Do-it-yourself pump repair “Malysh”: review of the most popular breakdowns

For household needs, you use a submersible electric pump Malysh, but does it, like any other equipment, require intervention over time? Although its design is simple and quite reliable, without repair experience it is difficult to find a breakdown without resorting to the services of a specialist.

Agree, it would be nice to fix it yourself in order to save on the cost of a service organization worker visiting it.

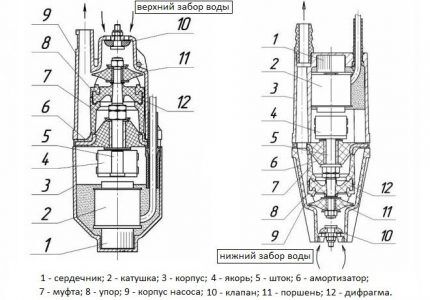

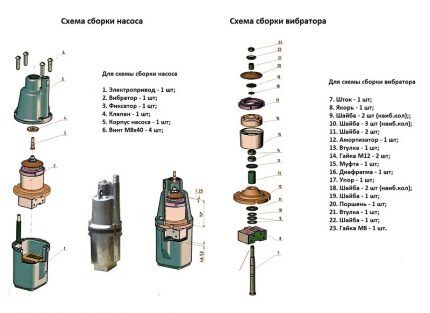

We will tell you how to repair the Malysh pump yourself, without the help of specialists. The article describes the main types of faults and ways to detect them. Schemes of the device and assembly of the component elements of the unit have been selected, which simplifies independent work.

To make information easier to understand, we offer a step-by-step process for fixing breakdowns, accompanied by a video. In fact, this is not difficult - it is enough to have a repair kit, which is necessarily included in the delivery of the pump.

The content of the article:

Pump modifications and characteristic differences

Vibrating submersible pumps invented a long time ago. Back in 1891, Russian engineer V. G. Shukhov used the principle of vibration for a pump. By the way, approximately the same system is used in a car fuel pump.

Later, the Argentinean T. Belloc modified the scheme - it is used without any changes today.

The Italians were the first to produce such devices for domestic needs. In the USSR, their development was undertaken in the late 1960s by the designers of the Moscow Dynamo plant under the leadership of M.E. Breitor. And since 1971, household vibration pumps began to be produced at enterprises in the USSR - the passion for unification had an impact.

Pumps were produced in Yerevan, Livny, Moscow, Bavleni and many other enterprises. We can name only the most famous brands: "Baby", “Neptune”, “Strunok”, “Sega”, “Rucheek”, “Harvest”, “Bosna”, “Chestnut”.

All of them, in fact, differed in name and body shape. And that's not always the case. This also includes Italian and Chinese designs. For example, “Dzhereltse”.

All these are variations of the same scheme. Sometimes the names changed, but the essence remained the same. For example, the now famous “Kid - M” was a little earlier “Sega” and "By a trickle". That's why breakdowns of "Rucheyok" and the methods for eliminating them are very similar to their closest competitor - “Malysh”.

If you ignore the confusion with different names, then briefly all the variations come down to three or four types of submersible pumps:

- "Baby" — a model of a submersible vibration electric pump with bottom water intake. The most powerful modification of all, but poorly suited for bottom work - it can pick up dirt or silt from the bottom and fail.

- "Baby - M" option with overhead water intake. A little weaker, but it doesn’t pick up dirt from the bottom.It rarely fails due to overheating - simply, even if the water level drops and the intake runs out, the body still cools - it remains submerged.

- "Baby - K" - a model with a lower water intake, but is equipped with a thermal relay and a three-wire wire with grounding. The presence of a thermal relay has a positive effect on service life and reliability, but increases its cost. Previously, this modification was exclusively for export.

- "Baby 3" — compact model with a diameter of 80 mm for narrow wells.

In any case, vibration pumps are valued for their compactness, cheapness and simplicity. In addition, they tolerate quite well water hammerthat occur when a water main is blocked, for example. Although you shouldn’t get carried away here either - such frequent practice still damages the pump.

Design and principle of operation of the unit

The principle of operation is simple. The mechanism for drawing and lifting water using a piston and valve has been known since the ancient times of Heron of Alexandria. The whole difference is that the circuit has been redesigned for an electric motor.

Electrical alternating current changes its direction several times per second. In Russia, the standard is 50 Hz. This means that the current changes polarity 50 times per second.

Accordingly, an iron core placed in a magnetic field created by a current with such a frequency will vibrate with a frequency of polarity reversal. If a piston with a valve is added to such a core, a pump will appear.

The pump housing consists of two halves. One of them contains an electric coil that creates an electromagnetic field, and the other contains all the mechanics with a steel core.

The coil has a U-shaped core. When assembled, this part is called a yoke. It is pressed into the body and filled with a compound for tightness and insulation - plasticized bakelite resin with an admixture of quartz sand for reasons of better thermal conductivity.

The other half of the housing houses the hydraulic chamber. It contains a core on a rubber shock absorber. The movement of the core is corrected by a rubber membrane. There is a piston on the core. And to direct the flow of pumped out liquid, a check valve is installed on the intake pipe.

Simply put: the coil is magnetic, the core vibrates, the shock absorber acts as a seal on the housing and returns the core to a neutral position, the membrane prevents the core from swinging, the piston pushes the water, the valve ensures that it moves in one direction.

That's the whole design - simple and effective.

Main types of malfunctions and their causes

All faults can be reduced to two types:

- electrical part;

- mechanical part.

In turn, each of them can be divided into two subgroups. This is a complete inoperability and partial disruption of work.

Partial loss of pump functionality does not necessarily mean a violation of regulation. Sometimes the reason lies in the failure of its individual parts. But let's start in order.

Type #1 - electrical faults

The most common malfunction is coil failure. Complete burnout or breakdown of insulation on the housing. Detachment from the compound body occurs less frequently. There is only one reason for the malfunctions - dry operation, without water, which causes the coil to overheat.

Then the insulation burns, the compound burns out and, due to the difference in thermal expansion of different materials, the filling separates and the yoke falls out of the body.

Sometimes the pump stops pumping altogether, but the housing may break. This is the most unpleasant breakdown, which can only be avoided by following the operating rules.

Type #2 - mechanical failure

There is a complete variety of causes and consequences:

- Liming of parts. Occurs from pumping hard water. This is a white limescale deposit similar to limescale in a kettle. This is not particularly noticeable during operation, but after long-term storage, for example in winter, the lime may jam the piston. The malfunction is rare; as a rule, it only makes disassembly more difficult and slightly reduces the pump’s performance.

- Violation of the integrity of the body. The impression is that it was precisely cut with a file or router. Usually the top edge of the body. The reason is simple - contact with the concrete surface of the well during operation.

- Pump working cavity clogged. For example, sand. Sand and pebbles, branches, algae - all this disrupts the tightness of the valve to the bed. Not critical, but unpleasant - the pump does not develop the required power.

- Loosening of threaded connections. Occurs from vibration, occurs infrequently. For example, the nuts securing the piston are loosened.The consequences can be the most dire - up to the destruction of the hull.

- Violation of rubber properties. Leads to a decrease in pump power. In rare cases, complete cessation of performance occurs.

The most capricious part and sensitive to the weakening of rubber properties is, oddly enough, a massive shock absorber. Too elastic rubber contributes to the core breaking, too hard - a decrease in vibration amplitude and loss of power.

In addition, when the core is rotated in the shock absorber, the projection of the base of the rod (a part called an anchor is pressed onto the rod) does not completely coincide with the yoke and is less attracted to it. A hard piston moves water worse. A broken piston does not pump at all.

When the valve loses elasticity, it works worse, but the pump does not fail completely. We also observe when the valve adjustment is violated.

Sometimes there is simply a loss of power. Often the reason is to turn on the pump again without immersing it in water. Most often this happens due to neglect of operating rules.

For example, hanging a pump on a steel cable and without a shock absorber - the pump mount must be shock absorbent! Therefore, the kit includes a fishing line or nylon cord and a shock-absorbing ring for fastening.

Troubleshooting algorithm

If the pump refuses to work or does it somehow unconvincingly, then first of all disconnect it from the network and remove it to the surface.

Stage #1 - careful external inspection

This is followed by disconnecting the supply hose and visual inspection. Are there any visible damages?

Unfortunately, cracks in the case can only be cured by completely replacing the case. But even here it is worth remembering that they will not simply appear in injection moldings - there is another reason hidden somewhere.

If the housing is intact, use a tester to check the resistance of the coils and the presence of a short circuit to the housing. A working yoke will show a resistance of about 10 ohms. Any of the contacts (except grounding) should not provide a short to the pump body.

If it exists, it’s bad. Replacing the coil yourself is very difficult and the attempt gives poor results. However, recommendations on this issue will be a little later.

If everything is fine with the housing and electrics, you need to bleed the pump. That is, just blow into its intake and supply holes. Air should flow freely in both directions.

But if you blow sharply into the supply pipe, the valve should close and block the air supply.

If this does not happen, then it eloquently indicates a violation in the pump adjustment. Then we’ll just shake the pump. Nothing should rattle inside it. The cause of extraneous sounds is peeling of the compound or destruction of the mechanical part.

If there are doubts about the need for disassembly, and the pump has simply lost power, then you can try to do without disassembly. First of all, rinse the pump with a stream of water. The task is to wash away sand and debris from the inside.

Then you can try putting it in a bucket of water. Add 9% vinegar (about 100 g per bucket) or a bag of citric acid to the water. We leave it for six hours. Then rinse again with running water. The purpose of the procedure is simple - to remove liming.

Next we check the valve adjustment. It should lie loosely and have a gap of 0.5 - 0.8 mm. Simply loosen the locknut and clamp nut on the pump intake and adjust.As soon as we get it right, we fasten it with a locknut. The process is easy to control.

We lower the pump without a hose into a bucket of water. So that only the hose pipe is visible. And turn it on. In a working and adjusted pump, the water column rises by about a meter.

It is by this fountain that we judge the adjustment. As soon as we get the maximum value, we fix the result.

We have listed the simplest ones. The rest requires disassembly.

Stage #2 - a closer look from the inside

The first step is to disassemble the pump. It is advisable to first make marks on the body. So that you can assemble it correctly later.

Unfortunately, it is easy to unscrew the mounting screws only on a new pump - during operation, the threaded connection becomes so oxidized that disassembling it is still a task. The best help is patience and WD40.

By the way, in the past, at the factory, the connecting studs were generally cored to prevent loosening. Today they act a little more humanely and use nuts with a plastic lock. These are exactly what should be used during assembly.

If disassembly is unsuccessful, you need to resort to a hacksaw or angle grinder (grinder). Only very carefully, without damaging the case. It is better to replace the standard screws with internal hex bolts - they are then easier to unscrew.

By the way, you should disassemble and reassemble according to the same principle as car wheels or an engine block - we tighten or loosen the fastenings gradually, crosswise.

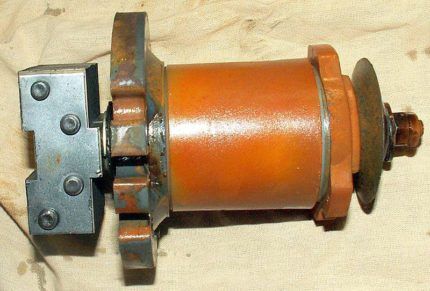

The pump splits into two halves - the yoke is filled with compound in the upper one, and all the mechanics are held in the lower one.

Step #3 - Troubleshooting the Electrical Problem

In the electrical half we look at the compound. If it has peeled off, then by gently tapping the body with a hammer, we identify the area. If it is small, then you can try to cure the problem by filling it with epoxy resin.

If the unit falls out of the body, then apply a shallow notch to the compound (with a grinder) no deeper than 1 mm.

And we secure the assembly in place using sealant, which is used when repairing car glass. Epoxy resin is not suitable - it is not flexible enough and will simply burst later from vibration.

It is difficult to press the coil into place - you may need a press with a force of about 300 kg. You can try and rewind the coil if it is burned out. But this is more complicated.

First, the body is heated to remove it. Up to approximately 120 degrees. Until the compound peels off. It is better to do this in the fresh air - burning compound is not very good for health.

Carefully chipping, free the coil housings (there are two of them) from the remnants of the compound. Unwind the old wire from them. Then new windings are wound. Wire with a diameter of 0.65 mm, PETV brand.Turn to turn, approximately eight layers each coil.

The coil terminals are connected by soldering to a moisture-resistant wire with a cross-section of 0.75 in double insulation. And then the coil is poured into the housing with epoxy resin with the addition of calcined quartz sand.

But in general, this repair method is not very reliable - at the factory, equipment and materials allow it to be done more efficiently. And electrical repairs can only be recommended as a last resort. In other cases, it is better to contact the manufacturer.

However, if you have a lot of free time and a winding machine and skills in working with electrical devices, then you can try. But most often it turns out to be cheaper to completely replace the coil along with half the housing. By the way, this is what they do in factories. This can be considered a unit repair.

Stage #4 - correction of mechanical problems

It's easier with mechanics. Carefully remove the assembly from the pump housing. First of all, we visually determine the problems: destruction, ruptures, broken washers, and so on. If there is blackness and burning, we check the electrics again.

If there are traces of mechanical wear on metal parts, we check the gaps and shock absorber and once again double-check the electrical half for peeling of the compound. This can be done by tapping with a hammer - the sound will be dull at the place of delamination.

It’s just that sometimes the yoke and armature wear out because the coil moves and falls out of the housing. This is not always noticeable on an old pump due to contamination.

During disassembly, tears of the membrane and shock absorber sometimes occur.The membrane does not particularly affect the performance of the pump and, if it can be glued with rubber glue, then this can be enough. But in this case it is better to replace the shock absorber.

We wash the insides of the pump to remove sand, if there is any. We remove limescale using the same principle as descaling a kettle - citric acid, vinegar, descaling agent. Just do not use strong alkali or other powerful products - you need to clean the case, not dissolve it.

Next, look at how the rod armature is oriented in relation to the coil. Their projections must match. No - we turn it by loosening the fastening nuts. The distance from the anchor to the yoke should be 5 - 8 mm.

This clearance is adjusted using washers and locknuts on the base of the rod. A greater distance will not allow the pump to develop power. Anything less leads to the breaking of the yoke and anchor, and sometimes the hull.

If the anchor on the rod becomes loose - which is extremely rare - it is secured by core punching. Sometimes the rod itself ruptures in the area of the piston mounting thread or the thread becomes loose - this is just a replacement.

If the piston is worn out or has lost elasticity, then everything is simple. We replace it with a new one from the repair kit and adjust the gap between it and the bed in the body. This distance should be within 4 - 5 mm.

It is easy to adjust - by adding or removing spacer washers 0.5 mm thick. You will find them on the rod itself above and below the piston.

When changing the piston, be aware of the steel bushing pressed into the center. It's easy to take it out of the old one and press it into the new one.You don't even need special tools. As a rule, it enters by pressing with your hand.

Sometimes a vice or just a bolt with a couple of washers and a nut helps out - we simply put the piston and bushing on the bolt in sequence and tighten it with a nut - the bushing snaps into place as it should. You can even try to do this directly on the stem.

The membrane is changed extremely rarely - only if it has completely crumbled. And so, if it is intact and the rubber has not lost its elasticity, then do not pay much attention to it. The main thing is that it exists.

A caliper with a depth gauge will be a good help in your work. We use this to measure the distance from the seating edge of the body to the valve bed, and then from the valve to the shock absorber. And we bring them into line.

The pump valve is also easy to change - a screw and two nuts. The distance between it and the intake hole is adjusted by simply tightening the screw. As already mentioned, the gap should be in the range of 0.6 - 0.8 mm.

Shock absorber rod check valve and the piston are secured with locknuts. We take this seriously.

If this fastening later comes loose due to vibration, it can lead to serious damage - this is precisely one of the main reasons for the destruction of the case or the failure of rubber parts.

We collect carefully. On pumps with top water intake, pay attention to the coincidence of the holes in the housing and the shock absorber - this is why we made marks before disassembling the pump. In appearance, both sides are the same and can be easily confused. If this happens, the pump will simply refuse to work.

As stated, we pull the housing screws crosswise, gradually. And very tight. The nuts must be new, with a plastic retainer. Grover's washers won't hurt at all. We remember that the pump vibrates strongly during operation, which threaded connections do not like.

We check everything again. We measure the resistance of the yoke winding and blow the pump back and forth. If everything is fine, we move on to testing it in a bucket of water. We lower the pump into the water, leaving the hose connection outside. Or we use a piece of short hose for such purposes. And we look at how our water is pumping. Everything is fine - good. Weak - adjust the valve.

After restoration of functionality the pump is installed in the well or into a well.

Conclusions and useful video on the topic

A small video tip on repairs and diagnostics that will help you make repairs:

We always remember about safety! Therefore, even after making sure that the coils are intact and that there is no short circuit to the housing, never hold the pump by the housing when checking! Always only on a dielectric spring suspension!

And we never use the power cord for such purposes. Security is never too much.

Do you have anything to add or have questions about troubleshooting pumping equipment? Please leave comments on the post. The contact form is located in the lower block.

An excellent compact pump, I have used it and never let it down. As for me, its main disadvantage is that it vibrates strongly and stirs up the water in the well so that as a result it becomes quite dirty. That is, there is no hope that it will collect clean water, but for private needs it is an excellent thing.During all this time I had to disassemble it only once - to clean it.

At the dacha we collect water from a well. There is an electric pump “Malysh” there. It worked uninterruptedly for almost five years, but now it's malfunctioning. I thought I would have to buy a new pump, but decided to try to repair it myself. To my surprise, it wasn't that difficult. So far it works great. I hope it will last for more than one year.

The pump worked for almost 2 years. Now it has stopped pumping - it makes noise, but there is no water. I try to lower it into a barrel - it works fine, but in a well it doesn’t work at all. What can be wrong?

Apparently the pump motor does not develop the necessary power to raise the water

Hello. In our case, there was a rigid hose purchased from LEROY. As soon as we changed the hose to a soft one (20 meters deep), REHAU has been pumping for about 5 years.

Did you actually read what you wrote?

“In the other half of the body there is a hydraulic chamber. It contains a shock absorber on a rubber shock absorber. The movement of the pump is corrected by a rubber membrane. There is a piston on the pump. And to direct the flow of pumped out liquid, a check valve is installed on the intake pipe.”

Judging by the drawing, we are talking about a rod.

Why show such videos? He's a master of all trades, he put the pump valve upside down, not to mention the adjustments.

Please tell me how the coils are connected in parallel or in series?

What happened to me was much worse, I was pumping water from a pond for irrigation, and then one day I turned it on and my fish ran through the water and almost jumped out because of what had broken through the body. Now I’ve warmed it up on a fire and pulled out the transformer and I want to unwind it carefully so that the coil frames remain intact and wind a new wire and fill it with epoxy resin with filler, I always take ebonite or carbolite sawdust for these purposes, a little bit is enough and the mass becomes after hardening like plastic, elastic and not pricks. And the best filling is dental plastic for gums, it is pink and very small and the name is protacryl.

Hello. How to change the power cord if it has come off at the root?