How to make a septic tank with your own hands from barrels using plastic containers as an example

Local sewerage with its own treatment plant will allow you not to break away from civilization in settlements that do not have basic infrastructure. If you make a septic tank with your own hands from barrels as a cleaning object, the cost of improvement will be minimal. But for a successful result, technological subtleties are needed. Isn't it true?

We offer everyone who wants to acquire an autonomous sewer system on their own site useful information that thoroughly covers all aspects of its construction. The practical application of the information we provide is a guarantee of long service life and flawless operation of the system.

This interesting article presented to your attention introduces various structural types of homemade septic tanks. It describes in detail the technology for constructing a sewage treatment plant from waste barrels. Construction methods are illustrated with simplified graphics, photos and video applications.

The content of the article:

Advantages of a homemade septic tank

Despite the fact that manufacturers offer a fairly wide range treatment systems, design and construction of homemade septic tanks (for example, from barrels) is quite relevant.

The hand-held device option is in demand for the following reasons:

- the ability to reduce costs to a minimum by purchasing components, as they say, at random - where it is cheaper, and secondly, using existing means at hand;

- installation of equipment can be carried out according to the so-called modular scheme, having previously calculated options for adding and complicating the system.

Let's say you first equip a toilet. In the future, you connect a bathhouse, a kitchen sink, even a garage sink to the cleaning system. Of course, this will be easily feasible only if the “tie-in” points are prepared in advance - pipe bends brought to the surface or close to it, reserved for a time.

No one knows the weak points of the treatment system and its capabilities better than the master who built the septic tank. Although you should not allow shortcomings, only he will take them into account during operation.

It’s no secret that manufacturers and sellers of any equipment, as a rule, do not inform buyers about the shortcomings, “showing off” only the advantages septic system. A self-builder will know what can let him down.

Knowing the approximate norms of water consumption by the family, taking into account the frequency of residence and the characteristics of the area around the house as a whole (type of soil and groundwater level), you can avoid both unnecessary expenditure of effort and money, as well as “accidents” caused by poor throughput of the purification system.

You will learn the intricacies of constructing a septic tank that operates without emitting odor and does not require pumping from another popular article our site.

Varieties of designs and schemes

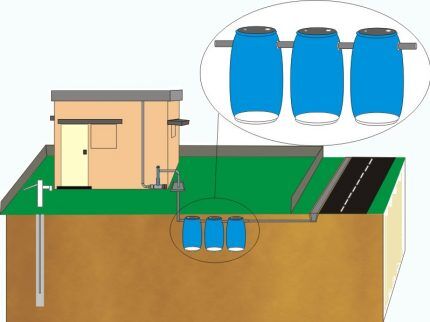

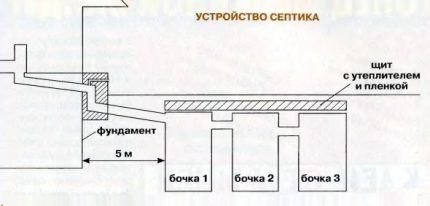

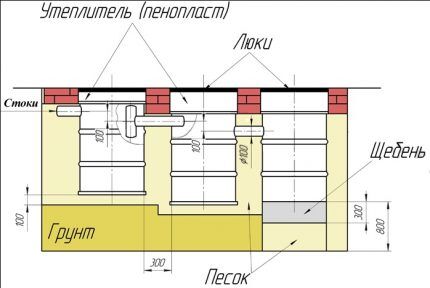

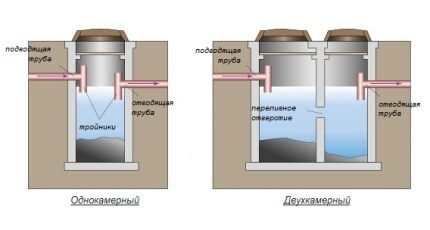

A homemade septic tank constructed from barrels consists of several containers (chambers) installed in a given order. They are sequentially connected to each other by pipes so that the sections are filled in a strictly defined order. This is achieved by installing cameras at different height levels.

The operating principle of a multi-chamber septic tank is similar to the operating principle cesspool with overflow. The entry and exit of pipes into the chambers is made in such a way that water begins to flow into the next container before the water level rises to the inlet pipe.

Gradually accumulating in the chamber, the water settles. The heaviest particles of contaminants settle at the bottom of the tank, while smaller and lighter particles continue their path through the system.

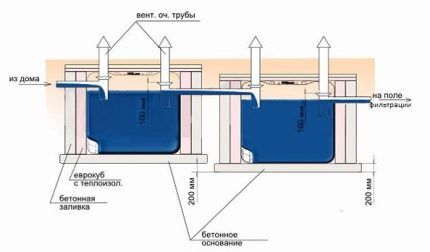

In order for the methane generated during wastewater treatment to be freely removed from the system, it is necessary to arrange ventilation. It is installed vertically at the exit from the house or at the exit of the last section of a homemade septic tank.

In addition, at the drainage of water from plumbing fixtures, sinks, toilets, shower stalls, etc., it is necessary to provide a siphon - at least made in the form of an “elbow” - so that the unpleasant odor does not poison the existence.

The operating principle of a septic tank is based on the gradual separation of solid insoluble components and the liquid component of the wastewater. The more sections the sewage mass passes through, the higher the final degree of purification.

The most common is the three-section septic tank design, used for processing gray and brown waste streams. However, if it is necessary to purify contaminated water coming from a bathhouse or kitchen, using one or two barrel sections will be sufficient.

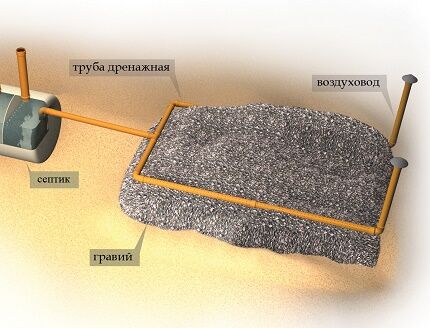

From the last barrel, access is made to the filtration field, which completes the cleaning process. This post-treatment system is an underground structure assembled from perforated pipes - drains.

The drainage pipeline is laid in trenches selected specifically for them, lined with geotexile, on top of which pipes are laid and a sand-gravel mixture is filled.

The function of ground post-treatment of gray wastewater supplied by baths, washing machines, kitchen drains, etc. can be safely entrusted to an absorption well built in the outermost barrel of the sewer system. In this case, the bottom of the container is cut out, and it itself is filled with gravel and sand so that the layer of this backfill is at least 1 meter.

As you can see, the scheme is quite simple, but its implementation in practice will require a lot of physical effort. Particularly labor-intensive work is associated with the development of a pit for sections of a septic tank and trenches for a sewer pipeline.

Construction of a septic tank from plastic barrels

Homemade treatment structures can be divided into groups according to the material from which the chambers are made, these are septic tanks:

- from plastic barrels;

- from used Eurocubes;

- from metal containers (welded cubes, cylindrical barrels);

- made of concrete rings;

- from car tires.

A metal tank is more rigid. In addition, it is easier to secure it from floating. But the main disadvantage of iron barrels is their poor ability to resist corrosion.

A septic tank made of concrete rings requires the use of special equipment when constructing sewer wells. It is difficult to ensure the proper degree of tightness for a cleaning station made from tires if there is no experience working with such materials.

A homemade septic tank made from plastic barrels has more advantages:

- light weight, which facilitates transportation, installation in the pit and assembly;

- corrosion resistance.This point is important not only from the point of view of reducing the hassle associated with replacing tanks, but also as an additional guarantee of cleanliness on the site;

- the optimal method of construction, because Electric welding is not required for installation of the system;

- the tightness of the containers, due to which there is no need to carry out work on waterproofing the sewerage structure;

- manufacturability of the source material. Polymer containers are much easier to process with cutting tools.

If necessary, minor cutting flaws can be easily corrected using cold welding tools.

Basic requirements for placement

In the event that you have to obtain permission to install a septic tank from regulatory authorities (SES, etc.), then carefully study SNiP No. 2.04.03-85. SNiP - “Building Norms and Rules” - a document similar to the standard (GOST), and it is the specified one that establishes the basic rules for the construction of external sewerage networks and treatment facilities.

Sanitary requirements are regulated SanPiN – Sanitary Rules and Norms.

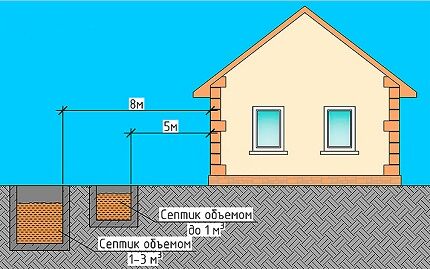

In any case, adhere to the following requirements for distances from the septic tank to the following objects:

- house foundation – 4-5 meters;

- well, borehole – 30-50 m;

- lake, pond – 30 m;

- bushes, trees – 2-4 m;

- road – 5 m.

Before installing an autonomous septic tank or cesspool made of plastic barrels its location must be discussed with the owners of neighboring plots. Although the regulations stipulate a distance from their fence to the septic tank of 2 m, the owners of a nearby estate may not be satisfied with the proximity of the sewer structure.

When deepening the bottom of the structure below 5 m, it will be necessary to obtain construction permits from the local administration.

But even if permission is not required, take into account the characteristics of the site. It makes no sense to install sewerage systems with ground treatment systems in clay soils that do not have the necessary filtration properties.

The lack of ability to pass water will be indicated by stagnation of flood waters during snow melting and periods of heavy precipitation. This means that the section is dominated by clay soils that do not allow water to pass through or into them.

On clay soils, sandy loams, clays, loams, storage tanks are installed. They make them made of concrete rings, plastic containers or a group of barrels. The storage tanks only accumulate wastewater for pumping out by sewage trucks, and do not process it.

A similar decision should be made if the groundwater level is close to the surface. Water-saturated soils will also prevent the disposal of the purified and clarified liquid component of wastewater.

Instead of a storage tank, a biological treatment station can be installed. It purifies wastewater by 98%, which allows it to be discharged onto the terrain.

Features and design standards

Having solid experience in constructing such systems, all the required calculations can be made “by eye”. But drawing up a detailed plan and developing a project, at least in sketch form, can be of great benefit.

Firstly, having determined the installation locations of the cameras and the laying of the highway, you will accurately calculate how much and what materials you need to purchase. If time is of the essence, then before you start work, it is quite possible that you can get some of what you need for free.

And legally - people, as a rule, easily part with things that they consider trash. It has been proven in practice more than once that you can even assemble a car by spending funds comparable to the price of, say, a new bicycle.

Secondly, careful execution of the sketch contributes to the adoption of new decisions and also disciplines. In addition, a well-executed scale drawing can reveal flaws in the original design and save you from unnecessary expenses. It may well turn out that the scheme can be simplified by discarding the superfluous.

When drawing up your plan, consider the following:

- even if you do not need official permission to install a septic tank, try not to disturb the ecology of the site;

- the septic tank sections should be located so that there is at least 5 m between them and the foundation - a distance that prevents soil erosion in the event of emergency flooding of the septic tank and leaks;

- the route of sewer pipes must be designed so that it is, if possible, without turns that contribute to clogging of the pipeline;

- the external line of the autonomous sewerage system must be provided with an inspection well for inspection and cleaning.

- For every 25 m of the sewer main, an additional inspection well must be constructed.

If the site is not pleasing with its dimensions, and the choice of location is a decided matter, then, if necessary, strengthen the walls of the pit.

If you plan to build buildings in the future, the functioning of which will require the use of water (bathhouse, sink, any kind of handicraft production), provide places for the “integration” of water drainage from them into the treatment system. Moreover, the discharge of water from the bathhouse can be carried directly into the last chamber of the septic tank, since there will be no large particles of dirt in the wastewater.

If you do not intend to use the services of a vacuum cleaner, do not make the first chamber too bulky so that it can be easily cleaned manually. In addition, provide either the possibility of easy dismantling of the camera or access to its contents for quick cleaning.

If, in accordance with the clayey type of soil, only the installation of a storage tank is possible on the site, then the design should be carried out taking into account the unobstructed passage of sewage disposal equipment.

The depth of the trench must be calculated so that the slope of the pipes is 2-3 cm per 1 meter so that the wastewater spontaneously moves to the place of processing and disposal.

Preparing building materials for work

The main materials needed to make a septic tank from barrels with your own hands include:

- pipes for the main with a diameter of 110 mm;

- fitting, corners, etc., in quantities appropriate to your project.

- the barrels themselves, intended for septic tank chambers.Select their sizes based on the approximate water consumption in the house, based on direct observations.

It is advisable to use barrels with thick enough walls so that the joining of pipes to them is as rigid as possible - otherwise the seam may lose its tightness due to mechanical stress.

Work out in advance the issue related to the freezing of cameras at subzero temperatures. You can use the old village method - place wooden sticks in containers.

At the very least, the ice expanding during freezing will compress the tree, which “took” part of the impact. Plastic bottles filled with sand will also help.

But in any case, the thermal insulation of barrels will not be unnecessary - take care of purchasing available materials in the required quantities.

Supporting materials will also be required. You need to buy a sealant to seal the seams. For this purpose, do not use silicone, it will not last long, and it will not be possible to cover it with any protective layer - no coating will stick to silicone.

The best option would be to use bodywork automotive sealant - it has good adhesion (ability to stick), mechanical strength, and can be coated with paint, mastic, etc. Polyurethane sealant has the best characteristics, but it is quite expensive;

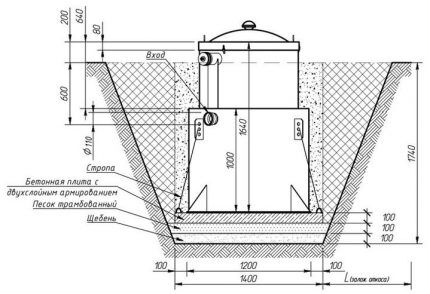

It is necessary to purchase cement, sand, and reinforcement for pouring the bases for the barrels. Sand should not have any special requirements in terms of quality.Let it be with pebbles, no big deal, the main thing is that it does not include lumps of loam and organic pollution.

Any steel rods are suitable as reinforcement. There is no need to cook the reinforcing mesh - just fasten the rods with wire.

You will need crushed stone, gravel, granulated slag or similar materials to fill the bottom of the pit (pit) before filling with cement;

A plastic barrel is lightweight, and therefore, when the container is not filled, it can be “pushed” to the surface by groundwater. To avoid this, have metal hooks, threaded rods, something you can grab onto.anchor» barrel.

It is appropriate to use commercially available threaded rods - it is convenient to make hooks from them, on the straight ends of which iron plates can be secured with two nuts, which need to be “sunk” in cement.

Construction of a pit with a concrete slab

How you decide to make the main pit - manually or using an excavator - decide for yourself. Calculate its area so that after installing the barrel in place it is convenient to compact the earth, poured into the gap between it and the wall of the pit. You can also provide thermal insulation for the container - slagish, polystyrene foam - in general, whatever will be more accessible.

Before pouring a concrete slab at the bottom of the pit, you need to check whether its depth is sufficient. To do this, you can install one of the barrels in the hole and see if it is deep enough to install a concrete base. If everything is in order, you can start filling the bottom of the hole with cement.There is absolutely no need to do this formwork, but it is advisable to fill it with sand and compact the bottom before doing this.

If there are doubts about the strength of the walls of the pit, then before pouring they must be strengthened with a board. Then it is enough to fill the bottom with a thin layer of liquid cement. After it has dried, you can lay the reinforcement and fill it “cleanly” - leveling the horizon. Don't forget about the embedded parts for anchoring the barrels!

Mix cement with sand - 3 parts sand to 1 part cement. It is very convenient to use an electric concrete mixer, but purchasing it only for this job (if there are no plans to build something else) does not seem advisable. It is enough to choose a suitable trough that is convenient for shoveling.

Mix sand and cement first without water - on the contrary, avoiding its premature entry, and then gradually adding liquid, bring the solution to the required consistency. To prepare small portions of cement, you can also work on a sheet of iron or plywood - if there is no trough. Before directly filling the foundation, moisten the backfill with water to compact it.

To level the fill, use a tool similar to a mop with a flat bottom. Pressing the sole to the surface, level the solution with light translational movements. This way, by the way, you will achieve better filling of the future site with mortar.

To prevent the mortar from cracking when drying, especially in hot weather, cover the poured area with a thick cloth after the cement has “set” and water it with water.For this purpose, a tarpaulin or similar synthetic fabric is better suited - the important thing here is not wetting the surface of the site, but slowing down the evaporation process.

Start installing the pipes when the barrels are installed, but not completely secured. Only when the entire structure is assembled can its elements be fixed. It is advisable to fill the barrels with water for stability.

All these points are important to take into account due to the fact that the final stage of assembly will be the treatment of the joints of pipes and barrels with sealant - while it dries, it is necessary to ensure the immobility of the structure.

Before applying the sealant, treat the areas of its contact with the plastic with coarse sandpaper (No. 80 -100) – for better adhesion and durability of the seam. By the way, you can also install triangular gussets on the same sealant for rigidity, 3-4 pieces per joint, between the barrel wall and the pipe. While the sealant is drying, wrap the gussets with wire, masking tape, etc. – so that they don’t “slip.”

After testing the system for water permeability, proceed to the final filling of trenches and holes. Compact the soil gradually, filling the soil in layers. You can throw stones, bricks, etc. into the gap for rigidity.

In those places where filled pipes and holes may be hit by equipment, make a protective flooring of at least boards before filling the surface layer of soil.

Assembly and connection of the structure

So, all materials are ready. The next step is cutting holes in the barrels for the pipes. There is no point in describing this procedure.The only thing I can advise is that you don’t immediately make the holes to size - let the pipes be inserted with force, and if necessary, trim the excess.

Next, you should take care of fixing the pipes in advance, otherwise when filling and compacting trenches and holes, the integrity of the seams can be compromised. Pipes can be fixed using all available means - wire, scraps of boards, bricks, whatever.

Before digging trenches and pits, it would be useful to assemble the entire structure, without fixing the parts, and place everything on the ground. The pipes can simply be placed on the ground next to the barrels. This will help you make more accurate markings on the ground. Having marked the contours of the highway and pits with poles and twine, you can begin digging.

Visual step-by-step guide

The process of constructing a septic tank with overflow from used barrels will be presented by a visual step-by-step instruction:

In the first part of the installation work, the components of the septic system were prepared and the receiving tank was installed in the pit.

Next, we construct a chamber that performs the functions of an absorption well:

The installation stages of the receiving and absorption chambers have been completed. Now we are starting to build a soil tertiary treatment system, for which we have already installed a beacon in the form of the first peg and made a device that determines the slope.

The installation of the septic system with a filtration field is completed, all that remains is to fill the pit with soil and put the structure into operation:

Conclusions and useful video on the topic

Video #1. The use of plastic barrels in the manufacture of septic tanks:

Video #2. The final stages of the device:

Video #3. The general principle of organizing an autonomous sewage system:

When your homemade septic tank made from plastic barrels is ready for use, work out the rules for its use for family members.Be sure to insist that non-degradable items - rags, cigarette butts, small items made of synthetic materials - are not thrown into sinks.

If you clean the chambers yourself, you can prepare a waste pit in advance. Practice shows that organic sludge extracted from a septic tank, mixed with soil and mowed grass, turns into a good fertilizer for the soil after three years.

Please write comments in the block below. Share your own experience and information useful to site visitors. Ask questions about controversial or unclear points.

I’m thinking about installing a septic tank for a toilet in my dacha, but I didn’t realize that it would require a concrete foundation. What does it do and why can’t the structure itself be installed directly on the ground? To drain water from the kitchen, I already have a septic tank, which I made myself from concrete rings. So its bottom is not covered by anything at all. The water leaves from there on its own, you don’t even need to clean it. And here: the containers are sealed in themselves, so why a foundation?

In this case, the foundation is needed so that the septic tank from the container you will use does not fall lower or sink into the ground. If you do not use a concrete foundation, then subsidence of the soil threatens to break the communications connected to the tank.

My neighbor at the dacha made such a septic tank with his own hands and talked about two buried plastic barrels. But he said nothing about the construction of the foundation slab at the base of the pit. I think that he didn’t do it, he just poured an ordinary sand and crushed stone cushion.His barrels are buried to a depth below freezing. When used year-round, the sewage system will not freeze. Insulation is probably an important point only when operating the system in winter.

The foundation in such structures is needed so that they do not “float” if the soil is flooded. Large containers can crack the asphalt if they are not anchored.

I was very interested in the topic of a septic tank made of plastic barrels. It is not yet possible to buy a ready-made septic tank or make a permanent one from concrete rings, and a homemade one made from tires does not inspire confidence in me. There is a well on the property; you don’t want sewage from the septic tank to get into the aquifer. Another question is whether such barrels can withstand soil pressure? How can you strengthen them to avoid this?

To strengthen plastic barrels, you can use metal frames, for example. This solution will allow you to remove part of the load from a homemade septic tank; you can also use wooden frames instead of metal. Some people line barrels with bricks, but this is cost-effective if you don’t buy the brick and get it for free.