How to construct a cesspool without a bottom: diagrams and arrangement rules

The very first point of autonomous sewerage on a site very often turns out to be a cesspool without a bottom. It's not difficult to do.Since the design of such a sewer structure is extremely simple, it does not require special construction skills or commercially available materials.

But still, negligence in the construction of such a useful facility can turn into a big disaster. The article we presented describes in detail the rules for constructing a treatment point for an independent sewer system. The nuances of its operation and maintenance are given.

The content of the article:

The principle of operation of a pit without a bottom

A cesspool is a reservoir of gray waste from human activity, i.e. wastewater generated during household activities, cooking and hygiene procedures.

It is arranged at a certain distance (defined by sanitary standards) from the house. To install such a sewer system, you need to dig a hole, strengthen and protect its walls from moisture, install an upper ceiling, and also connect a sewer pipe to the tank.

Wastewater flows inside the tank, and the ceiling reliably protects others from unpleasant odors. The settled liquid component of the wastewater seeps into the underlying soil layers, and solid inclusions settle on the surface of the sand and gravel filter.

Over time, the tank becomes filled with insoluble solid sediment and its contents must be removed. For this, a special sewage disposal machine is used, although a small hole can be cleaned using a regular bucket.

The effluent inside the pit changes slightly in composition over time. They are partially processed by microorganisms, the solid fractions turn into sediment, and the liquid part is separated. In order to reduce the amount of waste, in order to use the services of sewer trucks as little as possible, the pit is made “without a bottom”.

The walls of the tank for gray waste are carefully sealed, and a gap with soil is left at the bottom. A filter is made from natural materials on top of the ground: sand, crushed stone and gravel. The liquid part of the wastewater slowly seeps into the ground, and the solid fractions remain inside the sewer tank.

Wastewater passing through the filter receives additional purification.Finally, liquid waste is processed in the soil with the help of microorganisms that live there.

In order to speed up and enhance the processing process, add biological agents, which are based on the action of natural bacteria. Similar preparations are also used inside storage sealed cesspools to perform biological treatment of wastewater and reduce the volume of sludge.

The “bottomless” sewer design is very convenient. It allows you to remove the liquid part of the wastewater in a natural and safe way. As a result, the tank fills more slowly, and you have to pay for the services of vacuum cleaners less often.

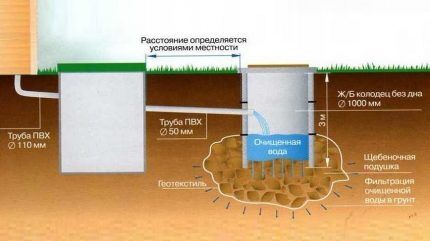

An interesting variation of a pit without a bottom is a post-treatment system in the form of a filter well. It is installed after the septic tank, in which the primary wastewater treatment is carried out.

Both sections are connected by an overflow pipe. First, the wastewater enters the sealed sewer section.

Here the waste settles, solid fractions settle to the bottom, light technical pollution accumulates at the top, and the so-called “gray waste”, i.e. Water purified from the listed contaminants reaches the overflow level and moves into a container without a bottom. Wastewater is filtered and disposed of in the ground as described previously.

The use of special microorganisms turns the structure into almost a full-fledged septic tank, which operates on the basis of similar principles.

It makes sense to make such a two- or even three-chamber structure only for a house in which a significant number of people live, and therefore it is planned to receive a large volume of wastewater. And for a summer cottage, you can arrange a relatively small cesspool.

Calculations and technical standards

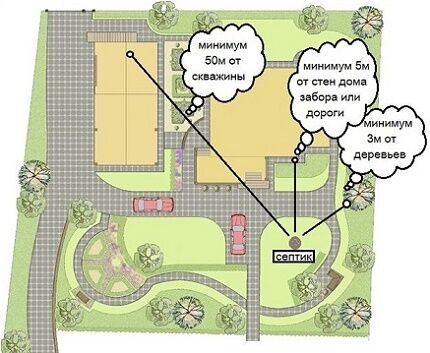

To cesspool functioned correctly, you need to correctly select the location and calculate the volume of the container. To begin with, you should remember that, according to sanitary standards, such a structure cannot be used in areas where groundwater runs high. The bottom of the container should be at least 1 m above this level.

An approximate calculation of pit volumes can be made based on the average standard: 0.5 cubic meters. m for each person who lives in the house permanently. Sump depth usually varies between two and three meters. This is dictated by the peculiarities of the operation of suction pumps, which do not serve structures deeper than three meters.

It is also necessary to take into account the following point: the pit is cleaned when the container is filled to two-thirds of the total volume, and not to the very top. It is best to make the dimensions of these two-thirds multiples of the dimensions of the suction tank.

This is beneficial, since the vacuum cleaners do not charge for the amount of sewage pumped out, but for each specific trip, i.e. You will have to pay even for the removal of a small amount of waste at full cost.

On different soils there are different standards for placing a cesspool.It is usually recommended to place this structure at a distance of at least five meters from a residential building and at least 25-50 meters from a source of drinking water.

The standards are dictated by the danger of soil or source contamination by wastewater. This can happen during spring floods; improper installation of sewerage can also cause similar troubles.

The greater the filtration qualities of the soil, the faster wastewater penetrates inside, and the more stringent standards should be followed when designing a cesspool.

The best option is to install a structure with a conditional bottom buried in sandy soil.Filtration of wastewater into clay soils is impossible, therefore, in areas with a loamy or sandy loam base, pits without a bottom are not installed.

When installing a structure on silty or clayey sand, whose properties are close to sandy loam, the rate of penetration of wastewater into the soil is increased by using perforated rings. The result is a variation of a cesspool without a bottom with permeable walls.

And one moment. If special equipment is used to clean the cesspool, it is necessary to provide convenient access roads. The maximum permissible distance between the suction pump and the object is no more than four meters, but the shorter this distance, the more convenient it will be for the suction trucks to work.

What can a cesspool be made from?

A variety of materials are used as material for the walls of such sewers:

- brick;

- monolithic concrete;

- ready-made concrete slabs;

- concrete rings;

- wood;

- gas silicate block;

- plastic, etc.

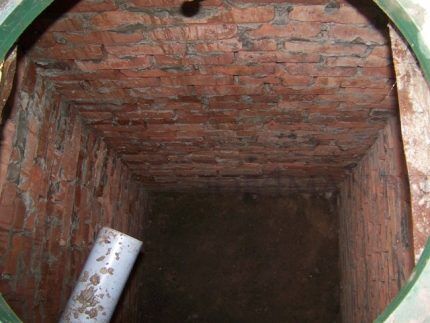

Brickwork for a cesspool is quite suitable, but its installation will take a lot of time. In terms of costs, it will not be cheap, but it makes sense to consider this option if the owner of the site has at his disposal a sufficient amount of brick unclaimed for other needs.

Of course, special beauty is not needed here, but you shouldn’t take a very low-quality brick either; nevertheless, the constant impact of wastewater has a serious destructive effect on the walls of the pit.

Some novice masons prefer to get their hands on just such objects, since all the flaws will still be hidden under a layer of waterproofing and the top floor. But excessive negligence can play a cruel joke on an inexperienced master: an uneven brick wall often turns out to be extremely fragile.

The gas silicate block is noticeably larger in size than brick. With this material the work will go faster. Wood is not the best choice due to the same damaging effects of runoff.

A pit lined with boards will have to be repaired almost every year. Filling with monolithic concrete is carried out traditionally: using formwork. A gap is left at the bottom for a sand and gravel filter. The structure must be reinforced.

Concrete rings are the most popular and convenient choice for cesspool structures. But it should be remembered that low-quality designs are unacceptable. Of course, a cesspool is not a well, but it must be built correctly. There should be no chips, cracks or other similar damage to the structure.

The disadvantage of concrete structures is the impressive weight of the structure, which complicates installation and complicates repairs. What to do if the concrete rings of a sewer point sag, described here.

Plastic containers are widely used to create sealed cesspools, but if you make a hole for the filter, you can use a sewage container without a bottom. Plastic is a lightweight material.

Just in case, you can weigh it down or secure it plastic container. Especially if in winter it remains unfilled, so that the structure is not displaced by frozen soil or floats up during a flood.

Another option worth mentioning is waste tire cesspool. It’s not difficult to build: dig a round hole of suitable size, and put tires inside, one on top of the other.

Tires protect the walls of the pit from collapse and prevent runoff from penetrating into the ground. The tires should be connected to each other, and the joints should be treated with sealant. A traditional sand and gravel filter is placed at the bottom of the structure.

It is customary to install tire pits in sandy soils, in areas with low groundwater levels, where there is no threat of heavy spring floods. Otherwise, during the flood period, the environment may be contaminated with untreated wastewater due to depressurization of joints.

The advantages of such a structure are low time consumption and the use of inexpensive materials. But you should understand that the service life of such a structure is short - only a few years.

Installation of an object made of concrete rings

Since concrete rings are the most common option for constructing a cesspool, it makes sense to consider it in detail.

Here is the general scheme for performing installation work:

- Perform markup.

- Dig a pit.

- Install the rings.

- Bring a sewer pipe to the property.

- Make a hole for the pipe and insert it into the container.

- Seal all connections.

- Apply a layer of waterproofing material.

- Place a sand and gravel filter at the bottom of the structure.

- Backfill the pit.

- Install the top cover with cover.

- Cover the ceiling with soil or decorate it.

You can also dig a pit for a small hole by hand.You will need a bayonet shovel to dig, a bucket on a rope to remove the soil, a shovel to pour it into the bucket, and a partner on top to pull the bucket out. The concrete ring is placed on the ground and dug inside.

As a result, the ring gradually lowers, preventing the walls of the pit from collapsing. For a large cesspool, it is still better to spend money on renting an excavator. The speed of work will increase significantly. Here you can also first place the ring on the ground and then begin work. You will need an excavator with the appropriate bucket size and an experienced operator.

The trench for the sewer pipe must have slight slope, 2 - 3 cm per linear meter. If soil freezing in winter is typical for this area, then the pipe above this mark should be insulated.

A hole for the pipe is punched in a suitable place after it is laid. If you make such a hole in advance, you may simply not guess the height of the pipe entry.

The joints of the concrete rings, as well as the pipe entry point, are treated with a solution. Then a layer of waterproofing material should be applied. Inexpensive coating insulation will do.

This step is not considered necessary if all joints are securely sealed. However waterproofing layer will protect the structure from damage, and this will significantly increase its service life.

The bottom filter is formed from river sand and gravel. You can also use crushed stone of suitable fractions. First, sand is poured in a layer of about 30 - 35 cm, then two layers of gravel or crushed stone of approximately the same thickness.

Small particles should be at the bottom, and large ones at the top. Now you need to install the top floor. Usually, for this purpose, a ready-made concrete slab of suitable size and configuration is taken.

There should be a hole in the ceiling large enough so that you can not only lower the suction hose, but also send a person to inspect the condition of the container after cleaning it. This hole is covered with a lid so that foreign odors do not disturb others.

Some owners prefer to make a double lid. It reliably protects against odors and freezing of drains in winter. A layer of soil is usually applied on top of the ceiling so as not to spoil the landscape.

The lid, of course, must be left free; it must be 20 - 30 cm above ground level. Now you just need to monitor the level of waste in the container and remove it in a timely manner.

If everything is calculated correctly, then cleaning will only be necessary a couple of times a year. After the cesspool is cleared, do not allow a person in overalls to be lowered down.His task is to inspect the walls of the structure and check their integrity.

Periodically wash the bottom filter or replace it completely. All work inside the cesspool must be done only in the presence of a partner, who is at the top for insurance.

Construction of a cesspool with overflow

A pit with an overflow is a more complex sewer facility in a technical and structural sense. Its installation will require more effort and investment, but in the end you will be able to turn to the vacuum cleaners much less often.

In overflow sewer treatment points, two or three chambers are installed, the first of which are equipped with a sealed bottom. The finishing chamber is always constructed according to the type filter wells.

The following selection of photos will introduce the main stages of construction of such a treatment facility:

Biological products for cesspools

The presence of special bacteria in the container can significantly increase the efficiency of the sewer system, as well as reduce the rate of its filling. Usually these are specially selected complexes of anaerobic (i.e., capable of existing without oxygen) microorganisms. These bacteria are able to process wastewater, decomposing it into more or less clean water and neutral sludge.

This biological treatment of wastewater significantly reduces the risk of soil contamination. If the degree of purification is high enough, the water can even be used for irrigation, and the resulting sludge can be used as fertilizer.

In practice, after biological processing, the amount of liquid in the wastewater increases, it is quickly disposed of in the soil, and sludge accumulates more slowly than when using a cesspool without bacteria.

Such drugs are sold in the form of concentrated liquids, granules, powders, tablets, etc.The packaging contains detailed instructions that must be followed. Powdered and granular preparations usually need to be pre-diluted in a small amount of water, and concentrates are immediately sent down the drain.

In this case, you should pay attention to the list of chemicals that have a detrimental effect on these microorganisms. Such substances, such as chlorine, are found in various household chemicals. Owners of automatic washing machines should pay special attention to what goes down the drain.

If all instructions are followed exactly, then there will be no need to replenish the colony of bacteria in the cesspool. They reproduce and maintain the required numbers.If the unpleasant odor from the cesspool has become stronger or has changed towards worsening, this may indicate that a significant part of the microorganisms have died and the colony needs to be restored.

Methods for cleaning cesspools are discussed in detail. in the next article, which we recommend that you familiarize yourself with.

Conclusions and useful video on the topic

The process of creating a cesspool is clearly presented in this video:

The procedure for filling the walls of a cesspool with monolithic concrete is shown here:

This video shows how to clean a cesspool yourself using a pump:

A cesspool of this type is a convenient and useful structure. It can be used to dispose of waste safely and efficiently. It is important to strictly follow the technology and adhere to established sanitary standards.

Please write comments in the block below. Tell us about how you built a cesspool with a filter bottom in your dacha or suburban area. Ask questions, share your opinion and useful information, post photos related to the topic of the article.

Our two-ring, two-cube cesspool worked great for about 5-6 years. Then a quiet horror began, because our everyday life depended on the fullness of the pit! It filled up in 10-12 days, and we cannot call for pumping more than once a month! They decided to move the drain from the washing machine and kitchen faucet into the yard to “water the path” in order to somehow reduce the load on the sewerage facility! The bacteria didn't help much; they mostly work in the summer. I have no idea what to do! Is it really necessary to dig a new cesspool???

Don’t worry, it’s almost certain that your cesspool’s functionality can be restored. Apparently, the soil has lost its filtering ability and cannot absorb liquid. There may be several reasons why this happened.

The most common is the formation of a fatty film on the bottom and walls of the pit due to the large amount of fats and soaps dumped into the pit. This can be corrected by using special products (Roetech K-87, Doctor Robik 809, or similar), after pumping out the dirty liquid from the pit.

Another reason may be siltation of the bottom. It can be solved by mechanical cleaning or the use of biological anti-silting agents.

Making a cesspool without a bottom is not difficult. It won’t be so expensive if you use either second-hand brick or plastic. But, while thinking about my pit, I remembered that this structure would not last for one year, so I walled up 2 reinforced concrete rings. The joints were sealed with mortar. I placed the lid on top. We installed a PVC pipe from the house to the pit and now we use the sewer system without any problems.