Concrete rings for sewerage: types, markings, manufacturing methods + review of manufacturers

It is difficult for a person accustomed to convenience to do without hydraulic structures in his country house.

To build a simple septic tank, collector or well, concrete sewer rings are often used as the most optimal and economical option. Concrete products are attractive due to their low price, simplicity and speed of installation.

From this article you will learn about the types of sewer rings, their sizes, and features. We will introduce you to the best manufacturers of these products and their prices.

The content of the article:

General characteristics of rings

Concrete rings must be selected based on the sewerage project, where the size of the well and its type are justified by calculations. In this case, the product should have a light gray color, indicating that it has been well dried.

On the surface of sewer concrete rings, the presence of visible defects in the form of voids, protruding crushed stone, and other flaws is excluded.

Concrete products are an excellent material for constructing a sewer system. But you should know that in this category of building materials there are many types that differ in characteristics and sizes. Let's look at this in more detail.

Classification by design

According to their design, concrete rings are divided into two large classes: folded, with a lock-type connection and straight.

The first of them have protrusions at the top and grooves at the bottom. When installing, the products are inserted into one another. The protrusion is combined with the groove and the result is a strong, sealed connection that is not subject to shifts in any conditions.

Using rings with a locking connection, you can get not only a sealed, stable barrel, but also a perfectly straight one. In case of unstable soils this is the best solution.

Straight or solid rings have smooth walls. They are joined together using additional elements - metal brackets, and then the seam is sealed with cement. Rings of this type are cheaper than the first ones, but also less reliable.

These products differ from each other not only in the way they are connected, but also in the presence of a bottom. In some it is present, and in others it is absent. The former are advantageous in that when they are placed at the bottom of the pit, there is no need for concreting.

Dimensions of concrete rings

In order to avoid problems during installation due to the wrong choice of rings, you need to know that they mainly differ in internal diameter. The wall thickness of different products also differs significantly - 70-200 mm.

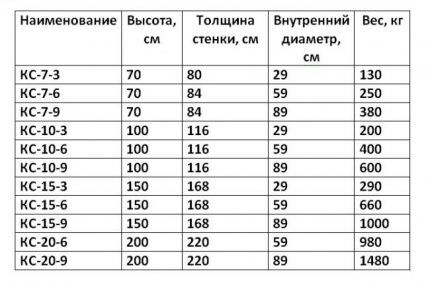

A table with the main parameters will make it easier to choose the sizes of concrete rings for sewer construction.

Regulates all parameters GOST 8020-90. In addition to the above, there are special tables in which, in addition to the linear dimensions of the ring, the useful volume and the class of concrete from which it was made are indicated.

Since rings with a height in the range of 0.8 to 0.9 m are mainly used for home sewerage, the differences in height are not very noticeable.

Having ready-made parameters, you can make preliminary calculations regarding the rational design of the sewer system.

The type of connection is not the only difference in the design of the rings. There are products with a bottom, which is an excellent solution for constructing the first settling chamber.

Product marking according to GOST

Manufacturers apply markings to concrete rings that comply with GOST standards. Reading it will make it possible to determine the purpose of the product.

The designations are deciphered as follows:

- KS — wall ring;

- KLK — an element of a storm sewer or drain;

- KO - ring for foundation or support;

- KVG - product for water well or gas pipeline;

- KFC — concrete ring for installing collectors or drainage systems;

- KSD - concrete ring with a bottom.

These characters are followed by two groups of numbers. The first is the diameter of the product, and the second is the height in decimeters. So the designation KS 20 – 9 reads like a wall ring with a diameter of 20 cm and a height of 90 cm.

Sometimes the degree of permeability is also present in the markings in the form of symbols "ABOUT", "P", "N". The first indicates a particularly low value of the parameter. The second is for reduced, and the third is for normal.

Most often, autonomous sewage systems are constructed from rings, the dimensions of which comply with regulatory requirements.

Purpose of concrete rings

Sewer settling wells are the main area in which concrete rings are used, but they are far from the only one.

Since the permeability of their walls is low, the products are used for the device:

- collectors as the main element of the city's sewer system;

- inspection wells;

- gas pipeline installations;

- water intake points;

- filter wells;

- laying all kinds of cables underground.

Concrete rings can be buried in any type of soil. The products easily withstand aggressive environments.

Main advantages and weaknesses

Despite the differences in concrete rings in design, size, purpose and price, they have common disadvantages and drawbacks.

The advantage of these products is:

- Long service life. If the ring is made of high-quality components and equipped with a reliable reinforcement cage, it will not change its strength characteristics for up to 20 years or more.

- More than satisfactory degree of resistance to compressive influences.

- Simple and quick installation.

- Moisture-proof walls provided that the waterproofing is carried out correctly.

- Smooth, high-quality, easy-to-clean surface.

- Resistant to groundwater and shear.

- High frost resistance.

Since concrete rings in sewer systems are used in an aggressive environment, such an indicator as low surface permeability is very important for them.

Reinforced concrete rings also have disadvantages. These include:

- Due to the large weight, installation cannot be done without the use of special equipment.

- For delivery to the installation site, access roads must be arranged.

- When using rings without a lock, it becomes necessary to carefully seal the joints.

- When products are subjected to uneven loads, cracks may appear.

To make the fastening of the rings to each other more reliable, they are fastened with plates on the inside. One of the ends is fixed on the lower element, and the second on the upper element.

A well made of large diameter rings is covered with a floor slab with sewer hatch. For a small structure, the hatch itself serves as the ceiling.

Technology for the production of concrete rings

Rings are produced from cement grades no lower than M200. For making rings according to GOST 7473-2010 apply brand M400. Additional ingredients include sand, crushed stone, water, and plasticizer.

There are two methods for producing concrete rings: by vibration casting and vibration pressing. The first is used for small production volumes, and the second is considered industrial.

What these two technologies have in common is the reinforcement, which is laid before filling the vibrating mold or vibrating press with concrete mixture. It is first tied into a ring whose height is equal to the height of the finished product. This gives the rings extra strength.

To firmly bind the concrete aggregates and turn it into a strong cement stone, the concrete rings are steamed after formation. This accelerates the hydration of the binder components. After the rings reach formwork strength, they are removed from the pallet and sent to the storage location.

Reinforced concrete rings are placed in a steaming chamber after formation is completed. During the heating stage, the temperature in the closed chamber is gradually increased - by 20-25 °C within an hour.

If this rule is not observed, cracks may form on the surface of the products as a result of excess stress in the concrete due to a sharp temperature rise.

The actual steaming is carried out at a temperature of 70 to 90 °C. Then there is a gradual cooling. Based on the operating principle, a distinction is made between periodic and continuous steaming chambers.

Rings are stored in a closed or open warehouse. They can be placed in rows or inserted into each other if dimensions allow.

Technology #1 - vibration casting method

The advantages of this method are that large areas are not required to organize production. A small area with hard surface is enough.

In addition, the forms used are lightweight. They are dismountable, so you don’t need a crane or crane beam to remove the finished product.

The manufacturing process consists of several stages:

- Lubricate and assemble the molds at the pouring site.

- Fill the forms with concrete.

- Concrete is compacted using a deep vibrator.

- Leave the mixture in the molds until it hardens. Typically the waiting time is between 6 and 8 hours.

- The structure is dismantled by 2-4 people.

Typically the cycle of pouring into molds with a volume of 6 - -6.5 m3 takes from 4 to 5 hours.

Technology #2 - vibration pressing of rings

Manufacturing using this method does not require many molds, since the productivity of the brick making machine allows you to produce about 35 products in 8 working hours. The concrete mixture is fed into a stationary vibropress mechanically, using a belt conveyor or concrete paver.

When using a conveyor, the mixture is placed into the mold manually, while a concrete paver allows you to do without the use of manual labor.

The technological process consists of several operations:

- The outer removable formwork and the locking part of the pallet are placed inside the vibropress.

- The spreader of the concrete paver is brought to the form.

- Unload the mixture into the mold and remove the spreader to the side.

- A hydraulic punch is installed above the mold.

- The pressing process is started. In this case, the grouting ring rotates and forms the locking part. It has limiters that allow you to clearly define the dimensions.

- The punch is removed from the mold.

- The product is stripped. A special device is used for this. Sometimes they use a device from a forklift, attaching it to a crane beam, or use the forklift itself.

- Dismantle the lower grips holding the ring.

After the mold is removed from the ring, another pallet is placed in it and returned to the brick making machine.

If you compare a vibropress with a vibroform, its advantages become obvious, affecting not only productivity, but also the quality of the final product.

A hydraulic cylinder (punch) mounted on a rotating beam ensures strong pressing. Since aggregate fractions that differ in size are alternately affected by vibration of different frequencies, vibration compaction is of higher quality.

The result is a high-quality surface that cannot be obtained using a vibroform. The lock, formed by pressing, is characterized by high strength indicators.

Technology #3 - home production

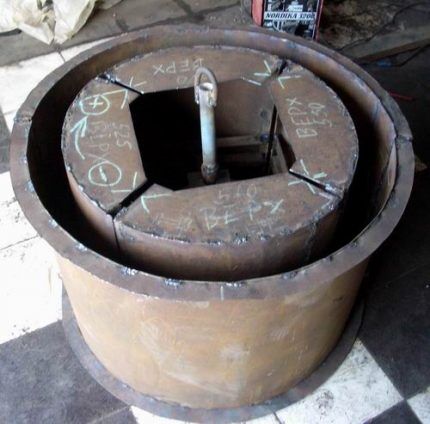

Reinforced concrete rings can also be made at home. For this, in addition to materials, special forms will be required. You can also make them yourself.

It is easiest to use thick-walled barrels. One of them is large in diameter, and the cross-section of the other should differ to a smaller extent in order to obtain a wall about 8 mm thick.

The bottom of both vessels is removed. The inner barrel is made 10 centimeters higher than the outer one. For convenient removal of the formwork from the finished product, a longitudinal cut is made on the barrels, dividing them into two parts.

To prevent the walls of the form from bending, spacers are needed to keep the formwork from deforming.When preparing for use, the small part of the mold is inserted into the larger one. At the same time, make sure that the gap is uniform around the entire circle.

Drill holes for the fixing pins. Next, studs are inserted into the prepared places and tightened tightly with nuts.

There is another option for making a mold - from a metal strip and wooden blocks. A blank is made from the strip, the width of which is equal to the height of the reinforced concrete product with the addition of 10 cm.

Cuts are made along the upper side, and after that a ring is made from the blank. To give it rigidity, a wooden frame is made by cutting wooden pieces about 23 cm long and attaching them under the side. To prevent the walls from sagging, the height is also strengthened.

If you have experience working with wood, you can also make wooden forms. A metal ring is used to secure the wooden planks. It is attached to the outside of the larger diameter mold and to the inside of the smaller part of the formwork.

We also recommend reading the article where we provided detailed instructions on how to make concrete rings with your own hands. More details - go to link.

The best manufacturers of concrete rings

Concrete rings are produced by many Russian enterprises. Among them are companies whose products are in particular demand.

Place #1 - VTG Stroy company in Moscow Region

The VTG Stroy company in Mytishchi has recently begun producing reinforced concrete rings for various purposes, including sewer rings. Here they make wall products, with a bottom, additional panels, concrete covers, and a separate well bottom.

There are folded rings and those without a lock.There are passports and certificates for everything.

The following products are especially popular:

- the KS ring is rebated and straight with a cross-section of 90 - 100 cm, complete with a lid and hatch;

- product KS with and without a lock with a diameter of 90 – 150 cm in the same configuration;

- KS ring both with and without a lock with a lid and hatch with a diameter of 90 - 200 cm.

The enterprise's capacity is large enough to ship products to all regions of Russia. The cost of one ring is about 2.1 thousand rubles.

Place #2 - Dialog Stroy company

A company from Novokuznetsk, Dialog Stroy, supplies the entire region with reinforced concrete products.

The assortment includes the following product names:

- KS 7-9 - with a wall thickness of 80 mm;

- KS 10-9 - with the same walls;

- KS 15-9 - with walls 100 mm;

- KS 20-9 - with walls of the same thickness.

For individual orders, it is possible to produce rings with other parameters. The price of products starts from 1.7 thousand rubles.

Place #3 - LLC TSK Sinegorye company

The products of the company "TSK Sinegorye LLC" are popular among consumers. Here they produce reinforced concrete rings for sewer wells, hatches for them, bottoms, and additional rings.

The average cost of a ring is about 2.7 thousand rubles. The company is located in Kirov, but deliveries are carried out throughout Russia.

Place #4 - YugStroyKomplekt enterprise

The Krasnodar company YugStroyKomplekt also produces a wide range of reinforced concrete products. The height of the rings is 0.9 m, the diameter is from 100 to 200 cm. The price of one product is from 1.4 thousand rubles.

Conclusions and useful video on the topic

Technological process for manufacturing sewer rings using the vibrocompression method:

The process of making rings with your own hands in the following video:

To perform flawlessly installation of concrete rings, you need to study information about these products and the features of their installation in advance. The next important stage is preparation, including system calculation and design.

To prevent accidents in an autonomous sewer system, when installing it, you must follow existing standards.

If after reading the material you have questions, ask them in the block below, and we will try to answer them promptly. There you can supplement this article with interesting information on the topic.

I recently bought a house and was faced with the problem of poor sewerage. I looked through a lot of information and came to the conclusion that the well needs to be replaced. Thanks to the detailed recommendations you provided on the production and installation of concrete rings, I came to choose the company. The installation of the well was carried out efficiently and quickly. I haven't had any problems in this direction for over a year now.

Be sure to carefully check each concrete ring for cracks and chips. Make sure that it is not deformed, check for the presence of reinforcement. Be sure to check the certificates and look at the labeling. Because, for example, I encountered an unscrupulous supplier company when I was making a well at my summer cottage. Everything ended well, but it took a lot of nerves.

What was wrong with the rings? What should you pay attention to first when buying rings for a well?

Do not choose the cheapest rings for a well, ask for paper confirming quality, and also personally carry out the inspection yourself so that there are no chips, cracks or other damage.

In general, there is no secret; normal manufacturers provide all the necessary documents confirming the quality of their products, plus guarantees. Also be careful when unloading the rings so as not to damage or break them.