Sewer pipes for external sewerage: types and review of the best brands

Are you concerned about the arrangement of internal communications and the drainage system outside the house? Agree, it’s great when a country house has all the benefits of civilization, despite its remoteness from the metropolis.

But to build a system, you need sewer pipes for external sewerage, and you don’t know which ones are best to choose?

We will tell you which material is suitable for various operating conditions - the article discusses the characteristics of pipes made from existing materials, the advantages and disadvantages of each option.

There is also a rating of the best manufacturers of plastic and cast iron pipelines, selected photographs depicting their products and video recommendations from sewerage professionals.

The content of the article:

Requirements for external pipelines

External sewer networks have to function in difficult conditions. Pipes covered with earth are forced to bear the weight of the soil, on which people, and often cars, can move.

They are also affected by soil water, which can provoke a displacement of the connecting points, which can lead to depressurization of the sewer network.

Systems must constantly withstand the static/dynamic effects of wastewater transported through pipes.

That is why special requirements are imposed on elements of external sewer networks.

Pipes must have the following qualities:

- strength and rigidity;

- the ability to withstand temperature fluctuations without losing performance;

- frost resistance;

- wear resistance, long service life;

- resistance to aggressive chemical environments.

For the manufacture of external sewer systems, various materials can be used (polymers, steel, cast iron), but they all must comply with the above factors.

It should also be taken into account that the quality of the pipeline is influenced not only by the specific properties of the pipes, but also by the quality of installation and laying of the system.

Our website also has other useful materials on sewerage rules.

We recommend that you familiarize yourself with them:

- Laying sewer pipes in the ground: technological rules and nuances

- Calculation of sewer slope: formulas and standards

- How to lay sewer pipes in a private house: laying diagrams and rules + installation stages

Differences between external and internal sewage systems

The pipes that are used for laying external systems differ significantly from the analogues used for internal communications.

Detailed information about pipes for internal sewerage is discussed in this article.

Characteristic features include:

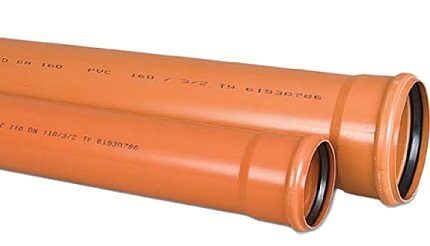

- Color. Orange (red) color, which makes the pipe easy to locate, therefore avoiding unintentional damage to the network during excavation work.

- Wall thickness. For parts for external sewerage, this parameter is always higher than for internal sewerage (when using PVC systems, these figures are 3.2-3.4 mm versus 2 mm), since the pipeline laid underground has to withstand heavy loads.

- Materials. Red pipes are usually made from materials of increased resistance (for example, unplasticized polyvinyl chloride, which is particularly durable).

- Heat resistance. Thanks to the increased thickness and reliability of the walls, as well as the addition of specially selected components, the heat resistance of external systems is higher than that of internal ones. But they may also need insulation. We recommend that you familiarize yourself with the types insulation for sewerage.

- Life time. Orange-colored products tend to last longer than gray ones.

- Price list. The cost of elements for external sewerage is approximately 20% higher than for internal sewerage.

Experts warn against using gray pipes for laying external sewerage systems. It is difficult for them to withstand increased load (especially for a long time), which can lead to breakthroughs and accidents.

Let's take a closer look at what materials can be used for the manufacture of external sewer systems.

Classification of pipes by type of material

The most popular among users are plastic sewer pipes. But, in addition to plastic, external pipes for sewerage wiring can be made from other materials. Let's look at the features of each type of pipe, highlighting their advantages.

Type #1 - plastic products

Polymer sewer pipes appeared not too long ago, but have become widespread, displacing traditional analogues in the specialized market.

Such components have a number of undeniable advantages:

- a light weight, facilitating transportation, storage, laying;

- smooth inner surface, facilitating the unhindered passage of wastewater and preventing the settling of salts and other sediments. Thanks to this feature, with proper installation and operation, plastic pipes almost never form blockages;

- wear resistance — plastic pipes do not rot or corrode;

- exploitation - such products have a sufficient service life, although shorter than their cast iron counterparts (maximum 50 years).

Most often, components made from the following materials are used for the manufacture of external sewer systems.

Option #1 - polyvinyl chloride (PVC) pipes

Polyvinyl chloride (PVC) - an affordable, popular plastic, widely used for the production of various products, including pipes for internal/external networks.

Such components are especially recommended for sewer systems that require a large flow area (collector, culvert, storm).

Among the most significant disadvantages of PVC pipes are:

- Sensitivity to aggressive materials. If you plan to remove acids and oils through such components, it is better to purchase special uPVC pipes with special properties.

- Temperature elongation of material. Because of this property, it is not advisable to install such parts for transporting hot liquids (over 60 degrees C).

PVC pipes have the following positive properties: good resistance to mechanical stress, high strength and UV resistance, making such products suitable for open areas.

There are two types of PVC pipes:

- Pressure, withstanding high pressure (<10 atmospheres). They are used in systems that experience constant increased exposure to various environments.

- Gravity. Recommended for systems with unexpectedly high pressure (the liquid in the pipe moves by gravity at a moderate speed).

Most often, the second version of products is used in external pipelines.

PVC pipes can consist of one or two layers.In the latter case, unplasticized material is used for the outer layer, and recycled foam polymer is used for the inner layer.

According to their hardness class, PVC components are divided into the following categories:

- Rigid pipes (class S) with maximum wall thickness, designed for installation at a depth of up to 8 meters. This type can be used for any work, but is most often used in industry.

- Medium-hard products (class N) used at a depth of 2-6 meters. They are suitable for installing pipelines under not too busy roads.

- Lightweight components (class L), sufficient to create systems that are laid at shallow depths (0.8-2 m). Not suitable for laying under the roadway.

The most common pipe for external sewerage is a product with a diameter of 10-11 cm. In this case, sewage from a country house is easily transported through the network.

Pipes made of unplasticized polyvinyl chloride are used in underground laying of external communications where it is known that there will be no significant load on communications.

If this factor is taken into account, then the scope of application of PVC products is quite wide:

We discussed more information about PVC and HDPE pipes for external sewerage in our other article.

Option #2 - polypropylene products

Pipes of this type are not very often used for laying external sewer networks due to the insufficient rigidity of polypropylene parts.

However, they can be used for laying free-flow storm drains or for installing systems in sandy soils.

Among the advantages of this type of product:

- High heat resistance. The installed systems can withstand the transportation of hot liquids (up to 80, and occasionally up to 95 degrees Celsius).

- Chemical inertness. Plastic is not subject to corrosion and does not emit harmful substances.

In addition to the already mentioned lack of density, the disadvantages of polypropylene include its sensitivity to ultraviolet radiation.

Option #3 - polyethylene pipes

This material is widely used for the construction of external pressure pipelines. The advantages of PE pipes include:

- ability to withstand water hammer;

- resistance to active substances;

- long service life (50 years or more).

Among the disadvantages of such products are susceptibility to ultraviolet radiation and insufficient heat resistance - polyethylene pipes can be used in the temperature range from -40 to +40 degrees Celsius.

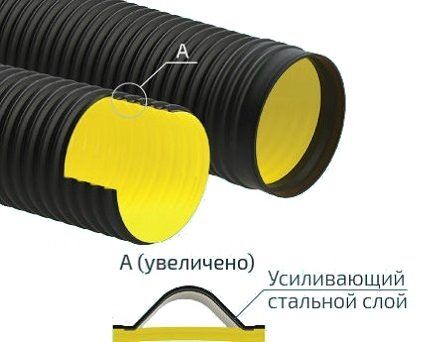

Option #4 - corrugated products

A common disadvantage of plastic sewerage elements is their lack of strength. To correct this flaw, a special design was invented - a corrugated pipe with greater mechanical rigidity.

Thanks to the folded outer surface of such products, their area increases. This allows the pressure exerted by the soil to be redistributed, as a result of which the pipelines can withstand increased loads.

There are two types of corrugated pipes:

- Single layer with a peculiar ribbed surface inside and outside. Such material is relatively cheap, but wastewater removal is much worse.

- Double layerhaving a folded outer surface and a smooth inner surface. Thanks to this, the flow passes freely through the pipe without forming deposits or blockages.

Such products can be made from various types of polymers. The most commonly used is low-density polyethylene, polyvinyl chloride.

Pipes with a corrugated surface are connected using the socket method using special rubber cuffs. When installing pipelines, it is also possible to use the cold welding method.

In another article on our website, we examined in detail the characteristics and application features corrugated pipes for sewerage.

Type #2 - asbestos-cement pipes

To produce such products, a mixture of Portland cement with mineral asbestos fiber is used.

Such systems have a number of important advantages:

- Durability — the service life can reach half a century and even a hundred years.

- Relative lightness, greatly facilitating installation.

- Resistance to aggressive environments. Asbestos cement pipes can withstand almost all chemicals.

- Reluctance to overgrow the bell.

The disadvantage of this material is fragility and sensitivity to mechanical damage.

When making a purchase, it is important to carefully examine the ends of the pipes, where various damages are most often observed. At

Type #3 - ceramic products

Even in ancient times, ceramics were used to make parts of the sewer system.

This material is still popular today, thanks to such advantages as:

- Chemical inertness. Ceramic systems allow the transportation of almost any liquid media.

- Special structure of the inner surfacewhich prevents the formation of plaque and deposits of salts and other substances.

- Temperature resistance external environment and liquids passing through the pipe.

- Easy installation.

Disadvantages include the fragility and short length of the pipes, which is why when laying the system it is necessary to increase the number of joints.

On sale there are ceramic elements with a diameter of 100-600 mm, which can have two connection options: with a socket and with a thread.

Before installing pipes, you should check the quality by examining the appearance of the parts and tapping them. A rattling sound that appears upon impact indicates the presence of a hidden crack.

Type #4 - cast iron systems

For a long time, socket pipes made of cast iron were considered the most popular solution for arranging external sewerage. As a rule, for private construction, elements with a diameter of 16 cm are sufficient.

Systems made from this material have many positive qualities. Among them are high strength, allowing the pipeline to withstand heavy loads and durability - the service life of cast iron systems is at least several decades.

As well as resistance to temperature changes and fairly simple installation, involving the use of a socket method.

At the same time, one cannot fail to mention some of the disadvantages of such products:

- Heavy weight. Due to the heaviness of the elements, it is impossible to lay a cast iron pipeline without the use of special equipment.

- Tendency to form deposits on the surface: over time this can lead to blockages.

- Inability to use on some soils, especially in salt marshes.

- Fairly high price traditional cast iron products.

Currently, cast iron pipes are used for laying industrial communications, while in individual construction they have been replaced almost everywhere by cheaper and lighter plastic analogues.

To see more information about the characteristics, types and installation of cast iron sewer pipes, go to this link.

The best sewer pipe manufacturers

Many foreign and domestic companies produce pipes made of various materials used for laying external sewers.

Place #1 - Dutch plastic manufacturer Wavin

The Wavin company, founded in Holland in 1955, specializes in the production of sewer and water plastic pipes. The company's products are in great demand throughout Europe.

For outdoor use, the manufacturer produces Pragma corrugated polypropylene pipes, which have double walls, as well as other product options.

The Pragma components are 6 meters long; they are easily connected into a system, since they have a socket at one end and a rubber seal at the other. The manufacturer recommends using these products to create a network of external gravity sewerage.

Place #2 - international company POLIPLASTIC

POLYPLASTIC is an international company, whose divisions are located in the CIS countries (Russia, Kazakhstan, Belarus).

Among the range of branded products, a large place is occupied by all kinds of sewer elements, including external pipes made of various types of polymers (polyethylene, PAC, polypropylene, fiberglass).

The products produced by the company are characterized by an optimal combination of low weight with increased ring rigidity, due to which plastic pipes successfully resist even significant loads.

The signature line of this manufacturer is the Korsis series, which includes:

- two-layer corrugated products;

- spiral parts;

- multilayer reinforced pipes.

All these elements are perfect for laying external sewer networks and other drainage systems. The company produces products with a length of 600 or 1200 mm, a diameter of 110-600 mm.

Unlike products from other companies, Corsys components have a corrugated black outer layer and an inner surface of light blue, yellow or orange.

Place #3 - German company Ostendorf

The famous German company Ostendorf Kunststoffe, which specializes in polymer pipes and other parts, was founded by the Ostendorf brothers in 1973.

Now the company is considered a leading manufacturer of elements of such systems in the specialized market. Products are supplied to many countries around the world, but the main consumer is Germany.

In 2011, the Ostendorf plant began operating in Russia. The enterprise, where the latest technological equipment manufactured in Germany is installed, uses imported raw materials and components.

Strict quality control is organized in production, which is carried out in accordance with German and Russian standards.

Due to the highest quality of products, they are in high demand among consumers, despite their relative high cost.

The KG line, intended for external sewerage, is made of solid polyvinyl chloride without impurities, which has increased strength, water resistance, durability, and thermal conductivity.

The convenient shape of the ends allows for quick and easy installation of various systems.

Place #4 - domestic company Politek

The Russian company Politek, founded in 1999, is a leader in the production of polymer products used for drainage, water supply, and sewerage.

The company's factories have installed the latest foreign special equipment, which allows them to produce European-class products.

Place #5 - German cast iron manufacturer Duker

Although metal products are now less common than plastic ones, the demand for cast iron pipes can be called stable. Such products are produced by several European companies, among which the following can be noted.

Founded in 1913 in Karlstadt (Franconia, Germany), the company initially produced products with socket systems.

In 1968, innovative socketless pipes were developed, allowing parts to be shortened and the remaining trim to be installed using a combination method.

Now the company is the only manufacturer of cast iron sewer systems in Germany, and the plant carries out a completely completed production cycle: from casting to applying external coating.

The company offers a wide range of different systems with different lengths, diameters and connections. All of them have excellent consumer qualities: wear resistance, resistance to aggressive substances, strength.

Place #6 - French company Saint-Gobain

The large concern Saint-Gobain (France) specializes in the production of modern cast iron products. For their manufacture, De Lavo technology (centrifugal casting) is used, followed by deep cooling of the structures.

Pam Global C systems are specifically designed for ground work, as well as the installation of high-quality, durable drainage systems. External sewer pipes have a diameter of 100-200 mm.

Conclusions and useful video on the topic

Below we offer a video that gives recommendations on choosing pipes for internal and external sewerage.

It is impossible to say unequivocally which type of pipe is the best.When considering product options, it is important to know for what purpose they are intended and under what conditions they will be used.

Only taking into account all the individual characteristics of the site, the owner can make a choice which option is best for him for arranging a sewer system.

Are you selecting pipes for sewer installation and still have questions after reading the article? Or did you notice errors or inaccuracies in the material reviewed? Please write to us about this in the comments below the article.

Or maybe you have already chosen the material and installed the sewer pipeline on the site? Tell us what type of pipes you preferred and how comfortable it was for you to work with them.

Good afternoon It was an interesting article, I learned a lot about myself. I changed the sewer pipes at my dacha about six months ago. I completely replaced everything with fiberglass (I read a lot on the Internet!) Everyone praises me, so I decided to change it! I ordered the work. The guys quickly delivered the pipes and changed everything. In general, everything turned out very well!

It seems to me that the time of cast iron and asbestos-cement pipes has passed; it is stupid now not to take advantage of the result of progress in the form of plastic products. They have too many advantages with a minimum number of disadvantages. Not only are they lighter in weight and easier to install, but they are also cheaper than their counterparts made from other materials. Good strong and durable pipes, resistant to external influences.