What is Penoplex: purpose + types of thermal insulation with a description of application and characteristics

An insulated room compares favorably with a conventional building due to its comfortable microclimate, which is why thermal insulation of houses and apartments has long become a prerequisite for putting a residential building into operation. Correctly selected materials reduce the load on supporting structures and reduce heat loss by up to 30%.

Penoplex construction products are an excellent example of a wide range of modern insulation materials. Let's take a closer look at what Penoplex is, what types it is divided into and what characteristics it has. We will also highlight the main advantages and significant disadvantages of this material.

The content of the article:

Pros and cons of Penoplex thermal insulation

For more than 20 years, the company, whose branches are located in various cities of Russia, has been producing and selling insulating material with high thermal protection parameters. Thanks to the wide range and high quality of its products, the Penoplex company has occupied a convenient niche in the Russian market and successfully exports goods abroad.

Penoplex slabs are made from a synthetic material - polystyrene by extrusion, that is, by mixing granulated polystyrene with a foaming agent under conditions of elevated pressure and temperature. Additives are necessary to give the slabs a homogeneous “air” structure of sealed cells.

Advantages of thermal insulation:

- minimal thermal conductivity;

- almost zero water absorption;

- resistance to biological environment;

- bending and compressive strength;

- wear resistance and durability:

- environmentally friendly - does not emit harmful substances.

Like all insulation materials, Penoplex allows you to minimize the cost of air conditioning and heating, and due to their light weight, installation of the slabs is easy and quick. The material itself can withstand temperatures from -70 °C to +70 °C, and it can be laid at any time of the year.

Another advantage is the variety of types - there are options for finishing the roof, facade, walls, differing in thickness and degree of thermal conductivity.

Also, the company's engineers have developed complexes for thermal insulation of brick, frame, concrete, aerated concrete, and wooden houses, and the manufacturer gives recommendations on the use of slabs or sprayed composition outside or inside.

The main disadvantage of the material is considered to be the flammability class - G4 or G3. Expanded polystyrene in this indicator is inferior to insulation with a natural base. For comparison: mineral wool has NG (non-flammable) or G1 (low-flammable). More characteristics of extruded polystyrene foam we brought here.

Another disadvantage is the high cost of plates and spray products. For example, a package of 10 mm “Comfort” slabs (4 pcs.) standard 585*1185 costs on average 1,650 rubles.

Types of products of the company PENOPLEX

To make it easier for customers to choose thermal insulation, the manufacturer has divided all products into 2 large categories:

- for professionals;

- for home and apartment.

Products from the first group are widely used for insulating industrial, sports, and agricultural buildings, laying pipelines and highways, and in the construction of runways and railway tracks.

The second category is products for the population, with which you can independently insulate dachas, cottages, and apartments. Let's take a closer look at the technical characteristics of XPS slabs related to different types of Penoplex.

Category #1 - professional thermal insulation

In total, there are 8 types of products in the category (if you combine Penoplex 45 and 45 C), differing in size, characteristics, and some even in shape. Among them there is universal thermal insulation, for example, “Base”, and special, designed for insulation of certain places, for example, “Pitched roof” or “Slope”.

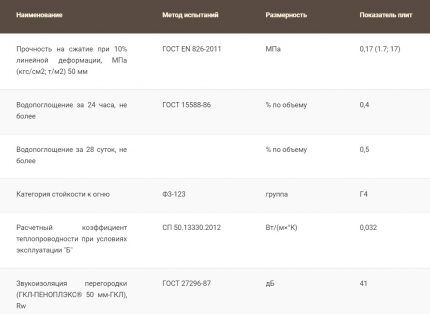

Type #1 - PENOPLEX BASE®

It is used if there are no load requirements for the building structures. It is used with equal success for insulating walls (internal and external), floors, roofs.

The thickness of Penoplex thermal insulation varies from 20 mm to 120 mm, the standard of slabs is 585 * 1185 mm.

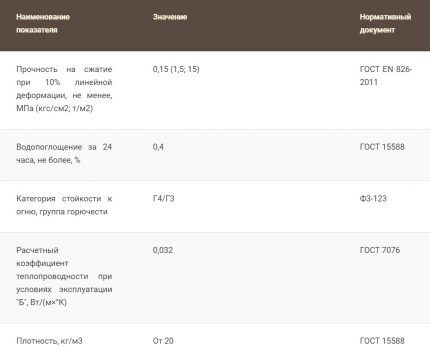

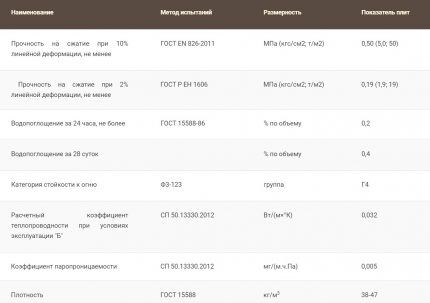

Main characteristics:

A distinctive feature of this type of material is its compressive strength of 0.17 MPa.

An alternative to Osnova is Facade, which is also particularly bioresistant, durable and reliable.

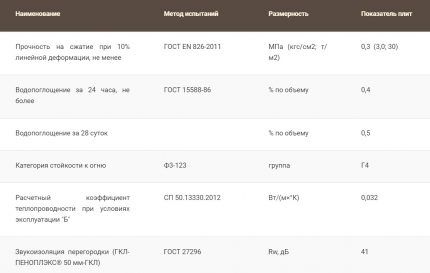

Type #2 - PENOPLEX® GEO

The main purpose is thermal insulation of buried structures - plinths and foundations of industrial buildings, parking lots and stylobates, floors (including special ones), inversion roofs.

Plates 585*1185 mm have a thickness from 40 mm to 100 mm.

Main characteristics:

The compressive strength is higher than that of Osnova - 0.3 MPa.

High-density Penoplex slabs are used in the arrangement wall drainage, reduce groundwater pressure on the foundation. The insulation also protects buried structures from freezing, preventing frost heaving.

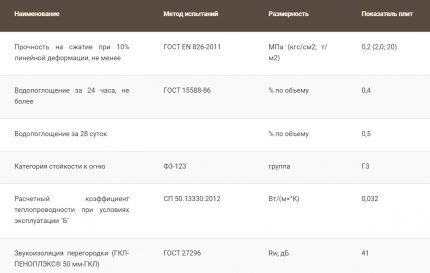

View #3 - PENOPLEX® FACADE

In terms of characteristics, “Facade” is closest to “Base”, so they are interchangeable. Thermal insulation is used for finishing external structures: outside walls of the house, ground and first floors.

The thickness of standard slabs (585*1185 mm) is from 20 mm to 150 mm.

Main characteristics:

The compressive strength is higher than that of Osnova - 0.2 MPa.

Specialists from the technical department of the Penoplex enterprise have developed the FACADE PRO system, one of the components of which is “Facade” slabs. The system effectively protects both walls and basements from moisture, cold, mechanical damage and deformation caused by temperature changes.

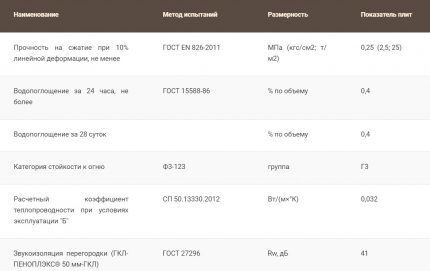

Type #4 - PENOPLEX® ROOFING

The main purpose of the slabs is to insulate the roof, but they are also used for thermal insulation of parking lots and stylobates.

Penoplex thermal insulation “Roof” does not differ in size standards – 585*1185, slab thickness – from 30 mm to 100 mm.

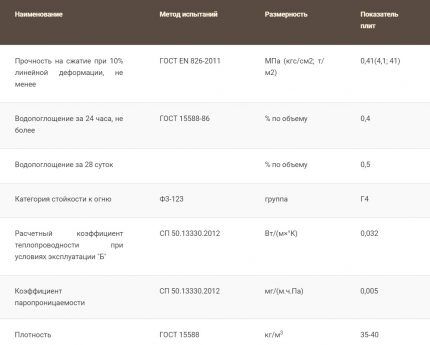

Main characteristics:

The flammability category is slightly higher than that of Osnova - G3, the compressive strength is also higher - 0.25 MPa.

In the absence of special roofing thermal insulation, you can use products similar in characteristics: “Osnovu”, “Geo” (for inversion types), “Slope”.

Type #5 - PENOPLEX® SLOPE

Thermal insulation is used as a form-building material to create a slope on flat roofs. The direction can be longitudinal or transverse.

There are several types of slabs based on the angle of inclination:

- A1, A2 – 1.7%

- B1, B2 – 3.4%

- B3 – 8.3%

The dimensions of the slabs are standard – 585*1185 mm.

Main characteristics:

The flammability category can be G3 or G4.

Using slabs, the surface of which is located at different angles relative to the roof surface, a system is created that directs rainwater to water intakes.

The advantages of Uklona are reduced load on supporting structures, quick installation without the involvement of a team.

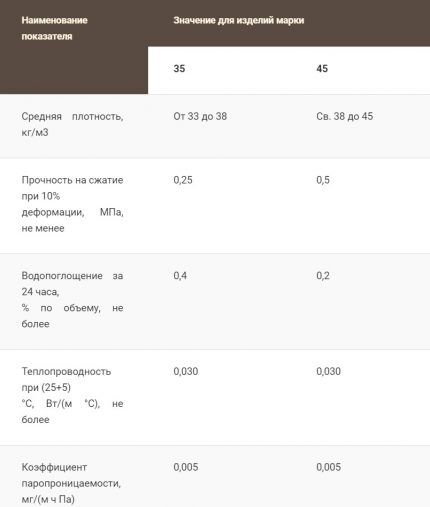

Type #6 - PENOPLEX® 45 and PENOPLEX® 45C

Both types of thermal insulation are intended for the construction of road surfaces and are used wherever there are increased load requirements.

Dimensions – 600*2400 mm, thickness – from 40 mm to 150 mm.

Main characteristics of PENOPLEX® 45:

Main characteristics of PENOPLEX® 45C:

The slabs are used for the reconstruction of city streets, laying roads, and in railway construction.

Thanks to Penoplex 45, the volume of excavation work is reduced, and it becomes possible to use local heaving soils without replacing them with more inert materials.

Penoplex slabs were used in the construction of the Crimea M-2, Don M-4, Amur highways, etc.

View #7 – PENOPLEX® BLOCK

The main purpose is road construction.

Dimensions:

- width – 600 mm

- length – 1200-3000 mm

- thickness – 120-1000 mm

Blocks are also available to order, so other sizes are possible.

Main characteristics:

There are two types of Blok products, differing in flammability class: without G4 fire retardant and with G3 fire retardant.

The blocks are made from several slabs glued together under a press. The finished products are durable and strong.

The use of blocks reduces the volume and time of work due to the lightness and standard dimensions of the products, thanks to which, in turn, calculations are quickly made. With their help, so-called “light embankments” are constructed.

View #8 – PENOPLEX® SEGMENTS

Segments are elements of various configurations and sizes that are used for insulation of pipelines. They differ in density - 35 and 45 kg/m³.

Main characteristics:

Segment length – 2400 mm, thickness – 30-100 mm, internal diameter – 60-1430 mm.

Segments with a density of 45 kg/m³ are recommended for laying pipelines using the channelless method. All types of structures located outdoors require protection from UV radiation.

Category #2 - insulation for houses and apartments

All slabs from the “amateur” segment have the same dimensions - 585 * 1185 mm, except for roofing elements, the length of which can be standard - 1185 mm, or increased - 2370 mm. In terms of properties, they are not inferior to products from the “professional” category.

The scope of use is wide:

The advantage of the slabs is that they are convenient to use in private housing construction - the manufacturer offers ready-made installation instructions and even a description of thermal insulation systems using Penoplex products.

Main characteristics:

| Comfort | Foundation | Pitched roof | Wall | |

| Compressive strength, MPa | 0,15 | 0,3 | 0,25 | 0,15 |

| Water absorption 24 hours, % | 0,4 | 0,4 | 0,4 | 0,5 |

| Fire resistance, group | G4 | G4 | G4 | G4 |

| Density, kg/m³ | from 20 | 27-35 | 26-34 | from 20 |

| Thermal conductivity, W/(m×°K) | 0,032 | 0,032 | 0,032 | 0,032 |

The difference in technical parameters concerns mainly strength and density; the remaining characteristics of Penoplex thermal insulation are approximately the same.

The most popular type is Comfort, used not only in suburban construction of private houses, but also for insulation of city apartments.

Penoplex slabs from the Comfort series are also used for arranging basements, ground floors, attics, and workshops. But do not forget about the low flammability category, which is why it is recommended to use thermal insulation in combination with fibrous non-combustible materials.

We have detailed instructions on how to do it yourself on our website. insulating the attic from the inside.

Category #3 - related materials in cylinders

Along with slabs and blocks, the Penoplex company produces products in aerosol cans.

The products have different purposes:

- winter foam FASTFIX® – for the “warm floor” system, installation of windows and doors, sealing joints and cracks on balconies, sealing holes for pipes;

- FASTFIX® polyurethane foam – for construction work, installation of window and door blocks, filling cracks and voids;

- household polyurethane foam FASTFIX® – a universal tool for all types of construction work;

- FASTFIX® adhesive – for installation of polystyrene plates on walls, roofs, floors;

- FASTFIX® cleaner – to remove products that have not yet hardened – glue or foam;

- FASTFIX® spray insulation – for thermal insulation of surfaces with complex configurations.

To use cylinders, guns or special thin tubes are used to carefully apply the composition to the surface. The chemicals are aggressive, so when working with spray cans you need to wear protective clothing and a mask.

The cost of building materials in cans is not so high (190-350 rubles), therefore, when using Penoplex products, we recommend using glue and foam from the same manufacturer.

Conclusions and useful video on the topic

About the manufacture and purpose of Penoplex:

Practical application - insulation of a loggia:

Thermal insulation of a reinforced concrete foundation covered with bitumen waterproofing:

Step-by-step video instructions for insulating a pitched roof:

Due to its resistance to biological damage, strength and low thermal conductivity, Penoplex has become one of the most popular options for insulating buildings and individual structures.

If desired, the slabs can be installed independently, without the involvement of specialists. However, before work, we recommend that you choose the most suitable type, study the instructions and make calculations so as not to overpay and use the quality of the product to the maximum.

Are you selecting the appropriate type of Penoplex for thermal insulation of your home and want to consult with our experts and other site visitors? Ask questions in the block below the article, describing in detail the areas you want to insulate.

If you have already been insulated with Penoplex and want to talk about your impressions and the effectiveness of this material, please leave your comments below.

Oh, Penoplex is a cool thing! Almost universal. Very high-quality slabs: they do not crumble, are durable, and provide good insulation. It's great that materials like this exist now. Some 30 years ago we had to struggle with polystyrene foam. I will never forget these tens, hundreds of electrified balls into which it breaks up. My balcony is insulated with Penoplex (floor and sides). Only I noticed that many people think that Penoplex is a material, and this is the name of the manufacturer. The material is called polystyrene foam. And my wife asked for one slab for handicrafts. She says it is very convenient to lay out and pin knitting on it. I also appreciated that the material does not crumble.

Expanded polystyrene is a modern and popular material, but it is not as ideal as you describe.The material is very flammable; when burned, it releases a bunch of toxic substances that if you inhale, you will immediately lose consciousness. If there is a fire, getting out of a house lined with polystyrene foam will be very difficult. The second significant drawback is that Penoplex is very popular with mice and insects, who like to gnaw holes and minks in it. And finally, one more minus - it itself releases harmful substances, which gradually accumulate in the room and affect the residents. It's suitable for exterior decoration, but I definitely wouldn't use it inside.