How and how to cut drywall: cutting tools + instructions on how to carry out the work

Drywall today is a popular building material, with which you can create not only durable load-bearing structures, but also complex decorative elements. Depending on the complexity of the product being designed, you need to figure out what and how to cut drywall correctly in order to get the desired result.

Agree, buying a new sheet after every mistake made is an expensive pleasure, especially considering today's prices for building materials. That is why it is important to decide on the tool in advance, as well as to analyze the cutting features in each individual case.

After familiarizing yourself with the tools and cutting methods, the article will present instructions with step-by-step implementation of the steps. The instructions will guide you in working with drywall, allowing you to make an error-free cut of the material the first time.

The content of the article:

Tools for cutting drywall

Many construction publications recommend that their readers use specialized tools for drywall, the cost of which is often too high. And only a qualified master can handle it.

If the tool is needed for a one-time use, for example, for wall cladding or suspended ceiling structures, then it is better to choose an inexpensive option.

For those who are not involved in professional installation of drywall, there is a short list of tools:

- Pencil, tape measure and ruler. In this case, you will need to arm yourself with a simple pencil, which will help you record all the necessary marks. A tape measure or ruler will allow you to take the most accurate measurements.

- Construction knife. Externally, the tool is very similar to a simple stationery knife, but more durable. Such a knife will easily cut a sheet of drywall, and it is enough to run the blade along the sheet once.

- Hacksaw. The good thing about this tool is that it has a thinner blade, which means it can help you get the most accurate cut possible. It is best to choose a hacksaw blade for metal.

- Jigsaw. To use such a tool, you need to purchase high-quality files, preferably designed for cutting metal. They have smaller teeth, which means they leave a minimum of nicks on the edges of the sheet.

- Plane. May be needed during the final stages of cutting a plasterboard structure. Using this tool you can give cut edges a neater look.

If you want to create more “sophisticated” shaped cutting elements, for example, circular or semicircular shapes, you can use an electric drill or cutter.

You can cut a perfectly even circle using a special electric drill with a crown.

It will be very difficult for a person who is working with cutting plasterboard sheets for the first time to make a straight, even cut, not to mention circular shapes.

That is why the simplest tools were chosen, which allow you to slowly but surely make an even cut along the marked lines.

Cutting methods with detailed instructions

Before you start cutting plasterboard sheets, you need to become a little more familiar with the features of this material. This material is made from gypsum with fillers, which is equipped on both sides with sheets of construction cardboard for additional strength.

Due to the cardboard sheets, the material acquires the correct shape and a perfectly flat surface, which makes it more convenient for further use.

The material is intended for the construction of small architectural forms: partitions, suspended ceilings and decorative elements. In practice, you often find furniture made of plasterboard, which is no less durable than any other wood substitute.

Next we will look at several types of cutting, each of which has its own characteristics.

The degree of strength of a material is determined by its type, which should be taken into account when carrying out work. Thus, there is a gypsum fiber sheet of increased strength, which may require a more effective tool when cutting.

Option No. 1 - cutting in a straight line

In this case, cutting the material is carried out along a straight line, previously drawn with a pencil or chalk. It is recommended to start cutting the sheet from the back side - this is the strongest part of the cardboard.As for the front side, its structure is slightly different, since it is adapted for primer and other types of finishing.

The plasterboard sheet is laid on a hard surface so that there is not even the slightest deflection. Next, a ruler is applied to the marking line, which is firmly fixed by hand. If you try to make a cut without a ruler, there is a high risk of ruining the sheet.

The cut is made clearly along the edge of the ruler, and it is important to ensure that it does not come off. After completing the cut, the sheet must be turned over and folded along the slot line in the direction of the uncut side.

So, a sheet that is not completely cut is broken along a straight line, and the cardboard from the outside is cut along the bend.

In this case, the back side for cutting was not chosen by chance. Thanks to its denser structure, cutting cardboard will be much easier, which means the line will be perfectly straight. By the way, it is recommended to use a special metal ruler to take measurements during construction.

Option No. 2 - figured cutting

This method is used when it is necessary to create a non-standard shape of a certain structural element. In this case, the procedure becomes somewhat more complicated, so it is advisable to have at least a little experience working with drywall and a high-quality cutting tool.

At the initial stage, markings are also carried out, in this case figured. To obtain the most even circle, you will need a special template or compass. You can create an unusual shape with circular elements using a pattern.You can cut a perfect circle in any of four ways.

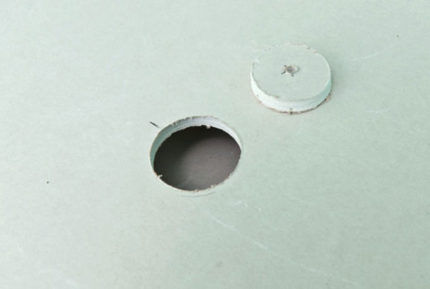

In the first case, shaped cutting of drywall is done using an electric drill with a crown. This method is suitable for cutting out a circle of small diameter, for example, for socket, and no marking is required here. It is enough to make a barely noticeable mark, which will serve as a guide for the master.

The second method involves using a jigsaw. Before starting work, a precise marking of the shape along which the cut will take place is carried out. The main advantage of a jigsaw is that the diameter of the cut circle in this case does not depend in any way on the diameter of the crown, as is the case with an electric drill.

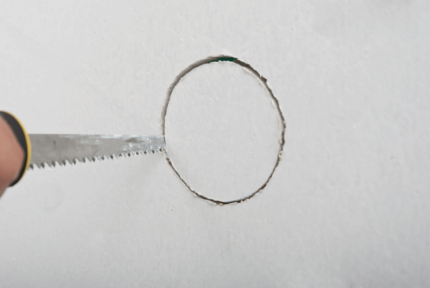

In the third method, a special hacksaw is used as a cutting tool. According to the principle of its operation, it resembles a knife with teeth, but with a reinforced handle. This hacksaw is especially convenient for working with drywall, because it can be used not only in classical, but also in figured cutting. This tool is ideal for cutting out any non-standard shapes, for example, flowers or butterfly wings.

The last method does not involve the use of a special tool. In this case, you can get by with a regular knife and hammer. The material is cut along the contour of the marking, and it is better to try to insert the knife as deeply as possible. Upon completion of the cut, it is necessary to place the sheet on a flat surface with a recess so that the area with the cut element ends up exactly in this recess.

If a really deep cut was made, the drywall should break in the desired direction. The bottom layer is cut off and the edges are sanded if necessary using sandpaper.

This method is perfect for people who have previously worked with cutting plasterboard sheets and know how the material will behave in this case.

Option No. 3 - cutting the installed sheet

Of course, it is as convenient as possible to cut a sheet that has not yet been fixed. However, in practice there are often situations in which cutting of the material is required after its installation on the frame.

This is due to the fact that the sheathed surfaces must be “adjusted” to the window slopes or corners. The sheet is fixed to the wall with a small margin, and the excess centimeters are removed after installation.

Here it is important to make sure that the sheet of drywall is securely fixed to the frame. After the first cut, several more cutting movements are carried out so that the cut area can simply be “squeezed out”. If necessary, you can cut the sheet on the other side.

The presented methods for cutting drywall are effective only if you need to do a small amount of work.

If you need to cut plasterboard sheets in large quantities, the best solution would be to turn to professional craftsmen.

Conclusions and useful video on the topic

You can learn how to cut drywall quickly and smoothly from this video:

An overview of the best tool for cutting plasterboard is presented in this video:

The article presented the best ways to cut plasterboard using improvised tools that everyone can find at home.

By following the sequential instructions, you can cut the drywall yourself while maintaining all proportions. So, you will no longer have to spend money on the services of a specialist, which will obviously cost you more than replacing a damaged plasterboard sheet.

If you have experience in cutting such durable building material as drywall, then you can always share it with our readers. You may know simpler methods of cutting material that you have previously used. If you wish, you can leave your comment in the special field under the article.