How to properly pump a well: methods for pumping after drilling and during operation

When a well appears on the site, providing a steady flow of water, this is a joyful event, because complex and expensive work has been completed successfully. Do you agree?

But the quality of the resulting water may cause some confusion among ignorant site owners. It resembles a stream of very liquid mud rather than drinking water. Don't be alarmed, this is how it should be.

Drilling a well is only half the battle. To provide your home with a sufficient amount of usable water, you need to learn how to pump a well, and then perform a series of simple, but quite labor-intensive operations. We will tell you how to cope with this seemingly difficult task.

Below we will describe the reasons why wells require pumping and how to eliminate them. You will also find information on how to perform pumping yourself, and what you will need for this. The article is accompanied by visual photos and video materials that will help you understand this issue in more detail.

The content of the article:

Why does a well need pumping?

Dirty water coming from a well at first is a completely natural and natural phenomenon. Small particles of soil and other insoluble inclusions are mixed with water, forming a suspension that is not suitable for people or even for household needs. The only way to get rid of it is to pump out the contaminants along with the water.

Understanding the causes of siltation will not only allow you to put the well in order initially, but will also help organize it correct operation. Typically, such severe water contamination in a well is observed only immediately after drilling is completed.

However, owners of a new well should remember that similar problems may arise later.

Small clay particles, together with larger inclusions, accumulate at the bottom of the shaft, which leads to silting of the well. Most often this happens if the well is not used regularly.

For example, if the dacha (and well) have not been used throughout the winter, the owners may notice serious siltation. The skills acquired while pumping a well will also be useful in solving this problem.

Depending on the composition of the soil, sand deposits of impressive thickness can naturally accumulate in the well. They also create significant problems that can be solved by pumping large volumes of water from the well or cleaning it.

Well pumping stages

Information about the need to pump a well will be useful at the design stage. If drilling is entrusted to a professional team, and not to amateur drillers, then the contract usually includes pumping services.

Stage #1. Preparing for work

Professionals usually have special pumping equipment capable of pumping out approximately 3-6 cubic meters of dirty water per hour. Of course, this increases the cost of the work, but you should not immediately abandon this addition.

Although the process of pumping a well yourself is relatively simple, it will require not only time and effort, but also certain material costs. In addition, you will need minimal skills in working with pumping equipment.

No one can accurately predict how long it will take to pump a well. It is believed that this procedure takes from 12 hours to two days. In practice, the process of self-pumping can take several weeks or even months, depending on the situation.

A number of factors can affect the work time:

- well depth;

- the nature of the soil and pollution;

- professional level of performers;

- features of pump operation, etc.

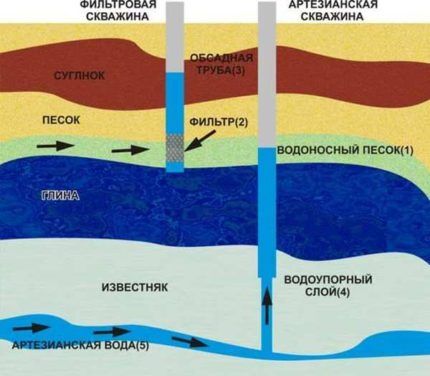

Usually, one working day is enough to pump a not too deep well, in which the aquifer is located in a sandy or limestone layer. But extracting sand or clay deposits dissolved in water from a deep “artesian” well can last weeks or months.

If the work takes a long time, experts do not recommend immediately putting an end to the expensive structure. Most often, the well can be successfully pumped. Although it also happens that even professionals cannot cope with pumping a well, and are forced to declare the structure unsuitable for operation. Fortunately, such cases are very rare.

The biggest problems during pumping await owners who have to remove clay deposits dissolved in water from the well. There are cases when a decision was made to scoop out both clay and almost all the water.The result of this labor-intensive process was a clean, easy-to-use well.

Each well is a structure with individual characteristics. Even if it was possible to pump a well in a neighboring area in a matter of hours, this does not guarantee the same success for the new structure. Usually, with wells “for limestone” there are more problems during pumping than with wells “for sand”.

For a variety of reasons, the duration of pumping may be maximum or minimum. Delays can also result from pump failure, which will have to be completely replaced. This situation is not uncommon even when pumping a shallow well.

Stage #2. Selection of equipment and preparation of the drainage site

Before starting work, several important issues should be resolved. First you need to stock up on the necessary equipment, and then provide a place for dumping the pumped out dirty water. The main tool for pumping a well is a pump.

You should not use the same pump for this that was chosen to supply clean water to the house. Not everything pump equipment copes with pumping large volumes of water containing a lot of sand, dirt and other suspended particles.

For your home, it is better to buy expensive equipment that will ensure uninterrupted water supply for a long time. Inexpensive models are more suitable for pumping, the breakdown of which will not affect the family budget.

Most often, independent work on pumping up a well is carried out using a domestic inexpensive model like "Baby" or “Spring”. The more powerful one has proven itself well "Aquarius".

According to reviews, submersible pumps do an excellent job of pumping wells “Water cannon”, although a sand plug may initially form in the device.

Models in which water passes through a metal impeller in the shape of a “snail” are not very good in combination with sand. This element gets clogged very quickly and has to be cleaned or replaced frequently. Sometimes such pumps break down almost immediately. It all depends on the model, immersion depth and the nature of the contamination.

Experts strongly do not recommend using vibration pumps for wells, giving preference to centrifugal models. It is believed that vibration can negatively affect the condition of the well, disrupt the connections of the pipe string, rock the casing, etc.

At the same time, many owners describe positive experiences of pumping or cleaning a well using inexpensive vibration equipment.

If the drilling work was carried out by specialists, you should obtain from them not only a passport for the well, but also recommendations on equipment for pumping it. Not only the type of pump can matter, but also its performance.

If the owner of the well has chosen a budget option: the already mentioned “Malysh” or “Rucheek” pumps, he should take one point into account.During the cleaning process, especially in areas with complex, clayey contaminants, such a pump can quickly fail, since it is still designed to work with clean water.

Two or three “dead” budget pumps for pumping a well after drilling are considered almost the norm. Some owners even “buried” five inexpensive units in this way.

In the process of preparing a submersible pump, you should also make sure that its cable has the required length, comparable to the depth of the well. If necessary, the length of the cable is increased, while observing all the requirements of electrical safety standards.

Another important point is the cord on which the pump will be suspended during work (an electric cable cannot be used to lift the device from the shaft!). Budget pumps are equipped with no less budget cords.

The unit will have to be removed from the shaft quite often for washing; a fragile cord may simply break. As a result, problems with flushing will be added to the hassle of retrieving a fallen pump.

In some cases, this led to the loss of the entire well. To prevent such a sad situation, you just need to invest in a reliable and durable cord or cable of sufficient length. During the work process, it doesn’t hurt to periodically inspect it to identify any abrasions.

You immediately need to decide where the pumped water will be discharged (and its total volume can be several tons or more).There is a rule: dirty water must be poured out at some distance from the well, otherwise the pumped out water will simply return to the well shaft, it will have to be pumped out again and again, the process can last indefinitely.

In addition, the reverse flow of water into the shaft can negatively affect the strength of its walls, since water entering under pressure can break the connections. After that, the liquid that penetrates through the cracks in the joint will be able to erode the soil surrounding the well.

Some of the pumped water can be used on the site, for example, for irrigation. Of course, for this it is necessary to first purify the water from contaminants. You can make a simple sand trap.

To do this, take a barrel of suitable volume and make two holes in it: the first - in the upper part of the container, the second - approximately in the middle of the barrel.

Contaminated water is fed into the sand trap from above, it settles for some time and exits into the second hole located in the middle part. Dirt, sand, silt and other particles remain at the bottom of the container. Periodically, the sand trap should be emptied of this sediment.

Stage #3. Well pumping

When cleaning a well after drilling, perform the following simple operations:

- The pump is lowered into the well so that it is at a certain distance (30-40 or 50-70 cm) from its bottom.

- The pump is turned on and water is pumped out.

- After some time, the equipment is removed and washed by immersing it in a container of clean water.

- The washed pump is lowered back into the well and pumping of dirty water continues.

- The procedure is repeated again and again until a steady flow of clean water appears.

Of course, if the pump fails, it must be replaced with a new device. It should be remembered that as flushing proceeds, the bottom of the well may drop slightly. The pump is lowered in this way: immerse it until it reaches the bottom, then select 30-40 cm of cord and secure it. Sometimes the recommended immersion depth is 50-70 cm.

If you install the pump too high or too low, the results will not be satisfactory. In the first case, the cleaning will be of poor quality, since the main contaminants simply will not get into the pump.

If the pump is suspended too close to the bottom of the well, the flow of contaminants may become too intense. As a result, the pump will quickly clog and may soon fail.

There is another option for the development of events. If the immersion is too low, the pump may simply be sucked into silt or sand. It is not always possible to free a pump stuck in this way; even powerful equipment is sucked in very strongly by sludge.

Sometimes this leads to complete loss of the well. Again, it makes sense to remember the need to purchase a strong cable for hanging pumping equipment.

To pump out dirty water as efficiently as possible, do not leave the pump in a static state during operation. Experts recommend smoothly moving it in a vertical plane by about 4-6 cm.

Do not make sudden movements to avoid damaging the equipment.This technique allows contaminants to be lifted out of the plug in parts, which significantly prevents clogging of the hose.

To ensure the correct immersion depth of the pump, do not rely on the length of the cord noted when the pump was first immersed. After each flushing, the pump must be lowered again to the very bottom and then raised to the desired height. If water stops flowing, the equipment should be immediately disconnected from the power supply.

Perhaps the pump was still sucked into the sludge, or it simply burned out, or became clogged. In any case, the device must be removed from the shaft and inspected. If after flushing the unit works as before, you can continue pumping.

If the pump breaks down, work will have to be stopped in order to purchase new equipment. You can prevent downtime by purchasing another pump in advance. If it is not needed during the pumping process, it can be sold or used for other household needs.

What to do if pumping takes too long?

Some wells take almost months to pump. If the work goes on, but the result is not noticeable, it makes sense to remember the main mistakes that novice craftsmen often make when performing this type of work.

Here are the most common:

- Pump suspended too high, therefore, the bottom layers of water are not purified.

- Pump mounted too low, it often becomes clogged and may soon break or be sucked into the muddy sediments.

- Dirty water pours back into the well shaft, which leads to re-contamination of the well.

Simply checking each of these points will allow you to identify and fix the problem before the situation becomes truly difficult.If the work takes longer, it makes sense to spend money on the services of specialists or simply consult with more experienced craftsmen.

Causes of siltation and how to eliminate it

When silting or sanding well cleaning can be done using different methods. As a preventive measure, after some inactivity or when slight siltation is detected, turn on the pump for several hours and pump out the water with accumulated silt. Problems are indicated by a slight decrease in the well's flow rate.

When figuring out how to properly pump a new well, you can find various recommendations, some of which apply to cleaning already completed and commissioned structures. For example, there is a method of cleaning a well using a fire truck.

In this case, a large amount of water under pressure is supplied inside the well, which makes it possible to break up the contaminants accumulated there, partially wash them out and facilitate further cleaning of the water source.

The idea is interesting, but it applies to structures that are already in use and for some reason need to be cleaned again. It is difficult to pump the well immediately after completion of drilling operations in this way.

The same can be said about working with a bailer. This is a manual cleaning method in which special bailer (a heavy metal product) is thrown to the bottom of the well in such a way that it breaks and scoops up the dirt and sand accumulated at the bottom. The bailer is removed, freed from sediment and again thrown to the bottom of the well.

Wells are also pumped using a motor pump: Caiman, Hitachi, Honda and so on. The cost of such a unit can be approximately a thousand dollars, or even two or three thousand, depending on the model.

This method, like those described above, will be useful in the future if necessary. revive a completed well and clean it of dirt, sand or silt. But after drilling is completed, pumping equipment should be used.

Conclusions and useful video on the topic

Visual information about drilling a well and its pumping is presented in the following material:

It will also be useful to study video materials on cleaning domestic wells:

Successfully flushing a well can take a lot of time and patience. But with the right approach, this problem can be solved quite successfully.

Do you have experience in dealing with well siltation? Please share information with our readers and suggest your way to solve the problem. You can leave comments in the form below.

Naturally, one can only expect one thing from just drilling a private well.The water will be terribly dirty and of any color: from brown or gray-green due to the inclusion of clay particles, to red from ferruginous sandy rocks. First, you need to pump out several tens of liters of water; if the water still does not become clear, then you need to come up with something else. For example, install a series of filters. In a well with a water intake in sand, you should use a filter, and also install a mesh filter in front of the surface pump and at the water supply entry into the building. If you plan to use water for drinking purposes, regardless of the degree of turbidity, you must take the sample for testing to the SES.

I have a similar well at my summer cottage, and I also have problems with drinking water, or rather, with its quality. A neighbor suggested that this well needs to be pumped up. After searching for information on the Internet, I decided to do it myself. In fact, there is nothing complicated, especially if you have worked at least a little with pumping equipment. Yes, there will be costs in any case, but it will still be cheaper than hiring workers.

Good afternoon Can you give me some advice? We drilled a 32 m well. The aquifer is 3 meters, but the water flow is very small. There is water around the pipe and it does not go deep. Drillers claim that the water will go out, it will come back in the well, you need to pump it for two days... But how can this be done if the water is pumped out in 15 - 20 minutes. The water flows almost clean, without impurities and odor. We turn off the pump, wait 30 minutes and after turning it on again it lasts for about 20 minutes. Submersible pump “Aquarius”. The drillers came and tried to break through the filters by washing. The result is zero. There was little water left. What can be done in such a situation? Maybe you need to drill the well again?

Natalya, what do you mean “enough for 20 minutes”? How much water does Aquarius pump out in twenty minutes? I pump water out of a well in 4 minutes and am not upset, because... in these 4 minutes about 150 liters are pumped out - for everyday use this is a lot, but for efficient pumping it is just right. You probably have good filters installed on the casing pipe, which create an “obstacle” to dirty water. I envy you. If you want the well to pump longer, use a pump with a lower capacity or a hand pump that was used in the recent past... but why?

Hello Natasha, you just didn’t finish drilling the well, you had to drill even deeper, I think about 4 meters.

Hello, please tell me, they drilled a 23-meter well for me, at first there were 4 buckets of water, then 6, now 14, and it’s not increasing any more, a month has already passed. I pump it out 4-5 times a day. Tell me what should be done?

Hello, in your case, contact a specialist to investigate the causes and identify a solution to the problem. Only on site can this be determined by taking the necessary measurements, assessing the condition of the well bottom, the quality of the available water, engineering equipment and geo-features. It is quite possible that the problem can be easily solved.

Hello. We drilled a well 20 meters, returned to 15, the drillers said that the water here is better. I pumped for a month, the pressure was excellent, the water was clear almost from the very beginning, but with a smell and as it stood it turned brown. Is there any way to improve the situation? The neighbor's depth is 5 meters, the water is good. Maybe raise mine higher too? Is it possible?

Hello! I see that you are not the only one who has a problem with muddy water from a well, so I will share with you my experience in this area.

There can be quite a few reasons, so based on the general information I received from your question, I will list the possible causes of the problem, as well as ways to solve them:

1. The strainer is damaged. Replacement of this element with a disk cleaner.

2. High content of iron elements. The problem is solved by a special filter, which performs the process of deferrization of water from the well.

3. Incorrect assembly and installation of pipes. If this problem occurs, then the specialists must fix everything themselves! This may include depressurization of the column, washing out of the gravel backfill.

4. Bacteria, algae and microorganisms. Conduct a laboratory analysis of the water; if the problem is confirmed, then flush the well and chlorinate it.

First of all, carry out normal pumping of the well, this may be enough.

Hello, we drilled a well of 27 meters, the water is cloudy, yellow, smells of iron, what should I do?

Good afternoon. I drilled a well, pumped it for several days - the water came out clean, but every time the pump was turned on, the water came out cloudy, for about 3-5 minutes, then clear again. Why is this happening and what needs to be done? The well is 2 months old.

You need to clean the well from silt and sand deposits at the bottom. To do this, you will need a submersible vibration pump with a bottom water intake. You need to attach a special bracket to the bottom. Next, attach the pump to the cable and lower it to the very bottom, make rotational movements, lowering the equipment up and down.

This way, you will raise all the sediment along with the water to the surface. After such cleaning, you should always have clean water from the well. Periodically you will have to repeat this procedure to remove silt deposits.

Hello, we drilled a well 36 meters long, I pump it out for 5 days, at first the water flows clean, after half an hour of pumping it becomes turbid and the pressure weakens.

Hello Alexey, I have the same problem. We recently checked the well, it was in production for two days, then it stood for a week, then we turned it on again, the water came out dirty, we washed it again for several hours, the water was clean again. I turned it on like he did for about 1 minute, I turn it on again, the water is dirty, muddy with sand, at first I didn’t understand, everything seemed to be clean and dirty again, I thought about it, later, as I realized, this is due to the fact that when the pump stops, reverse outflow of water into the well, and in connection with this there is a reverse movement of the sands that have settled around the well at the bottom, and turbidity of the water... this is an assumption. Since Skoltkotraz has not tried it, this happens precisely after turning off the pump for a while. Now I pump the well with periodic stops, for 10 minutes per hour. I control it automatically via my phone, it’s very convenient. How did you solve your problem with cloudy water???

We drilled a 15 m well, 10 m of water. I have been pumping 3.5 cubic meters per hour for the 7th day now - the water is not decreasing, but it is muddy.

I join the question. We drilled a well 10 meters deep, a filter at 5 meters, and what is below is a sump. The pump hangs half a meter from the bottom. It has been working for more than a week, 12 hours a day, but the water is not clear, somewhat cloudy, but without sediment. What's this? Should I download further or something else? Thank you.

Well 23m, clean water came out after 2 months every day for 2 hours, roughly two cubic meters

They plugged a well into a 15-meter pipe, there is water after 10 meters in the pipe, but there is no water pump, no water-pumping motor (Marcus, which costs 7 thousand rubles), it doesn’t pump it out, what should I do?

Hello! We have approximately the same problem as Natalya. Two days ago we drilled a 20 m well. We started pumping with the “Malysh” pump; after turning it on, water flows “by a thread” within 15-20 minutes. What to do? Is there really no water in the well?

drilled to 13.5m. to limestone. casing. the pipe was lowered to 12 m, the rest was washed away with fine sand. After washing there was a lot of water, but with fine sand. raised the filter 10 m. changed the slot filter to a mesh p-64. p-72. the problem remains. the dust sand does not end. we download for 12 hours for 10 days. what to do next??? please tell me!

Hello! Tell me, please. We drilled a well 8.5 meters, the water is at 4 meters. We’ve been pumping it with our baby for 2 weeks now and we still can’t pump it, the water is like slime, white but with sand, or muddy. We tried boiling it and it’s completely rusty(((

The company "Vodorezerv" LLC drilled a 40-meter well. For two days, as it is written in the passport, the water was pumped out. When the pump was installed at a depth of 16.5 meters, the productivity was 400 liters per hour. A month and a half later, another company installed a pump at a depth of 22 meters. from the well 10 liters per two hours in the form of yellow-red water. what to do?

On Sunday we drilled a 10m well. They said there was water in the garden. We left without touching anything. The working week passed, we arrived in the garden, poked our head into the well, but there was no water. What to do ?

We drilled a well 15 meters water at a depth of 4 meters we pumped for the third day the water is dirty what to do

We drilled a 20m well, installed a pump, baby, we pumped every day for 8-12 hours for more than a week, the water comes out a bit cloudy, and when it stands, it turns the color of clay

Hello! The well is 30 m long. The pump hangs at 25 m. It pumped for a month, one might say continuously. There is a lot of water. Dean level 4 meters from the surface. The SES approved drinking. But as soon as I turn off the pump, for an hour, sand and clay come out, after 2 hours it’s clean again.

Hello. Please tell me how to drill a well of 27 meters; the water surface starts at 9 meters. I pump water 50 cm from one pump, baby, then the water runs out. I roughly calculated and measured 300 liters in half an hour. This is fine? Thank you!!!