat loss is reduced to zero;

- strength and durability of the coating;

- high antistatic properties;

- non-flammable material;

- environmentally friendly material that does not emit harmful vapors and compounds.

Cork wallpaper is divided into two types: the first - with a natural porous structure, the second - coated with a layer of special varnish. Cork as insulation is available in rolls and slabs of various sizes.

Installing such insulation is very simple - for this you need to have rolls of wallpaper, a sharp knife and specialized glue.

Option #7 - penopolyurethane

Polyurethane foam - material, spattering on the walls in liquid form. It has excellent waterproofness and thermal insulation properties. After hardening, it has a loose structure, so it is almost impossible to plaster the wall.

For effective application, formwork is made, usually wooden, to be filled with the substance. polyurethane foam. After hardening, construction is required hydro and steamprotection from a layer of polyethylene film, which is attached to adjacent walls, floor and ceiling.

Option #8 - liquid ceramic insulation

Another innovative way to save heat in a room is liquid ceramic ultra-thin thermal insulation - Gastrointestinal tract. She has high waterproofing, thermal insulation and noise insulation properties.

Its functionality is in demand in the housing stock in preparation for the heating season. Warm paint suitable for insulating ceilings, balconies, interior walls, for facades of cottage and multi-storey buildings.

It is in demand for pipe thermal insulation and pipelines, is used for sealing heating points: boiler houses, heating networks and other structures.

Thermal paint Gastrointestinal tract used for painting surfaces of various types, for example, concrete, metal, brick, aerated concrete and other building materials.

Among the advantages, manufacturers note:

- absolute safety for human health;

- reflectivity of the material;

- endurance to low temperatures - can withstand temperatures of minus 60 °C;

- The material is strong, durable, resistant to sunlight.

Among other things, this type of ultra-thin ceramic thermal insulation has high energy efficiency. The thickness of paint applied to the wall is from 2 to 5 mm.

Option #9 - uhkovata

Ecowool — a type of new insulation based on cellulose materials. This material is made from waste paper, antiseptics and fire retardant.

This insulation is absolutely not fire hazardous. In aggressive conditions, cellulose wool performs well.

On to the pros ecowool can be considered:

- environmental friendliness;

- safety;

- hypoallergenic;

- absence of condensation formation, respectively, all kinds of decomposition, fungi.

This type of insulation has good soundproofing and thermal insulation properties. Protects the building from cold in winter and heat in summer.

With the invention of cellulose insulation, it became possible to build lightweight structures - the pressure on the foundation due to the lightness of the insulation material became much less.

Ecowool used for insulating any type of structure: it is poured into any, even the smallest holes, it fills the entire space, which facilitates the process of its installation.

Using a pressure blowing unit, cotton wool is supplied to the surfaces it insulates. Before this, it is disheveled in the hopper of the application machine. Thanks to this technology, wool can be fed up to 30 m.

There is another way to install ecowool - This is the wet application method.

For brick or concrete walls, effective insulation is to increase the thickness of the wall with decorative stone, plaster or brick. The wooden walls in the room are additionally lined and insulated with wood.These types of insulation are quite expensive and require considerable capital investment.

In some cases, in addition to wall insulation, it is worth taking care of floor insulation And ceiling in the house.

Recommendations for carrying out insulation work

Insulation work is best carried out in the summer, when air humidity is minimal.

The walls for insulation in the room must be perfectly dry. You can dry them after additional plastering and finishing work on leveling the surfaces using construction hair dryers and heat guns.

Stages of surface insulation:

- Cleaning the surface of decorative elements - wallpaper, paint.

- Treating walls with antiseptic solutions, priming the surface with deep penetration into the layers of plaster.

- In some cases, when installing polystyrene foam and electric heating elements, the walls are pre-leveled using waterproof plaster for bathrooms.

- Installation of insulation must be carried out in accordance with the instructions prescribed by the manufacturer for this type of material.

- Mounting a protective partition for applying the final finish, or covering the surface with a construction mesh, its plastering.

- Creating a single composition with the overall design of the room.

Insulating walls inside a house is one of the most effective ways to protect your home from the penetration of cold and the negative effects of condensation; the main thing is to follow the technological sequence of steps. You can read more about the technology of insulating a home from the inside in this material.

Conclusions and useful video on the topic

Modern types of wall insulation, properties and characteristics:

Tips for insulating walls in an apartment - analysis of common mistakes:

Insulating a house, done using even not the most expensive materials, is not a cheap pleasure. There are now many types of insulation available for interior use, which are presented in a wide price range. Therefore, choosing inexpensive and high-quality material will not be difficult.

A warm home in winter and comfortable coolness in the hot season, as well as a reduction in utility bills will show that the thermal insulation of the room is done well and of high quality.

What material did you use to insulate the walls of your house? What guided your choice and are you satisfied with the result? Please tell us about it in the comments section. There you can ask a question about the topic of the article, and we will try to answer it promptly.

I really don’t recommend insulating living spaces with glass wool. Yes, it is cheap, but it can be harmful to the health of the people living in this house. The fact is that formaldehyde resins are used to bind the fibers in glass wool, which release a harmful substance called phenol, which is a rather strong poison. If you don’t have the money for expensive insulation, then you can use cheap polystyrene foam.

Insulating houses with glass wool is probably really harmful, as the person above wrote. I don’t understand at all why there are so many options for insulation, if you can insulate any room with eco-wool. Excellent material. And the ecological situation does not suffer, and protects from cold in winter, and from heat in summer. Our house was insulated this way, and it turned out great. And the sound insulation has improved a lot.

To insulate the walls of a house from the inside, we highly recommend a new insulation material - fire-resistant airgel thermal insulation. It has a number of unique characteristics.

Could you somehow develop your idea and give more details. It’s not clear to me from your message who recommends it and what unique characteristics this fire-resistant airgel thermal insulation has. So far, I’ve googled it myself and immediately see that the price of this miracle material is 30 times more expensive than the now standard polystyrene foam. With such a price, it must have truly unique characteristics in order to find its buyer.

As for the insulation of internal walls, my opinion is that now the best option is extruded polystyrene foam. Unlike mineral wool, it has good density, which simplifies installation, and has effective thermal insulation.

The use of vapor-permeable materials inside is generally unacceptable, because... dew point will collect in them, followed by fungus and mold. Using polystyrene foam is a good option, but it is not always possible due to the reduction of space and the complexity of the structure that must cover it. In my case, also because of the labor costs for drywall and frame. Insulation using liquid thermal insulation turned out to be the least simple. There are a lot of types of it and all manufacturers beat themselves in the chest that their liquid thermal insulation is the best and will solve all your problems. I settled on Akterm thermal insulation because... the only company where I received adequate advice and was able to come see and touch the material before purchasing and see how it works.I applied it to a leveled wall, the coating had the consistency of putty, with a spatula I got a surface that I didn’t even have to level after. The result is that the room has become really warm; you can even put your hand on the wall and it is warm, unlike other non-insulated walls.