Construction of a drain pit: popular design schemes + analysis of the rules for determining depth

The construction of a local treatment plant makes it possible to ensure high-quality processing and filtration of sewage waste to the state of industrial water. However, this option for organizing autonomous drainage is not cheap.

An alternative solution for country or country houses is to build a drainage pit with your own hands. There are several options for homemade cesspools, differing in materials of manufacture and functionality. Which one is preferable? Let's try to figure it out.

The article describes popular drainage pit designs and also provides step-by-step instructions for their construction. Practical recommendations will help you make the right choice and organize sewage disposal yourself.

The content of the article:

Drain pit is part of an autonomous sewer system

To collect household and household waste, a storage tank is required, which must be emptied regularly using special equipment. This is usually a large container or structure buried in the ground.

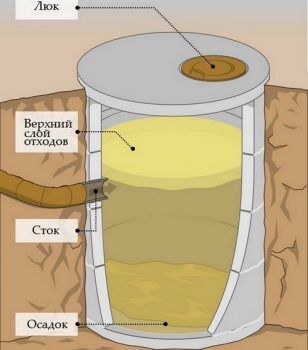

The sizes and shapes of cesspools may vary, but some components must be present in all designs:

- storage tank, the volume of which meets the needs of the home owners;

- drain inlet, through which sewage flows into the reservoir;

- technical hatch, necessary for control and maintenance;

- ventilation pipe, removing harmful gases to a safe height.

Ventilation is often neglected, leaving a hole or gap for air to penetrate inside, or even completely sealing the hole. This is wrong: the unpleasant smell of gases at a certain concentration is also dangerous.

Anyone who feels discomfort from walking in the morning chill has long ago installed a full-fledged sewer network. It includes connections to the toilet, sinks, bathtub or shower, and a pipeline connecting points inside the house to a buried reservoir nearby.

The minimum “dacha” set that allows you to regularly wash and keep your house clean is a toilet + shower + sink in the kitchen. Accordingly, the sewer system inside the building connects the plumbing fixtures.

The outer part of the system is a pipe from the wall of the house to the storage tank. A straight and relatively short pipe (but according to SNiP standards no shorter than 5 m) is an ideal scheme for moving wastewater.

Sometimes it is necessary to install complex communications connecting several hoses, for example, to drain wastewater from a house, bathhouse, garage or summer kitchen.But in this case, instead of a regular drainage pit, a septic tank is installed, which, in addition to collecting and storing it, also purifies the water, and then discharges it into the ground (well, ditch) for further treatment.

Types of cesspools based on material of manufacture

To construct drainage pits, both factory-made blanks and improvised material are used, for example, car tires or red brick left over from building a house.

Let's look at the design features of different models and find out which storage tank will last longer.

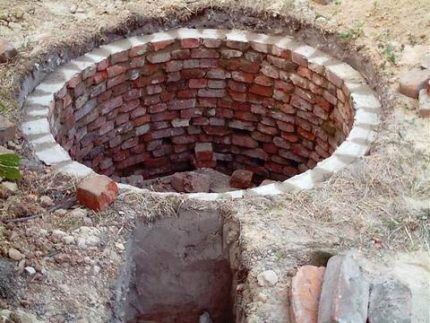

Brickwork with waterproofing

With the advent of ready-made concrete rings, the installation process of which reduced the construction of the pit several times, brick began to be used less and less. It makes sense to use it in extreme cases, when it is not possible to purchase another, more modern material.

Sometimes it remains in large quantities after building a house, and if time permits, you can build a brick cesspool.

Brickwork is done in the traditional way, but the bottom is prepared first. A concrete slab is laid on a sand and gravel bed, which is fixed in the ground using reinforcement.

The finished slab can be replaced by pouring cement mortar. Concrete slabs can also be useful in the construction of the upper part - the floor to which the technical hatch is attached.

Thus, brick pit installation includes the following elements:

- concrete bottom;

- brickwork around the perimeter;

- floor slabs;

- hatch with cover;

- plastic ventilation pipe.

When arranging a tank consisting of relatively small elements, it is important to properly seal it so that wastewater does not enter the adjacent soil. It consists of two stages - waterproofing the inside and outside.

Coating mastics based on bitumen, as well as modern penetrating materials such as Penetron, have proven themselves well.

Well made from car tires

The most unreliable solution, the service life of which does not exceed 10 years, is raking out tires.Automotive rubber is not intended for use as sewage parts, so over time it does not withstand the effects of aggressive chemicals and breaks down.

In addition, difficulties arise with sealing the joints between the tires to ensure sealing of the well.

The bottom of the pit is equipped in the traditional way for all storage tanks: a concrete slab is laid or a cement screed is made. In the upper part, a deck is usually built from durable boards and a hole with a cover is left for maintenance - pumping out sewage.

A tire storage facility cannot be large in volume, so be prepared to frequently call the vacuum cleaners.

It should be understood that after some period (in some cases - from 3 to 5 years) it will be necessary to dismantle the rubber structure and build a new well, because tire drain pit cannot be repaired.

For this reason, experienced builders recommend installing more durable structures designed to last 50 years - for example, storage tanks made from concrete blanks.

Monolithic concrete tank

The construction of a volumetric container made of concrete is fundamentally different from the construction of structures from individual ready-made elements (bricks, blocks, tires). It does not involve assembly, but the creation of formwork followed by concrete pouring.

The result of construction work should be a durable, reliable, sealed concrete tank with a service life of at least 50 years.

The procedure for constructing a drainage pit made of monolithic concrete:

- preparation of the pit, leveling the bottom;

- reinforcement and concreting of the base;

- construction of formwork;

- installation of reinforcement for walls;

- gradual pouring of concrete;

- installation of floor slab;

- waterproofing of the structure;

- ventilation and hatch device;

- backfill

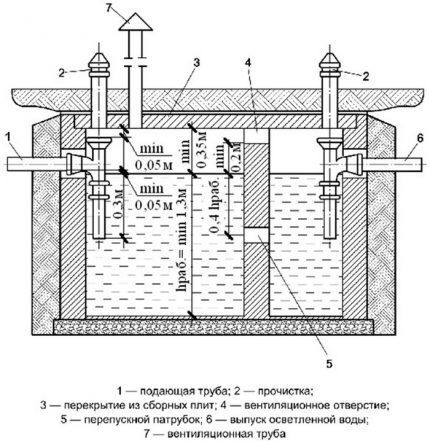

Often, when building a simple septic tank, a more complex design of two chambers is used.Simply put, a concrete partition with an overflow hole is installed approximately in the center of the structure.

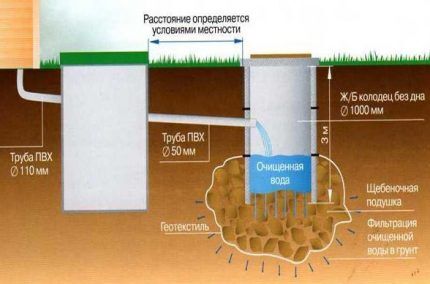

The two-chamber structure partially clarifies the wastewater, and the use of an additional filter well allows part of the sewage water to be sent directly into the ground.

Feature pits made of monolithic concrete is a long construction period and compliance with standards for the preparation of cement mortar.

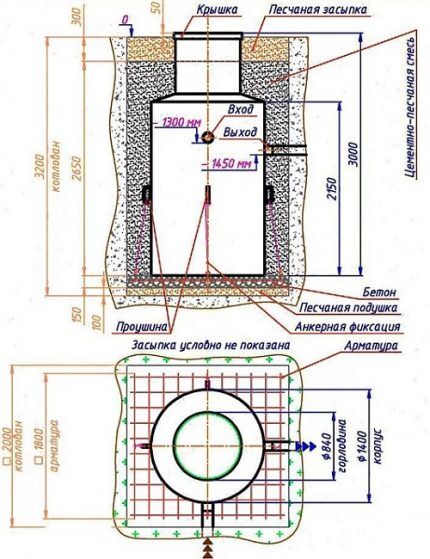

Sump from concrete rings

Construction from prefabricated concrete blocks is preferred for several reasons:

- construction speed — construction takes less time;

- relative accessibility — the cost is considered affordable;

- durability — if the construction rules are followed, the structure will serve for more than 40 years;

- strength - a well made of heavy rings fastened with a locking joint is much stronger than a structure made of tires or bricks.

Concrete rings, as well as other parts for construction (bottom, floor slabs, extensions), can be purchased at the nearest enterprise that produces reinforced concrete products. Alternative option - make reinforced concrete rings on one's own.

You will have to rent equipment and hire a team of workers, but installation will take place quickly, unlike creating a monolithic tank.

In addition to concrete blanks, you will need backfill for the base (sand and gravel), waterproofing for sealing joints and external sealing of the finished structure. To give the structure strength and stability, dry cement is added to the backfill soil.

Despite the presence of cesspool designs without a bottom, it is recommended to make single-chamber tanks sealed, since insufficiently purified water pollutes the soil and fertile soil layer.

Factory made plastic container

If you want to install a drainage pit in one day, pay attention to ready-made models made of modified plastic, presented on the autonomous sewage market by well-known companies.

They differ in shape and size, but all have sufficient strength not to collapse under soil pressure or the movement of groundwater.

Installation of a plastic container is carried out according to a simple scheme: dig a pit, strengthen the bottom (in case of unreliable soils or high groundwater), install the reservoir, connect it to the pipe and backfill it.

The process of pumping out sewage waste occurs in the usual way - using sewer trucks.

Read more about choosing and installing a plastic tank in this article.

Review of popular schemes

Despite the material of manufacture, sewerage structures can have different designs. The difference concerns, to a greater extent, the number of cameras - from one to three. Let's consider the schemes that are most suitable for providing private houses with autonomous sewerage.

Separate storage tank

Scavenging from one sealed chamber is the simplest option. It does not pollute the environment, therefore, it is safe and environmentally friendly. Such a pit takes up minimal space, and since it is underground, it does not interfere with growing flowers or setting up beds nearby.

Restrictions apply to planting trees, which with their roots can depressurize the sewer structure.

A single-chamber storage tank is relevant for those who rarely use the sewer system, that is, rarely visit their dacha. There is another option - if a single person lives in the house, and the sewer system consists of a minimum of active points of use (toilet, shower, sink).

When constructing a tank, it is necessary to remember that it is not filled to the very top, but to the level of the pipe inlet, therefore it is only used to 2/3 of the volume. A simple storage tank requires regular pumping, and for this you should prepare a convenient access road for sewer trucks and it is better to conclude a contract for constant maintenance.

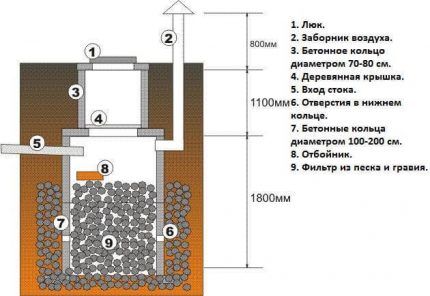

Drain pit without bottom

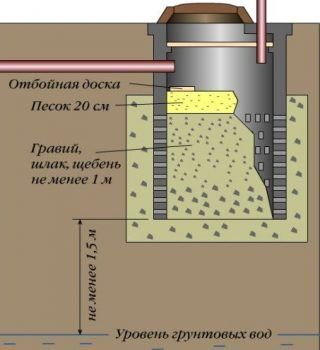

Single drive option – pit with filter bottom. The main purpose of the filter is to pass part of the wastewater directly into the ground in order to reduce the load on the structure and reduce the number of calls to specialists for pumping out waste.

The design of the bottom of the tank differs from the solid bottom of a sealed chamber. This could be a structure made of concrete blanks, a brick well or a plastic container.

In soils with low permeability, for example, in plastic sandy loams, it is advisable to arrange additional perforation of the walls. To do this, small holes are formed approximately 10 - 15 cm apart.

They are placed along the entire height of the soil filter in a checkerboard pattern.These methods increase the filtration area and, as a result, speed up the recycling process.

Two important conditions for a filtration device:

- sandy or sandy loam soil - loose, with a high degree of water permeability;

- low level of water horizons.

Dense clay soils, hard sandy loams, loams of any consistency simply will not absorb water, so the perforation device is useless.

This scheme is more suitable for construction of filter wells, which are the second or third compartment and are installed after the drive. The quality of post-treatment of partially clarified water in the ground is much higher than that of unsettled sewage from the first storage cesspool.

Pumping out waste from a pit without a bottom is carried out a little less frequently than from a regular pit. If the filter becomes clogged, the pumping mode is the same.

Two-chamber septic tank made of concrete rings

A more complicated version of the drainage pit is a double tank.

It can have different designs:

- concrete container divided into 2 parts by a partition;

- 2 wells connected by an overflow pipe.

Despite some differences in design, the goals of constructing two-chamber models are the same - to separate waste according to the degree of contamination. In the first section, which is a full-fledged storage facility, waste processing by anaerobes begins, resulting in the formation of solid sediment and turbid liquid.

In the second, the wastewater is even more clarified, and there is much less sediment.

If the second container is equipped with a compressor, then the cleaning will be more effective, since the processing will also be carried out by aerobic microorganisms. Two-chamber models, in fact, are no longer just storage tanks, but septic tanks capable of partially purifying sewage.

Brief process construction of a two-chamber septic tank of concrete rings is represented by the following photo selection:

How to determine the depth of the cesspool?

The dimensions of the drainage pit, including its depth, depend on the volume of wastewater. First, we calculate the total number of drains per day, multiply by 10-14 days (depending on the frequency of pumping), and find the required working volume. Working - that means only up to the pipe insertion level.

If you need a working volume of 4 m³, then add another 1/3 and get a tank volume of 6 m³. Knowing the volume, we calculate how many concrete rings are needed or what is the length/width/height of the monolithic structure.

When constructing a pit, we add 0.3 m to level the base and install a sand and gravel cushion. We calculate the depth of the drainage pit so that during installation, part of the neck (approximately 0.2 m) is visible above the ground surface.

A small ledge is insurance against spring floods. If there is a risk of seasonal flooding, the neck can be raised by 0.5 m.

Calculating the depth of a hole without a bottom is slightly different. The pit for the cesspool with perforation is deeper than the sealed analogue due to the installation of a meter-long sand and crushed stone filter. In order not to make mistakes with the calculations, we simply add the thickness of the filter pad to the height of the structure.

When making calculations, do not forget about the location of the water horizons - from the base of the cesspool to the upper aquifer there should be at least 1 m.

Conclusions and useful video on the topic

The rules for the construction of storage tanks and septic tanks are very similar, so we recommend viewing the following interesting thematic material.

Construction of a brick pit with overflow in conditions of high groundwater:

Useful information on the construction of a two-chamber structure:

Detailed information about the construction of septic tanks:

Having become familiar with the design features and characteristics of cesspools, you can independently equip a sewer system in a suburban area. If difficulties arise in drawing up a diagram or calculating the depth, we recommend contacting experienced engineers.

Do you have practical skills in constructing a drainage pit on your garden plot? Share your accumulated knowledge, ask questions on the topic and participate in discussions. The comment form is located below.

In my village I have a cesspool made of 2 concrete rings. But the problem was that we laid the plastic pipe (drain) shallowly and did not insulate it. Since our winters are cold, it burst. I had to change it, an unpleasant procedure, of course. By the next winter, they installed insulation; three seasons passed until it froze. The neighbor has cast iron pipes, they are better, but, alas, we didn’t have them. The neighbor does not have such problems.

First of all, you need to decide on a place for the drainage hole. It should be away from the foundation and well or water well. And you also need to immediately decide how the sewage pumping machine will arrive.In addition, you need to know the volume of the planned pit, and it is also necessary to equip a technical hatch. And then it all depends on your financial capabilities: it could be a brick pit with a concrete floor, or it could be a well assembled from concrete rings.

I was interested in the design made from old car tires. The price, compared to others, is just a pittance. Yes, you can do it yourself. How are the joints between them usually sealed?

Hello. Detailed instructions for constructing such a structure can be found in this article on our website. It should be noted that if the groundwater level is high, such a design is not advisable. In addition, cleaning such a pit is difficult.

at what distance should the cesspool be from the neighbor's property?