Water ball valves: types, classification, design and principle of operation

Water taps of various designs are found in every home.I don’t really want to call in a plumber every time the faucet breaks, do you agree? But in order to cope with the repair, you need to know the design of a ball-type water tap and its main parts.

This is where we will come to your aid - this article discusses the existing types of ball valves, their design, classification, marking features and operating principle. Thanks to the knowledge gained, you will be able to handle all types of repairs yourself.

For a better understanding of the material, we provided the article with visual photos and diagrams showing the design of a valve with a ball mechanism, and also selected videos that provide information in an accessible form on how to turn off and install the valve.

The content of the article:

Classification of water ball valves

The most popular are ball valves, invented 100 years ago. They are easy to install and affordable. The consumer is presented with a number of design options with functional and design differences.

When talking about ball valves, it is worth separating the concepts of “water tap” and “mixer”. Both varieties are united by a common structural element - a locking or regulating part in the form of a body of rotation of a rounded configuration.

Actions to lock the pipeline or regulate the flow are performed by rotating this element around its conditional central axis.

Taps can either be installed between elements of the water supply system or be the end point of the pipeline.

In the first case, the devices are called shut-off devices, and in the second they play the role of water-folding devices and most often are well-known mixers.

A mixer is a mechanism for mixing water and regulating its temperature, while a walk-through faucet can only regulate the amount of pressure.

Shut-off ball valves are divided into pass-through, i.e. installed in a straight section of the pipeline, angular, i.e. located in an area with a change in flow direction by 90º, and three-way, i.e. supplying flow to two receiving pipes.

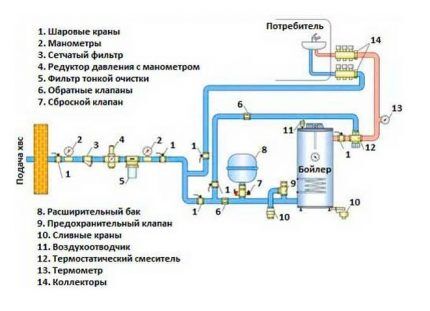

Fittings with ball valves are used in water supply and heating circuits.

According to throughput parameters, cranes used in thermal systems are divided into:

- Full bore. Ball devices in which the diameter of the outlet hole of the ball plug, also known as a valve, is equal to the diameter of the pipeline on which the valve is installed.

- Reduced. Plumbing fixtures in which the diameter of the outlet hole of the ball plug is smaller than the same size of the pipeline in most cases by one standard size.

Reduced type valves allow you to shut off the heat main quickly, but without the threat of water hammer.

By type of connection to the water supply system:

- Threaded. Fittings with internal or external conical or cylindrical threads. Mounted by screwing in couplings or screwing in pipe fittings. The most common type in public utilities is easy to install and makes repairs easy.

- Combined. Devices equipped with internal and external threads.On one side they are connected by means of a coupling with an internal thread, on the other by a nipple fitting.

- Welded. Mounted by welding. When executed flawlessly, the connections provide perfect tightness and do not require periodic adjustment of the position of the couplings, like the previous version. However, they are inconvenient to repair, because along with them, part of the pipeline must be dismantled.

- Flanged. Installed using flanges on critical pipelines. They can be repeatedly dismantled and then reinstalled. They periodically require monitoring of bolted flange tightening.

IN autonomous water supply systems The most commonly used are conventional threaded devices, which make it possible to assemble a pipeline of any complexity from all known types of pipes or their combinations.

By type of housing:

- all-welded, the body of which is a single structure;

- collapsible, when the body elements are bolted together and can be easily disassembled.

The first type of product is considered the most reliable, but in the event of a malfunction, such a device cannot be repaired. Collapsible taps are more likely to fail, but can be easily repaired.

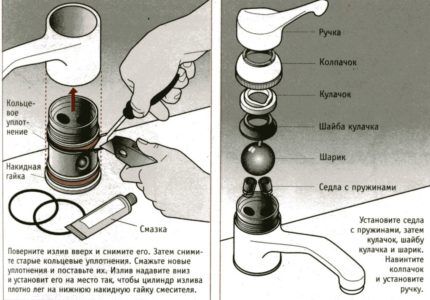

Information on how repair ball mixer, discussed in our other article.

By type of fluid passed through:

- for cold water up to +35 ºС;

- for hot water up to +90 ºС.

The devices are controlled using a lever or butterfly valve.The choice of a crane with a specific control method depends on the location of the fittings and the preferences of the owner. Valves with a lever are often installed on the central sections of the pipeline, and with a “butterfly” - on the branches of the system.

Mixers with a ball mechanism are installed in kitchens, bathrooms and are the end points of the water supply system.

Design and principle of operation

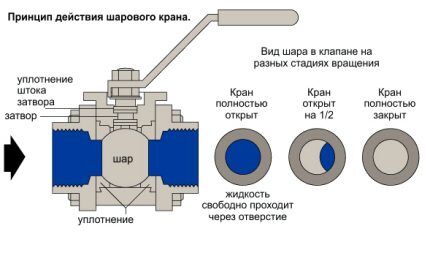

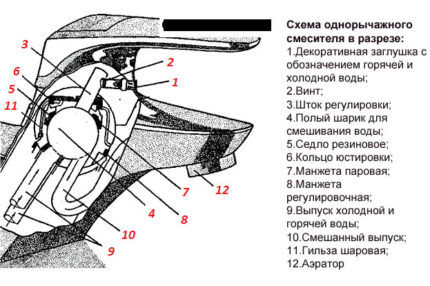

The body of the shut-off device is a piece of pipe expanded in the middle part. The extension contains a seat made of sealing material, inside of which there is the main element - a ball, also known as a shutter or plug.

The ball can rotate freely inside the seat. It has only one through hole in the shut-off valve.

Control devices and valves that redirect flow may have 2 or 3 holes. If the tap is used to regulate the pressure of hot or cold water, then there are two holes, if the device is a mixer, then there are three holes.

The principle of operation is very simple: when the axis of the hole in the ball is aligned with the axis of the faucet body, water will begin to flow out of it.

Those. when the plug is deployed so that its hole coincides with the direction of the pipeline, as if continuing it. In this position, the flow of liquid, steam, gas passes through the pipeline, including through the tap, freely.

When the ball valve is turned 90º, the passage for water, steam, gas is blocked by the side on which there are no holes. In this position, the flow of the medium stops completely, because it rests against the solid wall of the valve.

However, with this simple device you can regulate the flow parameters. When turning 45º, for example, the flow will only be blocked by half.

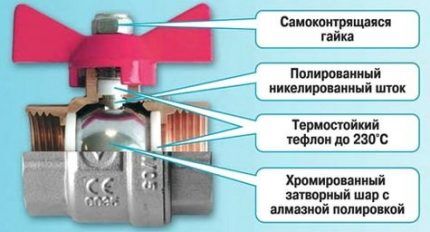

To control the ball, a rod connected to a lever is used. There are o-rings on both sides of the rod. The hole in the body through which the rod passes is also equipped with a washer and an O-ring.

Ball valves are made of brass or various grades of steel. Brass devices are considered more reliable, their service life exceeds 10 years. Steel products are very rarely used in everyday life; they are mainly used for industrial pipeline systems.

More recently, manufacturers began to produce cranes whose body is made of high-strength plastic. Unlike brass, such devices are not subject to corrosion and are much cheaper.

The only disadvantage of plastic products is that they cannot be used for hot water.

These taps are most widely used in everyday life.A feature of their design is that the ball is not rigidly connected to the stem and can move under the influence of water, pressing against the sealing ring, thus sealing the tap.

A floating ball is used in mechanisms whose nominal size does not exceed 20 cm. Such devices are installed in internal water and heat supply systems. Almost all domestic and imported household faucets also have a floating ball mechanism.

The design of the valve body with a floating ball can be either welded or dismountable. Sealing elements can be of different hardness. Small household appliances are usually collapsible and have soft seals.

There are valves in which the locking element is fixed on the axis of the stem, and the seals are pressed against the ball using tightening bolts or springs. To facilitate closing/opening, the trunnion is equipped with bearings.

This design is the most reliable, but due to its high cost it is used extremely rarely in everyday life and usually in the most critical areas of the water supply system.

Marking of ball valves

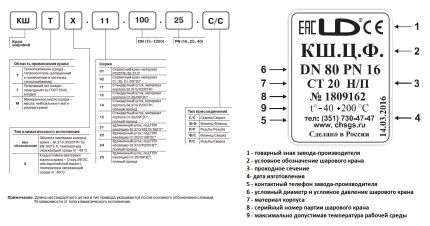

Each manufacturer has its own range of manufactured cranes, but all Russian-made products, as well as imported devices sold in the Russian Federation, comply GOST 52760. This standard regulates the marking of shut-off and control equipment, which includes ball valves.

Labeling must include:

- nominal bore (nominal diameter), denoted by the abbreviation DN;

- nominal pressure indicator - PN;

- the value of the design (working) pressure;

- an arrow indicating the direction of water movement;

- maximum operating temperature;

- release date.

In accordance with GOST 4666 devices made of cast iron are painted black, and those made of stainless steel are painted blue. Taps for hot water are marked in red.

Installation and operating rules

The design of the ball water tap makes it easy to install it yourself where it is required. The crane must be mounted in a place so that during operation it does not interfere or is not subject to mechanical stress.

At the same time, unimpeded access to the crane must be ensured in case of control of operation, correction of repairable damage and dismantling if replacement is necessary.

The locking device is installed on metal or plastic pipes according to the following algorithm:

- The old faucet (if any) is removed and the threads are cleaned of any remaining tow and sealant.

- The threaded seal is wound tightly.

- A new, appropriately sized locking device is screwed on. Please note that the thread on which the product is screwed must not be rotten; it must have at least four turns. Otherwise, it is necessary to replace the entire pipe or part of it.

When installing a water supply system from scratch, first of all, you need to mark the place where the tap will be installed. The pipe is then cut at this point, the corresponding thread is made, onto which the locking device is screwed.

To cut pipes, special equipment is used - a pipe cutter. But you can also use improvised tools, although it is not so convenient, and the cut will not be as even and smooth. You can read more about choosing a pipe cutter for copper pipes In this article.

Do you have a water supply system made of metal-plastic pipes? ABOUT types of pipe cutters For such a pipeline, you can read our other article.

In both cases, before installation you need to pay attention to the arrow indicating the direction of flow and be sure to comply with this condition. Before screwing the faucet, it is recommended to wrap the thread with FUM tape. This will ensure the most reliable sealing.

After installation, it is necessary to check the functionality of the locking device. To do this, you need to turn on the water and check for leaks, gradual formation of drops, or smudges. It is also necessary to make sure that nothing interferes with the control of the crane, i.e. the lever or “butterfly” has free movement.

To install the device using the welding method, electric welding is used. IN welding process It is important not to damage the ball mechanism and o-rings.

First, one pipe is welded, then the second, while in the vertical sections the valve must be installed in the “closed” position, and in the horizontal sections in the “open” position.

The operation of ball mechanisms does not cause difficulties; they are used either closed or open.It is theoretically possible to regulate water supply using a ball valve.

However, it is worth considering that such a faucet is, first of all, a shut-off device and too intensive use will lead to rapid wear of the seals. To regulate the flow, it is better to use ball mixers or a needle valve if it is impossible to install a mixer.

Do not install household taps where process water containing solid impurities passes through the pipes, because they will quickly damage the O-rings, rendering the locking device inoperable.

Advantages and disadvantages of ball valves

Ball valves are very popular in a wide variety of industries. They are considered reliable shut-off devices and are part of the water supply system of city apartments and private houses.

In addition to reliability and simplicity of design, products of this type have many other advantages:

- long working life, long service life;

- rarely break down, easy to repair;

- high degree of tightness; if installed correctly, there are no leaks;

- convenient to use, turning or pressing the lever is enough to shut off the water flow;

- a huge range of sizes and types;

- Easy to install, you can install it yourself without involving a plumber.

Ball valves have no disadvantages, they are affordable, and every hardware store will offer you a choice of several products of various sizes.

A mixer with a ball mechanism will relieve its owners from labor-intensive and frequent replacement of gaskets, as well as problems with water leakage, which are so often found with outdated valve taps.

How to choose a good ball valve?

As already mentioned, modern manufacturers produce more than 4 thousand different types of ball valves, so for an unprepared buyer choosing a shut-off device is a difficult task.

When choosing a mechanism, in addition to the main parameter - the throughput diameter, you should pay attention to the following factors:

- Appearance. A high-quality product has no chips, nicks, or dents. Its surface is smooth, the manufacturer's markings are clearly visible.

- Permissible pressure. Of the two options, it is better to choose the valve with the maximum allowable pressure, which will be greater. Please note that this figure for hot water should be at least 20 kg/cm², for cold water - at least 10 kg/cm². The greater the permissible pressure, the better the product will withstand water hammer in the water supply system and heating, periodically occurring in the pipeline.

- Housing version. For connecting household appliances, shower cabins, water supply system wiring inside the house or piping in the apartment It is better to give preference to simpler and more repairable collapsible cranes. For the most important areas, such as a central water supply, the best option would be an all-welded housing.

- Case material. The highest quality products are made from brass.Be careful! Under the guise of a brass faucet, they may sell you a fake made of silumin, a cheap, low-quality metal. You can identify a fake by weight: brass The crane is heavy.

Steel products look solid, but quickly rust and fail. Of course, this does not apply to stainless steel devices, which, however, are quite rare. If only cold water will flow through the tap, then you can choose a plastic product.

When choosing a faucet, focus on the average price; too low a price should alert you, because... You are probably being offered a defective or counterfeit product made from cheap steel.

As for the cost of ball valves, the most expensive are Made in Italy devices. Spanish, Czech, and Hungarian devices are slightly lower in cost. Russian and Ukrainian manufacturers occupy an average price niche, combining quality and reasonable cost.

The cheapest products are traditionally made in China. The quality of Chinese mechanisms leaves much to be desired; they can only be used as temporary locking devices.

Conclusions and useful video on the topic

Detailed instructions for installing ball-type fittings step by step:

Problems of ball water taps:

The ball valve is a useful invention that has greatly simplified the design of a safe water supply system. Installation is hassle-free, no need to call a plumber or use complicated tools.

Familiarization with the design of different types of ball water taps will help you perform a number of simple repair operations with your own hands without the involvement of plumbers.

Are you selecting shut-off valves for your water supply system? Perhaps you still have questions after reading the material? Ask them in the comments - we will try to help you with your choice.

Or maybe you recently repaired a ball valve? Did everything work out for you or did the breakdown turn out to be too complicated and you had to buy a new faucet? Share your experience in the comments block - it may be useful to other users.

I decided to replace the faucet in the kitchen sink because I didn’t like turning off the water by turning the mechanism counterclockwise. The time is 24.00, I close the ball valve under the sink so that cold water does not flow and... a butterfly in my hand with the central part of the valve with a ball, water under pressure of 6 atm, or even more. With the help of the unit on duty, after 3 hours we managed to find a plumber, and in that hour I was looking for the keys to the basement of 80 sq. m. Houses. As usual, not a single tap was working in the basement, and it would be impossible to close the valve at the entrance to the house without agreement with the management company. This is for at least another hour. As a result, the entire 3-room apartment turned into a beautiful swimming pool; the faucet stood for about a year.After this incident, I take only brass taps, avoid China (I used silumin), and before carrying out such work, I first shut off the main line in the place where I am going to repair or replace it.

This is correct - at the entrances of pipelines into the apartment you need to install the highest quality taps, you can’t skimp. And, for example, I don’t put plastic fittings on other pipes. It is too fragile: you turn the handle several times, and the locking device remains in your hands! Our water is hard, so I try to open and close all the taps once a week, this way less buildup accumulates.

Why does the Bugatti faucet not open completely when opened all the way, but when closed it closes completely?