How to insulate a cold apartment from the inside: suitable materials + installation instructions

The cold weather is approaching and are you thinking about insulating your walls? Agree, you don’t want to freeze in a cold apartment and receive astronomical heating bills every month.But you decided to correct the situation, but you don’t know how to do it correctly?

We will help you - the article discusses in detail how to insulate an apartment from the inside correctly, and what materials can be used for this. Detailed instructions for installing insulation are provided, supplemented by a video.

The content of the article:

Types and features of insulation

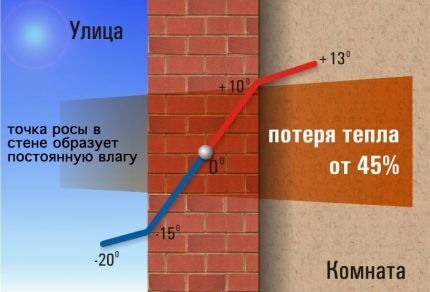

It should be noted that wall cladding with thermal insulation must be carried out in accordance with building codes and regulations. If the wall of the apartment is poorly insulated from the inside, then moisture will accumulate in the thermal insulation layer, and subsequently mold and mildew will form. We talked about methods of combating mold on walls Here.

If it is impossible to carry out external insulation measures, the internal laying of thermal insulation will need to be carried out as competently as possible.

Moreover, it is extremely important to choose high-quality vapor and heat insulating material, carefully seal cracks and joints, and ensure good ventilation in room.

But before carrying out insulation work, it is necessary to select the right materials that will be guaranteed to perform the function of heat conservation.

Among the building materials existing on the market, we will consider the most popular types of insulation, highlighting their advantages, disadvantages and installation nuances.

Option #1 - stone wool

The loose material is elastic, so for its installation you will need to make a lathing from a metal profile. After the insulation layer, you will need to cover the frame with plasterboard, and then only finish the walls.

Main advantages:

- good thermal insulation characteristics – considered universal, has high heat retention rates;

- fire safety – prevents the spread of fire, withstands up to 1000 °C;

- biological and chemical resistance – the material is not destroyed by chemicals and prevents the appearance of mold stains;

- soundproofing – provides sound protection in the room;

- vapor permeability properties – maintaining natural air exchange;

- environmental friendliness – does not emit harmful substances.

In addition to the advantages, the material also has several disadvantages. Some of them are the need to use gloves when working with mineral wool, it is forbidden to allow contact with moisture, for thermal insulation you should additionally use vapor and waterproofing.

Option #2 - glass wool

A type of mineral wool, characterized by a smaller diameter of the fiber and a longer length, as well as the material of manufacture - the raw material is molten glass.

However, it lasts much less - only 10 years. During installation, the material shrinks up to 80%. It is necessary to work with it in special clothing, gloves and a mask, since the fibers are highly brittle.

Option #3 - extruded polystyrene foam

The material is made from polystyrene foam using the extrusion method - squeezing the prepared mass out of the extruder. The result is a material made up of small closed cells of the same structure, up to 2 mm in size.

On the market you can find a brand of EPS called Penoplex boards. It is often used to insulate wall structures, but it has a high flammability class - from G3 to G4. We examined the characteristics of Penoplex thermal insulation in more detail in this article.

EPPS has high thermal insulation properties, as well as:

- low thermal conductivity;

- resistance to loads and deformation;

- water absorption coefficient – up to 0.5%;

- absolute biostability;

- light weight;

- durability;

- ease of use.

Among the disadvantages of the material are the low level of noise insulation and the possibility of use in temperature conditions from -70 to +75 ° C.

This material does not absorb water and will not allow moisture to form at the dew point.

However, when using it, you should not forget about cold bridges. It is necessary to carefully insulate the joints of the plates and their contact with the wall using foam or use it to join the plates together. Keep in mind that polyurethane foam will need to be applied over the entire plane of the sheet, without leaving cracks or gaps.

We wrote more about the advantages and disadvantages of extruded polystyrene foam in another our article.

Option #4 - expanded polystyrene foam (foam)

The material is considered environmentally friendly and absolutely safe for use as thermal insulation for walls inside an apartment. Its demand in construction is explained by the best heat, sound, and waterproofing properties of the material.

Type of material marked PSB-S is a foam type polystyrene in which micropores are filled with a special non-flammable gas. The material contains a substance with self-extinguishing properties in case of fire - a fire retardant.

This type of foam does not support combustion, has a flammability class of G1 and is marked on the packaging with the letter C.

The material is recommended for use as insulation because it has low flammability, does not spread fire and goes out within the first few seconds.

Another type of foam, labeled PSB, unlike the previous type, does not have the specified fire safety properties and is classified as class G3, G4.

It does not contain substances that prevent the spread of fire and is used mainly for the manufacture of packaging containers. Therefore, it is better not to use such material for thermal insulation.

Among other materials, PSB-S has the following characteristics:

- environmental friendliness;

- low thermal conductivity and water absorption;

- ensures fire safety;

- has good sound insulation;

- resistant to the formation of microorganisms and moldy fungi on it;

- lightweight and inexpensive;

- easy to use;

- durable.

However, when installing it, do not allow esters, kerosene, acetone-containing substances, or gasoline to come into contact with the surface, which can partially or completely damage its porous structure.

Option #5 - liquid nanothermal insulation

An innovative material with thermal insulation properties, which together provides protection against the formation of a humid environment inside, corrosive processes, atmospheric influences, as well as noise insulation.

They can be used to insulate various types of surfaces - concrete, brick, wood and others.

Pros:

- versatility;

- comprehensive protection;

- high level of quality;

- environmental cleanliness;

- safety;

- simple installation;

- low consumption.

Buyers note that the substance is easy to apply to the surface, even in hard-to-reach places, but cannot be used at temperatures below 5 °C.

Option #6 - polyurethane foam

A similar type to the previous version, which is applied to the surface by spraying from special equipment. If you do not have the necessary equipment for this, it is better to order such a procedure from specialists.

When using this material, there is no need to additionally lay a waterproofing layer. During the spraying process, the substance foams on the wall and dries quickly, leaving no gaps for possible penetration of cold from the street.

This coating does not form cracks, there are no joints or cavities, but forms a single surface. Therefore, it is suitable for insulating walls of any size and shape.

To finish the walls, you will need to glue the reinforcing mesh, plaster the surface, and then glue the wallpaper or paint it with a water-based composition.

Option #7 - cork agglomerate

The technology for obtaining the material is a process in which granules made from balsa wood are heat-treated. No synthetic substances are used, making the agglomerate considered environmentally friendly.

Cork material has high thermal insulation properties, is durable, and meets established safety requirements. In addition, it provides a high level of noise insulation and prevents vibration.

When using the material, you will maintain dryness and warmth in the room, your health, and also save yourself from the problems of frequent replacement of insulation due to rotting, deformation or mold.

Option #8 - fiberboard

Thermal insulation material is intended for indoor use in wall, floor and other structures in order to give them increased elasticity, protection from sound penetration and heat loss.

The plates retain heat well, which allows you to maintain a stable temperature in the room for a long time. The material is made from wood fibers that are pressed under high temperature.

Therefore, when using this type of insulation, you will need to additionally lay a layer of vapor barrier.

One nuance should be highlighted - before installing the slabs, they must be kept in a room with a similar humidity level where the installation will take place.

Insulation with the material can be done by gluing, inserting into a previously prepared building structure, or fastening to a wooden plane with nails.

The material is pliable, easy to cut, and when installing overlapping slabs, sealing the seams is not required.

Preparing walls before insulation

Before insulating the walls of a cold apartment, they must be prepared in a special way. This will prevent them from freezing, protecting against the formation of moisture in dew point, and prevent heat from escaping to the street.

If your room has undergone cosmetic renovations and wallpaper is pasted on the walls, it will need to be removed from the part where the heat-insulating layer is supposed to be laid.

In the case where the walls are painted with water-based paint or whitewash, it is advisable to remove it by washing it out. After the walls have completely dried, you will need to apply a primer mixture to them.

Old paint should also be removed from the surface as much as possible. If you fail to do this, the wall must be treated with a special primer for painted surfaces.

After cleaning and priming the walls, you need to glue the corners and areas between the floor and walls using serpyanka fabric.It is better to first seal existing gaps and cracks in panels or brickwork with foam, plaster, cement or other substance.

If there are wide cracks, you need to fill them with tow, and then use foam to completely eliminate them.

When the wall surface is completely prepared for laying thermal insulation, proceed to the actual installation process.

DIY insulation instructions

Due to the variety of thermal insulation materials, you can choose any of those on the market to insulate your room.

Let us consider in detail the most popular options for internal thermal insulation of a room.

Method #1 - mineral or glass wool

To lay the material, you will need to make a frame from profiles and prepare sheets of drywall in advance for the purpose of subsequently closing the structure.

It is better to buy moisture- and fire-resistant plasterboard sheets - they will additionally protect the insulated wall from the penetration of dampness from the outside.

Step-by-step instructions for laying thermal insulation material:

- Install the profile along the entire perimeter of the wall, along the ceiling, walls, floor, and also make partitions between them in increments of 30-40 cm.

- Place mineral wool or glass wool in the prepared cells, leaving no empty spaces.

- Cover the structure with thermal insulation tightly with a vapor barrier film, make an overlap of 20-30 cm on the floor, ceiling, and adjacent wall.

- Seal the vapor barrier material to the floor and wall using double-sided tape.

- Cut the sheets of drywall with a construction knife into pieces of the required sizes.

- Install them using a screwdriver.

- Remove excess vapor barrier with a knife.

- Treat joints, cracks and holes with self-tapping screws with finishing or acrylic putty.

- After drying, level the surface with putty.

- Wait until it dries completely, then sand the wall with a fine mesh.

After completing the entire procedure, prime the surface and after a few hours it will be ready for finishing with decorating materials.

This mineral wool has improved insulating properties compared to other similar materials. It can also be used for soundproofing ceiling.

Method #2 - PSB-S foam

A universal and most popular type of insulation, which is widely used in construction due to its low cost and decent heat saving performance. Choose high-density material with a width of 35-50 mm or more.

The frame method is carried out according to a similar scheme as when insulating with mineral wool. Let's look at the method of gluing to a plane in more detail.

Follow this order of work:

- Apply an antifungal primer to the walls that you plan to insulate to prevent the subsequent formation of mold.

- Wait until the surface is completely dry.

- Install a waterproofing layer - this will provide additional moisture protection.

- Mix the adhesive solution in a bucket or other container by hand or using a drill and a whisk attachment.

- Start attaching the sheets from the bottom left corner and lay them in a checkerboard pattern.

- Measure the width and length of the plate required to fit on the wall and carefully cut a piece.

- Glue the prepared part of the material using the prepared mixture.

- After completing the entire procedure, leave the wall to dry for 1-2 days.

- If desired, you can additionally secure the foam with umbrella dowels: drill 5-6 holes in the insulation along the edges and in the middle, then drive in the dowels and plastic nails.

- Seal wide joints with polyurethane foam that does not contain substances that can damage the material - read the instructions. It is enough to cover narrow cracks with an adhesive mixture.

- The final stage is the installation of the reinforcing mesh by applying an adhesive or putty base to the surface, which will make the structure more reliable.

- After drying, level the surface with finishing putty.

Before wallpapering walls, be sure to apply a primer to the surface.

In addition to the presented methods of laying insulation, you can perform thermal insulation using other materials.

If you have a loggia, it is also advisable to insulate it. We have provided a guide to insulating a loggia yourself next article.

Conclusions and useful video on the topic

Rules for choosing insulation for an apartment:

Which thermal insulation is better to use:

Features of laying insulation from inside the room:

If you decide to economically insulate your home, use budget options using polystyrene foam or mineral wool. If you do not want to reduce the usable living space in the room, we recommend using ultra-modern methods of applying liquid thermal insulation using spraying or painting.

For connoisseurs of environmentally friendly and safe materials, it is better to give preference to insulation of natural origin - from wood, balsa wood or other compounds.

Have you successfully insulated your apartment and now want to share your work with other visitors to our site who also want to do insulation? Write your recommendations, add unique photos of the DIY insulation process and photos of the finished work. And also ask questions to our experts in the comments section below this article.

At first I was led by an advertisement for some kind of nano-putty that supposedly insulated as well as thick polystyrene foam. Just wasted money and time. I didn’t want to reduce the area of the room due to the insulation, but I had to, since the room is corner.

I made thermal insulation from polystyrene foam 5 cm thick. Everything according to my mind, myself, using technology. Wallpaper was pasted on top, now I even forgot that I have two walls in foam plastic. I stopped dampening the corner, so there is a result!

During the renovation I used Penoplex slabs. It does not crumble like expanded polystyrene foam. Although it costs a little more, of course. I didn’t even consider the option with fiberboard.Thermal insulation from it is weak, and subsequent surface finishing after installation of the slabs is complex. It is necessary to treat the walls in several layers with PVA glue with intermediate drying, and only then can they be covered with wallpaper. When the microclimate in the apartment changes, the wallpaper may begin to peel off.