Extruded polystyrene foam as insulation: pros and cons of the material + tips for use

The most popular material for insulating any buildings, both walls, floors and ceilings, is extruded polystyrene foam insulation nowadays. But, like most other building materials, along with its advantages, it also has its disadvantages.

In this material we will try to analyze its strengths and weaknesses in as much detail as possible. We will also tell you how to work with this material while observing fire safety measures.

The content of the article:

What is EPPS?

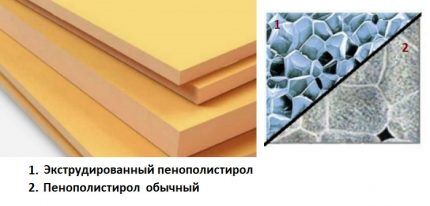

In everyday life, this material can be found under the name “foam plastic,” but this is fundamentally incorrect. These two materials are significantly different from each other. For example, extruded polystyrene foam (EPS) is one of the most deformation-resistant and durable varieties, and its heat-shielding properties are almost not affected by this.

High-strength EPS is produced on special production lines through chemical extrusion of the original raw material, which is pure polystyrene granules.

Using special equipment, raw materials are converted into foam, from which, in turn, small granules are produced. During the hardening process, these granules are pressed into layers of the required shapes and sizes, after which they can be used not only for insulating houses, but also for other purposes.

The main difference between extruded polystyrene foam and pressed polystyrene is in the characteristics of its granules. They are smaller, which makes this building material more resistant to physical stress. The size of granules of heat-insulating material produced by extrusion does not exceed 0.1 mm, while granules of non-pressed material can reach up to 10 mm.

In foreign interpretation, EPPS may be called XPS. It is produced in several varieties. After the abbreviation “XPS”, the markings of this material contain numbers from 25 to 45, which indicate its density.

The higher the value, the higher the density of the material. Particularly dense extruded material can even be used to insulate asphalt road surfaces, for example, the company's products Penoplex.

Now that we have figured out what EPS is, we will discuss in detail all its pros and cons.

The main advantages of the material

In fact, polystyrene is the same plastic, only endowed with different qualities. But just because it is somewhat lighter and less dense, it does not cease to be plastic, and therefore it has all the advantages of this material.

One of the main advantages of expanded polystyrene is lightness of the material, but its other advantages are also no less significant:

- Resistance to fungal infections. As you know, a fungus needs to eat something to survive. But synthetics, like food, are not suitable for him.

- The material does not rot or decompose. Only natural, biological materials are subject to rotting and decomposition. Eps is, initially, a product synthesized from artificial polymers, and therefore there can be no decomposition.

- Compression resistance. EPS, especially high density, can withstand enormous loads.

- No moisture absorption. Anyone knows that a plastic bag does not allow water to pass through. This quality is not alien to polystyrene foam.

- Frost resistance. The material does not freeze through because there is simply no moisture in it. It is airy, but at the same time absolutely “dehydrated”.

- Low thermal conductivity. As already mentioned, this material is literally filled with air, and air is the most intense heat insulator.

Due to the fact that EPS is essentially plastic, it has low vapor permeability, which in many cases can be considered a positive quality. Thus, polystyrene foam is successfully used for attic insulation.

Plus, polystyrene is resistant to most chemicals.

Another significant advantage is that:

- EPS, with its extreme strength, has a very low weight, which reduces the load on the foundation if the material is used to insulate the upper part of the building.

- It is very resistant to temperature changes. Temperature surges hardly expand or contract its structure, as happens with denser substances and materials.

- It is very easy to install, and since it can be easily cut even with a sharp knife, it can be used to form a block or segment of non-standard geometry of the required size with extreme ease.

- Installation work on insulating buildings using EPS can be carried out at temperatures from -50 to +70 degrees Celsius, that is, practically all year round and in any climatic zone.

- It adheres well to other building materials. Even plaster adheres perfectly to it.

And if you add in the durability of the material, you may get the impression that XPS is a panacea for all ills. But, unfortunately, insulation made from polystyrene foam also has a number of disadvantages.

Significant disadvantages of insulation

Despite the fact that the material has much fewer disadvantages than advantages, in some cases they become the key reason for refusing to use it.

As it turns out, plastic not only has advantages, and all the disadvantages of EPS are also related to the fact that it is of “polyethylene nature.”

The main disadvantages of extruded polystyrene foam are:

- Poor sound insulation. The material is able to slightly muffle sound waves, but it is not able to absorb them completely, nor can it reflect them.

- Sensitivity to ultraviolet radiation. Under direct sunlight, without specially hiding materials, for example, plaster and other finishes that, among other things, serve as protection, the EPS is destroyed.

- Low vapor permeability. In some cases this can be a plus. But not in all of them. Therefore, homes insulated with extruded polystyrene foam require flawlessly installed and effective ventilation. Otherwise, condensation will accumulate in the walls, which will contribute to their destruction.

- Low environmental friendliness of the material. No matter how manufacturers of expanded polystyrene protect their product, plastic always remains plastic. Even if it is porous, it will still decompose much longer than any non-synthetic substances.

- High cost of insulation This kind of thing also makes some people think. Moreover, the harder and denser its variety, the more expensive it is.

Separately, I would like to point out that, for obvious reasons, this material is very susceptible to attacks from rodents.

If there is open access to the EPS insulation layer, mice and rats make whole labyrinths of passages in it and even make their nests in them.

Therefore, it is advisable to carefully seal the layers of insulation with such finishing materials that rodents will not be able to get through to the coveted layer of polystyrene foam.

But the main disadvantage of this type of material is the low degree of fire resistance.As soon as the edge of the stove catches fire, the flame instantly eats it completely. Moreover, combustion is accompanied by the release of highly toxic substances into the atmosphere - phenols, which can cause no less dangerous harm to the lungs than the high temperature itself.

Ordinary extruded polystyrene foam can catch fire, depending on prevailing third-party factors, at temperatures from 250 to 450 degrees Celsius, which is why it should be used for insulation of wooden buildings and structures with the greatest caution.

In such cases, experts advise purchasing EPS, flavored with special fire-resistant additives during the production process.

Rules for working with material

Most often, extruded polystyrene foam is used to insulate foundations, floors, walls and ceilings of residential and commercial buildings. For example, for insulation of loggia walls/balcony or walls of a residential apartment from the inside.

But those who decide to use this material to insulate their own building should remember a few rules.

What are EPS boards placed on?

Extruded polystyrene foam slabs are easily attached to a flat and dense vertical surface using special types of glue. It can be Penoplex FASTFIX, TechnoNIKOL or dilutable adhesive mixtures such as Ceresit CT 83.

If you don’t want to bother with glue, or the surface structure does not allow it, you can resort to fasteners such as special dowels. In general, before insulation, it is advisable to level the surface of the walls with at least rough plaster and place the slabs on both of the mentioned fasteners at once - both on glue/cement mortar and on dowels.

Insulation of foundations and floors

In the case of foundations, all external sides are covered with EPS slabs, after which the newly made thermal insulation layer is covered with a layer of waterproofing. Often homeowners decide to insulate even blind area.

In this case, a layer of concrete is formed over a layer of expanded polystyrene, which, in turn, rests on a bed of sand and gravel mixture.

The concrete floor screed is also erected on top of evenly laid EPS slabs.

EPS is also used as one of the methods for insulating wooden floors. We talked about this in more detail in next article.

Cutting expanded polystyrene boards

Since the density of extruded polystyrene foam is an order of magnitude higher than that of regular polystyrene, a number of small problems arise with this. For example, this type of material can still be cut with a knife, but firstly, the blade must be extremely thin and strong, since a thick blade can cause the slab to discolor and crack.

And secondly, the creaking and grinding noise that will accompany such an “event” will be an order of magnitude higher than in the case of ordinary polystyrene foam. Therefore, before starting the procedure, it is recommended to lubricate the knife blade with machine oil.

Some people use a grinder equipped with the thinnest metal wheel to cut EPS blocks. Cutting, in this case, is efficient, but the whistle is so loud that it is better to put plugs in your ears. Among other things, this method is the most “unclean”. It will leave a huge amount of garbage behind.

If you decide to use a grinder for cutting polystyrene foam, we recommend that you familiarize yourself with rules of use this equipment.

The most effective and simplest method is considered to be cutting with hot wire. Take two nails, between which a nichrome wire is stretched. Voltage is applied to the nails through a transformer, the wire becomes hot and the process begins. Using this method, you can cut out the most precise blocks and shapes of a high degree of complexity.

But this method is also the most harmful.As already mentioned, phenol vapors released during the cutting process can cause significant harm to the human body, and therefore, this procedure should be performed in the open air, preferably in a draft or using a special respirator, or even a gas mask.

Fire safety measures

When working with extruded polystyrene foam, you must adhere to strict fire safety measures, otherwise extinguishing the fire will be much more difficult than it seems.

That is why, in case work is being done nearby using an open fire, for example, there is a furnace with which bitumen is melted, etc., you should always have a water supply hose, a fire extinguisher, or, at worst, a barrel of water and a bucket at the ready .

It is recommended to do the same when carrying out welding work in close proximity to the EPS. Moreover, it is advised to either shield the material from sparks and scale flying from welding, or pre-moisten nearby polystyrene slabs with water; it is better to do both at the same time. Only in this case will you protect both yourself and your building from fire.

Conclusions and useful video on the topic

You can learn about the criteria by which extruded polystyrene foam should be selected from the following video:

Considering that almost no one pays attention to the weak sound insulation of insulation, sensitivity to ultraviolet radiation is treated by the fact that the material is always protected by a layer of finishing, and low vapor permeability as a minus is eliminated by the presence of good ventilation, of the total number of shortcomings, only “not environmentally friendly” and the “expensiveness” of the material, but these shortcomings are also easy to refute.

The very concept of “not environmentally friendly” suggests that that the material is extremely durable, because over time, especially with proper use, it does not break down into its components. Isn’t this a criterion for considering the “non-environmental friendliness” of a building material as a plus? Well, regarding the high cost of EPS, there is an excellent proverb: “The miser pays twice.” With all the ensuing morals and consequences.

Have you thought about using EPS as insulation and want to clarify a couple of nuances of its use after reading our material? Ask any remaining questions to our experts below this post - we will try to help you.

If you are a professional installer of XPS and want to give useful advice to beginners or supplement the material presented above with valuable comments, write your comments in the block below.