How to disassemble a submersible pump: popular breakdowns + detailed disassembly instructions

Your own well on the property allows you to use running water without any restrictions - you don’t need to choose a specific time to do laundry, take a bath, wash your car, or water the flower beds near the house. Agree, it’s great when water always flows from the tap without interruptions and there is no supply schedule/unscheduled shutdowns.

Problems with water supply may occur if the pump breaks down. Knowing how to disassemble a submersible pump, you can independently identify faults and fix them at home. We will talk about how to correctly diagnose a breakdown in this material. We will also consider in detail the instructions for disassembling the pump with your own hands, providing the article with step-by-step photos and useful video recommendations.

The content of the article:

Why does equipment break down?

A submersible well pump provides convenience and ease of use of the well. It lifts water from great depths to the surface, where it flows through communications to water intake points.

Produce household submersible pumps domestic and foreign enterprises. And although the pumping equipment is reliable, breakdowns may occur from time to time during operation.

The smooth and smooth operation of a submersible pump is often disrupted by the following reasons:

- high (more than 50%) concentration of suspended particles in water;

- “dry” operation, when the device operates without touching the water;

- voltage drops above the permissible level that regularly occur in the network;

- poorly secured cable connections;

- the unit cable is not correctly attached in the well head area;

- The submarine cable is not secured correctly.

Malfunctions are caused by the absence of a filter or its excessive contamination and unstable operation. pressure switch or poorly functioning hydraulic accumulator.

In the absence of grounding, electrochemical corrosion affects the metal elements of the equipment. The pump stops pumping water normally and requires immediate maintenance.

Very often, the cause of the malfunction is errors made by users during the process. pump installation and its operation. Manufacturers and service center employees recommend that customers, immediately before connecting devices, carefully read the instructions and strictly follow everything that is written there. This will avoid many problems and extend the life of the pumping equipment.

Troubleshooting overview and troubleshooting tips

Any changes in the operation of submersible devices clearly indicate problems and malfunctions. Such moments cannot be ignored. Timely repairs extend the life of the device and ensure its normal functioning in a mode convenient for the owners.

You need to think about servicing the pumping unit if the following points are found:

- a pronounced decrease in water pressure;

- increased noise from the well;

- intense vibration of the casing;

- pulsed flow of water from the tap;

- increased energy consumption;

- knocking out plugs when the unit is activated;

- humming of a switched-on engine when there is no bleeding.

In this case, you need to remove the submersible apparatus from the well using a safety cable, disassemble it, identify the area of problems and eliminate them.

Moreover, the same malfunction is eliminated differently for different types of pumping equipment.

So, depending on the design features and operating principle, submersible pumps can be:

- centrifugal - their main element is an impeller (“Aquarius”, “Vodomet”);

- vortex — similar to centrifugal ones, but they have a high circular velocity of the fluid (“Vortex”);

- vibration — in vibration machines the main element is the piston (“Baby”).

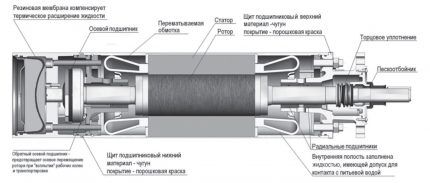

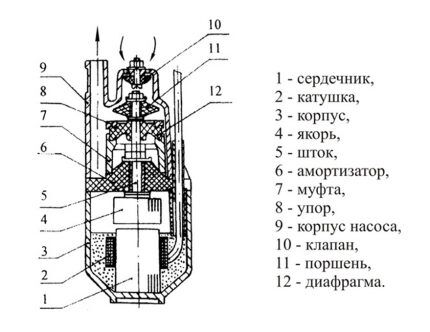

Before moving on to popular pump breakdowns, we suggest once again recalling their structure.

Next, we will consider a list of common breakdowns of vibration and centrifugal submersible pumps, as well as recommendations for eliminating them at home.

Problem #1 - the pump does not work

If the device does not function, the electrical protection may have tripped. It is necessary to disconnect the device from the power supply, and then turn on the automatic plug again. Then you need to connect the electric pump to the network.

If a phase is knocked out again, the problem should not be looked for in the submersible equipment, but carefully inspect the cable and fuses. In this situation, it is better not to connect the device to the network until the circumstances of the malfunction are clarified.

Blown fuses needs to be replaced immediately. If they burn out again, the reason lies in pump power cable or in the area of its connection to the electrical network. All these elements should be checked and any damage found should be repaired. Only after complete maintenance can the pump be used again.

Problem #2 - pressure drops

A significantly reduced level of water pressure in centrifugal models clearly indicates excessive impeller wear, silting or at its displacement along the shaft. This situation is also provoked by mechanical filter cloggedlocated on the suction pipe.

The solution in this situation is to thoroughly check the impeller, clean the impeller and filter, and replace the worn impeller.

A noticeable weakening of the pressure in vibrators is caused by a suction valve that has stopped closing or a deposit of silt and sand that has appeared on it. The same problem occurs when the piston of the vibration mechanism loses its elasticity. The cause may also be a loose piston, shock absorber or solenoid. All these nuances can be eliminated at home without much effort - just tighten the fasteners or replace the valve.

Or the reason for the drop in pressure in vibration and centrifugal pumps may be even simpler - low voltage in the network. In this case, installing a stabilizer will not hurt.

Problem #3 - pulsed water supply, noise and vibration

Increased noise from the well indicates shaft failure or loosening the nuts, fixing the position of the rod on the shock absorber in the vibration pump. In the first case, the shaft needs to be replaced with a new one, in the second, the loose fasteners must be tightened with a handy tool.

If the pump begins to vibrate strongly and this is reflected in the casing, it may be faulty shaft or stock. The equipment should be removed, disassembled and damaged parts repaired. In case of fatal damage, replace with new ones.

Problem #4 - excessive energy consumption

If you notice an unexpected increase in your electricity bills, you should pay close attention to your submersible equipment. May need impeller balancing submersible centrifugal electric pump.

Either silt or sand got into the housing and this caused mechanical friction. The load increased, and the unit began to consume more electricity to pump a standard volume of water.

Increased consumption could be caused by worn-out screw cavity And bushings on the shaft of the screw unit. They must be replaced with new ones as quickly as possible and the pump will return to operation as before.

Problem #5 - constant traffic jams

Always triggered protection when the submersible vibration pump is turned on (knocking out plugs) - result violations housing tightness engine compartment. Moisture that gets inside has a negative effect on the control electronics and interferes with normal operation. The result is often a short circuit, followed by additional problems, even burning out the equipment.

Also, the reason for knocking out the plugs may be a break/short in the cable or coil of the electromagnet, overheating of the electromagnet due to low voltage in the electrical network, or false operation of the plugs. In this situation, you will have to replace the cable or coil (depending on where the fault is found), check the plugs and replace them if necessary, and install a stabilizer.

A short circuit triggers the protection of centrifugal pumps stator windings or anchors electric motor and jamming device with various debris particles. To fix the problem, you will need to clean the unit from possible blockages, take it to a service center for rewinding, or install a new coil.

Problem #6 - the pump hums, but does not pump

When a submersible pump hums loudly but does not pump water from the well into the communication system, there may be several reasons. May be, network voltage dropped and the equipment simply does not have enough power to start normally. If voltage drop is typical for your region, it makes sense to play it safe and install stabilizer.

Other possible causes for centrifugal models: wear or silting of the impeller, loosening of the impeller to the shaft, clogged coarse filter, breakage of the key connecting the impeller to the shaft. Also, if the pump has been stored for a long time without water, the impeller may “stick” to the housing. Or dirt accumulates in the housing and the device jams.

To eliminate these breakdowns, you will need to clean all contaminated elements, replace faulty ones with new ones, and tighten the fastenings.

The same problem with the hum of an electric vibration pump can occur due to: wear of the valve or piston, displacement of the electromagnet, crumpling of the shock absorber and loosening of its fastening. Repair work in this case will consist of replacing worn parts, tightening fasteners, installing the electromagnet and shock absorber in place and securing them securely.

To troubleshoot problems, the equipment will have to be removed from the well, carefully inspected and repaired.

Detailed instructions for disassembling the pump

To identify and troubleshoot a submersible pump, it must be disassembled into its component elements. To do this, you will need a spacious workplace and a stable wide table, a vice, Phillips and flat-head screwdrivers, a set of keys and pliers.

The disassembly process is not complicated, but it requires precision, thoroughness and attention.

It is carried out step by step in a certain order.

When the pump part and the engine compartment are separated from each other, troubleshooting is much easier and more convenient.

Subtleties of disassembling the pump section shaft

To accurately determine the location of the problem, try to rotate the shaft of the pump section. If this is not possible, then that is where the problem lies.

Upon completion of activities related to repair/replacement/maintenance of the pump part, reassemble the equipment, carefully following the instructions. Then connect it to the engine and return it to the workplace.

Step-by-step process for disassembling an electric motor

If the problem area cannot be identified in the two steps described above, there is a good chance that it lies in the engine. To finally make sure of this, you need to take the following important steps.

Assemble the engine block following the instructions in the instructions. Make sure that all parts are in their original places.

Typical breakdowns of pumps of different brands

Equipment from popular domestic and foreign brands has its own characteristic failures. Devices from a Danish manufacturer Grundfos, despite the reliability and endurance, they need regular replacing mechanical seals. If this is not done in a timely manner, water will penetrate inside and damage the winding.

It is not advisable to service the unit at home. The specific design requires that repairs be carried out by an experienced specialist, ideally an employee of a company service center.

For units Gilex often fluid leaks from the motor. It can be replaced, but only with a similar composition.

Some craftsmen believe that it is not necessary to buy an expensive substance. You can get by with glycerin or transformer oil. However, this is not the best advice. The equipment does not tolerate filling with alternative means very well and can completely fail after such an operation.

It is better not to repair the device yourself, but to entrust this task to qualified specialists. They are guaranteed to fill the engine with the original composition and do so in strict accordance with the manufacturer’s wishes. After servicing it will work just as well as on the first day of purchase.

In devices "Baby" Russian enterprise Livgidromash often fails coils. Dry work provokes this problem. A loud noise when turned on without pumping water indicates break of the central axis, to which membranes with an anchor are attached. This breakdown is easy to detect after disassembling the unit.

Replacing an axle even at home is not difficult. But finding a part on sale is really a problem.

Pumps "Aquarius" have the property overheatI. This drawback is especially active when the equipment operates in shallow wells. Repairs are expensive and sometimes amount to about 50% of the original cost. In such cases, many users prefer to buy a new device, albeit from a different manufacturer.

The same problem is typical for models "Stream". Despite the modern design and compliance with current European standards, they do not tolerate continuous operation very well.

The manufacturer says that the devices can continuously pump water for no longer than 7 hours. However, almost always such a load leads to overheating. To avoid problems, it is better to take breaks and let the equipment rest every 2-3 hours. In this way, the service life of the pump can be extended.

Pump equipment "Water cannon" It is considered to be quite reliable and operationally stable. Most breakdowns here occur due to improper use. Also, when equipment comes into contact with contaminated water, it quickly becomes clogged with silt and sand. In this case, the pump part of the unit requires replacement.

When a problem cannot be solved at home, you should seek help from the professional technicians of a certified service center. They will quickly determine what happened to the equipment and restore its functionality. Or they will recommend purchasing and install a new pump, if the old one cannot be repaired or it is not economically profitable.

Conclusions and useful video on the topic

This video describes the process of disassembling a submersible pump. How to do everything correctly and what tools are required for this, see below:

The pump is clogged with sand and does not pump water. The following video will tell you how to deal with one of the most common problems of pumping equipment:

The pump in the well turns on, hums, but does not pump water. The two most common causes of this problem are discussed in the video below:

Knowledge about the rules for disassembling submersible pumping equipment will definitely be useful to owners of private houses with wells. By focusing on popular pump malfunctions, you can recognize the type of breakdown and fix it yourself. This is convenient when the service is far away, and the pump, for certain reasons, works intermittently and does not allow comfortable use of water.

Have you encountered a pump breakdown that we did not mention in this material and want to share your experience of repairing it? Tell us about it in the comments block, add photos demonstrating the process of fixing the breakdown - our readers will be grateful to you for your help.

Or do you need help diagnosing a problem? Ask your questions to our experts - use the feedback form below.

Patriot 3250, I pumped water into the hydraulic tank for a long time (1.3 years of use), took it out, the studs were rotten, pumped it half-folded, on one stud. I can’t unscrew one, I’m waiting for the oil to penetrate inside, I’ll look for other suitable studs (bolts). Poor quality bolts are my conclusion.

Patriot 3250, I pumped water into the hydraulic tank for a long time (1.3 years of use), took it out, the studs were rotten, pumped it half-folded, on one stud. I can’t unscrew one, I’m waiting for the oil to penetrate inside, I’ll look for other suitable studs (bolts). Poor quality bolts are my conclusion..

Can anyone tell me how much oil should be poured into the motor of a submersible pump with a diameter of 75 mm, I accidentally spilled it and I don’t know how much, there are some marking parameters by which you can determine the level

Thanks in advance for anyone who responds