DIY pumping station: connection diagrams and installation rules

A pumping station is excellent equipment that allows you to automate the process of drawing water from a well.A set of technical devices activates the launch of the system when it is necessary to replenish supplies and turns off the units at the right time. The level of comfort will increase incredibly. After all, even outside the city it is necessary to enjoy the achievements of civilization, don’t you agree?

However, it is not enough to just buy incredibly useful equipment; you need to know how to install and connect it. We invite you to read the article, which covers all the issues in great detail. This information will be useful to all owners of suburban housing, no matter whether the pumping station is connected with their own hands or hired workers are invited to install it.

In our article you will become familiar with the types of pumps used in groundwater intake systems. Also here are all possible options for the location of equipment and connection to an autonomous water supply. The information is supported by diagrams, photo materials and videos.

The content of the article:

Purpose and design of the pumping station

The pumping equipment station performs two functions at once - it supplies water to the water supply system of the house and automatically maintains the set pressure in it.

This allows you to lay an extensive water supply network and connect household appliances to it - a shower cabin, a boiler, a dishwasher and a washing machine.

A typical station design includes:

- Pump;

- Hydraulic accumulator;

- Automation block;

- Inlet mesh filter - necessary to prevent particles of impurities and possible contaminants from entering the system;

- Pipelines, hoses and necessary fittings.

To prevent the outflow of liquid from the system when the pump stops or the pressure decreases, a check valve is installed in the water intake area. A source of water intake is also required. For this purpose, a well or borehole is constructed.

It is possible to use a reservoir (pool) with imported water and open reservoirs if the characteristics of the unit allow pumping contaminated liquid.

If the intake is carried out from a natural reservoir (pond, river, lake), the water is used only for household needs and irrigation.

If water is extracted from a well or well, an analysis is required. According to the results of the study, the water belongs to the drinking or household category.

You can read more about the design and operating principle of the pumping station in our other article.

Types of pumps used

Ready pumping stations - these are installations with a surface pump that draws liquid from the well due to vacuum. The design of the pump itself can include ejector, or be remote - in this case it is located in the well.

However, when assembling and installing a pumping station with your own hands, you can also use a submersible or well pump, especially if you already have one.

Models with internal ejector

Installations with a built-in ejector are capable of lifting water only from a shallow depth - up to 8 m. But at the same time they provide powerful pressure exceeding 40 m.

They are not afraid of air getting in, so it is not necessary to fill the system with water before starting work - the station will first pump air and then start supplying water.

They have good performance and reliability. The disadvantage is the high noise level, which is why they are installed in the house only if there are ancillary soundproof rooms.

Models with external ejector

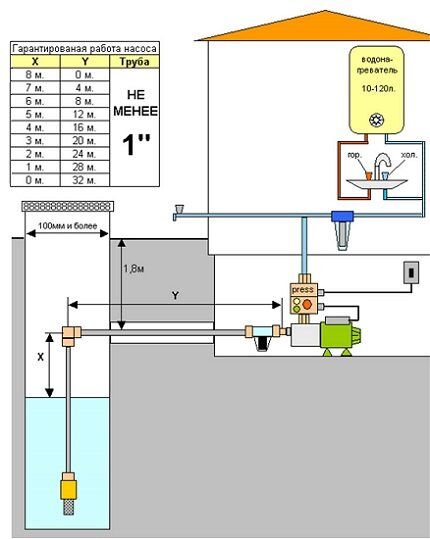

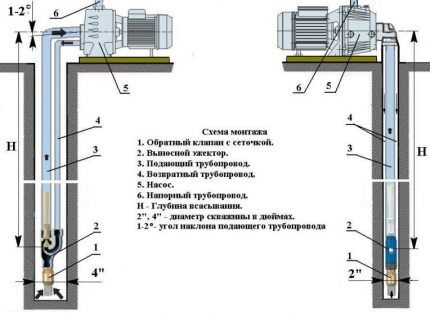

Stations with a remote ejector are installed when it is necessary to extract liquid from a great depth - 20...50 m. In this case, the ejector is lowered into the well (well) as part of the intake unit. Two hoses from the installation are connected to it - pressure and vacuum (suction).

According to the first, the liquid is supplied to the ejector and forms a vacuum region in the suction chamber, the second - lifts up water from the well. Such units are characterized by low noise levels. They do not consume a lot of electricity, but their efficiency reaches only 30-40%.

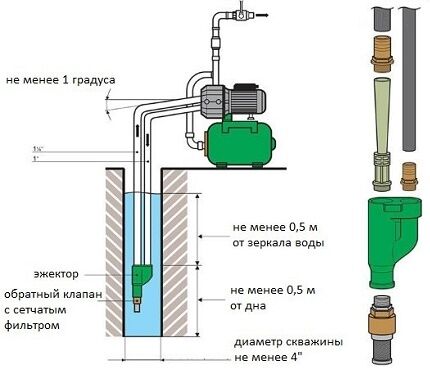

Submersible pump type

Systems with a submersible (well) pump produce virtually no noise; water can be drawn from any depth and at a sufficient distance from the well or well from the building. It is not afraid of small leaks in the pipeline and air leaks.

However, submersible pumps are quite expensive. They require clean water - installing a powerful filtration system solves the problem, but in this case it will need to be cleaned regularly. Repair and maintenance are complicated by the need to lift the unit to the surface.

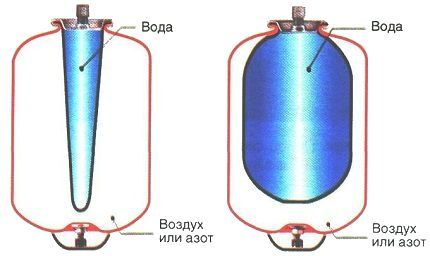

Design and principle of operation of the hydraulic accumulator

The starting current of the pump exceeds the operating current by 3-5 times and has a destructive effect on its design. Therefore, the pump life depends on the number of starts. To reduce them, a membrane must be installed in the system. hydraulic accumulator.

In the home water supply system it performs the following functions:

- Protects the pump from wear and increases its service life - thanks to the liquid reserve in the membrane compartment, the number of unit starts is significantly reduced.

- Maintains constant pressure in the water supply and protects against pressure changes.

- Eliminates the occurrence of water hammer in the system, destructively affecting connected devices and pipeline fittings.

- Provides some water supply in case of power failure.

The device is a sealed vessel, the internal volume of which is divided into two containers by an elastic membrane. One of them is filled with air, and the second is intended for pumping water.

The hydraulic tank works as follows. Water is pumped into an elastic container until the upper pressure threshold is reached. The pump then turns off.

The pressure in the system is maintained by an air gap in the accumulator; the compressed air plays the role of a damper. When the volume of water decreases (consumed by consumers) and the pressure reaches the lower set limit, the pump turns on again and fills the hydraulic tank with water.

A hydraulic accumulator is selected based on calculations that take into account the number of residents, the number of water consumption points, the maximum permissible number of pump starts and its power, and the required pressure in the system.

Insufficient working volume of the tank will lead to constant activation of the pump and its wear. A container with a reserve threatens stagnation of water and a decrease in its quality, with a harmful effect on the inner surface of the membrane.

Pump station control unit

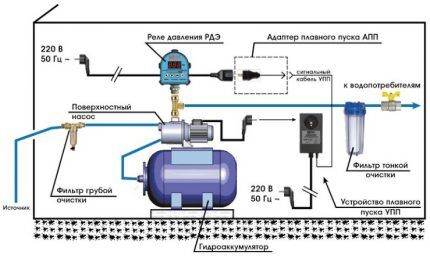

The standard set of pump station control devices consists of a fitting, pressure switch and pressure gauge and installed on the pressure pipeline.

The pressure gauge is used to monitor the current pressure in the system, and the relay is the most important element for controlling the pumping station. It controls the supply of water to the pressure tank according to specified parameters and ensures automatic operation of the pump, turning it on and off.

The main operating elements of the relay are the minimum and maximum pressure springs, which are triggered when the pressure in the network reaches the value specified by the settings. At low pressure, the spring opens and closes a contact that turns on the pump motor.

Exceeding pressure compresses it, and when the maximum threshold is reached, the contact opens. The pump turns off and the water supply stops.

The automation unit is a more complex device with advanced capabilities. In addition to switching electrical circuits when responding to increases and decreases in pressure, the automation unit protects the system from dry running.

When choosing a control device for stations pumping water from shallow excavations, it is better to give preference to the option with protection against dry running.

It will protect the pump from overheating and turn it off if for some reason (dirt has entered, the liquid level in the source has dropped below the intake unit) water stops flowing into the system.

The pumping station operates in cycles, each of which can be divided into two stages:

- The pump turns on and lifts water from the source. It fills the system and hydraulic tank until the pressure exceeds the upper threshold.After this, the pressure switch turns off the pump motor and the water supply stops. The pumping station goes into sleep mode.

- When consumers are turned on (opening taps, using water-consuming equipment), water comes from the hydraulic accumulator tank. Fluid flow from the hydraulic tank is carried out until the pressure drops to the lower threshold. This causes the pump to turn on again and the water to rise.

The number of cycles per hour must not exceed the maximum number of starts allowed for the pump used.

Advantages of using a pumping station

Installing an autonomous water supply in your home provides independence and comfort.

The pumping station provides the following advantages:

- Increases the efficiency of the water supply system.

- Increases the operational safety of equipment and pipelines.

- Provides a certain (depending on the capacity of the hydraulic tank) supply of water and its supply even when the power supply is turned off.

- Maintains constant pressure and stable water pressure.

- Increases the durability of appliances and household appliances connected to the water supply system.

- Automatic operating mode (timely switching on and off of the pumping unit) reduces equipment wear and energy costs.

- Possibility to choose the installation location of the unit.

- It has compact overall dimensions and light weight.

- Easy to install.

In rural areas, cottage and holiday villages, water supply communication networks often suffer from low pressure and unstable pressure.

In this case, the pumping station can be connected to an existing main water supply - this will solve problems with pressure drop and lack of pressure in the water supply.

Pump installation technology

Before starting installation work, it is necessary to decide on the location of the pumping equipment.

Step #1 - choosing a location

When planning the placement of the unit, it should be taken into account that:

- The location of the pumping station in close proximity to the water source ensures stable suction and smooth operation of the equipment.

- The installation location must be dry and warm, well ventilated.

- The equipment must not touch walls.

- It is necessary to ensure free access for repair work and preventive inspections.

The option of installing a pumping station with a surface pumping unit, especially with an internal ejector, should be carefully considered, since such a system has a high noise level.

There are several installation options. Let's look at them in more detail.

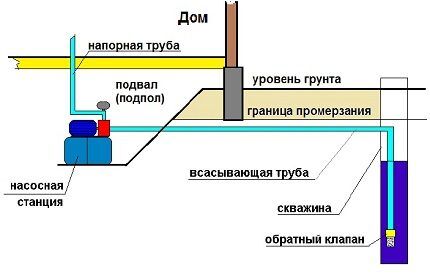

Option #1 - in the house

The most optimal place for the proper functioning of the station is a heated room. It is ideal if the house has a soundproofed boiler room.

An extreme option is to install equipment in common rooms (corridor, bathroom, hallway, pantry). But in this case, it is placed away from the bedrooms and sound insulation is provided - for example, by making a casing or cabinet.

Option #2 - in the basement

Quite often, a pumping station is installed in the basement or basement. However, care must be taken to create optimal conditions for placing the installation - the room must be sound, heat and waterproof.

You can arrange a special box in the underground, with access to the equipment through a hatch.

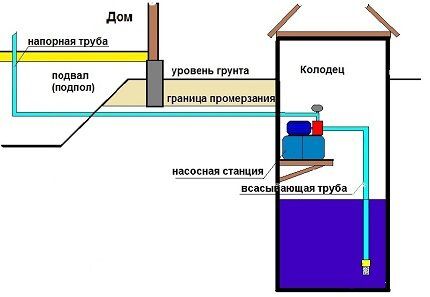

Option #3 - in a well

The pumping station is installed on a specially constructed platform in the well. The depth of the installation surface must be such that all equipment is below the freezing level. The well itself is insulated from above.

The disadvantage of this scheme is difficult access to the equipment.

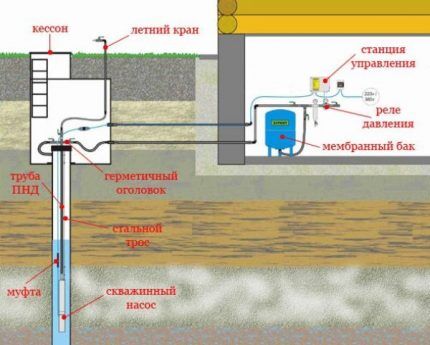

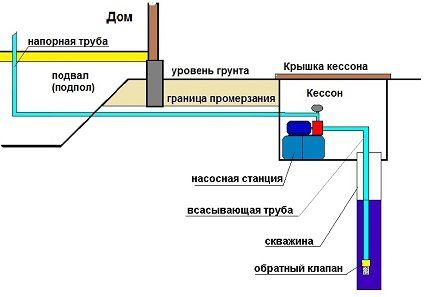

Option #4 - in a caisson

A room of sufficient width for subsequent maintenance is arranged around the well, buried below the soil freezing level. At the surface of the earth, the caisson is closed and insulated, leaving only a small hatch for maintenance.

The pit device will allow the use of a pump with a built-in ejector in cases where the depth of the water surface from the surface of the earth is 9-11 meters.

Option #5 - in a separate building or extension

In this case, no noise will be heard in the house. However, simply insulating such a room will not be enough; heating will also be required. This leads to additional costs for electricity and heating systems.

When installing a station with submersible pump There are no problems with sound insulation. All elements of the system, except the pump itself, are installed in any heated room of the house.

Having decided on the installation location of the pumping equipment station, we begin its installation.

Step #2 - carrying out preparatory work

Prepare a solid base for the pumping unit - concrete, brick or wood, and level the surface for installation. You can use a special metal bracket.

Since the pump vibrates quite strongly during operation, backlashes form in the pipeline connections and leaks appear. To reduce vibration, as well as its destructive effect, rubber pads or a mat are placed under the pump supports, and the installation itself is securely fastened - the legs are screwed with anchor bolts.

The main condition for the uninterrupted operation of a pumping equipment station is the unhindered flow of liquid from the source.

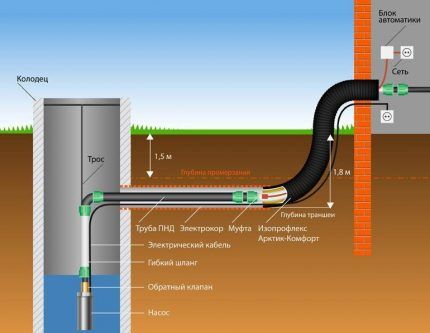

The main problem that needs to be solved with year-round water supply is frost protection. Therefore, a trench is dug under the pipeline - from the foundation to the well or caisson (pit) of the well.

The trench should be straight in plan, preferably without turns or bends, so as not to reduce the pressure. To prevent the effects of negative temperatures on pipes, they are buried below the freezing level of the soil in the area.

When forming a trench, it is necessary to take into account a slope of 0.03 towards the water intake to drain liquid from the pipeline during the conservation period.

In the case of closely located groundwater, the water supply system is laid above the critical level, but in this case it is insulated and an additional heating cable is used. Also, serious thermal insulation and heating will be required if the water supply is installed above ground level.

Step #3 - assembling the water intake unit

The water intake unit depends on the type of pump used.

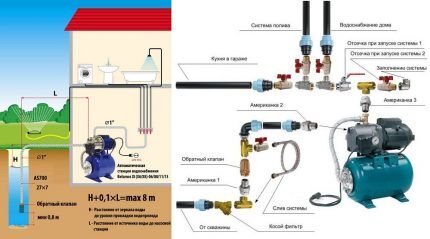

- With standard connection scheme – a station with a surface pump and a built-in ejector is a check valve with a mesh filter connected to a polypropylene pipe through a coupling.

- Installation with external ejector. A check valve with a mesh filter is screwed onto the suction compartment of the ejector, and two pipes are connected on top.

- When using a submersible (well) pump, a coarse filter is included in its design. Therefore, a check valve and a pipe are connected to the unit. The pump has a decent weight, so it is suspended on a strong cable.

The assembly is lowered to the required depth, taking into account that the minimum distance from it to the bottom of the source is 1 m when using surface pumps and 0.5 m for submersible (well) pumps.

It should also be borne in mind that the level of the water table changes throughout the year - in summer it decreases. If the suction depth is on the verge, then during this period you can completely lose the water supply.

Step #4 - installation of surface elements of the station

Fundamentally, the installation schemes for a pumping station will differ depending on which pumping unit is used.

The basic rule: any additional device is installed through American ball valves and check valves. This will allow devices to be removed for replacement or repair without having to drain all the water from the system.

It is also necessary to provide for the possibility of draining water from the system - for this, a branch is formed in the pipeline by installing a tee, to which a drain valve is connected.

It is advisable to install a coarse filter on the supply pipeline. On the pressure side (in the line leading to consumers) there is a fine filter.

Installation of a finished surface-type station is not difficult, since the main elements of the system are already connected to each other. It is a hydraulic accumulator with an electric pump and a control unit installed on it.

In addition to the main fittings, a device is installed in such a system to fill it with water before the first start-up. Similar to the drain device, a tee with a connected ball valve and funnel is inserted into the pipeline.

You can see more details about the features of choosing a pumping station and the rating of the best offers on the market according to equipment owners In this article.

In other cases, the system elements are installed independently. When installing a surface station, a pipeline (or two pipelines, if a remote ejector is used) from the well is connected to the pump.

Next, install the hydraulic accumulator and control unit.For a station with a well pump, these will be all the main surface elements in the circuit. The most convenient way to do this is to use a 5-pin fitting, which is mounted in the pressure pipeline in a convenient place. A pressure switch and pressure gauge are screwed into it.

A hydraulic accumulator is connected to the side entrance of the fitting. For ease of maintenance, it is connected through a ball valve with an American connection and a drain is arranged.

Connect consumers to the pumping station. Most often, the first element is the cold water distribution manifold.

Step #5 - first launch of the station

The electric motor of the pump has more power, so it is better to provide the pumping equipment station with its own power supply line, arrange grounding and install a voltage stabilizer.

Check the pressure of the air chamber of the hydraulic accumulator. It should be 10% less than the pump activation pressure. However, this setting is done in operating mode. First, it is necessary to achieve the following values: for a hydraulic tank with a capacity of 20-30 l - 1.4...1.7 bar, with a capacity of 50-100 l - 1.7...1.9 bar.

Before starting the installation with a surface pump for the first time, the working part of the system is filled with water. To do this, unscrew the plug from the filler hole located in the upper part of the pump.

If the pipeline has a filler funnel, it is better to use it. Pour in liquid until it is completely filled and begins to flow out. Then the hole (valve) is tightly closed.

Startup sequence:

- The pump is connected to the mains.

- The valve of the filling funnel of the pipeline with a surface pump is opened slightly to remove any remaining air that has entered the system.

- Turn on the unit - within 2-3 minutes water should flow from the outlet of the pressure pipeline (or an open water supply tap).

- If the liquid does not flow, the pumping equipment is turned off, water is added to the system and turned on again.

After a successful start, the equipment should be “run in” and, if necessary, the settings of the valve body and pressure switch should be adjusted.

Basic operating rules

After putting the pumping station into operation, periodic maintenance is carried out. It is necessary to clean the coarse filter promptly. Without this, the performance of the installation gradually decreases, the water flows in jerks, and a completely clogged filter will lead to “dry” operation and shutdown the system.

The frequency of purification depends on the content of impurities in the pumped water.

You can read information about common pumping station breakdowns and how to fix them in the next article.

Once a month, or after a long period of inactivity, winter conservation or repair work, check the pressure in the air compartment of the hydraulic accumulator. If necessary, air is pumped up.

When using the station only in summer, it is necessary to drain all water from the system before frost sets in.

Conclusions and useful video on the topic

The video will demonstrate the basic rules for connecting a pumping station:

Instructional video on setting up and operating a pumping station:

How to make a pumping station based on a submersible pump:

Correct installation of a pumping station provides a private home with water supply with parameters that are not inferior to a city apartment - constant pressure and sufficient pressure.

In order for the system to operate as efficiently as possible, before selecting and installing equipment, you should seek advice from a specialist and perform an evaluation calculation.

If you have experience in assembling and installing a pumping station yourself, please share your knowledge in the comments to this article. If you have any questions after reading the material, do not hesitate to ask them in the comments below.

I have encountered pumping stations three times in my life. Twice in rented apartments, and now self-made in my own home.

In the first case, there were constant problems with the hydraulic accumulator; the bulb was changed every year. The reason was never found out.

In the second rented house, the owners installed a station in the bathroom under the boiler. Over time, we got used to the constant noise, but I did not sleep peacefully. The vibration during pump operation is strong, the nuts constantly need to be tightened.

Now I have everything done correctly, but instead of a standard hydraulic tank with a bulb, I installed a sealed stainless steel box, and the pressure in the system is not satisfactory. I just can’t decide to buy a normal hydraulic accumulator. The watering season has begun, and everything will need to be redone in a new way, and it probably won’t work out quickly.

I installed a pumping station in my parents' house. They are already elderly, such conveniences will not be superfluous. I read a lot of material about how this is done and everything worked out.True, after a while the water began to flow in jerks, as if something was stuck there. My parents complained, but when I arrived, I still didn’t understand what the problem was. I had to call specialists. It turned out that the filter needs to be cleaned periodically. After cleaning everything worked like clockwork again.

I have a question: we bought a pumping station, connected it according to the entire circuit correctly, the pressure is normal. But it doesn’t lift water from the well.

Hello, Sergey. Please answer a few questions:

— What brand and model of pump do you have?

— Is the unit selected correctly taking into account the water level?

- What type of well do you have? rocked production before launch, did it work before?

— Is there a hum/knocking/creaking sound coming from the pump?

— Does the pump’s performance correspond to the well’s flow rate, the required pressure and the calculated water flow?

Happy New Year!