Do-it-yourself repair of the Aquarius pump: overview of typical breakdowns and their elimination

Pumps of the Aquarius brand are the most reliable equipment, actively used in private households and at dachas.Its significant advantage lies in the simplicity of its design: most breakdowns can be eliminated without contacting a service center. However, it is not worth taking on such a serious matter without theoretical preparation. Do you agree?

For those wishing to repair the Aquarius pump themselves, we are ready to help in solving this difficult task. The article we have presented introduces in great detail the nuances of diagnostics, identifying irregularities in operation, and methods for restoring technical capabilities.

We describe in detail the specifics of the pump design and the rules for assembling/disassembling the unit. The process of performing repair operations is thoroughly analyzed. Photos, diagrams and videos are used as valuable information supplements.

The content of the article:

Typical design of the Aquarius pump

Design centrifugal pump “Aquarius” not overly complicated. The motor and pump part are enclosed in a long narrow stainless steel housing.

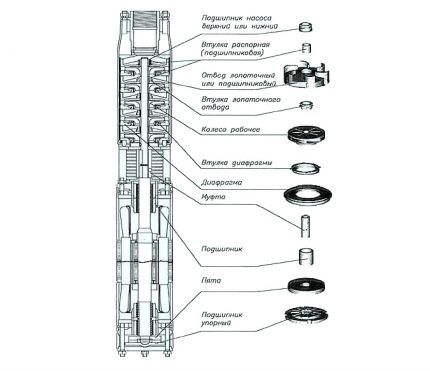

A drive shaft is attached to the motor located in the lower compartment of the device. The elements of the pump part are sequentially placed on it: blades, drive rings and impellers.

The position of the elements is fixed by a clamping cover with an internal threaded connection. The oil-filled single-phase motor contains a rotor, a stator and two bearings.

A reliable automatic control unit is provided for efficient pump control. An external device is attached to the power cord, with which you can adjust the operation of the device.

The minimum diameter of the well in which “Aquarius” can be used must be at least 120 mm. The depth of water supply can vary between 1-20 m.

Through a three-quarter-inch hose connected to the pump, the consumer can receive up to 120 cubic meters of water per hour. To regulate the water pressure in the system, a special valve is provided at the outlet of the working hose.

Common causes of breakdowns

“Aquarius” is successfully used not only in wells, but also in wells, natural reservoirs and large containers that meet the operating conditions declared by the manufacturer.

Pumps of this type are quite successful in pumping water that is significantly contaminated with sand. Unfortunately, violation of operating rules leads to frequent breakdowns of the device.

Among the factors causing malfunctions are:

- prolonged work with liquids whose contamination level exceeds half of the limit declared by the manufacturer (no more than 20 g/l is allowed);

- pumping hot liquids (if the ambient temperature is more than 35 degrees);

- frequent and sudden changes in voltage in the electrical network;

- violation of the integrity of the fastening at the installation site of the electrical cable or in the shell of its underwater part;

- flaws when hanging the pump;

- no filter;

- lack of grounding;

- malfunction of the pressure switch, hydraulic accumulator, etc.

Obviously, the duration of the pump’s operation is affected not only by its operating conditions, but also by the condition of the house’s plumbing system as a whole.

A number of serious problems can be avoided if you take care of correct installation of the pump. Great importance is attached to the immersion depth of the pump. If this figure is exceeded, the device will work with constant overload and will soon break down.

It is extremely rare, but situations still occur when the water in which the pump is immersed freezes. This is very dangerous for the device because water expands when it freezes. As a result, pump components may be damaged.

If the device is stored at temperatures below zero, all moisture must be thoroughly removed from the device.

In order for the pump to work correctly, you should choose a model that exactly fits a specific well. You can read more about how to choose a pump for a well in our other article.

First of all, you should focus on the well's flow rate. It should significantly exceed the pump performance.

The fact is that many wells are prone to silting or sand accumulation.

As a result, their debit is noticeably reduced. If the pump capacity has been precisely matched to the well flow rate, a dangerous situation may occur.

The pump will pump water out of the well faster than it comes in.The well will be empty, and the equipment will run idle, in the so-called “dry running” mode. This is fraught with overheating and complete breakdown of the device’s engine.

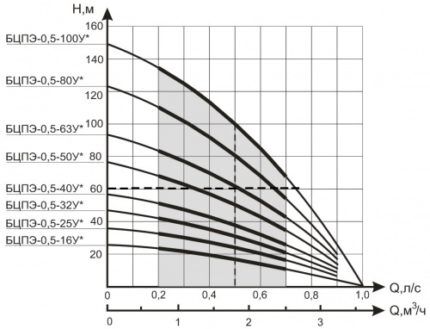

The second important factor is the nominal pressure that the pump in the water supply system must provide. For different modifications of the Aquarius it can be either 32 m or 63 m.

The nominal value includes transportation in horizontal sections of the water pipeline and pressure loss when water passes through the pipeline.

A correctly selected pump will not be subjected to excessive overload; under such conditions, the device will last longer and work more efficiently.

Disassembly, assembly and repair

So, the pump is not working, has stopped pumping water, or is simply showing a sharp decrease in performance. First, it should be disconnected from the power supply and water supply system, and then removed from the well.

You may find information about how to remove the pump from the wellif he's stuck there.

Simple diagnostics will help you understand in which part of the device the breakdown occurred.

To do this, the pump is briefly plugged in and listened to. If the unit hums, most likely its pumping part is faulty. This is not the most difficult type of breakdown. But the absolute silence of the device indicates a high probability of problems with the electric motor.If the magnet burns out, the entire motor will have to be replaced.

If the damage is too serious, you may need information on how to properly replace broken pump new.

Another stage of diagnosis is examination of the device shaft. You just need to scroll it by hand. If the shaft moves smoothly, everything is fine in this department.

If you have to make a noticeable effort to scroll or it doesn’t move at all, most likely the device is clogged with sand and needs to be washed.

The pump is flushed as follows:

- Remove the protective metal mesh.

- Dismantle the cable channel (for large cross-section models).

- Unscrew the four mounting bolts.

- Take out the engine.

- Remove the plastic transmission couplings.

- Carefully turn the shaft using the end part of the 12 mm wrench, while holding the upper part of the pump stationary.

- When the shaft rotates a little, a stream of water from a hose is applied to the pumping part.

- The washing is continued, combined with careful turns of the shaft until the shaft begins to move freely.

After this, the washing can be considered completed, the device is assembled in the reverse order and turned on. In order for reassembly to be completed correctly, you should remember the position of all parts during the disassembly process.

The pump will also have to be disassembled to carry out various repair work. In service centers, a special press is used for this, but in a home workshop you will have to make additional efforts and use improvised tools, for example, a jack.

Even before starting work, it is necessary to learn how to properly disassemble the Aquarius pump.

To do this, perform the following operations:

- Remove the pump from the well.

- Disconnect it from the power supply.

- Remove the water supply pipe.

- Firmly compress the pump housing at its bottom and top.

- Support the bottom edge of the device on a sturdy base, such as a table or workbench.

- Remove the retaining ring from the groove using a suitable tool such as needle nose pliers.

- Remove the impellers one by one.

- Remove the bearing assembly with the thrust cover on which it is located.

- Inspect all pump components for wear and damage.

- Replace all damaged parts.

- Reassemble the device.

The edges of the pump housing should be clamped in such a way as to loosen the clamping ring. Once this part is dismantled, the remaining operations will no longer require excessive effort.

In order not to confuse the reassembly sequence, it is best to provide a place in advance for the removed parts. They are laid out in order, while maintaining the correct position of the working rings relative to the concepts of “top” and “bottom”.

During reassembly, you should pay attention not only to the correct position of the working rings, but also to their position relative to other parts.

Once all the elements are assembled, the impellers should still be able to rotate freely. Contamination of the pump with foreign particles of sand or silt can cause another unpleasant breakdown.

If the shaft of the switched-on device was jammed, and after that the engine did not turn on, the stator winding may have burned out. Eliminate such a malfunction, i.e. Rewinding an engine at home is not easy. It makes sense to entrust this operation to experienced specialists.

If the winding is fine and the engine still does not start, the problem may be with the capacitor or the condition of the electrical cable.

With a capacitor, everything is relatively simple: the damaged element is dismantled, and a new, working one is installed in its place. You should also check the contact points between the electrical cable and the engine, as well as the integrity of the cable itself.

Sometimes it is enough to simply re-solder the contacts. If there is a break in the electrical cable, you need to determine the location of the break and eliminate the fault. The repair site should be additionally protected with a special heat-shrink sleeve.

But the repaired cable, to a certain extent, remains a “weak link”. It may make sense to replace the damaged cable with a new, solid wire.

During disassembly, repair work and reassembly, it is recommended to keep the engine in an upright position to prevent oil from leaking out of the engine.

Sometimes problems with the motor of Aquarius pumps arise not due to a lack of voltage in the network, but due to its surges. To solve this problem you should use an autotransformer or Voltage regulatorby connecting it to the network.

This measure can be taken even at the pump installation stage, so as not to eliminate breakdowns caused by poor-quality power supply, but to prevent them.

As a result of a sharp decrease in network voltage, a noticeable decrease in pump performance may be observed. As soon as the power supply returns to normal, the pump will work at full capacity.

If this does not happen, perhaps the decrease in the pressure of water supplied to the system is caused not by pump failure, but by a malfunction of the water supply pipe.

In this case, you should remove the pump and carefully inspect the pipe to identify breaks and repair them. In addition, it is also necessary to check the integrity of the connections between the pipe and the pump nozzle, head adapter, etc.

A decrease in pump performance can also be observed in cases where the filter holes become clogged.

Simply cleaning and rinsing the filters will usually solve the problem. If, after cleaning the filters, the pressure in the system has not been restored, you should look for other faults.

You may be interested in our other article about manufacturing a filter for a well.

An indicator indicating problems with the pump may be frequent tripping of the RCD.

The picture looks like this: the pump turns on, runs for a short time, and then turns off automatically. This situation indicates that there are problems with the stability of the voltage in the network, or that the device is clogged with sand and needs to be flushed.

Regular pump maintenance

Proper care of the Aquarius pump will minimize the likelihood of sudden breakdowns. To do this, the pump must be removed from the well for inspection. Raise and lower the pump carefully to avoid damaging the casing walls and the pump casing.

This is a labor-intensive procedure, especially if we are talking about a large immersion depth, but experts still recommend performing a diagnostic inspection of the pump twice a year.

First, an external visual inspection of the pump housing is performed. Identify possible chips, cracks, traces of corrosion and other damage.

If this step is neglected, damage may become even more serious when disassembling the pump. When external damage is detected, action should be taken to eliminate it, for example, by cleaning and treating areas that have been corroded with special compounds.

After this, remove the engine compartment cover. Here they check how freely the motor shaft moves. If its rotation is difficult, it is necessary to rinse the device from contamination, as described above.

During the diagnostic inspection, the condition of the bearing and seal is also checked for wear. If necessary, they are replaced immediately.

Another important procedure is replacing the pump lubricant. In this case, you should use only those lubricants recommended by the manufacturer.

If a pump located in a well breaks down, these substances can leak out of the housing. The entry of foreign oily impurities into water can significantly deteriorate its quality.

Some good advice

High purity vaseline oil is used as a lubricant in Aquarius pumps.

This composition is used in pharmacology for the manufacture of ointments. In this case, the manufacturer hides the name of the company supplying this product.

In total, the Aquarius pump engine contains about half a liter of Vaseline oil. But to restore the lubrication, it is better to contact the manufacturer to avoid contamination of the well with technical oils. Authorized service centers usually provide this service without any problems.

If the Aquarius pump is intended to be used in an automated water supply system, it is imperative to install check valve. The device is not equipped with this element; it will have to be purchased separately.

It is recommended to give preference to a valve equipped with a brass flapper. Such devices are characterized by increased wear resistance and a longer service life.

If the pump will only be used for irrigation, there is no need to purchase and install a check valve. In this case, you can block the flow of water into the hose. In this case, the pump will operate at idle speed; the device is designed for such loads.

If there is a need to replace the capacitor, it will be useful to consider the following information. “Aquarius” pumps use devices with a capacity of 14-80 uF, designed for 400 V. This is a bipolar dry capacitor made in the Czech Republic, the dielectric component of the device is polypropylene.

Depending on the model or time of manufacture of the pump, a capacitor from TESLA, AEG, Gidra, etc. may be installed in it. Models with both wired contacts and petal contacts were used.

All this allows us to conclude that similar models from any manufacturer are suitable for Aquarius pumps if their characteristics meet the specified technical requirements.

Water pipes in a self-contained water supply system usually use either half-inch or three-quarters of an inch. But the pump or pipe that connects to the pump outlet must be at least one inch in diameter.

These sections of the water supply can be connected using an adapter. When using a pipe with a smaller diameter, a slight decrease in pump performance may be observed.

Some amateur craftsmen tried to reduce the performance of an overly powerful pump by removing part of the working rings. Such actions can be fatal to the device. It is best to initially select equipment with the required performance.

Conclusions and useful video on the topic

The process of disassembling, reassembling and repairing the Aquarius pump is clearly presented in the following video:

The procedure for inspecting and cleaning a device that has worked in a well for 11 years can be viewed here:

An interesting experience in changing the oil in the engine of the Aquarius pump:

You should not disassemble the pump without first studying its structure and operating procedure. The result can be even more serious damage than what an amateur repairman is trying to fix.

Care, accurate knowledge and common sense usually lead to positive results when repairing this reliable and effective device.

Are you familiar with pump malfunctions firsthand? Or do you have experience in repairing its individual components yourself? Please write about this in the comments to our article. Many Aquarius owners may find your recommendations for troubleshooting useful.

Aquarius pumps usually do an excellent job of their intended purpose. However, the weak point in their design is precisely the abrasion of the plastic working rings. Fortunately, they can be found on sale and purchased for independent replacement. From my own operating experience, I know that this pump does not tolerate power surges well, which often happens in our rural areas. To avoid this problem, at the dacha I connect the pump through a stabilizer.

Good afternoon. Pump Aquarius BCPE 05-32U, 650W. Please tell me the correct assembly of pump impellers. When disassembling, there was a stainless steel plate under the plastic stop, and a plastic impeller underneath. Although in all the photos that I found it was the other way around (a stainless steel ring completes the cassette). Couldn't the manufacturer have assembled it incorrectly? Or are these build options? In addition, the pump worked for 6 years without any issues....

Thanks in advance.

Good afternoon. Yes, that's right, you found the right photos. The impeller is assembled in the following sequence - blade outlet, impeller, stainless washer. As far as I know, there is no alternative assembly.

There can be many options why the assembly turned out to be incorrect - perhaps it was assembled incorrectly at production, perhaps someone got into it before you purchased the pump. It is possible that you were not entirely careful during the analysis and confused the details yourself.

In any case, the fact that such a pump worked for 6 years without complaints and with adequate efficiency cannot be called anything other than luck.

Good afternoon, please tell me, between the pump and the engine there is an insert made of non-ferrous metal, there is a retaining ring in it, and this insert has shattered. Is it really possible to find it and what could it be called? Thank you.

Hello. Please tell me what to do if I bought an Aquarius pump NVP 0.32-63u and installed it according to the installation procedure, but it hums, the pressure doesn’t seem to be low, but when I open two outlets it drops decently, but the main reason is the increased sound, since it’s standing at me in the basement. Tell me how to act in this situation

Does anyone know the resistance of the starting and main windings of the Aquarius pump, the color marking of the wires and the circuit diagram of the capacitor box? Thank you in advance.

Hello, please tell me what is the resistance on the stator winding Aquarius 40 75