Why does back draft occur in the chimney and how to correct the situation correctly

A fireplace in your own home is the dream of any romantic.Who among us has not longed to find ourselves in a cozy chair by our own fireplace on a winter evening, blissfully absorbing the warmth spread by a living fire with our whole body?

But the smoke that fills the room and does not want to go up the chimney does not fit into this idyllic picture. Backdraft in the chimney is the name of this unpleasant phenomenon. Why does it occur and how to deal with it? We have collected information about this for you and provided it in this article.

We also paid attention to ways to check draft in a chimney and examined in detail the best options for solving the problem with draft.

The content of the article:

What is backdraft?

Before understanding the reasons for this phenomenon, you should understand the essence of what is happening. The heating device installed in the house, together with the chimney, forms an exhaust structure.

The air pressure inside and outside the device is not the same. Because of this difference in pressure, draft arises - an aerodynamic directed flow of flue gases.

Safe and efficient operation of a heating device requires that combustion products move from the burning fuel along smoke exhaust paths. The air masses in the chimney have a lower density, as a result of which they tend to rise. They are replaced by colder outside air. This is exactly what a change in flow should ideally be.

But sometimes a phenomenon called backdraft occurs. In this case, the smoke generated as a result of fuel combustion is directed not outside through the chimney, but into the room.

The occurrence of backdraft is not just an unpleasant, but also a dangerous phenomenon. The penetration of combustion products into the room leads to serious poisoning, and carbon monoxide is fatal.

The first signs of a malfunction in the movement of air masses may be not only smoke entering the room, but also a quickly smoked glass window in the firebox door. At first, the craving may just be weak, but if you don’t take action, it will reverse over time.

Sometimes another phenomenon associated with the movement of smoke occurs - the air flow changes its direction to the opposite direction for a multiple time. This is how the thrust overturns.

Causes of reverse thrust

There are several reasons for backdraft to occur. The main one can be considered mistakes made in the process heating system design. Perhaps the rules for using building materials were violated during its construction.

A problem of this kind will not arise at all if the chimney is designed in compliance with existing standards: the turn must be made at 90°, and the outlet must be positioned at an angle of 45°. Particular attention should be paid to the shape of the chimney section.

The most suitable shape is a circle. If there are corners in the design, turbulence may occur that prevents the removal of gases.

If we compare brick and metal chimneys, the draft in the latter will always be of lower quality. The problem is that the metal heats up quite quickly, but it cools down just as quickly. And cold air, as you know, sinks.

Common reasons include the following reasons why there is no draft in your chimney:

- Chimney obstruction. It may very well be that it is simply clogged with debris or smoked as a result of long-term use. Rapid smoking can also occur if the chimney is made up of pipes of different diameters. Under no circumstances should this be done.

- Errors in calculations. Incorrectly calculated cross-section of the smoke passage. Quite often, when designing a structure by non-specialists, disproportions arise in the sizes of the elements of the device: the combustion chamber and the chimney. A powerful stove, for example, can produce a larger volume of combustion products than a narrow chimney can remove. Therefore, you need to carefully follow chimney calculations.

- Design errors. The height of the smoke exhaust system is not sufficient for its effective operation. A short chimney pipe may cause insufficient pressure difference. The optimal height of the chimney pipe is five to seven meters.

- Narrowing of smoke channels. There are narrow and horizontally directed sections in the smoke exhaust paths. In such places, soot accumulates especially actively, which interferes with the free movement of smoke.

- Wind pressure. The chimney is located in the “wind backup” area.The cause of backwater could be, for example, a tall building located next to a chimney.

- Improperly organized ventilation of the room. Lack of ventilation or its improper arrangement leads to a lack of the required volume of supply air. Therefore, it is important to pay special attention proper organization of ventilation in a private house.

If the roof ridge is located above the level of the chimney, then the overturning of the draft may occur when strong wind occurs.

Atmospheric indicators should also not be excluded from the list of reasons for the formation of reverse thrust. High humidity in the outside air, as well as strong gusts of wind, can cause smoke to backflow.

The same phenomenon can be observed when the air at home is colder than outside. Due to the difference in pressure, a strong burning smell may occur.

To prevent poisoning, the room should be well ventilated. At the same time it will warm up at least a little. Wind, which creates turbulence in air flows on the roof, can also disrupt traction. This phenomenon is facilitated by the incorrect direction of the head relative to the ridge of the roof.

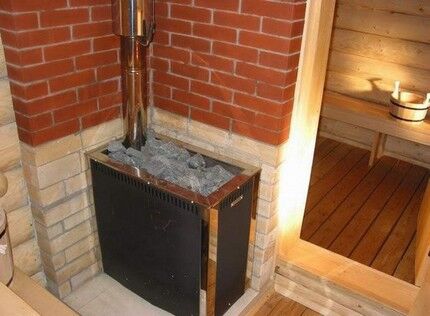

The location of the chimney is also important. For example, if we are talking about heating a bathhouse, this part of the structure can be located in the interior of the building.

This solution will allow for better heating of the room, providing decent draft even in severe frosts. If the pipe is placed along the outer wall, heating will take longer, and condensation may form in the pipe itself.

Methods for checking draft in a chimney

The presence of backdraft can be detected at an early stage of the problem, before smoke begins to fill your home.

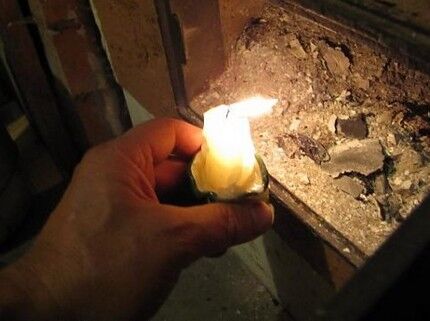

Let's start with folk methods. You can tear off a piece of toilet paper and bring it to the heating device. Toilet paper is thin enough to respond well to air movement. Look in which direction the leaf deviates. If it oscillates towards the room, then there is a reverse draft.

Exactly the same experiment can be performed using cigarette smoke. This looks even clearer. Cigarette smoke will unmistakably show you the direction of cravings.

The quality of draft can also be determined by observing the flame in the heating system. A white flame and roar in the chimney indicate too much draft, which is also not good, as it leads to excessive fuel consumption. A good result of the work looks like this: the flame has a golden-yellow color, combustion occurs stably and evenly.

To check using scientific methods, we need to arm ourselves with equipment. The most accessible device for ordinary users is an anemometer (wind meter). The appearance of the device and its varieties are presented in the video, which is posted in the final part of this article.

Options for solving the problem with traction

As it turned out, the reasons for the occurrence of reverse thrust can be different. Therefore, there are no standard solutions. You need to look for an option that matches the problem in each individual case.

If the outlet paths are blocked by debris or soot, you will need clean the pipe. If the tracks are not designed correctly, the structure will have to be completely dismantled and reassembled.

If the defect is the slow evacuation of combustion products, there are several ways to improve direct draft in the chimney. There are devices that help activate this process.

Option #1 - deflector and its varieties

A deflector can help solve the problem of how to further increase chimney draft. It is installed on the top of the chimney. This device “sucks in” the smoke located in the chimney shaft, using the power of the wind to achieve this goal.

The deflector has several functions at once:

- protection of the mine channel from external clogging and precipitation;

- increased draft in the chimney;

- extinguishing sparks that occur during incomplete combustion of fuel.

The operation of this device is based on the laws of physics. As gas moves through a narrowing pipe, its flow accelerates. At the same time, the pressure it exerts on the walls of the shaft decreases. A vacuum zone appears.

A deflector installed on the chimney creates this vacuum zone as air passes inside the narrowing channel in its structure. Gases rush into the rarefied zone located at the mouth of the chimney, and, with the help of draft enhanced by the wind, are removed from the pipe.

Even the simplest deflectors can increase smoke removal efficiency by 20%. The presence of such a device creates enormous advantages for the heating system, since it promotes complete combustion of fuel and better heat transfer. Therefore, it enjoys well-deserved popularity and demand.

Typically, the deflector consists of two cylinders - upper and lower, as well as a pipe connected to the lower cylinder, a protective cap and brackets designed for fixing parts.

The upper cylinder is not a mandatory element of the device. A model without it consists of the following elements:

- lower cylinder mounted on the smoke exhaust pipe;

- diffuser - an element that cuts air flows;

- two caps - direct and reverse.

The most expensive deflectors are made from copper. In general, ceramics and plastic, stainless steel, aluminum and galvanization are used to create them.Aluminum and steel products are considered the most popular.

Despite the commonality of functions, deflectors are very different. They differ not only in their appearance, but also in their design, as well as their sensitivity to air flows.

The following deflector models are considered classic:

- disc-shaped;

- ventilation TsAGI;

- Grigorovich's device;

- H-shaped;

- spherical "Wolper".

In addition to the universally recognized classics, there are also relatively new models, distinguished by unusual design solutions. This is a rotating model and a “weather vane” product. Their work is based on the same laws of physics that were already mentioned above.

Don't want to spend money on buying a deflector? And it’s not necessary - it’s quite possible to make it yourself, using available materials. How can we do it right? reviewed here.

Option #2 - special gate valve

If problems arise with the stove, you should check the position of the damper. The gate is a damper that is designed to regulate draft. It is usually installed on the uninsulated first meter of the chimney pipe. This damper allows you to make the heating equipment operate as efficiently as possible.

This device has several functions:

- after the fuel burns out, it is used to block the pipe, which allows you to retain heat for a long time;

- as a draft regulator, the damper is used to change the cross-section of the chimney: if there is excess draft, for example, the smoke channel can be narrowed;

- with its participation, it is possible to control the quality of fuel combustion.

The material for the manufacture of the gate is usually stainless steel, the thickness of which is 1 mm. Thanks to the polished surface of the product, soot can be easily removed from it.

The temperature that such a valve can withstand does not exceed 900 °C. It is quite durable and has a low coefficient of thermal expansion.

The gate is available in two models:

- horizontal retractable plate, which is most often used in brick chimneys;

- rotary gate or throttle valve.

The throttle valve is the same plate that is mounted on a rotating axis placed inside the chimney or pipe.

Due to the simplicity of the design make a valve for the pipe easy with your own hands. Such a homemade product in operation will be no worse than a purchased product.

Option #3 - chimney stabilizer

A product with such a telling name is otherwise called a breaker. This is a mechanism that automatically and dosedly supplies air into the chimney, allowing you to optimize the operation of the heating system without involving a person in it. To prevent excess pressure from being created, the breaker is equipped with a safety valve.

Stainless steel is used to produce a chimney draft stabilizer. The maximum temperature this device can withstand is 500°C.

The essence of the stabilizer is that it automatically adds cold air directly into the chimney. At the same time, the temperature and speed of gas movement inside the pipe decrease. As a result, the efficiency of using burned fuel increases without any changes in the operating mode of the heating device itself.

The breaker is usually installed on the chimney pipe. In this case, the distance from it to the heating device (boiler) must be at least 0.5 meters. The breaker should only be located indoors.

Since its operation is based on a system of precisely balanced weights, the influence of natural factors on the operation of this device must be excluded.

Setting up the stabilizer can be considered complete when the minimum draft value is set on its regulator in accordance with the data specified in the operating instructions for your heating boiler. You should set either the exact parameter or a division higher than the recommended one.

In addition to using the listed devices, to prevent backdraft, you can lengthen the chimney pipe, straightening it as much as possible. Bends and sharp turns of the shaft increase cavitation when gases are vented out.

Conclusions and useful video on the topic

If a problem with draft does not manifest itself in clouds of smoke throughout all rooms, this does not mean that it does not exist. A device will help you identify it; you can familiarize yourself with its design by watching this video.

This product may save your life by calling attention to the problem in time, since carbon monoxide, for example, has neither color nor odor.

This video contains information about the appearance of the TsAGI deflector and its components. You can see how to build this device yourself.

If you feel strong enough to make your own traction stabilizer, then this video will become a real guide to action for you.

Any device operating in your home must work properly and not create a threat to the life and health of people during its operation. Heating in this sense is no different from other useful devices. A deflector, gate and stabilizer will help make its operation stable and efficient..

Do you have a problem with chimney draft and are you trying to solve it on your own? Did you find the answers after reading our article? Or do you still have unresolved questions that we missed? Feel free to ask them in the comments section, and we will try to clarify these points.

When it's cold, I always have a problem with the backdraft of the fireplace chimney. In summer everything is fine, as it gets cold below +3 +5 so again. What can be wrong?

Hello, Garik. It would be nice if you attached a photo of how your chimney in the fireplace is arranged and a rough diagram. And so, without seeing an example, we can only give general advice.

Since the problem of reverse draft occurs only in cold weather, when the temperature outside drops below three degrees, it is necessary to insulate the chimney.I recommend using Knauf Insulation Thermo-teK basalt wool as insulation - the best option in terms of price/quality ratio.

I also strongly recommend installing a smoke vane on the chimney. This device is constantly positioned downwind, preventing cold wind from entering the chimney.

I just don’t understand how you can buy all this if you live alone and work does not provide material income. I just don’t understand how this is, even calling the master is not available. This is in Khokhland.

The oven worked fine until today. After cleaning the smoke flue, a strong reverse draft appeared. They can't eliminate it. What do you advise.

The chimney is direct straight from the stove.