Which pipe to choose for a chimney: regulatory guidelines and rules

Installation of a stove or fireplace involves the installation of a smoke removal system.In this matter, it is not enough to choose the right pipes for the chimney; you also need to comply with a lot of construction and fire safety regulations. Otherwise, the operation of heating equipment will be ineffective and unsafe.

Mistakes made when installing a chimney not only reduce the efficiency of the furnace, but can also lead to tragedy. Our material will discuss how to avoid the most common mistakes during installation. In addition, we will tell you how to choose the right chimney pipes.

The content of the article:

Regulatory requirements for the installation of chimneys

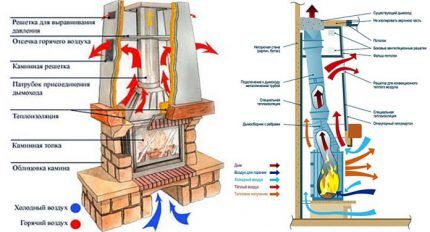

The main and only purpose of the chimney pipe is to remove waste gases from the heating boiler into the atmosphere outside the building where the stove, boiler or fireplace is installed. Moreover, the efficiency of heat-generating equipment directly depends on its correct installation.

You can install a boiler with excellent efficiency in your house, but make mistakes when chimney pipe installation. The result is excessive fuel consumption and lack of comfortable air temperatures in the rooms. The chimney must have the correct cross-section, location, configuration and height.

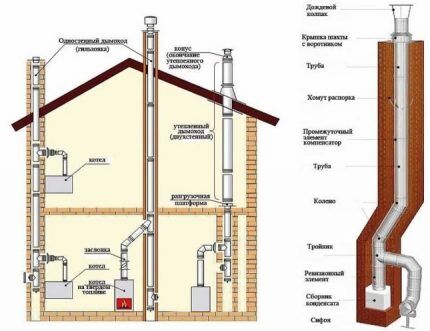

If there are two boilers in the house or a stove and a fireplace in different rooms, then it is better to make separate smoke exhaust pipes for each of them. The option with one chimney is permitted by SNiPs, but only a professional stove maker can calculate it correctly.

The diameter of the chimney is selected depending on the heating equipment used. When installing the boiler, it is already specified by the manufacturer with the outlet pipe.It is prohibited to connect pipes of a smaller cross-section to it, and there is simply no need for a larger cross-section. In the second case, to increase traction, you will have to install a gearbox, which costs a lot of money.

In case of fireplace or Russian brick oven everything is somewhat more complicated. Here you will have to make engineering calculations taking into account the fuel used and the size of the firebox. It's much easier to take a ready-made one brick kiln project, tested by time. Fortunately, there are many options with a clearly verified order of brickwork.

The higher and longer the chimney, the stronger the draft. However, this can lead to overheating and destruction of its walls. Plus, a strong increase in draft is a prerequisite for the occurrence of turbulence in the chimney, which is accompanied by hum and low-frequency noise.

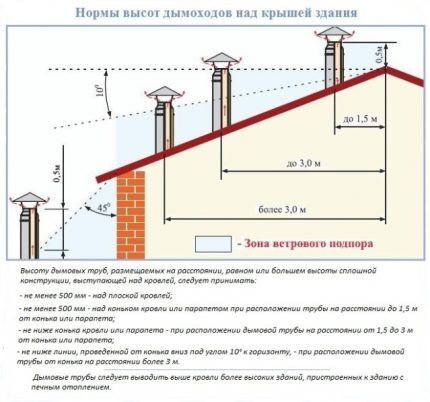

If the pipe is too low, the ridge can turn into an insurmountable obstacle to the smoke coming out of it. As a result, a reverse draft effect will occur with the flue gases tipping back into the firebox. How to normalize it will be discussed in this material.

During normal operation of the chimney, the horizontal wind flow, flowing around the section of the pipe above the roof, turns upward. As a result, rarefied air is formed above it, which literally “sucks” the smoke from the exhaust. However, this process can be hindered by the ridge of a pitched roof and even a tall tree in close proximity to the house.

Standards for the installation of a smoke exhaust system

Building codes require the chimney to be constructed as follows:

- Its length from the grate to the top point should be from 5 meters (an exception is possible only for buildings without attics and only in conditions of stable forced draft).

- The optimal height, taking into account all possible bends, is 5–6 m.

- The distance from the metal chimney to structures made of combustible building materials should be at least a meter.

- The horizontal outlet immediately behind the boiler should not exceed 1 m.

- When passing roofing, walls and ceilings inside the house, a channel should be constructed from non-combustible materials.

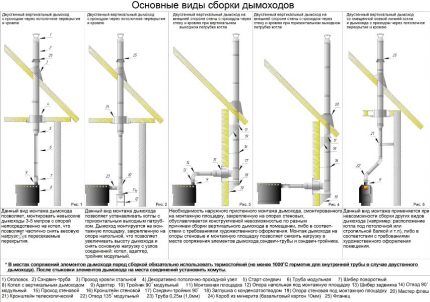

- To connect metal pipe elements, sealant should only be used that is heat-resistant with an operating temperature of 1000 °C.

- The chimney should rise at least 50 cm above the flat roof.

- If a non-brick chimney is constructed above the roof level by 1.5 meters or more, then it must be strengthened with braces and brackets.

Any slopes and horizontal sections inevitably reduce draft in the chimney pipe. If it is not possible to make it straight, then bends and displacements are best made from several inclined segments at a total angle of up to 45 degrees.

When installing ventilation and chimney shafts in parallel in one structure above the roof, in no case should they be covered with a common cap. The outlet from the stove must be elevated above the ventilation pipe, otherwise the draft will decrease and the smoke will begin to be sucked back into the house. The same applies to separate but adjacent hoods and chimneys.

Selection of chimney pipe material

Laying a chimney in a private residential building can be done in several ways:

- With passage through the attic floor and roof.

- With output beyond the external walls and exclusively inside the building.

- With passage only through the roof, bypassing the interfloor ceilings.

- With support directly on the boiler or stove or with fastening to the walls.

- With offset vertical center line and strictly straight design.

The choice of the final configuration depends on the layout of the living rooms, the location of the heating unit, as well as the individual design and architecture features of the cottage. In each case, it is recommended to select your own chimney option.

All that remains is to figure out which pipe to choose for the chimney and what material is best suited for this.

You can make a chimney from:

- bricks;

- iron or asbestos pipes;

- ceramics;

- concrete;

- heat-resistant glass.

Its cross-section can be either round, square or rectangular. Moreover, the first of them is the most optimal. Of all the materials, when installing it yourself, only heat-resistant glass can cause problems. Its installation will require the installation of a special supporting structure, which can only be assembled competently and with a guarantee by a specialist.

Option #1 - traditional brick

Chimneys from baked bricks have been made for centuries. These are traditional and well-studied designs for removing flue gases by professional stove makers.But they have to be done simultaneously with the construction of the dwelling; for heavy brickwork it is necessary to pour a separate foundation.

Among the advantages of a brick pipe are high fire safety, attractive appearance, well-studied design and additional heat transfer from the masonry. And among the disadvantages are the high cost of work, heavy weight and the need for a foundation, as well as strong roughness of the walls.

In general, brickwork is a reliable and effective option for organizing a chimney. And the existing disadvantages can be easily circumvented by simply installing a stainless steel pipe inside the shaft. The steel liner will prevent clogging with soot and take on part of the thermal load, thereby protecting the brick and extending its service life.

Chimney ducts made of brick are constructed mainly when using solid fuel. They are arranged mounted, i.e. installed on the ceiling of the stove, radical in the form of a separately constructed vertical outlet, and wall - located inside the load-bearing wall.

When using a metal liner with a round cross-section inserted inside a brick chimney, it can serve as a smoke exhaust for gas heating and cooking units.

Option #2 - galvanized and stainless steel

Galvanized and stainless steel are resistant to corrosion and the aggressive environment formed when condensate and furnace gases combine.They are light in weight and do not require an additional foundation; reliable fasteners to the wall will be sufficient for installation.

You can find steel chimney pipes on sale:

- Single-walled - without thermal insulation material.

- Double-walled - sandwiches with insulation between steel walls.

When installing a steel chimney outside the facade, it must be insulated, otherwise heat loss and abundant condensation will negate all the advantages of this option. Thermal insulation is used in sections of the chimney that extend beyond the roof and pass through an unheated attic.

In terms of the cost of components, a chimney made of stainless or galvanized steel will be cheaper than its brick and ceramic counterparts.

The chimney duct is assembled from:

- rain cap;

- tees;

- knees;

- inserts with inspection hatches;

- straight pipes;

- collectors for condensate.

All this just needs to be mounted together by inserting one section into another and coating the joints with heat-resistant sealant. Such chimneys are suitable for almost all types of fireboxes and fuels. Galvanized and stainless steel can easily withstand high temperatures and soot for decades.

The smooth surface of the steel walls optimizes the removal of combustion products and eliminates the accumulation of soot. Chimneys made of steel pipes are suitable for gas, liquid and solid fuel stoves. Metal modules are used to construct a chimney in whole or in part, connecting it to a brick channel or installing it in the form of a liner.

Option #3 - cheap asbestos cement

Pipes made from natural asbestos with cement as a binding material began to be widely used in our country during Soviet times. They were cheap, durable and produced in large quantities. They were mainly used in agriculture for land reclamation.

Initially, asbestos-cement pipes were not intended for the installation of chimneys. They are too fragile for this and cannot tolerate high temperatures. However, the issue of price in many cases plays an important role. If you have cheap material at hand, then you should definitely use it, leveling problem areas in one way or another.

Asbestos pipes have another problem - the roughness of the walls from the inside. Gradually, soot accumulates on them, which can catch fire and simply explode. Plus, with the constant formation of condensate inside from a mixture of vapors and combustion oxides, asbestos cement begins to collapse.

This material is cheap, but using it for arranging chimneys is associated with great risk. Such pipes should be cleaned more often. However, it is impossible to make an inspection hole in them; it will have to be provided in the area from the furnace to the asbestos cement.

Smoke ducts made from asbestos-cement pipes are mainly made in the mounted version. The priority is the simplest design of the device and the vertical arrangement of all elements. If it is necessary to perform a slope, pipes made of non-flammable materials are used.

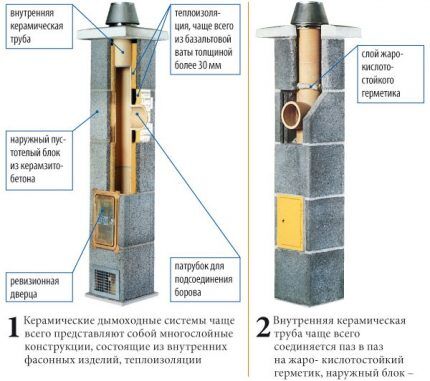

Option #4 - exotic ceramics and concrete

Ceramic chimneys are distinguished by their unsurpassed durability and high price. They are not afraid of overheating, soot aggressiveness and corrosion. These pipes have very smooth walls, so the soot does not even linger on it.

During installation ceramic chimneys assembled in the same way as steel ones. Only around them a box of expanded clay concrete is still being formed.Such pipes practically do not heat up. Even that small part of the heat that is given off by inert ceramics is absorbed by expanded clay concrete walls. A fire in a house due to a burnout of such a chimney is nonsense.

A chimney structure made of ceramics and expanded clay concrete weighs much less than brickwork for a similar purpose. But even in this case, you have to make a separate small foundation for it.

An even more massive monolithic base will have to be made for a concrete chimney. This option for removing smoke is rarely used precisely because of the complexity and labor-intensive construction of the structure. It will be necessary to install the formwork, and then wait for the concrete solution to harden.

Typical mistakes of beginners and self-taught

In first place among the mistakes is the incorrect height of the chimney pipe.An option that is too high creates excess draft, which increases the likelihood of tipping over and drawing smoke back into the firebox and the room with the stove. 5–6 meters are considered optimal, but much here depends on the size of the combustion chamber and the configuration of the chimney.

The chimney should not be overcooled or overheated as a result of intensive combustion of fuel in the firebox. Everything must be in moderation, otherwise the pipe may crack. To make it easier for yourself to identify these cracks, you should whitewash the section of the chimney in the attic. All soot “drips” will be visible on a white background.

Often, when installing a steel chimney, beginners forget to ensure condensate drainage. To do this, you need to make a special collection and insert inspection hatches into the pipe. Mistakes are also made in choosing the steel grade.

During normal combustion of wood, gas or coal in a fireplace or heating boiler the chimney warms up to 500–600 °C. However, the temperature of the smoke, even for a short time, can rise to 1000 ° C. Moreover, just a few meters from the firebox they cool down to 200–300 degrees and do not pose a threat to the pipe.

But its initial meter section from the boiler manages to heat up very strongly. The steel must be heat-resistant and able to withstand these loads. And the insulation of a steel pipe should be done only a couple of meters from the firebox in order to prevent overheating of this segment of the chimney.

When laying bricks by an inexperienced craftsman, vertical displacement of their rows relative to each other is often allowed. When building walls, this is allowed, but in the case of a chimney, it is absolutely unacceptable. This greatly reduces the efficiency of the chimney duct, as flow turbulence and soot deposits on the walls begin to form in it, which will require cleaning over time. You can read how to do this correctly in this material.

The foundation under a brick chimney must be extremely reliable, otherwise the pipe may be pulled to the side with subsequent partial or complete destruction. And if smoke removal is done for a gas boiler, then it is better to exclude brick. It quickly breaks down under the influence of the alkaline environment formed during the combustion of natural gas.

Conclusions and useful video on the topic

What mistakes are most often made when installing stoves and chimneys for them:

How to lay brick chimney pipes:

How to make a stainless steel chimney:

Reliable chimney pipes can be made from various building materials. The choice of options is quite extensive. The easiest way to make a chimney is from steel, and cheaper from brick.

But if you need the most durable and safe system for removing stove smoke, then the undisputed leader is ceramics. It is expensive, but will last for decades. The main thing when installing all options is to comply with construction and fire regulations.

After studying the material, are there still some unclear points that you would like to find out? Please leave your comments at the bottom of the article. Here you also have the opportunity to provide interesting facts on the topic of the article or share your own experience with site visitors.

A brick chimney is already a thing of the past. I don't really understand why it's still popular and people play it. Perhaps because of the cheapness. But modern chimneys are much more convenient and durable. Plus, it can be displayed at any angle. I installed a stainless steel pipe at the dacha - light, flexible, ductile, easy to assemble. Does not require any additional structures. And it looks nice.

I recently built a stove for a bathhouse. I used galvanized steel for the chimney. I made the pipe myself, securing the ends of the sheet with an ordinary seam lock. Then I painted the resulting pipe with metal paint. I brought it closer to the edge of the roof, so that there was 1.5 m between the ridge and the chimney. The height was determined to be level with the maximum point of the roof height. Our winters are always snowy, and this way there will be less snow and water going into the pipe. Well, of course, I didn’t forget about the chimney cap. The chimney turned out better than if it had been bought in a store or made of brick.

I’ve been planning to install a fireplace in my house for a long time, I thought it would be easy to install. After reading this information, I realized that there are many pitfalls and you need to approach the matter with the utmost seriousness. It is necessary to make engineering calculations and purchase exactly the right material. Reading you, I develop and learn a lot of new things for myself, it’s just all a dark forest for me. I would like to know: what exact calculations are taken to install a fireplace for a 2x4 house?

Sorry, clarification required. A 2x4 house? In the meantime, we are waiting for an answer from you, I want to say that in general, there is nothing complicated in the construction of fireplaces. The only thing is that if you choose an order from the Internet, you should better show it to an experienced craftsman for verification. I have come across very strange orders on seemingly authoritative resources without observing the alternation of seams, for example.

And a personal life hack - you can take a Lego set from your child with large parts and, immediately before construction, put it together to make a model of the future fireplace to check everything again. Although, in principle, if you gain at least a little knowledge, you can build a fireplace without such models.

At the beginning of the plot it is said that a brick chimney is expensive, and at the end that a chimney can be made “cheaper out of brick.” Where is the truth ?

Hello. Indeed, the author started talking. Apparently at the beginning of the article he meant about the material + cost of work + sleeve, but at the end of the article he forgot that not all of us are master stove makers and will be able to equip all this with a minimum of costs :)

Is it necessary to install a valve on a metal chimney pipe? A metal stove with a hob (I don’t know the brand - it was a gift), a heating stove, a log house. The height of the stove is 52 cm, I will make a stand with a height of 35 cm. The house is 4 by 5 meters, the ceiling is approximately 2.3 meters.

I would be very grateful for a comment or a link to a competent specialist. I’ve never come into contact with this myself, but my head seems to be “boiling.” Thank you.

p.s. By the way, the article is very useful!

Hello.A damper is needed at least to regulate the intensity of fuel combustion and to avoid drawing warm air into the stove pipe after heating.

Please tell me about the aluminum pipe, how will it behave on a long-burning boiler?

The melting point of aluminum is 660 degrees Celsius, plus aluminum is quite an active material. Under the influence of temperature, water, carbon and flue gases it will be intensively destroyed.