Homemade garage heater: how to make a device with your own hands

Rarely does anyone provide for heating when building a garage.Therefore, during operation, the premises have to be heated independently. Agree, buying heating devices for periodic use is sometimes costly and impractical.

Some craftsmen make the unit themselves, using inexpensive materials. We invite you to familiarize yourself with the three most popular solutions for organizing individual heating.

Before you make a homemade garage heater, you need to understand the operating principle of each unit, its structure and study the assembly procedure.

The content of the article:

General recommendations for creating devices

In an effort to save on expenses, many owners, when choosing among heater options, are in no hurry to purchase ready-made factory models.

After all, if you have the desire and the appropriate skills, you can always construct a heating device on your own.

At choosing a heater for the garage, which you can do yourself, many are guided by two parameters:

- The heating device should be easy to activate, quickly warming up the room.

- The device must have a simple design, devoid of complex parts and elements.

- Operation of the device must be carried out with minimal financial costs.

All these requirements are met by three options for the homemade heaters described below, which operate from different energy sources: gas, solid fuel and electricity.

The safety of the device is also important. Therefore, regardless of the heating method in the garage, it is necessary equip a ventilation system. After all, a decrease in the amount of oxygen and the accumulation of combustion products poses a risk to human life.

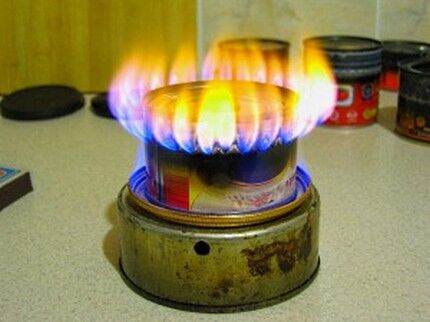

Homemade gas heater

The main advantage of this model is that its production requires a minimum of parts, which can always be found in the household of any craftsman.

The only disadvantage of a gas heater is the need to provide sufficient ventilation.

Preparation of materials and components

To make a gas heater for the garage, you need to prepare in advance:

- burner with valve;

- tin sheet;

- metal scissors;

- drill with a thin drill bit;

- rivets;

- riveter.

To make the grille, you will need a piece of fine-mesh metal mesh. It’s great if you have a regular wire colander sieve on hand, it will act as a protective grid.

Collet cylinders are convenient because when using them, you don’t have to use up all the contents at once. The presence of shut-off valves allows the devices to be used repeatedly.

If desired, the heating structure can be made using not only disposable cans used for refilling lighters, but also using a small refilled cylinder.

Cutting blanks and assembling the structure

When making the structure, the first thing to do is fix the heater to the burner.

Four rectangular ears are added in the direction of the four sides of the workpiece applied to the galvanized sheet. One of the ears should be made twice as long as the others. The blanks are cut along the intended contour, trying to make smooth, burr-free cuts.

The burner is screwed to the cut-out tin blank using bolts. The ears located on four sides of the workpiece are bent in the opposite direction and used to fix the strainer.

To attach the second protective mesh, take another piece of sheet metal and cut out a circle of exactly the same size from it. Elongated ears are added to the workpiece, necessary for attaching the mesh.

Stepping back half a centimeter from the edge of the circle, drill 10 through holes along the circumference. A strip is cut from a piece of fine-mesh metal mesh, the length of which corresponds to the diameter of the cut tin blank.

The bent ears of round tin blanks are fixed to opposite sides of the mesh strip using a riveter and rivets. When assembled, you should get a cylinder with mesh walls and tin ends.

The design, which includes two meshes, is advantageous in that it has an increased heating surface and is equipped with additional protection.

At the final stage, all that remains is to turn on the gas water heater and check its performance. The heat produced by this small device is enough to heat a small room or garage.

Potbelly stove from a used cylinder

Potbelly stoves, popular a hundred years ago, still hold their ground today, serving as the main source of heat in garages and utility rooms. And their main advantage is that they can work not only on wood, but also on anything that burns.

The minimum thickness of the walls of such structures should be 2-3 mm, but still the optimal option is 5 cm, thanks to which it will be possible to use any type of fuel. If we compare horizontal and vertical models, the former win in terms of ease of loading logs.

Vertical design

The simplest option for making a potbelly stove involves using a gas cylinder: the body of the heating structure is already ready, all that remains is to equip the compartments for storing fuel and the ash pan. The height of the cylinder is about 850 mm, the diameter in circumference is 300 mm, and sufficient wall thickness allows the use of any type of fuel.

To build a vertically installed structure, the cylinder is divided into two parts unequal in volume:

- top – occupies 2/3 of the structure and serves as a receiving chamber for laying firewood;

- lower – occupies 1/3 of the structure and serves to collect ash.

To make a potbelly stove, holes are cut in the wall of the cylinder to suit the size of each of the two sections for the arrangement of doors. The doors themselves can be constructed from a cut-out piece of a balloon wall or cut from sheet metal.

Grate bars are installed at the border between the upper and lower compartments. But since it is difficult to find a ready-made cast iron grate of a suitable size, thick rods are used to make it.

A hole for the chimney with a diameter of at least 150 mm is cut out in the upper part of the cylinder. This element can be welded from a piece of sheet metal. The main thing is that the diameter of the resulting pipe matches the size of the chimney in order to simplify the joining process.

The doors are equipped with locks and attached to the body by welding. If desired, the loops can be made from several links of a thick steel chain.

To close the gap formed around the perimeter of the doors, it is better to weld a small side - a strip of metal 1.5-2 cm wide - on the outside along the perimeter of the workpieces. All that remains is to connect the finished structure to the chimney and carry out tests.

Model with horizontal body

When the housing is positioned horizontally, the ash collection compartment is welded to the bottom of the structure. The main compartment is designed for loading fuel and unloading burnt coals. It is equipped with a chimney pipe with a diameter of 10 cm.

A hole is made in the side wall of the housing to install the combustion door. Its size should not exceed the diameter of the chimney pipe. The door itself is equipped with a latch and installed on hinges.

Holes are made in the wall of the housing, which will be directed downwards. They will perform the function of a grate.

To improve the heat transfer of a hot stove, the chimney can be made in the form of an elongated broken structure. The main thing when arrangement of a potbelly stove chimney – avoid horizontal areas. To improve room heating, some craftsmen build casings made of sheet metal around the cylinders.

But do not forget that a potbelly stove carries potential danger. Therefore, the room where it will be installed should be periodically ventilated.

On our website there are several articles on making a potbelly stove with your own hands. We advise you to read:

- Do-it-yourself potbelly stove from a gas cylinder: diagrams, drawings + step-by-step guide

- Do-it-yourself potbelly stove: diagram of a homemade potbelly stove for a summer house and garage

- How to make a potbelly stove using waste oil with your own hands: options and examples of making a stove

Making a tabletop fan heater

This type of device is a heater and fan rolled into one. If desired, homemade fan heater can be used as an improvised air conditioner.

This type of heater is convenient because it allows you to regulate the heating temperature and the rotation speed of the cooler.

Selection of required materials

To create a fan heater you will need the following materials:

- rheostat;

- switch;

- power connector;

- electrical wire;

- LED Strip Light;

- 12 Volt computer cooler;

- three-amp 12-volt power supply;

To fix the heating element, you will also need two ten-centimeter rods of copper wiring with a cross-section of 1.5 sq. mm.

The tools you need to prepare are:

- jigsaw;

- hammer drill or drill;

- soldering iron;

- hole saw;

- glue for woodworking;

- “moment” or superglue;

To clean wooden workpieces, removing burrs along the edges, you will also need fine-grained sandpaper.

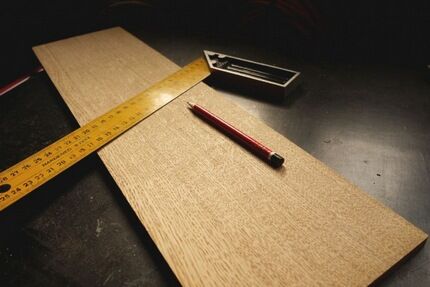

Assembly of body parts

The future heater will have the shape of a cube. The body of the device is assembled from wooden boards 9 mm thick.

Need to cut:

- two square blanks measuring 12*12 cm;

- 3 parts measuring 10.2*10.2 cm;

- two rectangular blanks 12*10.2 cm;

- four small rectangles measuring 1*1.5 cm.

To make the legs of the structure, 2 pieces, each 3 cm long, are sawn off from a wooden stick D12 mm.

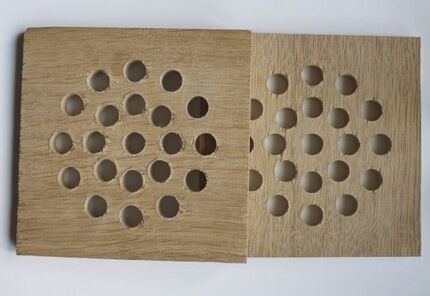

To simplify your task, make paper patterns, the dimensions of which correspond to the dimensions of the blanks 12x12 cm. Marking the location of the holes is applied directly to the patterns. They are applied to each side and drilled through.

In a workpiece 10.2*10.2 cm, maintaining a distance of 2.5 cm from the edge, make a hole D7 mm. On the second similar workpiece, two similar holes are made, maintaining a distance of 2.5 cm between them. On the third workpiece, 10.2 * 10.2 cm, a through hole of D9 cm is made in the center.

In each of the four rectangular blanks measuring 1 * 1.5 mm, holes D5 mm are made.

On the long side of a rectangle measuring 12*10.2 cm, moving 1.2 cm from the edge, make two holes D12 mm, maintaining a distance of 7 cm between them.

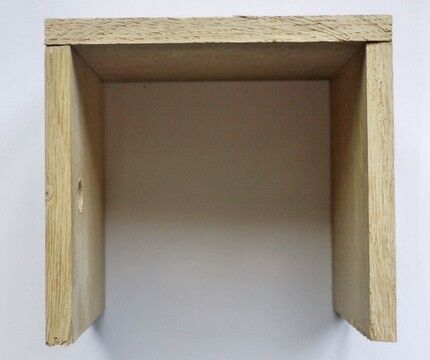

A square blank with a 9 cm drilled hole is installed inside the body. After this, the last rectangular part is attached, closing the body of the structure. At the final stage, the legs are glued.

Installation of heating elements

A spring stretched between two copper rods will act as a heating element. To determine whether the spring is suitable, you need to connect it to a 12-volt power source and take measurements using a multimeter.

So, to create a warm flow, it is enough if the multimeter readings are 2.5 A. With such parameters, about 30 V of heat will be generated with a power supply of 12 W.

The selected spring is soldered to copper rods, the ends of which are fixed to blanks measuring 1x1.5 cm. The assembled structure is glued to the corners of the body. The bare “tails” of the electrical cable are soldered to the ends of the rods. After this, a bar equipped with holes is attached.

Having fixed the cooler inside the case, the same manipulations are performed with the rheostat, switch and power connector.

If all structural elements are connected correctly, then when the rheostat is turned on, a blue light will light up on the LED strip. When the switch is turned on, the LED strip will acquire a red tint, which will create a violet color against the background of the main blue. After this, the heater spring will begin to heat up.

The assembled structure from the outside can only be sanded and treated with wood wax, or varnished in 2-3 layers.

Thanks to its presentable appearance, such a heater can be safely used not only for heating a garage, but also when arranging living rooms.

Alternative options for economical garage heating are described in this article.

Conclusions and useful video on the topic

Guide to Building a Compact Heater:

Option for making a homemade mini-stove:

What type of heating system to use is up to the owner of the premises to decide.With the proper skill and the ability to spend a little time, you can assemble any garage heater yourself.

Do you have personal experience with heating a garage? Do you want to share effective methods or talk about a homemade heater? Please leave comments and attach photos of your products - the feedback form is located below.

A potbelly stove made from a gas cylinder is a good thing. I have personal experience in manufacturing. I converted the gas cylinder into a regular stove: inserted grates, an ash vent, and made a door. But he reduced the combustion chamber by making a partition according to the scheme of a pyrolysis boiler. In this way, the wood combustion chamber was reduced and a chamber was created for afterburning the fuel. At the same time, smoke has decreased and the efficiency of firewood has increased. I plan to modernize it a little more: wrap it with a sheet of metal at a distance of 4-5 cm for fire safety and air convection.

So many interesting and simple ideas. I especially liked the design of the heater made from a horizontal cylinder, it was simple and extremely fast. And the resulting heater does not take up much space. I have already seen such options, but here it is described in detail how to do it easier, and with a minimum of fuss. I have just such cylinders, but smaller in diameter. I'm trying to do something, let's see what happens.

Yeah, just saw the sticks 10 cm long and everything will be fine.