How to make a partition with your own hands from plasterboard and profiles

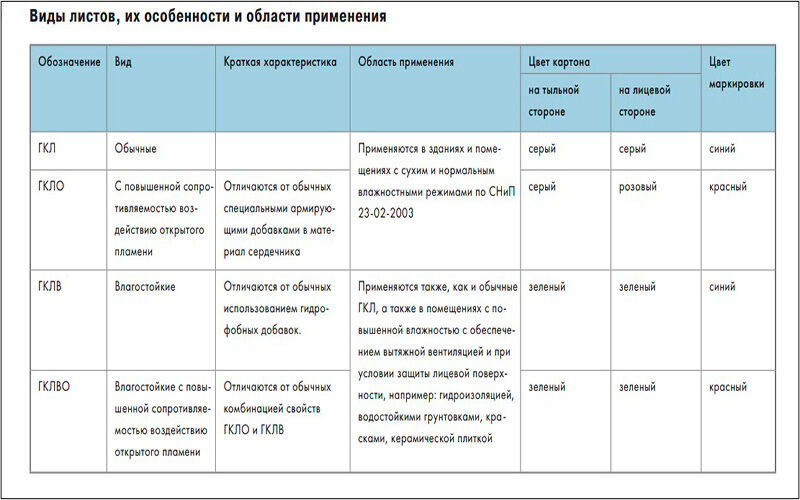

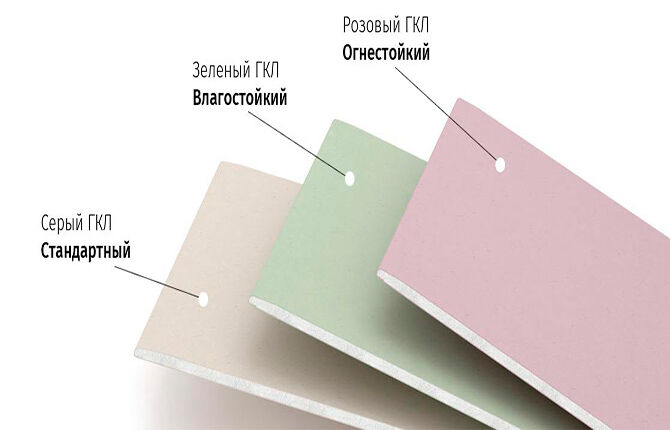

Drywall is well suited for arranging partitions in an apartment or house. The characteristics of the material allow it to be used in rooms with varying degrees of humidity.To make plasterboard partitions with your own hands, you do not need specialized knowledge. The task can be completed by a person with minimal construction skills.

The content of the article:

Types of plasterboard partitions

You can make a plasterboard partition of two types:

- wall between rooms;

- structures dividing one room into several zones (zoning).

Interior partitions are made solid. In order to reduce the degree of sound penetration, soundproofing materials are placed inside the structure. The wall separating two rooms is equipped with a doorway.

The structure used to divide the room into zones can be made with through holes. They are equipped with shelves, lighting is inserted, etc. A partition of this type does not need sound insulation.

Tools and materials

The list of devices for installing plasterboard partitions is selected separately for each case. To speed up work, hand tools are replaced with electric ones.

To make your own partition from plasterboard, you will need:

- Measuring tool with a scale in millimeters. Better than roulette. It is necessary in order to make markings on surfaces and structural parts.

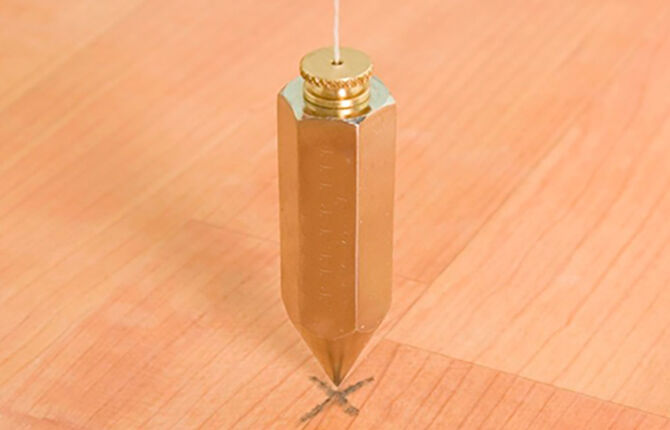

- Construction level and plumb line. They are used to assess the correct location of the partition in the vertical plane. You can make a plumb line with your own hands. All you need is twine and a heavy nut.

- Pencil or marker to make markings.

- Self-tapping screws for fastening drywall to profiles and metal structures to ceilings and floors.

- Screwdriver.

- Hammer.Necessary for drilling holes in a concrete base. If a small amount of work is expected, you can replace the hammer drill with an electric impact drill.

- Guide and rack metal profile. The number of parts is calculated separately.

- Construction knife with replaceable blades. Drywall sheets are cut with it.

- Metal scissors. Used for profile cutting. You can make cuts using an angle grinder with a metal wheel.

- Putty. For finishing, a gypsum mixture is used.

- Reinforcing mesh. Its canvas is mounted at the joints. This increases the strength of the finished structure.

- Container for mixing putty with a wide neck.

- Construction mixer or drill attachment for mixing the solution.

- Metal spatula.

- Semi-grater with abrasive mesh. To speed up the work, use a grinding machine.

Tools and materials are located near the workplace. This way, during the process of building a partition, you will not need to waste time searching for the right thing.

Preparatory work

Before making a partition from plasterboard, markings are applied to the surface of the material. After installation, it must be positioned strictly vertically. You can ensure correct positioning in the plane by using a plumb line.

In the place where the plasterboard wall will be located, a hole must be made in the ceiling. A line is drawn on the horizontal surface corresponding to the future location of the partition. Make holes along the edges of this line using a puncher. Dowels are installed in them and screws are screwed in.

A plumb line is attached to the head of the fastening element. In this case, the metal component of the tool should be at a distance of 5-7 mm from the floor.A dot is placed in the place where the plumb line points.

The same steps are repeated for the second fastening element located at the other end of the line.

After taking measurements, two points are obtained, located strictly vertically under the strip applied to the ceiling. A line is drawn on the floor based on these marks.

Worth checking out! Calculation of a plasterboard partition - examples of summary calculation of materials. About all this link.

Frame for a plasterboard partition

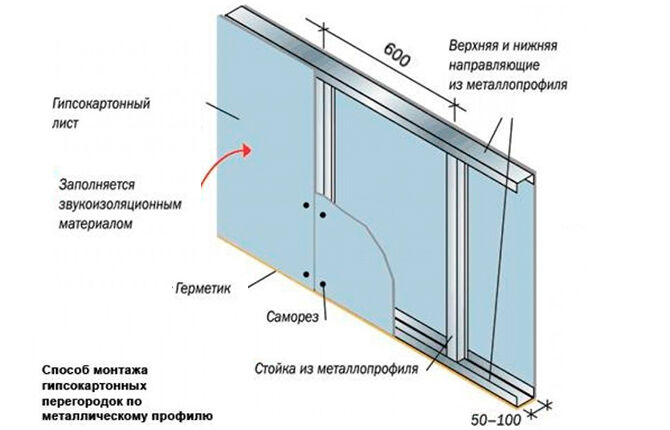

The base for fastening the sheets is made of a metal profile. Installation of plasterboard partitions involves attaching guide parts to the ceiling and floor of the room. They are installed along the marked marking lines.

The frame is assembled in the following sequence:

- According to the applied markings, the guide parts are measured and cut. Cutting is carried out with metal scissors or an angle grinder.

- Place the element on a horizontal surface and make holes with a puncher.

- Install dowels and screws.

- The rack profile is cut into sections corresponding to the distance between the guides.

- Install racks. The step between individual elements is selected separately. In this case, the size of the sheet is taken into account. The joint should be located in the center of the profile.

- The racks are attached to the guides with self-tapping screws.

- They make partitions between the rack profiles. Brackets are used for connection. You can cut the sides of the lintels to a depth of 40 mm. Install racks into the made recesses and secure with self-tapping screws.

The frame must be securely fastened between horizontal surfaces.If a plasterboard partition with a door is intended, a wooden beam must be installed at the opening. It will be used to hang the door leaf. The beam is fixed to the metal profile with fasteners.

Attaching drywall to the frame

The sheets are fixed to the base with self-tapping screws. The degree of clamping of the fastener is calculated separately. The head of the screw should go no more than 1 mm into the cardboard. Protrusion of the fastener beyond the drywall is unacceptable.

At the junction, the sheets are pressed tightly against each other. There should be an equal gap between adjacent canvases at the top and bottom. In places where the partition adjoins vertical and horizontal surfaces, you will need sheet cutting to smaller details.

Sawing drywall with an angle grinder is not permitted. When cutting, a large amount of dust is generated, which negatively affects human health. You can cut the canvas correctly with a construction knife with replaceable blades.

The sheet is laid on a flat surface and markings are applied to it. Using a knife, cut through the cardboard and part of the gypsum layer along the marked lines. The canvas is broken and the shell is cut from the reverse side. This makes it possible to make an even cut without the formation of dust.

In some cases it is provided soundproofing of partitions from plasterboard. To reduce the degree of sound penetration, mineral wool or polystyrene foam is used. The material fills the space between the frame elements. Additionally, electrical wiring or pipelines of the water supply system are located inside the partition.

Finishing

To make the surface of the partition even, all recesses are puttied with gypsum compound.Fill the joints between sheets.

To increase the degree of strength, a reinforcing mesh is fixed to the gaps. This makes it possible to create a single canvas.

For better adhesion of the putty to the outer layer of the sheet, primer is applied. Deeply penetrating compounds with antifungal action are selected. This way you can protect the material from rotting.

Plaster putty is applied metal spatula. The consistency of the composition is selected separately. Leveling the canvas is carried out with a wide spatula. Large gaps or recesses are puttied in several layers. Applying a large amount of solution at a time worsens the strength characteristics of the finished canvas.

The final stage is surface grinding. Irregularities are removed with a trowel with a fixed abrasive mesh or sandpaper. To speed up the work, electric grinders are used. This is how a plasterboard partition is obtained with smooth surfaces prepared for further finishing.

You can make a partition in the room yourself. This does not require specialized knowledge. During manufacturing, it is important to ensure that the frame is positioned correctly in the vertical plane and that it is securely attached to surfaces.

Have you made plasterboard partitions yourself? What tools did you use for this? Leave comments, bookmark the article and share it on social networks.

We also recommend watching selected videos on our topic.

Partition made of plasterboard. We do it ourselves - all the steps are in the video tutorial.

How to make a plasterboard partition with a door?