Insulation for exterior walls of a house: overview of options + tips for choosing external insulation

The use of thermal insulation systems in building structures can significantly reduce heating costs.The use of all kinds of insulation makes it possible to speed up the pace of construction and reduce the budget for building a house. In order for them to cope with their responsibilities, you need to know how to choose them. Do you agree?

We will tell you how to choose the right insulation for the exterior walls of your home. The article we presented describes all types of thermal insulation materials used in practice and their operating features. Independent owners of country estates will find facade insulation technology here.

The content of the article:

The feasibility of external wall insulation

Heat loss through walls averages about 40%, depending on the integrity of the structure and the thickness of the wall. With rising prices for gas and electricity, it becomes unacceptable to spend money on heating the street.

Therefore, it is necessary to insulate the walls from the outside, which provides the following advantages:

- thermal insulation of the house from the outside does not take away the useful area of the living space indoors;

- there is no load on the walls and foundation;

- the insulation layer performs decorative and protective functions for the walls, extending their service life;

- walls insulated from the outside do not freeze and are not saturated with moisture from steam, as with internal insulation;

- Thermal insulation materials also perform a soundproofing function.

But the main reason for insulating the facade of a house is still economic, because this simple procedure can almost halve the amount in receipts for heating.

To correctly select a material designed to reduce heat loss, you need thermal calculation. Our recommended article will introduce you to its examples and formulas.

Types of insulation materials

So what is the best way to insulate a house from the outside to reduce heat loss? Manufacturers offer many materials suitable for these purposes. But there are several main types. These include: polystyrene foam, basalt wool, glass wool, extruded expanded polystyrene, mineral wool and others.

A less effective method of insulation is to apply a layer of plaster to the outer part of the walls. This is an inexpensive way to reduce heat loss, but it requires experience and certain skills - just desire will not be enough.

Wooden houses are often insulated using a double frame. In this case, any of the listed materials is attached to the walls, and cladding is done on top. At the same time, an air “cushion” remains between the insulation and the decorative layers for air ventilation.

Option No. 1 - polystyrene foam

Expanded polystyrene has gained the greatest popularity among thermal insulation materials. First of all, this is due to its low cost. A distinctive feature of the insulation is also its low weight.

Other advantages of the material:

- low thermal conductivity;

- affordable price;

- long service life.

One of the disadvantages is that foam does not allow steam to pass through.This feature does not allow it to be used for insulating wooden houses.

Among other disadvantages, the most significant is that polystyrene foam is a flammable material that emits substances harmful to humans during combustion. In addition, the fragility of the material, which leads to damage to the insulation even with minor mechanical stress, significantly complicates its installation.

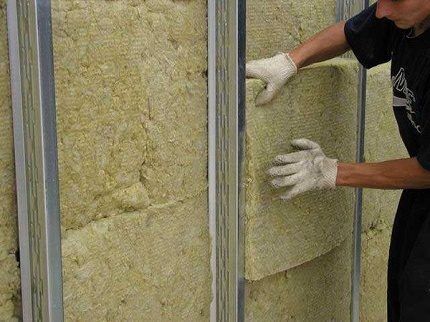

Option No. 2 - mineral wool

This material also enjoys well-deserved popularity among owners of residential and non-residential premises.

Advantages of mineral wool:

- high vapor permeability, which prevents wooden structures from rotting, and the bricks are not saturated with moisture, which prevents the appearance of mold and fungi on the surface of the walls;

- low cost;

- light weight of the mats, which makes it easier to work with them and reduces transportation costs;

- the material is not flammable, there are no toxic odors;

- long service life.

There are three types of mineral wool: slag wool, glass wool and stone wool (also known as basalt). Each material has its own characteristics.

Basalt wool is considered the most suitable for residential buildings, since it is made from safe raw materials, unlike glass wool. At the same time, the material is stronger and more durable than slag wool. But the high cost of basalt wool is its disadvantage.

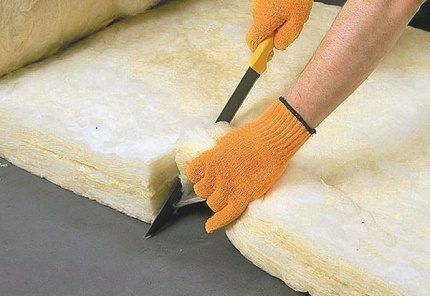

Modern glass wool is considered safe to use. Unlike the material of the same name, manufactured ten years ago, it does not irritate the respiratory tract. It can be used to insulate not only external, but also internal walls and ceilings.

It is easy to install and lightweight. Can be purchased in rolls or slabs. It is more advisable to buy rolled material for insulating long walls. Glass wool slabs are suitable for small walls.

The following advantages of the material are highlighted:

- does not absorb moisture from the air;

- no toxic odors;

- does not ignite;

- does not change shape during use;

- high performance vapor permeability;

- good sound insulation properties;

- does not interact with chemicals;

- can be used in all climatic zones of the planet.

In some cases, rolled glass wool will cost less than that made in the form of slabs. To cut it, you can use ordinary sharpened knives.

The material does not have many disadvantages. Among them:

- when insulating walls with glass wool, you need to wear protective gloves and goggles;

- the fragility of the fibers of the material, which is why a lot of synthetic substances are in the air during installation and interfere with safe breathing.

Despite the fact that modern insulating material is an order of magnitude more environmentally friendly and safer for humans; if there is a significant amount of polymer particles in the air, it is better to use a respirator.

Option #3 - uhextruded expanded polystyrene

This material is made from ordinary polystyrene foam.

After special processing, it receives the following benefits:

- increased compressive strength;

- low moisture absorption;

- low flammability or its complete impossibility, which depends on the amount of fire retardant substance;

- reduced thermal conductivity.

For such material you will need to pay a higher price than for regular foam. But extruded polystyrene foam more durable and reliable.

Another disadvantage is the smooth surface of the material slab. Because of this, solutions do not “set” with it, therefore, without preliminary preparation of the surface, such foam cannot be used in a “wet facade” design.

You will need to sand the smooth side with fine sandpaper to give it a rough surface. Additionally, you can apply a layer of adhesive primer, which will increase the penetration of the solution into the insulating material.

Option No. 4 - bulk insulation

Bulk materials can also be used for external thermal insulation.

Among them, the most popular are:

- vermiculite;

- perlite crushed stone;

- expanded clay

Vermiculite can be used not only to insulate walls outside the room, but also from the inside. It is used to insulate sewer and water pipes, floors, attics, and foundations. It can be produced in the form of slabs. There are technologies by which this material is added to concrete or mortars.

Vermiculite is a natural material that does not emit harmful toxic odors. Its advantages are: durability, lightness, fire resistance, low thermal conductivity and sound absorption.It also does not absorb moisture.

To insulate the outer wall, bulk material can be added to the mortar or poured between the main wall and the decorative one, built on a foundation made of facing bricks. This method is more expensive, as it requires expanding the foundation. An additional load on the foundation slab is also expected.

Vermiculite is sold in paper bags, usually 25 kg. This is very convenient during transportation, because for delivery you can use your own passenger transport.

Perlite, depending on the fractions, can be of different sizes. It is also used to insulate roofs and floors. Is a volcanic glassy a breed that has no smell. Widely used not only in construction, but also in metallurgy and agriculture.

Advantages of the material:

- porous structure;

- low cost;

- easily absorbs and releases moisture without losing its qualities;

- fire resistance;

- low thermal conductivity.

A perlite layer of just 3 cm has the same thermal insulation efficiency as brickwork 25 cm wide.

Expanded clay – granular porous material obtained artificially. When burning several components (peat, expanding clay, diesel oil, sawdust, sulfato-alcohol stillage) produces low-melting raw materials. It is foamed and heat treated to give it its final shape.

The material is sold in fractions from 2 mm to 40 mm. Expanded clay from 10 mm to 20 mm is considered the most popular. It is they who need to fill the space between the walls - the main and decorative ones.

A layer of only 100 mm replaces 1000 mm of brickwork in terms of thermal conductivity. In frosty weather, insulation will prevent the house from losing a lot of heat, and in the summer heat it will keep the room cool due to its extremely low thermal conductivity.

Advantages of wall insulation with expanded clay:

- this is one of the cheapest insulation materials;

- reduction in heat loss reaches 75%;

- can be used at any outside temperature and humidity;

- long service life;

- there is no burning or rotting of the material;

- expanded clay does not attract insects and rodents;

- You can insulate a house yourself, as it does not require high technical skills or special tools.

Expanded clay can be poured into the layer between the decorative and load-bearing walls in its pure form, or mixed with cement. The proportion is 1:10 - one part cement and ten parts expanded clay. You will need a concrete mixer and water to dissolve the cement. The prepared mixture is poured into the empty space between the walls.

You can also do it differently: first pour expanded clay to a height of 300 mm, and then saturate it with the prepared cement “milk”. Then add insulation again. And repeat this until the height of the insulation reaches the desired level.

Any of the methods will not worsen the thermal insulation properties of the material.

Facade insulation technologies

There are three main technologies for facade insulation:

- «well» method — construction of a multilayer wall;

- "wet" method - under plaster coating;

- "dry" method — “ventilated facade” technology.

Depending on the selected insulation method thermal insulation materials suitable for implementation should be selected.

"Wet" method is the application of a finishing coating to a layer of insulation in the form of a plaster mixture. Since the mixture is rich in moisture, it is necessary to use only materials that do not absorb water. Polystyrene foam is best suited for this, but mineral wool can also be used.

Depending on the strength of the wall and the integrity of the brickwork, the plaster system can be “light” or “heavy”. In the first case, the main goal is to reduce the weight of the thermal insulation layer.

The insulation is fixed to the wall with glue and dowels. From the outside it is protected by a metal profile made of thin aluminum. Only a thin decorative layer of plaster is applied to it to level the surface of the wall and give it a finished visual appearance.

In a “heavy” system, the insulation is fixed with metal anchors and pressed down with reinforcing mesh. A 5-5.5 cm layer of plaster is applied on top. This design is reliably protected from temperature changes and moisture.

With the “dry” method Insulation plaster is not used at all. The insulation is fixed to the wall with glue and mounting umbrellas. In this case it is ideal Penoplex, for which telescopic fasteners with wide heads and other mounting elements are specially produced.

On the outside, the insulation is protected by a membrane layer, the main task of which is to provide protection from atmospheric water. The membrane is fixed with spaced metal or wooden slats, forming a ventilation gap between the thermal insulation and the sheathing.

The gap width is up to 5 cm. The cladding layer can be made of various panels: wood, steel. It can also be half-brick masonry, tiles or siding. This method of insulation is more durable, unlike the “wet” one, and can reach a service life of half a century.

Using multilayer technology the surface is insulated with two more layers: insulation and an outer wall made of brick. This method of insulation was described above. Various bulk materials that are resistant to steam, condensation and moisture (expanded clay, perlite, etc.) are suitable for it.

Recommendations for choosing materials

To choose the right insulation, you need to take into account several more factors that may affect the quality of the work performed.

Condition of walls and foundation. If the house is old, and the foundation or brickwork is already cracked, then it is necessary to abandon heavy insulating structures. In this case, it is best to install lightweight and durable materials. It is better to attach them using special adhesives.

Architectural complexity of the building. Polystyrene foam and mineral wool are well processed and make it possible to provide reliable insulation of walls with recesses, patterns and other decorative elements.

Resistance to insects and rodents. Often under a layer heat insulator Small rodents and insects, such as mice or ants, can make nests for themselves.

If there is such a problem on the site, then it would be advisable to carry out insulation using bulk materials. Expanded clay is good because it does not attract animals.

It is also necessary to take into account other factors, such as the price of insulation, features of its installation, wall material, impact on the environment, fire resistance, etc.

If you plan to install a thermal insulation system from inside the house, it is worth reading next article, which describes in detail the materials and methods of their use.

Conclusions and useful video on the topic

To avoid common mistakes when choosing materials for insulation, we recommend watching the following videos:

With all the variety of available materials and insulation methods, you can always choose the most suitable one. Despite the fact that some work seems easy to perform, it is still better to entrust it to experienced builders and heating engineers.

Would you like to talk about how you selected insulation for furnishing your own country house? Do you have information that will be useful to site visitors? Please write comments, ask questions on controversial or interesting points, post photos in the block below.

Nowadays you can’t live without high-quality insulation. You cannot save on this, because this is a reduction in your expenses, which subsequently go towards heating. Even if, of course, it does not immediately pay for itself, the benefits of insulation are nevertheless tangible.

I initially thought of insulating it inside, but then I realized that it would be better outside. After all, this way I won’t “eat up” the useful space of the rooms, there will be less noise from the street, especially if the windows are soundproofed. I chose mineral wool for insulation and did everything myself.

Hello. Houses are usually insulated from the outside to avoid the dew point shifting inside the building structure. So, you were absolutely right in choosing this particular method of arranging the insulation.

Min. Vata is harmful to health. It has long been banned in Europe, for example, in Germany. It is better to use stone wool, or MDVP or bulk insulation.

Hello. Glass wool, stone wool, slag wool, basalt wool - these are all MINVATA (mineral wool). Its varieties. Therefore, recommending stone wool instead of mineral wool is the same as recommending Renault instead of a car.

In addition, no one forces you to smell mineral wool or eat it. It hides in layers and has no effect on health, except perhaps on the health of the finisher during work, and then it’s just enough to follow the rules of equipment. And now sandwiches have long been invented as the safest use of this type of insulation.

In addition, min. cotton wool is not a sound insulator. At all.

Hello.Is it true? May the mineral wool manufacturers forgive you :) Even logically think about how a material with a flexible fibrous and dense “skeleton” can have poor soundproofing properties. Remember the expression - “you can hear it like through cotton wool”, “like cotton wool in your ears”... And then look at the table of soundproofing characteristics of this material.

Yes, you need to insulate from the outside. In addition to the already indicated factor of saving the internal space of the house, external insulation extends the service life of the building, since the facade will be less susceptible to temperature fluctuations. They dissuaded me from using mineral wool. They say it's not good for insulating the outside, so I used polystyrene foam. Good material and very easy to install, produced immediately in convenient blocks.

In addition to wooden buildings, foam plastic cannot be used in aerated concrete structures. This applies specifically to the insulation of external walls. It can be used internally, but extremely rarely. Let’s say that the temperature in the building is always constant and people do not live in it for a long time. The best option for such walls is mineral wool. It is easier to install, and the price is not steep, like the other options presented.

Hello. Aerated concrete has high vapor permeability parameters. People who live indoors excrete and produce large amounts of liquid, which somehow turns into steam. It would seem that the mythical breathing walls should absorb all this steam, but at the same time, about 97% of the steam rushes out through the ventilation. In addition, the vapor permeability of walls is reduced by finishing materials - wallpaper, paint, plaster, and so on.

According to construction recommendations, the design feature of a building should first of all include several factors: thermal insulation, air insulation, vapor permeability. That is, the diffusion of vapors from the house should not rush through the walls, and a comfortable microclimate is ensured by properly equipped ventilation.

Therefore, in any case, although insulation with mineral wool will create the potential for vapor permeability, this method is not correct. With any insulation, it is necessary to provide a vapor barrier circuit, which will be located not only in the pie insulation on the outside of the building, but also, first of all, inside. Of course, to begin with, we provide high-quality ventilation.

The second step will be to create a vapor barrier that will prevent the diffusion of vapors into the material, in our case, into aerated concrete. And only then we proceed to the exterior finishing, including foam plastic.

EPS/EPS cannot be used, especially in wooden/brick/aerated concrete houses.

Why are you so strict with wood/brick/concrete? Of course, in most cases, ventilated facades are chosen, but this is not at all necessary :)

I just looked at the user comments... Everyone is talking about meters, sound insulation, harmful materials, because of which external insulation should be carried out.

I will make a small addition to the article.

There is such a thing as dew point. This is the place where the incoming cold steam from the street encounters a warm temperature at which condensation may occur. Same thing with your wall.Imagine, an ordinary thin wall is completely heated by the house, but at the same time it is cold in the house. You decide to carry out insulation, install insulation on the walls of the house “according to Feng Shui” and then live peacefully until a lush moldy garden begins to grow under your insulation. This happens due to the shift of the dew point inside the building structure and stopping the movement of moisture by internal vapor barrier materials.

It is necessary to insulate in such a way that the vapor barrier properties of the walls are reduced, and the thermal insulation properties increase gradationally. In addition, materials such as brick or concrete walls accumulate temperature and then release it in the opposite direction. Remember the hot summer, when a brick heated in the sun gives off heat in the evening. But the same thing happens in the cold. Imagine that with external insulation, they absorb cold in much smaller quantities, but at the same time they warm up from the inside.

Thermal insulation prevents the flow of air, however, unlike materials, it does not accumulate it. This means that internal insulation is in any case much less effective, that is, the cooling of the house in this version occurs much faster.

Next about cold bridges. Floor slabs, seams, etc., form cold bridges. If the insulation is internal, they are not closed in any way and cold air penetrates through them. Thus, it is external insulation that is much more effective than internal insulation in terms of heat and sound insulation and, in addition, extends the service life of building materials.