How to build a cesspool from tires: step-by-step technology for self-construction

It is difficult for a city resident, accustomed to comfort, to be in a dacha without amenities even for several days.It is irrational to build an expensive sewer system in an area that is rarely visited. But you shouldn’t give up the idea of somehow improving your temporary housing.

A practical and inexpensive option is a tire cesspool; this solution will significantly improve the quality of country life. We will tell you how to make a simple and budget-friendly cesspool yourself. The article we presented describes in detail the construction steps and provides valuable recommendations.

The content of the article:

What is a cesspool?

A cesspool can be defined as follows: it is a reinforced well that is dug in the ground to transport waste into it through sewer pipes. To avoid having to call a sewage disposal truck, you often need to make preliminary calculations.

The volume of water consumed by one person per day is taken as a basis. It averages from 150 to 200 liters. Thus, 3 people permanently living in a house in the summer spend 9000 liters (9 mᶾ) maximum or 6.8 mᶾ minimum in 15 days. This will be the required capacity of the pit.

Pros and cons of building from tires

The following arguments can be given in favor of constructing a tire cesspool:

- material available;

- the cost in some cases is zero;

- work on the device is not difficult;

The operation of a homemade tire structure is convenient, but remains effective for no more than 15 years.

The opponents of this decision are also right in their own way:

- Sealing is not perfect.

- If it is possible to dismantle the structure when all its possibilities have been exhausted, it will be with great difficulty. You just have to fill the hole with soil.

Tire pits are most often made without a bottom. When waste comes from the house, the liquid seeps through the crushed stone filter bed into the underlying soil layers, and thick waste in the form of silt remains at the bottom.

It is highly undesirable to pour water mixed with chemicals into such pits. However, they are ideal for the disposal of gray waste generated during hygiene procedures, cooking, etc.

DIY construction of a cesspool

Having decided to build a cesspool of tires without resorting to the help of specialists, you need to decide what types of tires to choose for this. Any tires will do, you can take tires from heavy vehicles, cars, tractors.

When choosing the first option, you need to be prepared to deal with huge and heavy tires. But the cesspool will be voluminous and roomy.

If it is impossible to dig a deep hole due to the proximity of groundwater, then the required volume is obtained due to the width. This is where tires with large dimensions are needed.

Components of the preparatory stage

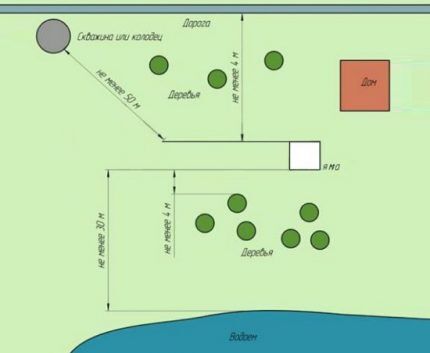

You should start by finding and preparing a place for an important point of the sewer system - a cesspool or drain hole. The main thing is to retreat at least a minimum of 5 m from the house, 2 m from the fence, and if there is a body of water, then the distance to it should be at least 25 m.

If groundwater is close, this distance is increased. If the terrain of the site is uneven, the structure is located at the lowest point of the site.

At the next stage, large diameter tires are prepared. In rural areas, tractor tires are easiest to find. On average, about 8 pieces are required per pit.

Subtleties of digging a pit

To facilitate the digging process, the top layer of soil is cleared of vegetation and debris. The parameters of the well must exceed the dimensions of the pit so that the walls can be sealed in the future.

It is also necessary to take into account the recommendation of experts regarding the depth - it should exceed the diameter by 2 times. Another 1 m or more is added to prevent the drains from freezing if you plan to use the pit in winter.

To dig such a hole, it is quite possible to do it with improvised means without the use of equipment. They take 2 types of shovels - bayonet with short and long handles and something in the form of a scoop, bent relative to the holder by 80⁰. The first is used to destroy the rock, and the second is used to remove the loosened soil.

Before starting excavation work, outline the contour. The easiest way to do this is with a tire laid on the ground - trace its outline with a sharp peg and add another 5-10 centimeters to it. Digging begins with a standard bayonet shovel with a long handle.

As you deepen, the long stalk becomes a hindrance, so they begin to use a shortened version.To ensure that the dimensions of the hole remain the same throughout the entire depth, a tire is periodically lowered into it for control. The bottom is designed with a slope relative to the hatch.

Installation of tires and organization of drainage

Having dug a hole, lay the tires on top of each other in a column, having previously cut off one of the rims. To protect the cesspool from melt water, the depth of the pit is calculated so that the upper tire rises half its height above the ground level.

If the selected tires are from heavy-duty vehicles, then using a knife or grinder to cut the cord will not work. This is due to the fact that there is a steel thread inside the tires. In this case, an electric jigsaw with a metal blade will help out.

You can even cut off the rim of tires where there is no such thread using a knife. You need to sharpen it well, moisten it with water and run the blade along a bar of laundry soap. Then the tool is driven into the layer of rubber, and moving around the circumference, cutting is performed relatively easily.

The gaps between tires are sealed. It is best to use bitumen-based sealants. Some people cover the cracks with a cement-sand mixture, but this is not worth doing, because... the design does not have sufficient rigidity and such a seal will quickly crumble.

To provide at least basic additional waterproofing, tires are wrapped in plastic film or roofing felt. Broken bricks and crushed stone are poured into the remaining gap between the walls of the well and the constructed structure and compacted well.A drainage well is drilled in the center of the finished cesspool using a drill, this will prevent stagnation of wastewater.

A pipe is inserted into the drilled shaft so that it protrudes 1 m relative to the base. Holes are made in it at different heights. The top of the pipe and the holes in it are covered with mesh material, which will protect it from clogging with large particles. The bottom of the pit is covered with a 10 cm layer of crushed stone.

Sewage pipes are located between the slopes - several if a shower and kitchen sink are connected to the sewer, or just one for the toilet. To prevent the spread of unpleasant odors, the pit is covered with a lid.

Making a floor slab for a pit

Upon completion of the construction of the homemade tire septic tank it is dug around the perimeter by 0.2 m to create additional support for the slab. Its manufacture is the most difficult and financially expensive stage of building a simple septic tank.

Boards are installed on the surface around the pit with emphasis on the end. The wooden floor can be replaced with a metal profile with high load-bearing capacity.

Formwork from boards is laid on the prepared structure. Holes are left in it for pipes and a hatch. Sometimes, instead of boards or profiles, corrugated sheets are used as formwork.

A mesh with a cell size of 1.5 to 2 cm is made from reinforcement with a diameter of 12 mm.The reinforcement at the intersection points is tied with wire or welding is used to connect the rod.

After completing this work, the surface is poured with concrete. To improve the filling of the mesh with the mixture and eliminate air bubbles from the pouring, the concrete is bayoneted during the pouring process.

When the entire area is covered, the mesh is slightly raised, ensuring that the reinforcement is completely embedded in the concrete. After this, pouring is continued until the required slab thickness is achieved. The product must stand to gain the necessary strength. This process takes up to 28 days. The slab can be made separately and then installed on the walls of the pit.

After the allotted time for the concrete to harden, the formwork supports are removed and construction of the hatch walls begins. They are laid out of brick, plastered from the outside, and a layer of bitumen is applied to prevent precipitation from entering the pit. Next, cover the slab with a layer of earth and level it.

Hatches are mostly purchased ready-made. You can purchase a concrete or cast iron product, but you need to take into account that they have considerable weight. Polymer-sand products have good characteristics.

Cesspool with overflow

From tires you can build not only a simple cesspool, but also something like a septic tank. The volume of cleaning will be small, but for a dacha with non-permanent residence this is quite enough.

The technology is similar to the standard one, but there are some differences:

- The bottom is covered with a thick layer (about 40 cm) of crushed stone, but a drainage pipe is not installed.

- The sidewalls of the tires are trimmed to increase the volume of the dump.

- A concrete pipe is placed in the center of the pit, oriented vertically. Its cross-section is ½ of the tire diameter, and its height is equal to the corresponding pit parameter minus 10 cm.

- In the upper part of the pipe, 1 large hole is made for overflowing the clarified liquid or a number of small ones. In the same area, a pipe with a diameter of 10 cm is connected, through which wastewater is drained from the house and the junction is sealed.

- The bottom of the pipe is concreted. The structure is covered with a lid with a hole for ventilation. According to standards, the height of the ventilation pipe should not be lower than 4 m.

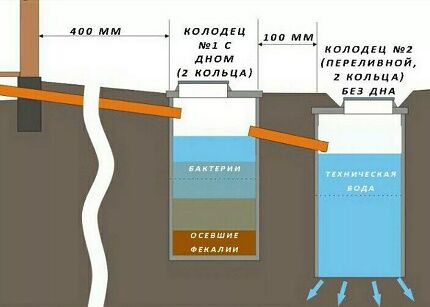

Can be done cesspool with overflow and in a different way. If the number of tires is sufficient, they dig not one hole, but two. They are connected by an overflow pipe. From the house, wastewater is fed into the first sedimentation shaft.

Here the sludge will settle to the bottom, and the partially purified liquid will flow through the pipe into the second compartment. Thus, it is possible to recycle a larger volume of wastewater, but such a design will be more expensive.

Device cesspool without bottom is impossible if groundwater is less than 2 m from the surface.

Between the level of water in the soil and the conventional bottom of the cesspool being constructed there must be a soil thickness of at least a meter. Only in this case will the wastewater disposed of in the underlying rock undergo sufficient purification to infiltrate into groundwater.

Rules and frequency of cleaning

The pit will have to be cleaned periodically, calling a sewage disposal truck each time. Can be used fecal pump or clean it manually, using a bucket with a rope tied to it, but such a procedure is both unpleasant and time-consuming, and the waste itself will have to be disposed of somehow. If neither the first nor the second methods work, you can use bioactivators.

Bacteria used to decompose organic matter are grown in a special broth. This biological material may be dry, but the bacteria in it are inactive.

In order for them to begin to multiply and perform their function, enzymes are used. Microorganisms retain high stability and vitality due to the presence of nutritious salts and enzymes in the concentrated preparation.

As soon as the composition enters the aquatic environment, bacteria are activated. The drug, reacting with organic masses, destroys their structure by decomposing molecules into gas and liquid and leaving sludge in the sediment. As a result of water absorption into the soil and gas evaporation, a significantly smaller amount of waste remains in the cesspool.

Bioactivators must be constantly fed. If a new portion of organic matter does not enter the cesspool within 2 weeks, they die. Microorganisms can perform their functions only at positive temperatures. Colonies of bacteria and washouts containing aggressive chemicals lead to the death of bacteria.

Biological agents pose no danger to humans or the environment. They simply activate natural decomposition processes, promoting an increase in the concentration of bacteria living in organic matter.

Modified microorganisms placed in tablets and gels, for example "Doctor Robik", are capable of processing not only organic matter present in wastewater, but also individual mineral compounds and paper. They have a long period of activity.

The system may malfunction, causing the pit to begin to emit an unpleasant odor and fill very quickly. If this cesspool is completely sealed, then an increase in water consumption explains the situation, but if the bottom of the pit is equipped with a filter layer, the matter is most likely a decrease in throughput as a result of silting of the bottom.

To save the situation, you need to empty the pit of the liquid contents, then pour water into the cesspool and leave it there for several hours so that the sediment at the bottom softens.

To decompose sludge, biological products intended for this purpose are added to the water, containing microorganisms that can destroy the sediment formed during the decomposition of organic matter. After waiting a few days, the pit is cleaned again.

We improve the cesspool hatch

The cesspool lid often looks like a foreign body against the background of a green lawn and flower beds. Therefore, many try to disguise it with something. There are many options, but you need to choose one so that the design of the site is not affected, and if necessary, the decor can be easily removed.

You can put an artificial stone on the hatch in the form of a boulder or small stones from which the slide is laid. There are stones on sale with indentations where flowers are planted.

You can decorate the hatch with a decorative cover. Products made from a polymer-sand composition look especially beautiful. Their colors are very different.Sometimes their surface imitates various materials. There are lids with sculptures in the form of stumps, anthills, animals, and cartoon characters.

He will introduce you to the features of constructing a cesspool from a barrel for a country sewer system. next article, the contents of which we recommend that you familiarize yourself with.

Conclusions and useful video on the topic

The author of this video shares his experience of installing a cesspool for a toilet in the country:

An interesting idea: the home craftsman did not cut off the lid, but used the inside to create horizontal drainage:

This master applied his non-standard solution:

The article presents a generalized technology for constructing a cesspool from tires. During the installation process, some nuances may arise; perhaps you will come up with some new solutions. The main thing is to act and your life at the dacha will become more comfortable.

Would you like to tell us about how you built a cesspool from old tires with your own hands? Do you have information on technology that will be useful to site visitors? Please write comments in the block below, ask questions about the topic of the article, and post photos.

I think this is a cheap way to arrange a cesspool. Some effort is required to construct the version without a bottom. First of all, you need to remember that the more spacious it is, the more wastewater it can accept. It is practically not a problem to find tires that have become unusable and after the hole is dug, you need to fit them to each other. Both a wooden and a concrete cover are allowed on top.

I think that the construction of a cesspool of this type is allowed in country houses, where sewerage is very rarely used, or in dachas. And there is nothing complicated about the device - the main thing is to choose the right place for the cesspool and determine the cleaning method. Then you determine the volume of the pit, calculating it taking into account the dimensions of the tires. We dig a well manually or mechanically, lay the tires one on top of the other, thereby strengthening the walls of the well, make a reliable lid and do not forget to monitor the cleaning.