Deepening a well with your own hands: a review of the best methods to “get to the bottom” of the aquifer

Wells have been used by mankind since ancient times. The technology of their construction has been perfected over centuries and remains almost unchanged.The problems faced by the owners of such structures remain unchanged. One of the most common is reducing the amount of water.

Often the only solution is to deepen the wells to the next aquifer. We will tell you how and in what way the water intake excavation is deepened. You will find out what you will need to stock up on to carry out the work.

The content of the article:

Construction and design of the well

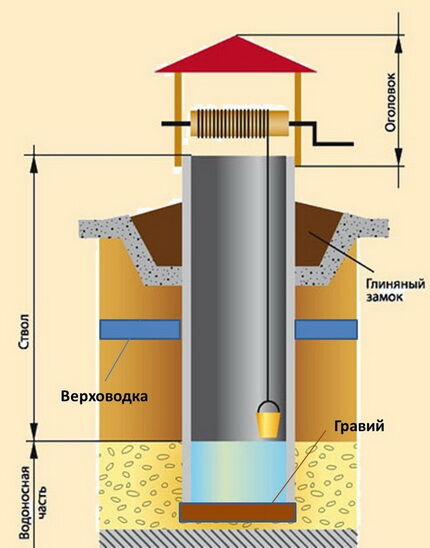

The design of the well has not changed for hundreds of years. The structure is a mine, the bottom of which is located in an aquifer.

The walls of the trunk are strengthened from crumbling. For these purposes, stone, wood or a modern version can be used - reinforced concrete rings. At the bottom it is usually settled filter, which is a backfill of gravel 10-15 cm high. There are more complex multi-layer filters consisting of crushed stone, gravel and sand.

The mine is closed by the so-called well house, which houses a mechanism for raising water.The structure can be equipped with a pump, which greatly facilitates the supply of water.

The main “competitor” of a well is considered to be a well. Each source has its own strengths and weaknesses. In order to choose the best option for you personally, we suggest that you familiarize yourself with comparative review.

However, despite the advantages of a well, many people prefer a traditional water source. With proper operation, the well will last longer than it, while maintaining cleanliness in the mine is much easier than in a tubular borehole.

A structure with a manual water lifting mechanism does not require electricity and can be operated in any conditions, while a well pump is always energy dependent. In addition, the well can be dug and equipped manually, without the use of special equipment and mechanisms. However, problem-free operation of wells is rarely possible.

Reasons for water leaving the well

The water level in the well may not be constant. It depends on a combination of many factors beyond the control of the owner of the structure.

The hydrogeological conditions of the area come first. Prolonged drought in summer and severe frosts in winter can lead to complete drying out of the well. This is a completely normal phenomenon and does not require any human intervention.

Practice shows that after some time the water will return.Most often, those who dug their wells at the beginning of summer suffer from the consequences of this phenomenon.

At this time there is a peak in the rise of high water, which causes the work to be mistakenly stopped before reaching the real aquifer. Therefore, experts strongly recommend engaging in digging a new well during the dry period or late autumn, and even better - in March, before the snow begins to melt.

It often happens that a limited-size aquifer gradually runs out. Moreover, if it does not have regular replenishment, and the operation was quite active. In this case, the question arises, which is better: to deepen the old well or build a new source. In most cases, deepening is more rational as it is the least expensive measure.

The same is done in the event of a sharp drop in the groundwater level in a given area. This occurs when the aquifer or lens cannot be recharged by infiltration of precipitation. In addition, the bottom of the well can become silted, making it impassable for water and forcing it to find other ways to escape.

It also happens that the precipitation level is normal, but there is still no water in the well. In this case, the reason may be the appearance in the immediate vicinity of a new well or borehole with impressive water abundance, which can temporarily “take away” water.

In this case, you need to wait four to five weeks; if the water level has not recovered, you will have to deepen the well shaft.

And another reason for the disappearance of water can be the wear and tear of the materials in the water intake part of the well shaft. In this case, water will flow poorly due to capillary channels clogged with destroyed material.

In addition, they sometimes become very clogged with dense silt and sandy sediment, which is difficult to distinguish under the water column and to remove. To free the water intake part from contaminants, you will need well cleaning, repair and complete sealing.

To deepen or not to deepen?

Drilling a dry well with your own hands is a very difficult and costly task, both in time and money. That is why it is extremely important to determine the feasibility of a future event.

First of all, you need to answer a few questions:

- A decrease in the amount of water in the well cannot be associated with the weather: prolonged frosts or prolonged drought.

- The water remaining in the well retained its quality. It has no foreign odors, is tasty and clean. If this is not the case, the bottom filter may become silted. The problem can be solved by proper cleaning.

- The water level in nearby wells has not changed.

If the answer to all questions is positive, it is quite possible that the problem is in your well, and it needs to be deepened. But there is still no need to rush to start work.

To begin with, it makes sense to carry out the following activities:

- conduct geological exploration by interviewing neighbors - owners of wells or wells;

- accurately determine the daily water flow;

- find out from the meteorological service or from the owners of exploited water sources at what depth their aquifer is opened;

- determine the ability of the soil to “hold” the walls of the mine without settlement.

Such labor-intensive preparatory work is due to the fact that all types of soil have their own characteristics and are characterized by certain nuances during work. Violation of technology and incompetence of the employee can lead to the blocking of the aquifer, or even destruction of the trunk when it gets into quicksand.

Quicksand is soil consisting of a water-saturated mixture of sand, organic matter and silt, which under certain conditions begins to move, which is dangerous not only for the well, but also for nearby buildings.

Mistakes in deepening a well shaft can be costly, both in terms of labor and money. The procedure can be carried out only once and if it fails, the only thing left to do is fill up the well.

At the same time, the cost of a new well dug nearby in some cases may turn out to be less than deepening the old one, and no one can guarantee success.

Experts recommend deepening the mine if several conditions exist:

- There is no quicksand at the bottom of the trunk.

- The well shaft is very deep, at least 10 rings. Otherwise, building a new structure will cost less.

- Good quality of water at the source.

- No deformation of concrete rings inside the trunk. If there are displacements, their value does not exceed 40 mm.

- The daily water flow is less than one ring.

The well will have to be deepened to the second aquifer. This is at least 5 meters, and there are no guarantees that the water in it is suitable for drinking.

Advantages and disadvantages of different methods

There may be several options according to which you can deepen a dry well at your dacha. Let's look at each of them and find out all the advantages and disadvantages of each.

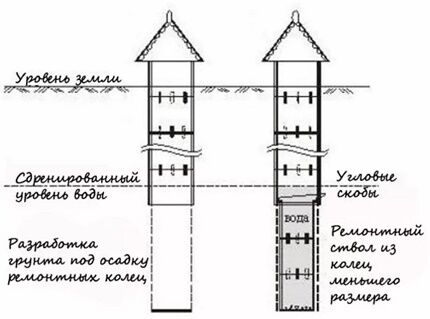

Deepening with rings of smaller diameter

The method involves building up the shaft from below with repair rings of smaller diameter. The main advantage of this method is the speed and minimal costs of its arrangement.

What are the pitfalls? First of all, you need to understand that the most common diameter of concrete rings for constructing a well is 1 m. Thus, for repairs you can choose parts with a diameter of 0.8 or even 0.6 m.

It is quite difficult to buy such factory-made rings; the quality of products produced by private owners can be very different.

Another complication is that you will have to cut the staples off the main rings before lowering the repair ring. Thus, the well will be left without a ladder, which is completely inconvenient. In addition, repair rings are extremely rarely equipped with brackets.

Thus, a well many meters deep is left without a ladder, which in itself is a problem. Another nuance: the narrower the structure, the more difficult it is to work in it.

A ring with a diameter of 0.8 m is very inconvenient for work; a ring with a diameter of 0.6 m is practically unusable. This applies to concrete rings, but there is also the option of deepening using plastic elements. You need to understand that the rigidity of the plastic in this case will clearly not be enough.

Drilling a well at the bottom of a structure

This method involves well drilling followed by lowering the casing into it and installing the pump. Thus, the well essentially turns into a borehole. This is a fairly economical and simple method.The disadvantages include the need for regular cleaning of a newly drilled structure, which cannot be done without specialists.

In addition, a well located in a not very abundant formation will produce a small volume of water at a time. The problem can be solved by installing a special storage tank, but this will require additional effort and expense. Another “minus” is that during a power outage the well becomes inoperable.

Deepening the well with dismantling old rings

To implement this plan, you will need to remove all the old rings and expand the resulting pit. Then the structure is deepened and the rings are mounted again.

Experts consider this method the most inappropriate and even dangerous. First of all, it is unlikely that it will be possible to dismantle the rings entirely. Most of the elements below the third ring are likely to be damaged. Thus, you will have to buy new parts.

In addition, working in a well with unreinforced walls is dangerous; if the depth of the structure exceeds 4-5 m, it is deadly.

Despite the claims of “craftsmen” that wet soil supposedly does not crumble, it can collapse at any moment without any obvious warning signs. It will be extremely difficult to save a person who finds himself at the bottom of a well at that moment, and in some cases it is simply impossible.

Settling the rings using a weight

After digging the shaft from below, the rings are settled with a load. This method can only be effective for a new well that was dug no more than a couple of months ago. Otherwise, the soil has become compacted so that uniform subsidence of the shaft is impossible.

Most likely, the barrel will rupture, which will be almost impossible to fix. In addition, simple calculations show that the force that needs to be applied to the top of the column must be very large.

It is unlikely that a well lid loaded with stones will provide it. Even heavy equipment, for example, “Kirovets” with attachments, may be powerless. Although, as practice shows, it is capable of pushing through about 5 concrete rings with properly carried out preparatory work.

One more nuance: the technique can crush the top ring, so you need to do everything very carefully.

Building up well walls from below

The method involves extracting earth from under an old mine and strengthening the resulting walls with brickwork or concrete. This method is used by owners of wells whose rings “sit” firmly in the ground and are impossible to settle.

The method is quite viable, but labor-intensive. If you plan to install brickwork, you should choose the material especially carefully.

The so-called “underburning”, of which there is quite a lot, will crumble very quickly in a humid environment, which is unacceptable. If you plan to use concrete to strengthen the walls, you need to take care of its quality. It is absolutely impossible to save on cement. The reinforcement must also be of high quality. The main difficulty with concreting will be the inconvenience of carrying out such work.

In addition, the work will take a very long time, since deepening the well in this way by more than 30-40 cm at a time is dangerous. This is due to the fact that when digging a mine there is always the possibility of sudden subsidence of the column.

If by this moment a layer of concrete or brick has already been built up, but it is still fresh and the cement has not had time to gain the required strength, the ring will easily break it. Thus, work needs to be carried out only in several stages, 30-40 cm each, with mandatory breaks for cement hardening.

Deepening the structure with repair rings

This is the most commonly used method of deepening wells. Craftsmen warn against the mine method of conducting work, when the assembled repair column is lowered by digging up the soil from below. In this case, it can easily get stuck and it will be very difficult to bring it down.

It is optimal to lower the elements step by step and make all connections directly inside the well.

For work we will need: a shovel with a short handle and a regular bayonet, a ladder, lighting equipment, a device for lifting the excavated soil to the surface, a winch, a jackhammer, a hand or electric drill, a level and a pump for pumping out water.

From materials it is necessary to purchase repair rings of smaller diameter than those in the well, sealant for processing seams, staples and fittings for temporary fixation of parts. Let's look at the process step by step.

Carrying out preparatory work

We start by inspecting the new rings and walls of the well. We check whether there are any serious irregularities that could interfere with the lowering of the structure.

We lower the drainage pump into the structure and completely pump out the water. We remove silt and sediment from the exposed bottom and lift them to the surface. If there was a bottom filter in the well, remove all the backfill. Remove all water-saturated soil.

Once again we inspect the walls of the well. If they are very dirty, we clean them. We scrape off moss and deposits from the walls of concrete rings. If the inspection reveals cracks and chips, we will well wall repair and seams between the rings.

Now you can start strengthening them. To do this, we connect the joints of the rings with special staples, at least 4 at each seam, which guarantees the immobility of the elements. Thus, we minimize the risk of deformation of the old column.

The deepening process itself

Let's start digging. We move from the center of the mine to its edges. We continue work until the walls of the pit begin to crumble under the pressure of water coming from outside.

After this, we lower the repair rings to the bottom, building a new column. If the soil is prone to crumbling, work should be performed differently. In this case, we dig the shaft to a shallow depth, lower the first repair ring and temporarily secure it with reinforcement.

After this, we continue to work, removing the soil from inside the structure and digging into it. Gradually the ring will settle, and the next one can be placed on it.

We fasten the rings together with staples or corners. Once the aquifer is reached, we fill the seams with concrete mortar and seal them. We fasten the old and new columns together using brackets. We fill the gap between the new and old ring with crushed stone.

Finishing work in the well

Once the repair rings are in place, the final stage of work begins. It consists of inspecting the entire shaft and identifying possible defects in the seams.

We carefully close and seal them. Let's start installing the bottom filter. This may be new or even old backfill, but in the latter case it must be thoroughly washed. After that disinfect the walls of the well shaft.

Deepening a well by digging

This method differs from the one described above in that the well is built up with repair rings from above. Moreover, their diameter does not differ from those that are already installed.

In essence, this is a continuation of work begun many years ago with the original digging a well. The main danger in using this method is the possibility of the old column getting stuck in the ground, especially if the well is located on clay rocks.

Carrying out preparatory work

We start by securing the rings. We fix at least 4 staples at each joint. We drill holes for them, install metal plates 0.4x4x30 cm and secure them with 12 mm anchor bolts.

In this way, the casing will be able to withstand possible soil movements. We pump out the water from the well and completely remove the bottom filter, if it was present in the structure.

Carrying out deepening work

A worker lowers himself down on a safety net and begins to dig. First, he selects soil from the middle of the bottom of the structure, then from the periphery. After which he begins to dig under two opposite points from the edges of the lower ring with a depth of 20-25 cm.

No longer necessary, otherwise there is a danger of uncontrolled descent of the element. The tunnel then gradually expands to a circular area.

During operation, the column must settle under its own weight. New rings are placed in the space vacated on top. Digging is carried out until the water begins to flow very quickly.

It should be noted that subsidence of the column does not always occur, especially if the well is “older” than 1-2 years. In difficult cases, you can use the side digging method as a way to lower the stuck ring.

Let's look at it using the example of the lower ring. We carry out the digging as already described. Then we take three stumps or strong stands made of timber and place them under the ring so that there is a distance of about 5 cm between them and the bottom edge.

These supports will subsequently take on the full weight of the settled structure.Then, in two opposite areas, remove the sealing solution from the inter-ring gap.

We insert nail pullers into the resulting gaps, and two people, simultaneously acting as a lever, can try to lower the ring. If all else fails, take a special shovel to dig up the side walls.

For its handle, reinforcement 10 cm long and 14 mm in diameter is used. The cutting part measuring 60x100 mm is made of 2 mm sheet iron. We insert the spatula 2-3 cm from the outer wall of the ring and begin hollowing out the clay.

To do this, hit the handle with a sledgehammer from bottom to top. In this way we go through the entire ring except for the areas under which there are supports. We managed to remove the clay to a height of 10-15 cm from the lower edge of the ring.

Now you can try the lowering attempt again with nail pullers or any other levers. If it doesn’t work, take the next shovel. The length of its handle should be 10 cm longer. We perform similar actions.

A small note: when the length of the shovel handle reaches 40 cm or more, it will need to be slightly bent. It will be more convenient to work this way. With proper lateral digging, the outer wall of the ring is gradually released, and it settles down. Similar work is carried out on other rings.

Final work in the well

Upon completion of the deepening work, all contaminated water is removed from the structure. All seams between the rings are securely sealed and sealed. If damage to old seams is noticed, they are also repaired.

We place a new bottom filter of the desired design at the bottom of the structure.Then we disinfect the walls of the shaft with a solution of chlorine or manganese. The well is ready for use.

Do not forget that the normal operation of the water intake mine workings and the preservation of its water abundance is directly related to competent arrangement, the rules for the implementation of which will be introduced in our proposed article.

Conclusions and useful video on the topic

Video #1. The process of deepening a well with repair rings:

Video #2. How to operate, maintain and deepen the water source:

Video #3. Is it always possible to deepen a well:

You can deepen a dry well in various ways. You need to choose one correctly, because such work can only be carried out once. A mistake will lead to wasted money, since deepening the structure is a very expensive undertaking. In terms of financial and labor costs, it is quite comparable to digging a new well.

Please write comments in the block below. Share your impressions and useful information on the topic of the article, ask questions. Tell us and site visitors about your own experience in deepening the water intake, and post photos.

Sometimes the water just drains away. In our village back in the 80s, a stream flowed through the middle of the village and there was water in all the wells. And now all that remains of the stream is a hollow overgrown with weeds and dry wells. Here you can dig 100 m to the rocks. Therefore, if the well is dry, it is not a fact that you will get to the water. And this trend is observed throughout the Central Federal District.

Likewise. Leningrad region. By the end of summer it began to dry out.There are no wells, the water level in the wells varies from one and a half meters in the spring to 10 in August. And for some, the water disappears even at 20 meters. Although this year there was snow and rain and the water stood at 2 meters. People's caissons were flooded from wells - wells without tops.

I already deepened the well a year and a half ago, but the flow rate dropped again. Is it worth bothering with it and deepening it further or will you have to dig a new well/well?

In this case, I can recommend going down into the well, of course, with all the insurance and necessary equipment. Carry out hand drilling a few meters to find out how much the water level has dropped. I think that getting a hand drill or making one yourself won’t be too difficult. There are materials on the Internet, as well as here on the resource, on this issue.

If the water level has dropped by 1-2 meters, then it makes sense to deepen the well again, but if more, then the idea is dubious. For example, 3+ meters to a new water level, plus the expectation that the water level will drop again in the future, it turns out that deepening the well is not advisable.

In this case, digging a new well is not profitable, so there is only one option left - drilling a well for water. Even if the water level in the well drops in the future, it will be easier to drill it deeper (immediately with a reserve) than to deepen the well every 2-3 years.