How to build a cesspool from concrete rings: diagrams + step-by-step guide

Are you looking for the simplest way to collect and partially recycle sewage for your dacha or seasonal home? Agree that installing a sewer system will significantly improve the area and make your stay outside the city as comfortable as possible. A regular cesspool made of concrete rings will do the job, but you don’t know how to build it correctly?

We will help you understand this type of septic tank - the article discusses the design of the pit and popular construction schemes. The process of designing a cesspool from rings with calculation of the required volume is analyzed in detail, and its phased construction is described.

The material is supplied with visual photographs and diagrams, and video recommendations for construction from experienced craftsmen are provided. Methods for decorating a technical hole are also considered.

The content of the article:

Design and purpose of the cesspool

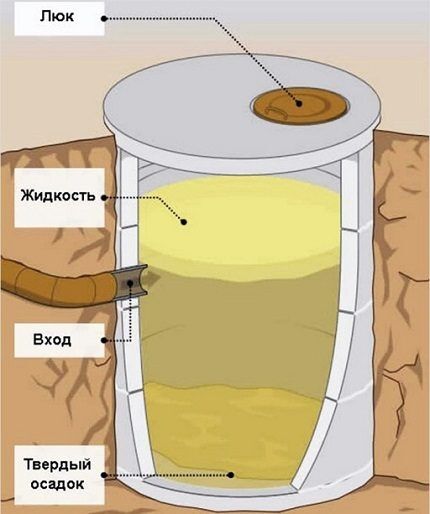

Cesspools, like septic tanks, serve to collect sewage. But these are primitive structures that are not capable of purifying liquid.

In storage tanks, the waste is only partially decomposed, unlike VOCs, where the effluent is divided into solid waste and liquid, which is further clarified and reaches a purity of 60-98%.

All varieties drainage pits can be divided into two categories:

- sealed storage containers;

- drainage pits with a filter bottom.

For users, two differences are important - the design of the bottom of the tank and the frequency of waste removal. The first type retains the entire volume of sewage, so it is emptied quite often, once every 1-2 weeks.

For the second type of pit, sewer trucks are called less frequently, since the container fills a little slower. Some of the liquid seeps through a kind of filter that replaces the bottom and enters the ground.

At first glance, the second option is more acceptable, but it can only be used for processing gray waste.

At making a pit without a bottom a number of factors must be taken into account:

- sanitary requirements;

- soil type;

- presence and location of aquifers.

If the soil in the selected area is clayey and cannot quickly absorb water, there is no point in making a filter bottom. It’s the same with aquifers – there is a risk of contamination and environmental damage.

There are many solutions for cesspools: build brick structures, concrete or car tires. Concrete structures and ready-made plastic containers are considered the most reliable.

Concrete tanks, created by erecting formwork and pouring, are more difficult to construct than analogues made from ready-made rings, which we will dwell on in more detail.

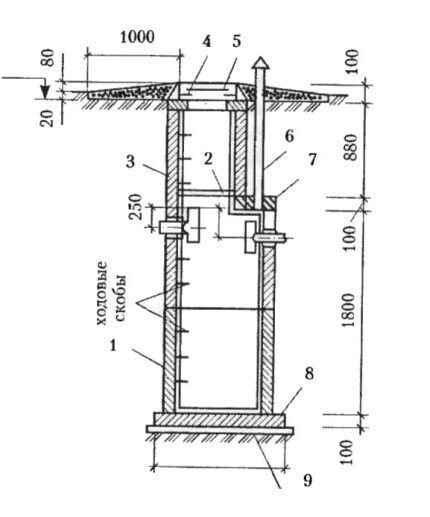

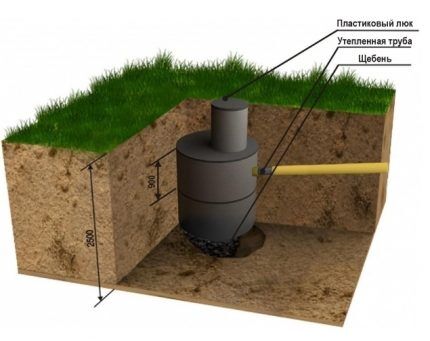

A cesspool made from cylindrical concrete blanks in its finished form is a well from 2 m to 4 m in depth. Rings in the amount of 2-4 pieces are placed one on top of the other, the seams are sealed.

The lower element, depending on the type of pit, may be closed or completely absent. Sometimes, instead of a ready-made factory blank, a concrete slab is placed on the bottom.

The upper part is designed in the form of a neck with a technical hatch and a tightly closing lid.

The main storage part of the tank is buried approximately 1 m, since the supply sewer pipe must be below the freezing level of the soil. The volume of the container is selected taking into account the amount of daily waste.

Why are drainage pits attractive?

The main advantage of drives is their affordable cost. It is for this reason that many people stop at the simplest device instead of purchasing a more expensive and functional septic tank.

The cesspool is also convenient for those who rarely come to the dacha - only in the warm season or exclusively on weekends.

If there are relatively few sewage drains and regular waste pumping is established, a cesspool is really a suitable option.

But for large volumes of waste it is better pick up a septic tank - a more expensive device that partially purifies waste and reduces contamination of garden soil to a minimum.

The latter is possible if a model with filter well or an infiltrator.

Disadvantages of a cesspool that may cause refusal to build it:

- limited volume;

- the need for frequent pumping;

- low (or zero) degree of waste treatment;

- a specific smell that is difficult to get rid of.

Those wishing to install a filtering sewer structure should know that from time to time, along with pumping, they will have to clean and even replace the filter - the gravel or crushed stone layer at the bottom of the pit.

Review of popular construction schemes

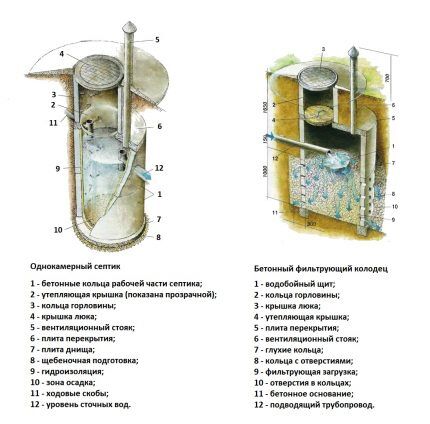

Even the construction of the two main types of cesspools can have nuances. Let's look at the features of the most popular schemes of concrete rings.

The first scheme is a sealed storage well made of two standard rings and one narrower ring for the neck.

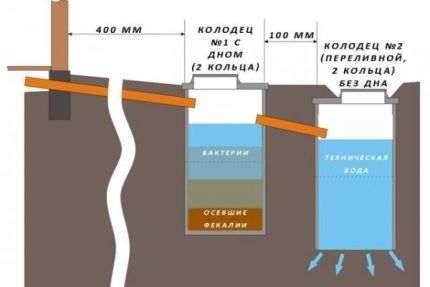

The following diagram clearly shows the difference between a storage tank and a tank with a filter bottom.

The third option is a modernized storage tank, a primitive septic tank.

Using a two-piece storage tank with overflow more appropriate, as it increases the degree of environmental friendliness. Sometimes models with three compartments are used - the more there are, the more effective the wastewater treatment.

Brief photo manual on pit construction

The construction of a cesspool using concrete rings includes a number of traditional steps.

So that readers can visualize the process, we suggest that you familiarize yourself with the photo report of the builders:

Project preparation and calculations

By starting construction without preparation, you risk violating sanitary standards and creating a device with limited functions. In order for the cesspool to work 100%, it is necessary to provide for all the nuances and complexities of construction.

Step #1 - determining the location for the drain hole

When choosing a place for a cesspool, it is important to consider two points: ease of maintenance and compliance with sanitary standards.

Accordingly, to facilitate the installation process and better functionality of the entire sewer system, the tank must be installed as close to the house as possible.

Many do just that - they bury the container 2-3 m from the building, not paying attention to the smell and forgetting about the norms and rules for using drainage pits and various types of septic tanks. By the way, the recommended minimum distance from the pit to the house is 5 m.

The diagram can be supplemented with the following information:

- sealed container installed in any type of soil;

- tank with filter - only in sandy, well-absorbing and permeable liquid.

The base of the filter structure must be at least 1 m higher than the aquifer.

To determine the depth of aquifers, it is better to seek information from a design or drilling organization that has carried out geotechnical surveys or drilled a water well in the construction area.

Step #2 - calculating the volume of the container

To determine the size and volume of the well, you need to make simple mathematical calculations. If a permanent home has a shower, toilet, and washing machine, then 1 person receives approximately 150-200 liters of sewage every day.

Let's assume that you want to install a sealed cesspool in the courtyard of a house where 3 people live - that turns out to be 450-600 liters per day.

Do not forget that when calculating we take into account at least 3 times the amount, that is, we multiply by 3 again, we get 1.35-1.8 m³. This is the minimum volume.

The dimensions of the neck and parts of the well located above the entrance of the sewer pipe do not need to be taken into account. That is, the resulting volume is the parameters of the part located below the pipeline.

Sometimes they are based on the timing of calling the vacuum cleaners. If the same family of 3 is served every week, then it turns out: 150 l (200 l) x 3 x 7 = 3.15 m³ (4.2 m³). Once every two weeks – 6.3 m³ (8.4 m³).

If a public utility or private company servicing your site has a vehicle in its fleet with a tank of 6-8 m³, it makes sense to install the maximum volume tank.

Step #3 - choosing concrete rings

The volume of the cesspool is calculated based on the size of the rings, so it is easier to purchase models from the range of a company located nearby, since delivery will be required.

Typical ring sizes:

- height - 0.89 m;

- diameter - 1m.

Rings with these sizes are produced by almost all reinforced concrete factories. For a small family, three blanks are enough, plus a neck and bottom.

The construction of cesspools is so popular that factories began to produce complete kits for their construction.

The set includes:

- lower element with bottom;

- standard rings from 1 to 5 pcs. — a larger quantity will cause difficulties with cleaning and pumping;

- narrowed neck;

- top floor slab with a hole for a hatch.

Rings can be regular or perforated for absorption wells. The hatch and cover are purchased separately.

In addition to standard concrete rings meter diameter, you can find larger blanks.

Preference should be given to rings with a tongue-and-groove locking connection, which guarantees a higher degree of tightness and strength of the finished structure.

Step #4 - preparing materials and renting equipment

In addition to a set of concrete blanks, the following building materials may be required:

- staples for connecting parts;

- sealant for sealing seams;

- bitumen mastic or other material for sealing the tank from the inside and outside;

- cement to strengthen the backfill;

- crushed stone, gravel and sand for preparing a leveling screed or filter layer.

Don't forget about buckets, shovels and winches for digging.

It is not possible to deliver concrete rings yourself - for large and heavy parts you need to rent a truck.

If the construction site does not have a winch, it is better to order special equipment with a manipulator. One person can't do it. The only thing you can do yourself is to dig a pit.

To install the workpieces, at least 2-3 pairs of workers plus a truck driver are required.

The ideal option is the help of friends with whom you can negotiate a low payment. If you don’t have special equipment drivers or installers among your friends, you can rent a car and pay for the services of a team of workers.

Often, the help of professional installers is offered by a company that sells rings for wells and drainage pits.

Instructions for building a cesspool

The installation of each specific tank has its own nuances related to the characteristics of the landscape, soil, location of the sewer network, etc. We will look at a typical diagram for constructing a cesspool.

Stage #1 - excavation development

The first stage is earthworks. They can be done alone (long, hard and free) or with the help of a team (fast and fun, but for money).

If possible, you can use a mini-excavator, then workers will only be needed to “grind” the walls and level the bottom of the pit.

The shape and dimensions of the pit must correspond to the configuration and dimensions of the tank. Accordingly, the result should be a round well, the width exceeding the concrete rings by 0.3-0.5 m on each side around the circumference.

This gap will be required for sealing/insulating the structure from the outside and subsequent backfilling with compaction.

There is one nuance that should not be forgotten - this is the level of soil freezing (the information is relevant for residents of central and northern Russia).

The sewer pipe for waste and the main part of the tank must be below this level for the system to function in winter. If you lay the network near the surface, when frost sets in, the liquid will simply freeze.

In this regard, to the dimensions of the working container it is necessary to add the height of the neck, which essentially serves as a technical hole. The neck should protrude 15-20 cm above ground level.

Thus, the tank will be buried, as will the sewer pipe cut into it below the freezing level.

Before the start of construction work, it is necessary to level the base with the walls and dig a ditch leading from the house (bathhouse, summer kitchen, garage) to the drainage pit.

When constructing a ditch, do not forget that in order to avoid blockages, the pipe must have a slope towards the pit - approximately 2 cm per meter.

Stage #2 - arrangement of the bottom

If you are installing an ordinary storage container, the bottom, like the walls, must be sealed. For a structure made of concrete rings, the best option is to make a blank from the same material.

The part is specially designed to decorate the bottom of the well and has a groove around its circumference. The only thing needed for its installation is a flat, dense base.

Possible subsidence of the base is eliminated by pouring a cement screed. It is prepared according to a simple scheme: for every part of cement - 4 parts of sand. For strength, you can add fine crushed stone in a ratio of 1:6.

The mass is prepared in a container, then poured over the entire area of the bottom of the pit and leveled.Within a week, the concrete screed is lightly irrigated with water so that it does not become covered with cracks. The lower element of the structure is installed no earlier than a week later.

For those who value time, there is a more practical solution - a pre-fabricated concrete slab. It is placed on a flat bottom, and the first concrete ring is placed on it.

Colonies of anaerobes, bacteria involved in the process of decomposition and purification of waste, settle on the backfill of crushed stone or gravel.

The thickness of the underlying backfill varies:

- shallow holes – from 0.3 m;

- tanks of 3-4 rings - up to 0.6-0.7 m.

The thickness of the filter bed placed in the well shaft must be at least 1.0 m.

The arrangement of layers is as follows:

- bottom layer - sand;

- middle layer — fine crushed stone;

- upper layer – coarse crushed stone.

Unlike a concrete tank, the “cushion” and filter are replaceable elements. When they become clogged with solid waste and stop allowing liquid to pass through, the old backfill is taken out and a new one is placed at the bottom of the hole.

Stage #3 - installation of concrete rings

The first ring, equipped with a bottom, is installed directly on the concrete slab (or screed). Smooth installation of the part guarantees a strictly vertical position of the entire structure, without tilting or distortion. Place a second one on the bottom element and immediately seal the seam.

To seal and waterproof seams, various solutions, coatings and roll materials are used. Using roofing felt glued to a bitumen mortar, joints and cracks are closed from the outside; it is not suitable for interior work.

Ordinary cement mortar is also considered weak: when the soil moves, it becomes brittle, causing it to crack and crumble.

There are many modern modified mastics and solutions that have sufficient strength and elasticity. Some of them can be applied to wet joints or seams that are already under water pressure.

Involve various abilities waterproofing a concrete septic tank to protect the walls from the destructive effects of aggressive chemical environments, which are often contained in sewage.

Here are some of the effective means for sealing joints and internal sealing:

- Hydro seals, which expand when hardening, tightly closing any cracks. Examples: Waterplug, Peneplug, Hydrostop. Their only disadvantage is their high cost.

- Solutions for application to the entire surface: Antihydron, Hydrotex, Bastion.

- Materials for caulking deep seams, impregnated with Kiilto FIBERPOOL fiber rubber - cords and ropes made of jute, flax, hemp.

- Rubber sealing strips, for example RubberElast.

- Liquid glassadded to cement mortar

- Water-based sealants: Peneplug, Penetron, Penecrit.

High-quality waterproofing ensures structural integrity for up to 35 years.

After making sure that the connection between the rings does not allow water to pass through, you can install the next part.

Approximately 20 - 30 cm below the depth of seasonal soil freezing it is necessary to make an inlet for the sewer line.At the same stage, a pipe is laid and connected to the tank. The connection point is carefully sealed.

In the northern regions, pipes passing above the freezing depth are additionally insulated, as is the upper part of the storage tank.

The neck is mounted on the 3rd or 4th ring, then the floor slab. The factory-made plate has a round hole for the hatch. Another hole, of a smaller diameter, is needed for the ventilation pipe.

The final touch is backfilling. If you add dry cement to the soil, the reliability of the structure will increase, and the risk of destruction by soil movements will decrease.

Stage #4 - design of the technical hole

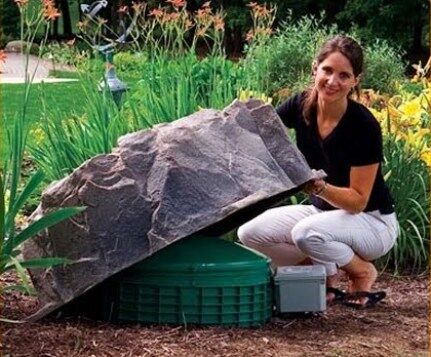

The best option for exterior design is sewer hatch with a tight-fitting lid. Its inexpensive counterpart is simply a wooden lid attached to hinges.

The hatch is necessary for servicing the cesspool - pumping out waste or replacing the filter layer.

Recently, it has become common to camouflage sewer structures, especially if they do not look aesthetically pleasing. For this purpose, decorative products are purchased that imitate green spaces or large stones.

But you don’t have to use purchased decor; you can assemble an elegant flower stand from wooden slats and decorate it with flowering plants.

Conclusions and useful video on the topic

A few tips from professionals will help you decide on the type of pit and build a tank from concrete rings according to all the rules.

Stages of construction of a cesspool with detailed comments:

Installation of concrete rings:

Useful information about hatches:

As you can see, constructing a cesspool from concrete blanks is accessible even to an inexperienced builder. But remember that to build a functional structure, it is necessary to comply with standards, a verified design, accurate calculations and, most likely, you will need the help of installers.

If you are not confident in your abilities, consider installing storage container made of plastic or even a factory septic tank.

Do you have personal experience in constructing a cesspool from reinforced concrete rings? Would you like to share useful information or ask questions on a topic? Please leave comments - the feedback form is located below.

Interesting stuff. It’s not often that you come across such high-quality instructions with videos, diagrams and illustrations. A quick question to the author: is the installation of concrete rings suitable for any type of soil? On my own behalf, I would like to add that you can indicate the approximate costs of renting equipment and materials. And it would be good if there was information on the wear of concrete rings, their strength and the impact of third-party factors on them. It was useful)

Good day, Sergey. Yes, a cesspool made of concrete rings can be constructed in all types of soil. Only in cases of high groundwater should attention be paid to waterproofing.

It is incorrect to indicate approximate costs. Due to the difference in prices depending on the region, which can sometimes be three or even five times.

Due to the strength and moisture resistance of concrete products, the service life is, without exaggeration, about a hundred years.

I have this situation. I started making my own cesspool out of concrete rings at my dacha. But I had to leave and my well stood unfinished for 2 years. The trouble is that I managed to dig in two rings and have two left. So around the dug-in rings the soil has already been compressed and compacted on its own. Now it’s impossible to dig them deeper and pull them back out. Can you think of something on how I can complete the well?

Buy two more rings of smaller diameter and dig them inside these two rings.

Hello. Please check it out https://engineering-en.techinfus.com/vodosnab/kolod-skvazh/uglublenie-kolodcev.html, section - “Deepening using rings of smaller diameter.” This is about water supply, but there is not much difference in technology.

Hello! Nikolay, I bought a garden in winter, I didn’t look into the hole under the snow, the water drained normally. In the spring, problems began - groundwater and frequent pumping (once a month 10m3 of the pit). The rings are on the slab, I want to drill 5-6 holes along the slope in the wall of the lower ring to drain wastewater. At what distance from the bottom edge of the ring should the holes be made? Or try it at the bottom? I’m afraid there’s just a base and a screed (I don’t know how thick it is), what do you recommend?

I’ll add: there is a slope, the rings around the circumference are covered with crushed stone, I understand that if you make holes in the bottom (what diameter, by the way, and how long is the drill needed?), they will silt up (preferably on the side). I’m already tired of paying for a car (1 thousand rubles a month, sometimes more often).