Wall-mounted gas heating boilers: types, how to choose, review of the best models on the market

Unbiased statistics claim that more than half of the heating boilers sold in the world are gas.And this is no coincidence, because gas is considered the most economical of the popular types of fuel.

When choosing a heating device for their home, owners want to find the most efficient and practical option. Often this is exactly what wall-mounted gas heating boilers turn out to be. Let's talk about how to choose the best model.

The content of the article:

Features of mounted boilers

Wall-mounted boilers appeared as a type of heating device later than their floor analogues. This is due to the fact that it was necessary to minimize the main disadvantage of floor structures - significant dimensions and weight.

After extensive research and development, engineers came up with a compact, mounted version. As the name implies, this design is hung on the wall. Therefore, it is compact and light weight.

This is true. The main advantage of wall-mounted models is their weight up to 50 kg and convenient dimensions. Thanks to this, they can be placed in any non-residential premises; there is no need to equip a furnace room.

This is an advantage of mounted boilers, but also a significant drawback. Compact models cannot be powerful. On average, they can be used to heat a building with an area of no more than 100 square meters. m.Therefore, the devices are especially popular among apartment owners.

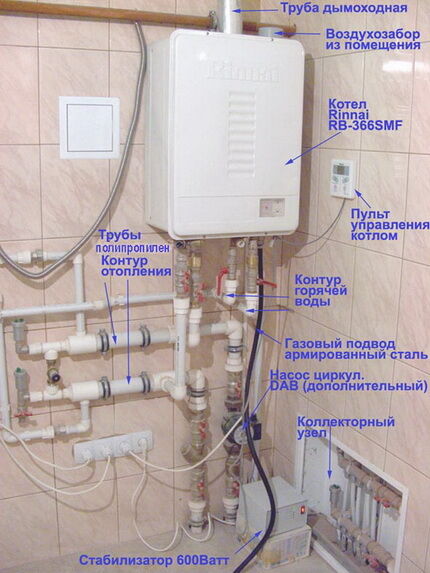

Another distinctive feature of mounted models is the complexity of the design. As a rule, the unit contains a pressurization system, expansion tank, circulation pump, automatic control, etc.

All this equipment constitutes a single system and is enclosed under the boiler body. On the one hand, this is very convenient, since it allows you not to think about problems with the arrangement of the circuit and its further operation.

The device just needs to be turned on and configured, then it will work on its own. However, if it breaks down, and this may well happen, skilled and often expensive repairs will be required. What will become an additional expense item for the family budget.

It must be admitted that due to the complexity of the design and the presence of a large number of parts that can fail, the service life of wall-mounted models is shorter than that of floor-mounted models.

Types of heating devices

The store variety is a little scary and disorienting. It is difficult to immediately decide on the right model. To make this easier, let’s get acquainted with the main features of devices that determine their performance characteristics.

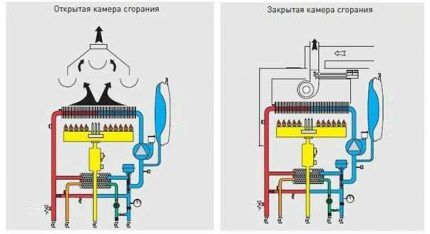

Gas burner type

Two types of burners can be installed in attachments. The simplest one is the so-called atmospheric one. The principle of its operation is very simple: gas fuel burns inside the unit. This requires air that enters the device from the room where the boiler is located.To ensure a continuous flow of air masses and at the same time get rid of toxic flue gases, it is necessary to install a chimney.

In this case, only the traditional vertical high chimney, correctly calculated and correctly installed. The draft is provided by the temperature difference between the room and the street. As a rule, with proper calculation, it is quite sufficient for the normal operation of the boiler. An atmospheric burner has significant advantages.

First of all, it does not require electricity to use. The boiler can be operated in the complete absence of power supply, which is very important for places where electricity is not always available. In addition, the cost of boilers equipped with such a burner is significantly lower than their analogues. However, you need to understand that for the safe use of such equipment, you will need to install effective ventilation in the room where it is installed.

It is advisable that such devices be installed in a separate room. A prerequisite for operating the device is the presence of a smoke exhaust. And another minus is the relatively low efficiency.

The presence of a closed burner implies that air is forced into it. For this purpose, an additional system equipped with a pump is installed. It takes outside air and supplies it to the combustion chamber and at the same time removes flue gases.

Such equipment is equipped with a smoke exhaust coaxial type. These are compact structures consisting of pipes nested inside each other.Smoke is removed through the inner part, air is drawn in through the outer part.

This chimney is very effective, takes up little space and is quite easy to install. It can be installed not only vertically, but also horizontally at a slight angle. In the latter case, the passage to the street is made directly in the wall.

The advantages of closed burners include high efficiency and complete safety during operation. They do not take air from the room, so they can be installed in bathrooms or kitchens. However, they require electricity to operate, otherwise the boiler will simply stop. The cost of devices with closed burners is much higher than that of equipment with atmospheric ones.

Number of device circuits

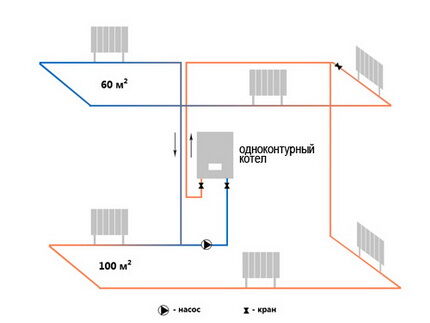

Mounted boilers can have one or two heating circuits. In the first option, the equipment is equipped with one heat exchanger, which is used only to heat the coolant fluid. Thus, the device is intended exclusively for heating. If hot water supply is also required, additional equipment is installed, which will certainly take up some free space.

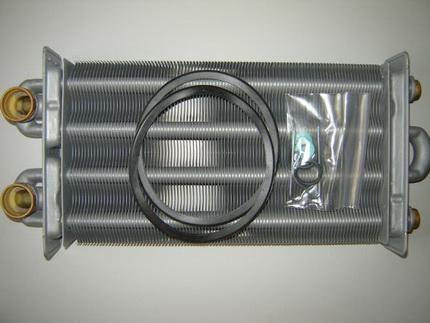

The main advantage of single-circuit models is their simplicity of design, which simplifies their installation and operation, as well as greater power compared to double-circuit analogues. The latter have two built-in thermal circuits. In one the coolant is heated, in the second - water for hot water supply. This makes their design more complex and vulnerable. Boilers with a so-called bithermic heat exchanger are produced.

It is divided into two segments, one for coolant, the second for hot water. Thus, a dual-circuit device works with only one heat exchanger. As practice shows, bithermal devices are not reliable enough and are not very convenient to use.

If necessary, it is optimal to purchase a unit with two separate heat exchangers. Boilers double-circuit type They spend their power not only on heating, but also on hot water supply, so it is somewhat lower.

Such devices are ideal for small apartments or houses. You need to understand that double-circuit equipment is most often not capable of providing a large amount of hot water. If your DHW needs exceed 15 liters per minute, it is worth purchasing a single-circuit model and additional heating equipment.

You should do the same if you have too hard water. In this case, the secondary heat exchanger will very quickly become covered with deposits and fail.

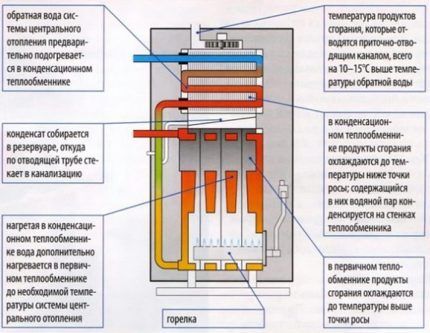

Use of condensate heat

Condensing units appeared on the domestic market not very long ago, while they are used very widely throughout the world. Their distinctive feature is the ability to use heat from water vapor generated during the combustion of a gas mixture. The latter is collected in the form of condensate in an additional heat exchanger. Here it gives off its heat to the coolant liquid.

In this way, it is possible to obtain additional thermal energy, which makes the use of a condensing boiler as efficient as possible.According to experts, the efficiency of such devices is above 100%, which may seem fantastic. However, this is reality. The device gains an additional 9-11% efficiency by using the heat of the exhaust flue gases. The average efficiency of such boilers reaches 105-111%.

The advantages of condensing equipment include economical fuel consumption. Compared to traditional convection appliances, it is about a third smaller. The gases discharged from the boiler have a low temperature, which makes it possible to install cheaper and easier-to-install plastic chimneys. The amount of toxic emissions from a condensing boiler is minimal, and the noise level during operation is also low.

The disadvantages of such equipment include a small temperature difference between return and supply. For traditional convection devices it averages 55° to 75°, for condensing devices it is 35° to 55°. Thus, to warm the room, you will need to install additional radiators or install underfloor heating systems. In addition, the condensate formed in the boiler must be disposed of.

This is quite problematic because it contains acid. It is unacceptable for it to end up, for example, in a septic tank. It is advisable to install a special system to collect condensate. However, for low-power boilers located in houses with centralized sewerage, this is not necessary.

Another significant disadvantage of condensing equipment is its high cost. Compared to traditional analogues, it is 20-35% higher.

Criteria for choosing a mounted boiler

Having decided on the required type of heating device, you can begin to select a specific model. It is worth considering the main criteria.

Device operating power

You can determine the required power of a mounted gas boiler based on the volume of the heated room and the required amount of heated water if you plan to purchase a double-circuit model.

It is very good if all the calculations are carried out by a specialist who can take into account all the heat loss of the building, its volume and many other factors. The calculated power in this case will be as accurate as possible. If this is not possible, the device is selected at the rate of 1 kW of generated power per 10 sq. m area.

Since these are very approximate figures, it is recommended to add 15-20% to the resulting value as a “margin”. It should not be too large, otherwise the boiler will not work efficiently and will quickly fail.

A good choice is equipment with a modulating or at least two-stage burner. They allow you to regulate the power of the device, which makes it possible to significantly save fuel.

Material for the manufacture of heat exchanger

In terms of performance characteristics, the best material for heat exchangers is copper. It is not subject to corrosion, conducts heat well, and is lightweight. Copper components can fail quite quickly when working in powerful boilers, but they serve well in wall-mounted models. Stainless steel is another material from which heat exchangers are made.

Such parts are low cost, light weight and have good thermal conductivity. But at the same time they are prone to corrosion and can burn out. As a result, they last relatively short time. Cast iron parts are practically not used in wall-mounted boilers because they weigh so much. It would be a good choice though. Considering the corrosion resistance and durability of the material.

Boiler control system

The most convenient equipment to use with automatic control. Such devices require initial setup, after which they do not require human control. Automation independently monitors all possible changes in the environment and makes adjustments to the functioning of the boiler. It would be very good if the device had an increased degree of protection.

Gas equipment is potentially dangerous, so this will not be unnecessary. Automatic control is only possible for volatile boilers. For devices not connected to electricity, only manual control remains. If this is the case, it is important to understand the boiler operation scheme and determine in which case and what kind of human intervention will be necessary. It's better to check this before purchasing.

In addition, it is worth paying attention to the method of igniting the boiler. The more common and inexpensive piezo ignition has a significant drawback. Its presence leads to excessive fuel consumption, since the pilot burner must be constantly burning. Electronic ignition is more economical, but depends on the availability of electricity.

Manufacturers with a solid reputation

Among the many manufacturers, users and experts identify several brands that can really be trusted.

German company Vaillant

Presents high-quality heating equipment in a wide variety of designs. These are single- and double-circuit equipment of condensation and convection type.

The power of the units varies from 4 to 280 kW. The advantages of Vaillant include high-tech equipment, which makes its operation extremely simple and comfortable. The manufacturer cares about the highest level of safety of its products.

The units are equipped with gas supply control systems, auto diagnostics and a variety of types of protection. The equipment has high efficiency. For condensation models it is about 109%, for convection models – 94%. Vaillant boilers can operate on different types of gas, are environmentally friendly and very economical. For the convenience of consumers, the company has deployed a wide service network.

The general disadvantages of the equipment include the lack of necessary voltage stabilizers in the equipment package and rather expensive service. In some cases, it may not be entirely fast. Users highly rate Vaillant brand equipment and consider it excellent.

Brand Buderus from Germany

Represents several lines of heating devices. Wall-mounted Logamax plus – condensing units with power from 14 to 100 kW, Logamax – convection units from 7.8 to 35 kW. Floor equipment is available in two lines. Logano plus – condensing units with power from 16 to 1200 kW, convection Logano units from 20 to 1200 kW.The range of equipment is very wide and includes all known modifications.

Boilers from Buderus are characterized by high energy efficiency, high-quality automatic control, making operation easier. They can be built into the remote control system and can be controlled remotely. The devices combine well with other branded equipment, are equipped with effective sound and heat insulation, are highly environmentally friendly and cost-effective, and have an attractive appearance.

Equipment from Buderus is reliable, high quality, economical, versatile and unpretentious. They rarely fail. Among the disadvantages, it is worth noting the completely plastic make-up taps and the lack of protection against possible power surges.

Italian brand Baxi

Produces a wide range of heating equipment. A distinctive feature of this equipment is the presence of a total protection system against a variety of threats: freezing and overheating of the coolant, lack of pressure, etc.

The devices are equipped with manual and electronic adjustment and control systems, highly informative LCD displays, and built-in automation capable of responding to weather changes.

Baxi boilers are economical and equipped with modulating burners. They can operate in two temperature ranges. The units are easy to install and convenient to operate. Among the significant shortcomings, it is worth noting some capriciousness of the electronics and the possibility of incorrect operation of temperature sensors.

Zhukovsky Machine-Building Plant

The largest domestic manufacturer of high-quality heating gas equipment.There are three main lines of production: “Comfort”, “Beetle” and “Universal”, within which more than 30 models of boilers for various purposes are produced. Their advantages include improved automation, which has led to an increase in efficiency up to 89% and a decrease in the toxicity of flue gases.

The equipment is capable of working with two types of gas, has non-volatile ignition, is equipped with overheating protection and gas mixture pressure control. The boilers are inexpensive and there are no problems with spare parts for them. Disadvantages include slight noise during operation of the equipment and low quality of manual welding carried out at the factory. Whereas there are no complaints about automatic.

Important advice. Don't skimp on quality. It is better to pay a little extra and purchase a device from a brand with a good reputation. It will last much longer than a fake of unknown quality, attractive only for its low cost.

We also recommend reading our article on how to conduct your own installation of a wall-mounted boiler.

Conclusions and useful video on the topic

Mounted gas boiler: features of models:

One circuit or two: which to prefer:

The best mounted boilers:

Wall mounted gas boilers are an excellent choice for small houses and apartments. Compact and at the same time quite powerful devices will heat the premises and, if necessary, provide hot water. When choosing equipment, it is worth taking into account all significant criteria and selecting the boiler that is most suitable for the existing operating conditions.

Please write comments in the block located under the article.Perhaps you managed to purchase a new model of a wall-mounted gas boiler? Share your impressions of using it, tell us about the nuances of using the device, are you satisfied with its performance?

For about five years now there has been a wall-mounted double-circuit gas boiler, chosen to save space. It copes perfectly with its functions for heating a house with an area of about 100 sq.m., despite the fact that the heating turns off when used to heat water. The only thing is that I have come across models only with electric ignition; in case of power outages, it is better to have a UPS or a generator, but they are not cheap.

For my private home I chose a gas single-circuit wall-mounted boiler. Since there is not much space in the boiler room, the wall-mounted option was the most optimal. I chose a boiler with a closed burner type, since the efficiency of such boilers is high. Although their cost is higher, they provide complete safety during use. In terms of power, I chose a boiler at the rate of 1 kW of power per 10 square meters of house area.