Chimney for a boiler room: calculation of height and cross-section according to technical standards

The main function that a boiler room chimney should perform is to remove flue gases from boilers into the atmosphere and disperse them in this space.It also has an additional function: they must create natural draft resulting from the difference between the temperature in the firebox and outside.

We will introduce you to the types of smoke channels, the classification of which is based on the design features and material of the pipes. Here you will learn how to calculate geometric parameters using a specific example. Our advice will help you decide on the type and size of the chimney.

The content of the article:

Types of chimneys

In large boiler houses, natural draft cannot ensure complete combustion; here it is created forcibly with the help of smoke pumps. The combustion process and the discharge of its products into the atmosphere should cause as little harm as possible to the environment and not cause emergency situations as a result of the occurrence of pressure in the furnaces that exceeds the norm.

Structurally pipes for boiler rooms They are very different from each other both in the type of supporting structure and in the material of manufacture. Based on the first characteristic, several types of pipes are distinguished.

Self-supporting boiler pipes

Such vertical structures can be single- or multi-barrel. They remove combustion products from boilers and boilers.

They are used regardless of the type of fuel, but subject to certain requirements:

- The temperature of flue gases passing through self-supporting pipes should not exceed 350 degrees C.

- Combustion products must not be chemically aggressive.

- The optimal snow load for self-supporting structures is 250 kg per kW. cm, wind - 30 kg per kW. cm in conditions of wind region II.

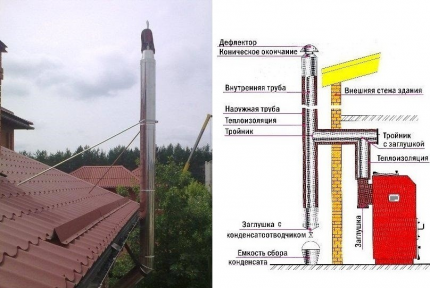

A self-supporting pipe is installed on the roof and secured inside the building. Its design features provide the possibility of transportation and installation on site, because it consists of separate sections, which are 3-layer sandwich pipes. The structure is attached to the foundation using anchors.

Inside the pipe there is a layer made of durable steel that is not affected by substances released during combustion. The outer layer protects against atmospheric influences.

The parameters of smoke structures must comply with the requirements set out in regulatory documents. Their calculation is based on factors such as the number of boilers, power, type of fuel. Air emissions standards must be taken into account. In some cases, chimneys are equipped with a platform, a ladder, an inspection hatch, and a light fence.

Column smoke structures

A pipe of this type consists of an outer shell made of high-carbon steel and inner barrels of different diameters made of stainless steel inserted into it to remove gases. The structure is secured into an anchor basket poured into the foundation. There can be either 1 or several. To prevent condensation from settling inside, thermal insulation is used.

The advantage of this design solution is a long service life and the prospect of connecting several boilers. The steel thickness and grade are chosen based on the temperature and aggressiveness of the combustion products.

The diameter of each trunk can reach one and a half meters, and if a common gas duct is planned to be used for several boilers, then a diameter of about 3 m is required. To prevent condensation from appearing, the trunks are covered with thermal insulation.

Features of near-facade and facade chimneys

Install near-facade chimneys for boiler rooms attached to the house or built-in. They are attached to the wall of the building using brackets. The components of a chimney are trunks and a frame or anchors.

The barrel has 3 layers: stainless steel inside, then thermal insulation and galvanized steel. The pipes are intended for boiler rooms where the boilers operate on gas or liquid fuel.

Near-facade and façade pipes transmit the weight load through an additional lower foundation and the wind load through vibration-isolating fasteners. This type of chimney, in terms of material costs, is the most economical due to the lack of supporting structures and a solid foundation.

The modular system used to create the gas exhaust barrels allows for easy replacement of damaged parts.

Truss type pipes

This metal structure consists of pipes mounted on a strong self-supporting truss-type column. The truss, in turn, is secured in an anchor basket cast into the foundation.Truss-type chimneys are suitable for use in regions with dangerous seismological conditions.

To prevent corrosion, gas outlets are coated with a primer and then painted.

The gas exhaust barrel is made up of modules consisting of 3 layers:

- internal, in direct contact with combustion products and made of special grades of stainless steel;

- 5-6 cm thick, acting as thermal insulation;

- external, protecting the heat-insulating layer from negative environmental influences.

For anti-corrosion coating, paints containing a high percentage of zinc are used. In some structures, stairs and platforms may be present inside the column to facilitate maintenance. The structural elements of pipes of this type are relatively lightweight and this facilitates both their transportation and installation work.

Chimney mast pipes

The central element of the mast pipe is the support tower - three or four masts, to which the chimneys are attached. All structural components are assembled on a base in the form of a concrete pad, starting from the bottom and gradually moving upward. When assembling, use a rivet connection or use self-tapping screws.

Typically, individual elements are transported to the installation site and assembled like a construction set. This process takes very little time - a few hours.The height of the chimney can reach a maximum of 28.5 m. Stability of the chimney is provided by stiffening ribs - steel guy wires with a cross-section of 1.6 to 2 cm. They compensate for the effect of transverse forces.

Materials for the construction of boiler pipes

Smoke exhaust systems are built from different materials - brick, steel, ceramics, polymer. Brick chimney, built over brick stoves and fireplaces, is characterized by good mechanical strength, excellent heat capacity, and a fairly high degree of fire safety.

These structures also have many disadvantages, which is why in modern construction completely brick chimneys are becoming less and less common. Regulatory documents limit the height of brick pipes to 30-70 m and the diameter to 0.6-8 m.

On the walls of a brick pipe with many protrusions and depressions inside, a lot of condensate and soot containing sulfur oxides always settle. The latter, reacting with water, forms acids that actively destroy bricks.

Surface unevenness and narrowing of the passage as a result of a gradual increase in the soot layer cause a decrease in the speed of smoke passage and tipping thrust in the smoke exhaust duct.

More resistant to condensation and external factors ceramic chimneys, they have high fire resistance. But this system has a lot of weight, because Inside there are metal rods that give it additional strength. This entails the requirement for the mandatory installation of a separate foundation and supports, which increases the complexity and cost of installation.

Polymer chimney pipes are appropriate in boiler rooms with a maximum temperature of 250 degrees C, during installation geysers. They are lightweight, flexible and durable, but are only relevant for gas equipment.

A device for removing smoke from stainless steel is an assembly consisting of individual chimney elements connected to each other using shaped parts: tees, pipes, deflectors, tees, bends. Steel chimneys mainly equipped with gas boilers.

Installation of such a chimney can be carried out after the construction of the building in a short time. There is a wide range of connecting parts, so the pipe can be given any configuration.

A modular chimney can be easily dismantled and moved to another location. The advantage of the design is its low weight, which allows you to do without a foundation, resistance to moisture, slight deposition of soot on the internal walls, and high speed of passage of flue gases.

Sanitary standards allow the use of steel pipes for the construction of chimneys with a height of more than 30 m; an exception is possible only if less than 5 tons of polyash fuel are consumed per day. The reason is that the service life of such structures is 10 years, and if high-sulfur fuel is used, it is significantly reduced.

Varieties whose body is made of steel alloy include coaxial chimneys, the design specifics and operating features of which we recommend that you familiarize yourself with.

Calculation of pipe parameters

To determine the height and diameter of the chimney for the boiler room, it is necessary to perform an aerodynamic design calculation. The diameter depends on the power of individual boilers or the entire boiler room.

The combustion of fuel and the effective removal of smoke are greatly influenced by draft, the creation of which requires a constant supply of air to the firebox.This is achieved both naturally and artificially.

If a smoke pump is built into the system, then the height of the pipe is not critical. This parameter is important mainly for accounting for harmful emissions into the atmosphere. To determine gravity, a mandatory calculation of both the height and cross-section of the pipe is required.

Determining the height of the pipe with natural draft

To create normal natural draft, it is necessary to comply with the condition of equality of the draft force and the total resistance that occurs during the movement of flue gases through the gas channels of the boiler and the chimney tract. It is possible to provide such traction provided there is little gas resistance, when the height of the pipe does not exceed 60 m.

Regulatory documents regulating the location and calculation of chimney heights are SNiP41-01-2003, SP 7.13130.2009.

You should also take into account the recommendations set out in the instructions for the boiler, in particular their following requirements:

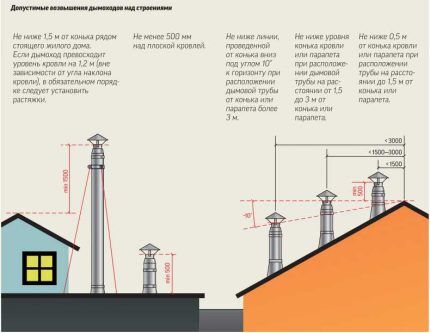

- The distance from the grate to the top of the pipe should not be less than 5 m.

- Above a flat roof without a high fence, the pipe should rise at least 0.5 m.

- In relation to the height of the fence and roof ridge, the pipe should exceed their level by 0.5 m if it is within one and a half meters of these structures.

- When the chimney is removed from the parapet and ridge at a distance of 1.5 to 3 m, its top point should coincide with their level in height.

If the chimney height is incorrectly calculated, many problems can arise, the main one being air turbulence or a wind pressure zone. The fire in the furnace can be extinguished by strong gusts of wind.

Compliance with fire safety rules is also a prerequisite when designing a boiler room pipe. It is necessary to insulate structures adjacent to the pipe.

To prevent sparks from the ventilation holes on the pipe from falling onto the roof when it is made of flammable material, the height of the structure is increased by 0.5 m. The boiler room pipe must be at least 2 m away from tall buildings and trees.

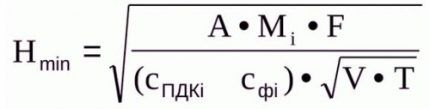

Since optimal draft occurs due to the difference between the total density of gases escaping into the chimney and a column of air outside equal in height, the calculation is performed using the formula:

The calculation is quite complicated, it is better if it is performed by specialists. Parameters affecting the height of the pipe:

- Coefficient A characterizes the meteorological situation in the region.

- Mi is the mass of flue gases that pass through the pipe per unit time.

- F is the speed at which particles formed during combustion settle.

- Spdki and Cfi are indicators of the concentration of various substances in the flue gas.

- V – volume of gas.

- T is the difference between the temperatures of the air entering and exiting the pipe.

If boiler room located in an extension to the house, the latter becomes a hindrance. In this case, it is necessary that the pipe head be located above the wind support zone.Otherwise, the heating equipment will not be able to function normally.

To determine how much the pipe needs to be increased, find the highest point on the house and draw a straight line through it, forming an angle of 45 degrees with the surface of the earth. The space below this line is the wind support zone, and the chimney should be located above it.

Calculation of pipe diameter

To calculate the diameter of the pipe there is a formula:

S = m/(ρr x w),

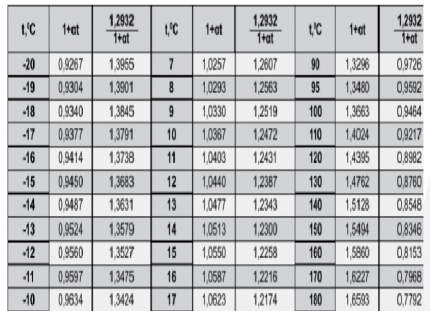

Here m is the fuel consumption for 1 hour, w is the speed of flue gases, ρr is the air density under operating conditions, it is determined by the formula: pв = pBну x 273⁄273 x tос. Where to is the outside air temperature, pBnu is the air density under normal conditions = 1.2932 kg/m3.

Let 50 kg of solid fuel burn in the boiler per hour, then per second it will be 50: 3600 = 0.013888 kg. The speed of movement of flue gases is 2 m per second. At an air temperature of -4 degrees C, the air density is 0.6881 kg per 1 cubic meter. m. Then S = 0.013888: (0.6881 x 2) = 0.010092 sq. m = 92 sq. cm. For a circular section d = √4 x 92: 3.14 = 10.83 cm.

The diameter of a cylindrical chimney can be calculated using another formula: d = 1000/1.163 x (r x Q√H), where r is a coefficient depending on the type of fuel used. For coal it is 0.03, for firewood 0.045, for gas 0.016, liquid fuel - 0.024.

Conclusions and useful video on the topic

A video with a visual demonstration of the process of calculating the height of the smoke channel for arranging a boiler room:

Here the author of the video shared his own experience in calculating and installing a chimney for a solid fuel boiler:

Another video to help the amateur designer:

It is not so important what fuel the boilers in the boiler room use. In any case, you cannot do without a flue gas exhaust system. The main requirements that chimney pipes must meet are good draft and throughput, and compliance with environmental standards.

Do you want to ask a question about a controversial or unclear point that you encountered while reading the information? Do you have useful information on the topic of the article that you would like to share with site visitors? Please write comments in the block below.

We installed a chimney in a bathhouse. The roof is flat, there are no fences nearby. The height of the pipe above the roof was taken to be a minimum of 0.5 m. This corresponds to SNiP, but in reality it turned out that this height was not enough and the draft was poor. We extended the chimney another 1.5 m and got wonderful draft. So SNiPs give the minimum permissible dimensions, which must be observed, and the technical characteristics need to be improved locally.

Strange, of course, the rules you used. Why rely on them if it may not make money, and if next time it will be higher than necessary? So, I would advise you to either figure it out yourself; everything is explained here in a very clear way, as for me. Or then contact the master. Preferably good. Because such rules are like playing roulette.

In this case, the chimney pipe was installed “by scientific poking,” as they say. We read that according to SNiP the minimum height should be 0.5 m, we took this literally and made the pipe height half a meter.And the fact that this is the most minimal indicator, which is not mandatory, the chimney simply cannot be lower.

It’s good that it was possible to increase the pipe to the required height, but for the future it is better to make a preliminary project that will take into account all the technical parameters. This way you will calculate the required length of the chimney and will not need to redo anything.

It’s good that the boiler room was made for a private house, in which case it’s not difficult to correct the defects. But if you made calculations based on gravity, you would know what height the chimney and its design should be.