How to insulate a wall in an apartment from the inside: the best technologies + work procedure

One of the most important conditions for living in an apartment is a good heat supply, for which either a centralized heating system or autonomous equipment installed by residents is responsible. However, the efficiency of heating directly depends on the correct thermal insulation of the premises.

Let's look at how to insulate a wall in an apartment to increase the air temperature and at the same time reduce energy costs for heating. For this purpose, we provide two detailed instructions on thermal insulation with popular types of insulation, in which each step is illustrated with photographs.

Also in this material we will consider less popular methods that can be used to insulate walls from the inside.

The content of the article:

When is it necessary to insulate an apartment?

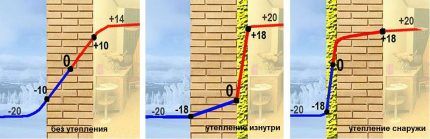

The preferred method of insulating the walls of apartments and houses is still external thermal insulation, which does not affect the dew point shift and heats the entire wall.

If a layer of insulation is installed from the inside, the wall freezes through its entire thickness, and Dew point moves closer to the living space.

However, the external method is not always suitable.Difficulties arise with installing insulation on panel high-rise buildings, as well as on walls adjacent to technical spaces, for example, an elevator shaft. If the building is a historical object, the appearance of the facade cannot be changed.

However, in some cases you simply cannot do without thermal insulation:

Without wall insulation, the efficiency of heating devices decreases. Frozen walls, cold bridges, and dampness create unsanitary conditions and become the root cause of diseases.

However, you can protect yourself from cold and disease by insulating one or more walls in the apartment from the inside using one of the methods given below.

Best methods and detailed instructions

The technologies that builders use to insulate walls depend on several factors: installation conditions, the required degree of protection, and the choice of material. The best options are considered to be combinations of modern thermal insulation materials and decorative finishes with an additional insulation function.

Option #1 - EPS on sheathing + drywall

Extruded polystyrene foam (EPS) is considered one of the most effective insulation materials if it is necessary to thermally insulate a room or an entire apartment from the inside.

It is sold in the form of rigid slabs consisting of several components: polystyrene granules, a gas mixture and a foaming agent.

The main advantages of extruded polystyrene foam:

- small thickness of the slabs, allowing you to save the usable area of the premises;

- minimal water absorption;

- resistance to temperature changes;

- light weight;

- simple processing.

This is a material that you can purchase and cut yourself into fragments convenient for installation. But there is also a minus - low vapor permeability. In an apartment with EPS insulation, it is necessary to have good ventilation.

Read more about the pros and cons of extruded polystyrene foam. wrote here.

We use 50 mm thick EPPS as a thermal insulation material, and for the construction of the frame (sheathing) we use wooden beams 50*50 mm and 50*30 mm with markings for holes. We use plastic dowels and self-tapping screws as fasteners. You will also need a vapor barrier membrane and adhesive tape for vapor barrier.

Minimum set of tools:

- marker and ruler for marking;

- a special hacksaw for cutting EPS boards into pieces of the required sizes;

- drill with drill bits for dowels;

- construction stapler.

A hacksaw for insulation is sharpened in such a way that when cutting the material it does not generate dust.It is also suitable for mineral wool, glass wool, and ordinary polystyrene foam.

Instructions for thermal insulation:

If you neglect to install the vapor barrier layer, the thermal insulation materials will become wet from condensation, which will appear in any case.

As a result, mold will appear, and the thermal insulation effect will noticeably decrease. If you find mold on the walls of your home, we recommend that you familiarize yourself with the best antiseptics against her.

The wall lined with plasterboard is ready for finishing: puttying, painting or wallpapering.

Instead of conventional extruded polystyrene foam boards with a glossy surface, an alternative material is increasingly being used - EPS with a rough top layer and grooves that increase the degree of adhesion.

The fixed slabs are treated with a basic reinforcing compound, and then paint is applied in 2-3 layers or wallpaper is glued.A “fur coat” made of EPS can raise the room temperature by 4-5°, which will certainly affect the saving of resources spent on heating.

Option #2 - ISOVER mineral wool + OSB boards

The second technology solution is similar to the first, although completely different materials are used for installation. The thermal insulation layer will consist of mineral wool, and the basis for the finishing will be OSB boards.

ISOVER products are certified and approved for use even in children's and medical institutions. It has a thermal conductivity of 0.038 W/(m K) and a flammability group NG - both indicators according to GOST R 31924 And 30244-94.

Advantages of mineral wool:

- retains heat well, has a low thermal conductivity coefficient;

- environmentally friendly and fireproof;

- Available in easy-to-install slabs;

- eliminates moisture accumulation;

- has light weight.

But there are also disadvantages: some types of mineral wool contain components that emit phenol, and manipulations with the material necessarily require compliance with safety regulations - the presence of special clothing and a mask (glasses).

Oriented strand boards (OSB) are laid on top of mineral wool on a lathing made of wooden blocks or metal guides. This is a material made from wood chips, resins and a polymer adhesive composition.

Due to their wood composition, the slabs are fire hazardous (class G4), so before or after installation they are coated with protective fire-resistant compounds - fire retardants.

Installation instructions:

If the walls are smooth and the material is prepared in advance, you can insulate a 20 m² room in 5-6 hours, working alone.

But this is facilitated by ISOVER products: mineral wool is easy to cut and install, and vapor barrier sheets do not even require construction tape for gluing, since they are initially equipped with a built-in mounting tape.

A prerequisite for insulation with basalt wool is the installation of forced ventilation. The device is mounted in the air duct, and the supply of fresh air is ensured by regular manual ventilation or special valves on windows.

If you plan to build a partition in an insulated room, then it can also be made using mineral wool, but it is better to replace OSB boards with sheets of plasterboard.

Isover is placed between two walls made of LGK, with each wall made of 2 layers of plasterboard. Such a partition will protect from cold and noise no worse than a full reinforced concrete wall.

Both presented methods also have disadvantages that must be taken into account when planning work.

Firstly, they take away part of the usable area and reduce the perimeter space of the living space, secondly, they require significant investments of the family budget, and thirdly, when using them, all the nuances of the technology must be observed.

Brief overview of other methods

They also use other technologies, among which there are both outdated, but cheaper, and modern, requiring considerable investments.

Liquid thermal insulation

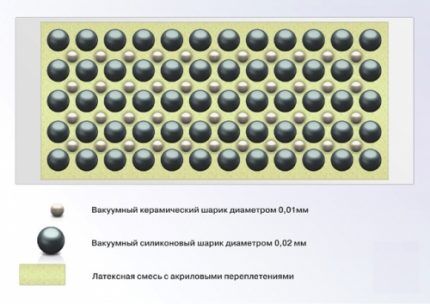

Liquid heat-insulating coatings can be used to insulate rooms both outside and inside. One of these products is AKTERM Concrete. This is ultra-thin insulation based on water dispersion. It contains an acrylic binder and evacuated microspheres. This determines the scope of application of the product - the composition can be applied to concrete, brick, metal, wood, plastic, foam blocks and limestone.In addition, indoors it is possible to apply AKTERM Concrete to plaster and putty.

Application area:

- insulation of window slopes;

- insulation of basements, balconies or loggias;

- the need to protect walls, ceilings and floors from freezing;

- AQUATERM Concrete is used in the “warm floor” system. It can successfully replace traditional foil;

- as protection for roofs and attics from overheating during the hot season.

One of the advantages of AKTERM Concrete is its economical consumption. For the product to fully perform its functions, applying a layer of 1 mm (maximum 2.5 mm) is sufficient. This means that 1 liter of thermal insulation will be enough to properly treat 1 square meter of surface.

Advantages:

- properly applied thermal insulation coating will last more than 12 years;

- there are no solvents or volatile substances in the composition, therefore AKTERM Concrete can also be used in residential premises - apartments, private houses;

- applicable in children's rooms;

- has no smell;

- effectively protects against freezing and retains heat;

- fireproof product;

- the coating does not collapse under the influence of direct sunlight;

- easy to apply with any tool - spatulas or brush. Airless application is also possible.

An important point for those who decide to use AKTERM Concrete to insulate walls in their home or apartment - the product is compatible with acrylic-based primers and water-based paints.

How to apply thermal insulation compounds:

- The first stage is surface preparation. It is necessary to clean the walls, ceiling or floor from remnants of wallpaper and plaster. Remove dust. For this purpose, you can use a regular vacuum cleaner.Upon completion, apply AKTERM Primer (deep penetration primer) to the surface.

- The second stage is processing. The finished thermal insulation is applied with a spatula or brush onto a prepared, dry and grease-free surface. It is important to observe layer-by-layer application. The first layer is 1 mm. It dries in 24 hours. If necessary, then apply 1 more layer. It is important that the material is completely dry.

- The fourth stage is the final one. The final color of the finished thermal insulation coating is white. But if desired, it can be painted with water-based paint. This can be done only after AKTERM Concrete has completely dried.

Working with liquid thermal insulation materials is not difficult. But it is important to choose high-quality products that will not only retain heat for a long time, but will also not contain substances harmful to the body. This is especially true in situations where it is planned to insulate residential premises (bedroom, children's room, etc.) using thermal insulation.

For personal safety during the preparation and application of AKTERM Concrete, you must use personal protective equipment:

- eyes are covered with transparent glasses or a special shield is used;

- gloves on hands;

- It is advisable to change into clothes that you won’t mind throwing away after work.

If the composition gets into your eyes or exposed skin, rinse them with water.

Key Features:

- long service life, more than 12 years;

- reduces heat loss;

- reliable protection against freezing;

- applicable in residential areas;

- homogeneous mass without separation;

- the coating does not contain organic solvents and volatile compounds, is fireproof, non-toxic, making it suitable for use both outside and inside residential and industrial premises;

- dries quickly;

- easy to apply with a brush, spatula, or airless application apparatus;

- without smell;

- has a durable finish;

- tinting in light colors is possible according to the ral classic system;

- Weather and UV resistance.

Material Compatibility:

- surfaces - concrete, processed metal, plastic, brick, gas blocks, foam blocks, wood;

- primers - acrylic based;

- paints are water based.

Installation of polystyrene foam or polystyrene foam

With the advent of EPS, it became impractical to use conventional non-pressed polystyrene foam (PSB), since it has deteriorated characteristics.

Namely:

- burns and melts, releasing hazardous substances;

- has fragility, due to which pieces break under mechanical pressure;

- not protected from rodents.

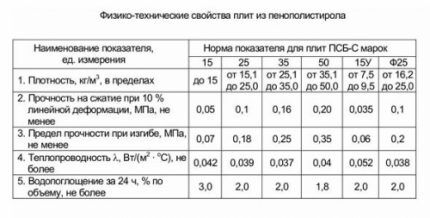

In terms of parameters, it is inferior to extruded polystyrene foam, and this can be seen in the table of physical and technical properties of expanded polystyrene boards:

However, light and thick slabs are still used when it is necessary to quickly and inexpensively insulate a room. We recommend using this material for cladding garages and utility rooms, that is, non-residential premises.

Spraying liquid ceramic insulation

To provide a “cold” wall with additional thermal insulation, substances are used that are applied according to the principle of painting, that is, using a special sprayer, spray gun or brush. We talked more about ways to insulate cold apartment walls in this article.

Advantages of liquid ceramic spraying:

- moisture resistance;

- mechanical stability;

- elasticity;

- ease of application;

- environmental friendliness;

- minimal load on structures.

The main advantage is the thinness of the applied layer while maintaining important thermal insulation characteristics.

In terms of efficiency, a 1-mm layer of LCD is equal to a 50 mm thick basalt wool slab and can increase the temperature in the room by 3-4 degrees. Builders love the sprayer for its ease and high speed of application.

After applying the liquid-ceramic mixture, additional hydro- and vapor barrier is not needed. A thin layer can withstand temperatures from -60 °C to +250 °C, and, subject to application technology, lasts up to 30 years.

Cork and polystyrene foam wallpaper

Of course, gluing with one layer cannot be compared with a full-fledged heat-retaining “pie”, however, wallpaper is actively used in corner apartments and in rooms on the first floors.

Expanded polystyrene wallpaper resembles ordinary non-woven wallpaper, has a thickness of 0.3-1.0 mm, is sold in 10-meter rolls, and is glued using the same principle - end-to-end. However, special glue is designed for them.

Disadvantages of the material: like PPS boards, wallpaper moves the dew point closer to the living space and is a flammable finish, like paper wallpaper.

In addition to the listed materials, eco- and glass wool, particle boards, wood concrete, foamed polyvinyl chloride and polyethylene insulation, fiberboard, honeycomb plastic boards, reflective thermal insulation with a foil layer - materials such as Penofol or Armofol are used.

Each of the listed insulation materials has the right to life and, in suitable conditions, performs its functions perfectly. We discussed in more detail all the popular types of insulation that can be used for the walls of a house from the inside, their pros and cons and characteristics in our other article.

When choosing a material, you need to focus on the technical properties, cost and complexity of installation - sometimes the installation technique causes difficulties for untrained amateurs.

Conclusions and useful video on the topic

Recommendations for choosing insulation:

Expert advice on choosing the right type of insulation:

Method for an uninsulated house or apartment:

When choosing thermal insulation technology, it is important to take into account the installation conditions. For example, for small rooms, installation on the lathing is not suitable, since it steals some of the valuable space, but for large rooms this is the ideal option, the most effective of all available.

The big advantage of all of the above insulation methods is that they can be done independently, some even without special training..

Are you choosing the best method of insulation for the walls of your apartment and do you have any questions? Ask them below under this article - our experts and other site visitors will try to help you.

If you have already managed to insulate the walls of your apartment, please share your experience with beginners. Tell us which material you preferred and whether the result met your expectations.

One of the rooms in our apartment was freezing, a very unpleasant situation. Corner room, which was planned as a children's room. I had to insulate it from the inside. Yes, the internal area has decreased, but what to do? They didn’t dare to insulate it themselves; they called a professional. He made it with extruded polystyrene foam, and it turned out very well. A wonderful material for internal insulation. But it’s not suitable for a wet façade; we saw it personally when it didn’t last even a year at the dacha.

I don’t know what kind of craftsman you had who insulated the facade of the house with extruded polystyrene foam and as a result it began to fall off. Or did you do the insulation yourself? Then you are solely to blame here!

The fact is that it is customary to use extruded polystyrene foam for external insulation of walls. Yes, you can use it indoors, but the loss of usable space is not the main disadvantage. The material becomes toxic when heated above 80*C, so not many people risk using it as internal insulation.

And now the salt, as they say - extruded polystyrene foam is not afraid of water! Even if you completely immerse the plate in water for a day, the humidity of the polystyrene increases by only 0.2%, just like that.This means that this insulation is not at risk of deformation and fungi at high humidity.

At your dacha this material did not last for a completely different reason. It is possible that errors were made during installation or the wrong adhesive or fasteners were used.

Can you provide a link to a manufacturer of insulation systems (preferably widely represented in Russian stores), who uses EPS in their system.

When we were finishing the room, we used foam boards and chipboard. In principle, it would be possible to use OSB, but they are expensive and not much different from chipboard. But if you use particle boards, you will have to tinker. Wallpaper on them does not stick well without impregnation. It was possible to buy it, but we solved the problem this way: we bought PVA glue, mixed it with clean water in a ratio of 1/4 and applied it in three layers with intermediate drying. Everything dried out quite quickly, but the consumption was considerable: it took two buckets in total. We applied this impregnation with a roller, with a brush it flies a lot around. The result was good: both warm and very cozy!

We, like many, were faced with the problem of temperature changes in the apartment during the winter period. While adults could still adapt to such conditions, children were susceptible to colds. It was simply impossible to do without additional insulation. After consultation with experts, we decided to choose polyurethane foam. The main advantage of this material is that it does not leave cavities for condensation to accumulate. All work in the apartment was done with high quality, so a positive result was not long in coming.

Can you provide a link to a manufacturer of insulation systems (preferably widely represented in Russian stores), who uses EPS in their system.