Which bathtub is better - acrylic or steel? Comparative review

The happy owners of brand new apartments, as well as those who have started renovations in the bathroom, find themselves faced with a difficult choice.The stores have a huge number of plumbing fixtures that are attractive both in appearance and in price, many of which are made from materials unfamiliar to the buyer.

Which bathtub is better: acrylic or steel? This is the question most store visitors ask themselves. In the article we presented, the technical characteristics are analyzed in detail, the positive and negative aspects of the popular types of plumbing are considered, on the basis of which you can make the right choice.

The content of the article:

The ideal bath: what it should be like

When imagining a “dream bath,” everyone, of course, endows it with certain qualities. In this case, the appearance of the object can be anything; it is important that the product has certain performance characteristics.

A good bath should have a low heat capacity. Only in this case will the water poured into the bowl cool as slowly as possible, which will give a person the opportunity to soak up plenty of time in a pleasant environment for the body.

It is advisable that the inner surface of the bowl does not slip, so water procedures will be completely safe. This is especially important for older family members and children.

The bathtub coating must be durable and resistant to various types of damage. Ideally, the bathtub should not be afraid of aggressive chemicals, falls of heavy objects or impacts, or abrasive cleaning agents.

The inner covering should be easy to wash. It is desirable that it is as difficult as possible for contaminants to gain a foothold on it. Then the simplest means will be enough to care for the surface of the bowl. It is important that the bathtub is durable.

If its walls are too thin, the bowl will deform and “play” under the weight of the person washing it. In this case, it is desirable that additional equipment, for example, hydromassage devices, be installed without problems.

The weight of the plumbing fixture should not be too large, otherwise there will be problems with its transportation and installation. The shape and size can be absolutely any. It is important that, according to these parameters, the bathtub is well suited for a particular room and fits perfectly into its interior.

All about the steel bath

It would be a mistake to think that all steel bowls are the same. They are made from two fundamentally different materials. The first is structural steel. Bathtubs from this material are produced by stamping.

A sheet of metal is placed under a heated press, which with force gives the bowl the desired shape. After this, the workpiece is sent for enameling. Structural steel is not resistant to corrosion and therefore needs protection.

In the factory, a layer of enamel is applied to the base. Unlike its cast iron counterpart, on which several layers are applied, one or a maximum of two layers are applied to steel. As a result, enamel has completely different properties.

It has no pores in which dirt could accumulate.But at the same time, the enamel adheres less well to the base and peels off quite easily as a result of mechanical damage or other impact.

As a protective layer, not only enamel can be applied to the base, but also a polymer that improves adhesion. This coating adheres to the metal better. In general, enameled bathtubs made of steel alloys are inexpensive.

They are very easy to clean because they do not retain dirt on their walls, and drips and stains from soapy water are not too noticeable on them. However, the service life of such a protective coating is short; it can be extended using products developed specifically for this purpose.

In addition, stainless steel is used to make baths. This is an absolutely safe and environmentally friendly material. The truth is significantly more expensive than structural steel.

Bathtubs are made from stainless steel by stamping; they do not require any additional processing. The surface of such products is extremely resistant to various types of damage, but is difficult to maintain because soapy water and limescale deposits are too noticeable on it.

In both cases, the thickness of the metal walls of the bath is considered an important aspect. It can vary from 0.15 to 0.35 cm. The best option is a thicker sheet.This bowl holds its shape well and does not sag during use. Thin-walled bathtubs are easily deformed, which is unpleasant. And if it is an enameled model, then in the areas of deflection the enamel begins to flake off and eventually chips off.

With landmarks choosing a steel bath Read this article, which you should read before purchasing metal plumbing fixtures.

Features of steel products

Like any other product, steel bathtubs have some features that affect their performance properties. Let's take a closer look at them.

The tendency of metal to deform

Almost all steel bathtubs are slightly prone to sagging and slight deformation of the bowl. This is especially true for thin-walled models that literally “walk” under the weight of the person in them.

The manufacturer is aware of this problem and may offer a special reinforcing frame complete with the product. This is a structure of several supports on which it must install steel plumbing. The supporting frame will provide stability and a stable position, eliminating vibrations of the bowl during hygiene procedures.

Such frames are especially relevant for bathtubs of large sizes or non-standard shapes. The design helps remove excess load from the walls and distribute it more evenly. As a result, the bowl becomes more stable and does not deform.

If such a frame is not included with the bathtub, it is advisable to make a similar one yourself. As an option, you can consider installing the bowl on foam blocks or bricks and blowing foam into the free space under the bathtub.

Minimal sound and heat insulation

Metal has low noise insulation characteristics. It practically does not absorb sound. For this reason, the process of filling a steel bowl is accompanied by loud noise. This is not the worst drawback, but for some it matters.

The same goes for thermal insulation. Metal has a high heat capacity. It very quickly takes heat from heated water, which, accordingly, cools just as quickly.

This is very unpleasant for those who like to lie in a warm bath for a long time, and it causes some inconvenience for everyone else. Therefore, the manufacturer recommends using an additional insulator when installing a steel bathtub.

It is produced in the form of plates; all products of famous brands are necessarily equipped with them. If your model is not equipped with such plates, you can do it yourself.

To make a homemade insulating layer, you will need foamed polyethylene, technical cork or similar materials. If they are not available, regular polyurethane foam will do just fine.

The insulation is applied to the outside of the bathtub and secured there. After drying, the bowl is placed in the chosen place. This insulating layer absorbs sound well and significantly reduces the thermal conductivity of the metal.

Advantages and disadvantages of using steel baths

Steel products have a number of advantages, we list the most significant of them:

- Sufficient service life for the price. With good care, a bathtub made of structural steel will last 10-15 years, and a stainless steel product will last even longer.

- Relatively light weight.The average steel bath weighs about 20 kg, which is several times less than its cast iron counterpart. Thanks to this, the product is easy to transport and install.

- Easy to care for. The porosity of the bowl coating is minimal. This prevents the accumulation of dirt and makes cleaning the bath much easier.

- Comfort to use. Steel bowls heat up very quickly. To do this, just rinse them with hot water.

The disadvantages of steel products have already been voiced. These are insufficient sound insulation, a tendency to deformation and high heat transfer. However, all these problems can be easily corrected if desired. Considering this, as well as the fact that the cost of such bathtubs is much lower than that of cast iron or acrylic, it is easy to explain the demand for steel products.

Secrets of choosing the best steel plumbing fixtures

When choosing a steel bathtub for your home, you need to know exactly what to pay special attention to. First of all, you should carefully examine the model you like for the thickness of the walls.

It should be 3mm or more. Unfortunately, it is not always possible to determine this by eye, so you need to estimate the weight of the product. If a bowl of impressive size can be easily lifted with one hand, you should refrain from purchasing it.

A high-quality bathtub cannot weigh less than 18-20 kg. If this is not the case, the manufacturer was simply trying to save on metal. The geometry of the bowl should be perfectly flat, just like its surface.

Steel baths are stamped, therefore, all depressions, bulges and bends are defects that should not exist.Particular attention should be paid to the quality of the enamel coating, if present.

It should be smooth, uniform, without the slightest sagging or drips. There should be no chips or cracks, even the smallest ones. Subsequently, they will become a place where rust appears.

If the bathtub coating is self-cleaning, even a small crack will lead to the loss of the properties declared by the manufacturer. And finally, it’s worth evaluating the bowl “by ear.” You should tap the surface of the bath with your fingers. A high-quality product sounds homogeneous, without rattling or extraneous noise.

What you need to know about an acrylic bathtub

The general name acrylic bathtubs hides products with different performance properties. They are united by the fact that polymer compounds are used in production: ABS plastic, PMMA substance or a complex including both artificial compounds.

More precisely, acrylic sheets are produced from these compounds, which are given the required shape under the influence of vacuum. The highest quality bowls are made from polymethyl methacrylate or PMMA.

According to the manufacturing method, these acrylic sheets are divided into:

- Molded. Manufacturing involves pouring molten polymer between two rigid panels and then curing the sheet while clamped. This is sanitary acrylic, which has maximum impact resistance, uniform sheet thickness and minimal shrinkage when heated.

- Extrusion. Manufacturing involves squeezing the polymer melt through a slot nozzle in a production plant. The result is acrylic sheets that are more porous, less dense in all directions, and more impact resistant than injection molded options.

Baths made from injection molded sheets are more expensive, but they are also significantly ahead of extrusion products in terms of practical and technical indicators. Unfortunately, acrylic bathtubs made from injection molded and extruded sheets are practically indistinguishable in appearance. Therefore, when choosing, you need to be very careful.

The process of producing sanitary ware from both types of PMMA acrylic sheets is carried out using the same technology. A bowl is formed from them under vacuum pressure. Then the back side of the acrylic sanitary ware is reinforced with fiberglass, after which technological holes are cut and the sides of the bathtub are trimmed.

Acrylic sheets made of plastic with the abbreviation ABS, called acrylonitrile butadiene styrene among chemists, are the cheapest and most impractical variety. The plumbing fixtures made from them are actually disposable and cannot withstand sanding, but due to their porosity they can be easily painted in a variety of colors.

ABS is a porous and very hygroscopic material; it quickly breaks down upon contact with moisture. Therefore, the service life of such products is short. The top layer of acrylic can have different thicknesses. The smaller it is, the more vulnerable the surface. A thin layer of polymer can easily be pierced by a sharp object, chipped off, or simply erased during intensive use.

In assortment acrylic bathtubs There are also products made by coextrusion from the ABS/PMMA polymer complex.During production, both types of materials pass through the extrusion nozzle, resulting in a two-layer panel.

This sandwich sheet for vacuum forming is laid so that the ABS is located at the bottom. The option is stronger than standard extrusion and cheaper than injection molded PMMA, but is inferior to the latter in terms of technical parameters.

Features of acrylic bowls

Acrylic bathtubs have several features that set them apart from the range of sanitary equipment. Let's look at them carefully.

Variety of sizes and shapes

The manufacturing technology of acrylic bowls allows us to produce products of various shapes and sizes. Perhaps no other material opens up the widest scope for designers’ creativity.

Absolutely any configuration and dimensions of the product are possible. In addition, during the manufacturing process, the holes necessary for the installation of special equipment are quite simply made.

Therefore, acrylic baths can be equipped with any devices for hydromassage, chromotherapy, lighting, etc. In addition, pigment can be added to the raw material for casting at the stage of its preparation, giving any desired shade. Thus, acrylic bathtubs come in a wide variety of designs, making it easy to choose the best option for your bathroom.

Presence of a reinforcing frame

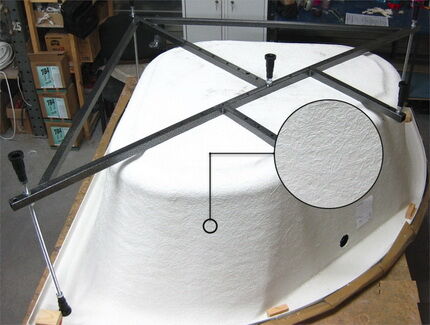

Acrylic bowls are plastic. Under the weight of water and a person in the bathtub, its walls and bottom may sag and become slightly deformed.To avoid this effect, each bowl is equipped with a special metal frame, which should relieve excessive stress and distribute the force evenly over the entire surface.

Given the variety of acrylic bathtub designs, you need to know that a responsible manufacturer develops a frame for each of the models they produce. Usually the design comes complete with plumbing fixtures, as it is used in installing an acrylic bathtub without fail.

This is a frame coated with anti-corrosion protection, made of square steel pipe. The frame must have height-adjustable legs, corner supports and intermediate stiffeners.

Looking at the frame, we can conclude about the strength of the acrylic bowl. The smaller it is, the more points of support the steel frame will have. The most durable bowls are equipped with frames with four support points.

The reinforcing structure can be entirely welded or prefabricated. The last option is more convenient. In addition, its presence is a signal about the strength of the acrylic bowl. A welded frame is usually attached to a low strength bathtub.

Maintainability and durability of acrylic plumbing fixtures

You need to understand that the service life of a product depends on its quality. The most durable bowls made from injection molded PMMA. If used properly, they will last 20 years or even more. Moreover, the products are repairable.

This means that, if necessary, you can remove chips and cracks that appear on the surface of the bathtub. Specially for this purpose, repair compositions are produced, which are liquid or paste acrylic.

The liquid is applied to the flaw on the surface and completely fills it. After the composition hardens, not even a trace of the defect remains. The durability of bathtubs made from sandwich sheets depends on the thickness of the cast acrylic layer. It may be different.

Practice shows that bowls coated with a 2-3 mm acrylic layer will last about three to four years. Products with a 4 mm layer of acrylic can last about seven years, and finally, bathtubs with a 5-6 mm layer of acrylic last 10-12 years.

Criteria and rules choosing a good acrylic bathtub are given in the following article, which we recommend that you read.

Pros and cons of acrylic products

Like any other, acrylic bathtubs have advantages and certain disadvantages:

- Low heat transfer. Acrylic bowls retain heat very well, losing about half a degree in 30 minutes. In addition, the coating is pleasantly warm to the touch. Fans of long bath procedures will appreciate this.

- Light weight. The weight of an average-sized acrylic bathtub is about 15-20 kg. This greatly facilitates its transportation and installation.

- High noise-absorbing properties. Filling the bowl with water occurs completely silently.

- Hygiene and safety. Acrylic is very smooth, so dirt does not linger on its surface. To clean the bowl, it is enough to use a soap solution or special products. In addition, the material has pronounced antibacterial properties. The surface of such bowls does not slip.

Among the significant disadvantages, it is worth noting the low resistance to aggressive chemicals and high temperatures. Caring for acrylic sanitary ware It’s also not easy, but now there are specialized cleaning products on sale.

Excessively hot liquids, a running hair dryer, varnishes, including hair sprays, solvents, adhesives, etc. are dangerous for an acrylic bowl. The use of abrasives to clean the surface is also unacceptable. They will scratch the coating, thereby hopelessly ruining it.

Rough mechanical impacts are also extremely undesirable for acrylic bowls. Falling a heavy object, even from a small height, will certainly lead to a crack or chip. The formation of a through hole is also possible. However, if the bathtub is cast, most defects can be repaired without a trace.

Secrets of choosing acrylic products

As already mentioned, the performance characteristics of an acrylic bathtub depend on its quality. Therefore, the first thing I would like to recommend to those who choose such plumbing equipment is to buy a product only from a well-known brand.

In this case, you will be able to see a certificate confirming the quality of the product, and in case of problems, make a claim. Unfortunately, it is quite difficult to identify low-quality acrylic by eye.

For those who decide to purchase a product from an unknown manufacturer, we can advise the following. First you need to carefully examine the end of the bowl. Here you can see the layers. The top one is acrylic, the rest are reinforcing. You need to evaluate their thickness and quantity.

It is desirable that there be at least 4 reinforcing layers. It is worth considering the surface of the bathtub. There should be no unevenness or roughness in life.

Then it is advisable to press lightly on the walls and bottom of the bowl. They should not bend too much like plastic panels. And the last test is for light. You need to take a flashlight or laser pointer and apply it alternately to the bottom and walls.

At the same time, you should cup your palms to the same area on the outside of the product and look through the resulting window into the light. If it is visible too brightly, the thickness of the product is insufficient.

With a comparative analysis of technical and practical characteristics bathtubs made of acrylic and cast iron you can find it here. We recommend reading the review dedicated to this issue.

Conclusions and useful video on the topic

Video #1. Secrets of choosing a steel bath:

Video #2. Choosing an acrylic bathtub:

Video #3. Comparative analysis of all types of popular baths:

It is impossible to clearly determine whether acrylic or steel is better. Each user chooses the best option for himself, taking into account all the operating features of the plumbing fixture, its advantages and significant disadvantages, and individual operating conditions.

Don't forget about the financial side of the choice. It is better to purchase high-quality equipment from the budget segment than an inexpensive product of a higher class.

Which bath do you think is the best and why? Share your own reasons for choosing. Please write comments in the block below, ask questions, publish thematic photos.

In a new apartment with finishing and plumbing from the developer, we received a steel bathtub.But it turned out to be too thin-walled. When I, a lady with not very much weight, stand in it, the bottom sag noticeably. If the husband is there, it’s generally scary. There is no way to change the bathtub yet, maybe we can somehow temporarily solve this problem - without dismantling the bathtub, put a frame under it or something else?

The easiest thing is to buy additional self-adhesive legs at a plumbing store and install them. Everything else will require dismantling. I would recommend a more thorough way - to build a podium for the bathtub.

I don’t know, the idea of buying a steel bathtub never occurred to me. For me, the choice has always been only between cast iron and acrylic, but cast iron is too bulky and heavy for an ordinary apartment. Therefore, of course, I choose acrylic. It is cheap and light enough that when its service life ends, you can easily buy a new bathtub. And the steel one even looks uncomfortable for my taste.