How to choose good dowels for aerated concrete: review of the best, pros, cons

Considering the characteristics of the foam concrete material, choosing a dowel for aerated concrete is not as easy as it might seem at first glance.There are many models, each with advantages and disadvantages.

Aerated concrete is a capricious material, and what is forgiven when installing fasteners on brick or expanded clay concrete can be a serious mistake with consequences for an aerated block.

The content of the article:

Requirements for fasteners for aerated concrete

Of all types of wall blocks, aerated concrete requires the most careful preparation for future installation of fasteners. The material is soft, it is easy to cut with a hacksaw or drill a hole with a regular drill with a feather drill. But easy workability turns into a negative when it comes to reliable fixation of the dowel inside the foamed cement-sand mass. The strength of aerated concrete is low. A small plate can be broken or crumbled by hand.

Therefore, the design of the fastening and specifically the dowel must meet 2 conditions:

- Low specific pressure on the surface of aerated concrete.

- Uniform distribution of pressure forces from the dowel plug.

The holding strength of the dowel can be ensured by washers or reverse cones. But the depth of their embedding (immersion) in aerated concrete must be sufficient to avoid chipping and cracking of the material.

One of the problems with aerated concrete is the fragile edge of the hole for the dowel. Therefore, some types of dowel plugs are simply driven into the aerated block even without pre-drilling. All dowel-type screw screws, as well as dowel-screws, are installed inside aerated concrete without drilling a hole.

A selection for you:

Types of dowels

For fastening on aerated concrete, you have to use long self-tapping screws with a diameter of 6-12 mm, a length of 120-180 mm, without plugs. This option is possible for walls made of gas-filled concrete up to 50 cm thick. In other cases, fasteners with enlarged plugs, large-diameter plastic screws, and specially designed dowels with drop-down petals are used.

The fastener inside the gas block is held solely thanks to the helical spiral on the surface of the rod:

- classic dowel inserts;

- plastic dowel plugs with an additional notch on the surface;

- specialized dowels for aerated concrete;

- RVT screws;

- chemical anchor.

The last option for blocks is used only in exceptional cases due to the high cost of fasteners. One package is enough for several installation points, but the cost of a container with resin is about 20 times more than even ordinary plugs and 10 times more than specialized high-strength models. Therefore, it makes sense to buy a chimanker only for situations where there is no other way to make a particularly strong fastener.

For fastening to aerated concrete, dowels or screws with a protective coating can only be used. The aerated concrete mixture contains lime; it is used as one of the gas-forming agents. After the porous mass has set, part of the lime remains in the mixture and “eats” the fastening metal.

Therefore, for aerated concrete, models with plastic or nylon plugs are more often used. It can be long - from 120 mm to 150 mm.

In addition, specialized reverse cone spacer models are often used to hang heavy objects, such as kitchen furniture. This is the only type of dowel that is not afraid of vibrations and does not lose its load-bearing capacity even under shock loads.

Facade dowels are usually installed on the external surfaces of aerated concrete walls. The cork material reliably seals the hole in the wall and prevents moisture from penetrating inside.

Review of the best dowels

Aerated concrete is widely used both as blocks for wall masonry and for wall insulation. The density of the cellular mass for different brands of aerated concrete blocks is very different. The heaviest blocks have small pores. This material is used to build walls. Their characteristics resemble poplar wood.

For such aerated concrete, you can use traditional fasteners - the same dowels or screws with coarse winding. In this case, the dowel plug can be taken.

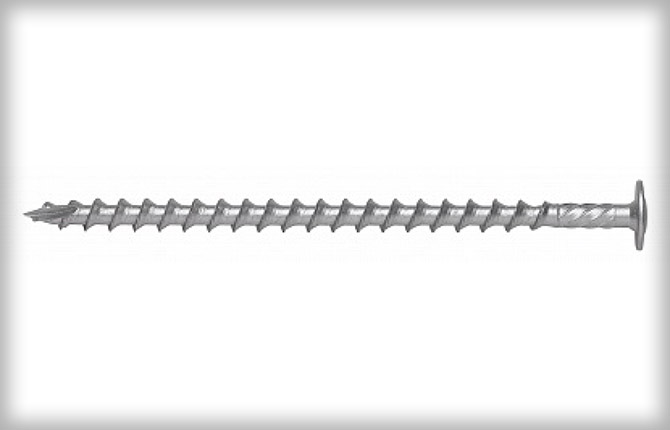

Self-tapping screw

It is possible to fasten on aerated concrete without a dowel if the density of the block is high. How to determine the suitability of aerated concrete? Just hammer a regular nail into the wall with a hammer. It should fit into the block material like it would into wood, without sinking too much into the material with each blow of the hammer.

Fastener characteristics:

- diameter 10 mm;

- length 185 mm;

- Torx 40 slot;

- zinc coating.

The peculiarity of the screw is the specific shape of the spiral.It has a reverse slope. This scheme ensures easy “entry” of fasteners and high resistance to pull-out load.

SORMAT can be used as a lightweight fastener. Resistance to pulling load is only 15 kg, shearing load – as much as 25 kg. This is enough for a couple of SORMAT to secure a shelf with a total weight of up to 15 kg on aerated concrete.

Very small objects can be mounted on a wall made of aerated concrete using self-tapping screws with a wide screw knurl and a large “hat”. The fastener can be screwed directly into aerated concrete or installed using an additional dowel, usually nylon or polypropylene.

Thanks to the specific shape of the “thread”, the self-tapping screw cuts deeply into the body of aerated concrete. Despite the short length of the helical spiral, the strength of the fastener is sufficient to secure a small object weighing up to 5 kg to aerated concrete.

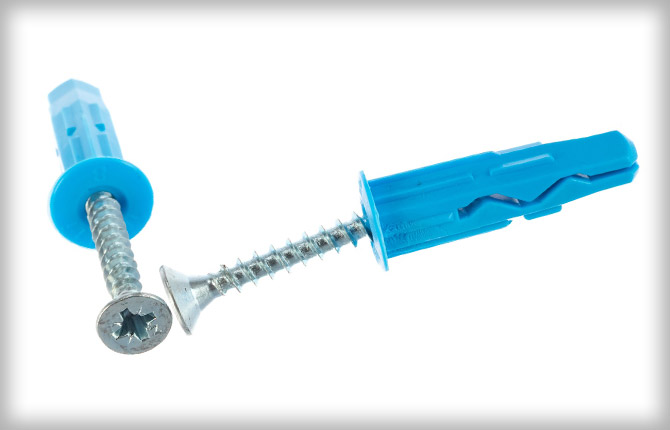

Universal

Small objects can be fixed to aerated concrete using universal dowels. Typically, such fastening is used on internal walls made of aerated block. The thickness of the wall does not allow the installation of full-length fasteners, so shortened fasteners are used.

As a rule, the best dowels recommended for use on aerated concrete have additional ribs and notches on the surface. They enhance adhesion and prevent the fastener from turning when the screw is tightened.

For aerated concrete, dowel plugs with a specific surface shape are used.

For main walls made of aerated concrete, it is better to use models with an extended plug and screw. This self-tapping screw has a screw knurled spiral on the rod along the entire length, almost to the very head.

The surface of the cork is “cut” so that the plastic remains smooth until it is installed inside the gas block. And only after tightening the screw, the rod pushes the spikes out, they “bite” into the aerated concrete and well fix the insert inside the block.

If aerated concrete requires a short dowel, then split models with circular one-sided notches hold better. The profile of such notches is asymmetrical, the slope is made towards the hole. As a result, the cork enters easily and comes out of the gas block with difficulty.

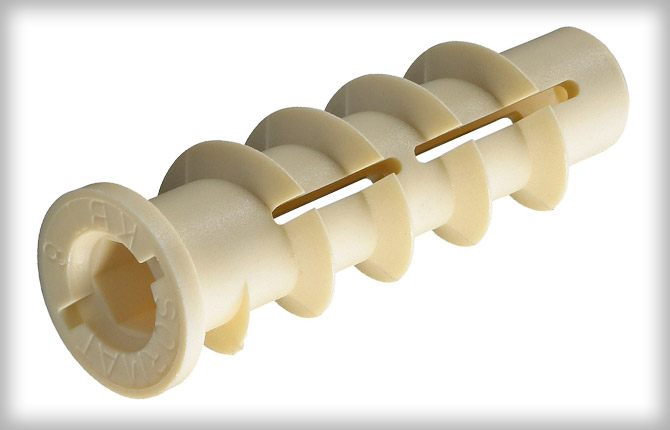

Specialized

This type of dowel includes models specially designed for installation on aerated concrete.

The most popular model is with protruding ribs twisted at an angle like a spiral. The fastening was developed specifically for installation in foam concrete and aerated concrete. It is believed that such a nylon plug can withstand loads of up to 150 kg.

Installation of a spiral dowel is carried out only with preliminary drilling of the wall. The hole diameter is selected 1 mm less than the minimum bushing diameter. This part of the plug is made conical, with a pronounced transition to a cone in the rear part. Hammer the cork in with a hammer. Moreover, you have to hit the dowel hard.

Sometimes they try to install a spiral dowel on D600 aerated concrete without taking into account the resistance of the wall material. If you hit too hard, you can break the spiral ribs on the dowel.Therefore, if you need to perform fastening on heavy aerated concrete, it is better to use more balanced plug models.

For example, a metal dowel-sleeve, known as a “crocodile”. The steel sleeve with 4 longitudinal cuts and perforated edges has a slight taper. This means that after drilling, inserting the dowel into the hole will be relatively simple. Using your fingers, you can simply insert the dowel halfway, and hammer the rest into the aerated concrete.

The surface of the “crocodile” is profiled in such a way that when the screw is screwed inward, the petals of the sleeve will unbend and cut into the aerated concrete with teeth and extruded waves. In general, the mount sits quite firmly inside the gas block. It can withstand a pull-out load of up to 220 kg and is second only to another specialized dowel – a driven expansion dowel, made in Germany.

This is one of the most durable and reliable fastening systems for aerated blocks. It is used mainly on medium and heavy aerated concrete. In this case, the resistance to pull-out load reaches 350 kg. It is used less frequently on lightweight aerated blocks, since the material often cracks during installation.

The design consists of 3 elements:

- Steel reinforced bushing with split petals.

- Bolt with nut and support washer.

- Slider with threaded insert.

To install, you need to drill a hole with the diameter indicated on the sleeve. Next, the dowel plug is inserted by hand and driven into the aerated concrete, like a regular nail. Now you need to rotate the bolt head, tighten the slider and insert the dowel petals. This is not a reverse cone, but the fastening strength is, as for aerated concrete, a record 300-400 kg.This model can only compete with professional façade dowels.

Professional

The facade dowel is huge in size. The length and diameter of the plug are 150 mm and 12 mm, respectively. When installed correctly, the fasteners can withstand heavy loads - up to 360 kg. But at the same time, the price for facade models is approximately three times less than for a German expansion dowel.

For example, a screw dowel-plug RVT. This is a cylindrical dowel plug with a regular helical spiral. A cut is made along the axis. This allows the plastic to deform when the screw is screwed in.

The screw dowel is considered more durable, “hardy” and reliable. For example, a “screw” measuring 10x50 mm with an M4 screw can withstand a pull-out load of up to 300 kg. But only on aerated concrete brand D500. On lighter brands, the strength is reduced to 250 kg.

There is a modification of the screw dowel. This is a self-installing dowel plug for mounting on drywall. It has the same shape, slightly smaller dimensions. But there is a difference - there is a feather drill on the spout.

It turns out that this type of dowel fastener works great on light grades of aerated concrete. Drilling a hole is not required to install the dowel. It is enough to place the cork on a cross-shaped screwdriver bit, turn on the screw and screw it into the gas block until it stops. But the dowel will gain full strength only after screwing in the self-tapping screw.

The strength of the fastener is relatively low. For example, for a 32x14x5mm cork, the pullout load is only 50 kg. This may not be much, but for lightweight aerated concrete, installation speed is often more important than safety margin.

Another type of dowel for gas block used by professionals is shown in the photo. It is not similar to any conventional type of dowel fastening.

The dowel is driven into gas-filled concrete without pre-drilling, like a regular nail. This type of fastener is designed for installation for medium and light grades of aerated concrete D400. It is not easy to hammer such fasteners into heavier material; you will have to hold the plate with your hands until the dowel enters the body of the gas block by at least a third. From lightweight aerated concrete, a metal dowel will simply fall out, since the expanding action from the wrapped screw will not be enough for reliable fixation.

The reason is that when fasteners are driven into cellular concrete, part of the protective coating is erased, covered with deep scratches, and the metal begins to rust. Sometimes so much so that rust spots appear on the surface. And although manufacturing companies claim that this only increases the strength of the fasteners in the wall, it is still better to use the dowel and nail indoors. If you had to use it on external walls, then you need to install it on any colorless varnish or paint.

Non-standard solutions

The range of dowels for gas blocks is not limited to universal, specialized and professional types of fasteners. For example, on gas-filled concrete, you can use a new type of plastic fasteners designed for installation on external foam block walls.

The standard length of the anchor dowel is 18 cm, but for conventional fastenings you can use shortened versions of 50 mm and 70 mm.

The main advantage of the dowel anchor is the high strength of the fastener. For aerated concrete brand D600 – 400 kg, for D300 – 140 kg.

Another option for non-standard fasteners is a thermoplastic dowel. This is a variation of the usual one, but the design uses a low-melting (polyethylene) dowel plug. In size and design, it is no different from most plastic plugs, only a special fire-retardant coating is applied to the surface.

For heavy aerated concrete, choosing a dowel is not difficult; you can use all types of fastenings for foam blocks or expanded clay concrete. The situation is much more complicated with a lightweight gas block. In this case, the plug and screw must be selected individually, focusing on the characteristics of the wall.

Tell us about your experience in selecting and installing dowel fasteners. Which models, in your opinion, can be considered the most successful for gas blocks?

Everything on aerated concrete is secured with ordinary dowels; you just need to choose the right size. No spacers or tapers are needed. Everything is holding up.

Aerated concrete is a treacherous material, so you need to check how the screw or screw holds. Often the dowel begins to shed sand, which means there is a chip or crack somewhere inside. We have to change it to something larger in size.