Review of the Vodomet water pump: device, types, labeling and specifics of operation

A borehole pump, by definition, cannot be cheap.When working in a filter well, it is regularly exposed to particles of sand and silt, and water has to be delivered from artesian structures to a fairly high altitude.

In search of a reliable device at an affordable price, owners of private plots most often choose the Vodomet water pump manufactured by the Gilex company. In this material we will take a detailed look at the design and operating principle of the equipment, and talk about the features of its selection and use.

The content of the article:

Design and principle of operation

Vodomet pumps have a fairly wide range of applications. With their help, you can pump water from wells of various depths, as well as from wells and open reservoirs.

They do an excellent job of providing autonomous water supply to a private home and are used for watering a plot, vegetable garden, etc. In this case, the diameter of the well must be 100 mm or more.

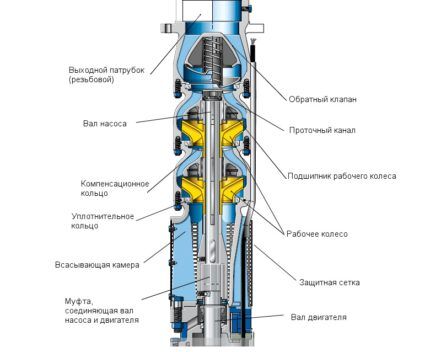

High quality stainless steel is used for the body. The top point of the pump is sealed so that during operation sand and other contaminants do not enter the housing from above.

The pump electric motor is enclosed in a sealed glass filled with oil. This design neutralizes the negative influence of external factors and protects the engine from damage.

The device is oil-filled, asynchronous, the motor rotor is squirrel-cage, mounted on rolling bearings.The motor is partially protected from overheating by a thermal protector built into the stator winding. In addition, an additional cooling factor is water passing through a special annular slot left between the housing and the motor stator.

To balance the external and internal pressure of the engine, a special membrane is used. This relieves the load on the motor seal. As a result, the technical characteristics allow the use of the Vodomet pump at a depth of up to 30 meters. The top and bottom covers are designed in such a way that all components of the device are in the correct position relative to the central axis.

An important feature of the pump design is the presence of so-called “floating” impellers, which have the ability to run in. The efficiency of traditional pumping equipment largely depends on the size of the clearance that is formed between its moving and static parts.

The larger the gap, the more internal fluid leaks occur inside the device, and the lower its efficiency. As the pump operates, the moving elements gradually wear out, which increases the clearance and the efficiency becomes even lower. The design of the “floating” impellers of the Vodomet pump gives them the ability to move in the axial direction.

The impact of operating pressure presses the edge of the wheel against the rear surface of the diffuser, which leads to contact between these rubbing surfaces.As a result, at the very beginning of the device’s operation, the special plastic collar installed on the impeller is quickly erased. The collar takes a shape that provides, relatively speaking, zero gap between this pair of rubbing surfaces.

After this bead lapping process is completed, two more surfaces come into contact: the ceramic ring and the anti-friction washer. But when interacting in water, these two elements are not erased. As a result, the clearance between the stationary and rubbing parts inside the pump becomes minimal, and the efficiency of the device increases significantly.

The bead grinding process may take several hours. During this initial period the pump will operate with some overload. That is why, at the beginning of the device’s operation, there may be a higher power consumption compared to the characteristics declared by the manufacturer.

For the same reason, pump performance at first may be slightly lower than expected. This is a natural phenomenon. As soon as the grinding process is completed and the increased load is removed from the pump impellers, all characteristics will return to normal. All pump elements with which water comes into contact are made of safe materials suitable for contact with food.

On the top cover of the pump there is its outlet pipe and two eyes, to which a cable and an electric cable should be attached.

The location of the cable outlet on the top cover is very convenient, since this does not increase the width of the pump.As a result, the device is suitable for a larger number of casings, even for fairly narrow structures.

The pump design already includes a capacitor, so there is no need to use a capacitor box when installing it. As a result, a three-core rather than a four-core cable is used to install the pump, which is much easier to install. Read about how to install equipment in a well yourself in this material.

Decoding the markings of various models

The pump marking in the form of letter indices reflects the design features of individual models:

- “BC” — the cable length of this model is 1 m.

- "A" (automatic) - the presence of a float switch that prevents a “dry running” situation.

- “PROF” — pumps for wells without an automatic shutdown system.

- "M" (main) - equipped with a fitting that allows you to use the pump on the surface as an element of the water supply system.

- "HOUSE" — additionally equipped with components for organizing automated water supply for a private home.

- “H” — presence of an electronic automatic pump control system.

Devices marked with the index “A” can be installed in wells or other structures where there is sufficient free space for installing a float switch.

Absence float valve in models marked “PROF” it does not in any way impair the performance of the pump. Even if the device is turned on up to 20 times within an hour (i.e. every five minutes), the engine will not overheat.

The set with the index “HOUSE” is included hydraulic accumulator, a set of shut-off valves, as well as an automatic control panel.

The model with the “Ch” index is most reliably protected from emergency situations.It ensures that the device turns off at the first sign of “dry running,” the engine starts smoothly when turned on, and makes it possible to maintain a certain level of water pressure in the system.

The top cover of the Vodomet submersible pump is equipped with an anti-friction bushing. This element supports the shaft on which the pumping part of the device is mounted. Here, on the top cover, there are suction windows. Their size, which is only 1.5 square meters. mm, prevents large particles of sand, silt and other inclusions from penetrating into the device.

Reasons for the popularity of “Water Cannons”

Vodomet pumps are products of the Gilex company. These pumps are produced in Russia and enjoy deserved popularity both in the Russian Federation and abroad.

Here are a few reasons why many choose them:

- higher level of efficiency compared to analogues from other manufacturers;

- high quality workmanship;

- ease of setup and operation;

- a wide selection of models designed to work in various conditions;

- resistance to adverse working conditions;

- long service life;

- acceptable price.

Some components for pumps are supplied from abroad. But all the main technological components were developed by Russian engineers and are produced on the territory of the Russian Federation.

Final assembly and testing of finished products is also carried out here. As a result, the Gilex company achieves two important goals: it produces high-quality pumping equipment and offers the buyer a relatively reasonable price.

Customer reviews are mostly positive. Not only the pump part is highly rated, but also the operation of automatic systems that protect the device from breakdowns. As you know, experts recommend using centrifugal pumping equipment in wells.

Unlike vibration pumps, the operation of which has a destructive effect on the walls of wells, centrifugal models extend the service life of such structures. Another feature of the pump in question, as well as other products of the Gilex company, is its adaptability to work specifically in Russian realities.

The designers took into account not only the necessary technical characteristics, but also the conditions in which the equipment would have to work, and the peculiarities of its operation with possible interruptions in the supply of electricity, and other similar factors. The diameter of the body of the Vodomet submersible pump is 98 mm, and the length varies depending on the power of the model.

These dimensions allow the pump to be used in most wells, since most often a four-inch casing pipe is used in their construction. Design features allow the “Water Cannon” to be used in a partially submerged position. This situation may arise if water is pumped from some shallow source or reservoir.

Vodomet pumps can operate even in difficult conditions, for example, pumping water heavily contaminated with sand. There is even positive experience in pumping contaminated wells or pumping up new structures using such units. However, one should not think that such conditions do not in any way affect the condition of the pump.

According to the manufacturer, the pump is designed for contamination of 2 kg per cubic meter. But practice has shown that this is too optimistic a recommendation. Of course, when pumping water with sand, the wear rate of a pump of this type increases several times.

The device will very soon require repairs or completely fail. Therefore, it is recommended to either choose cheaper or wear-resistant equipment for pumping the well, or purchase another pump designed specifically for pumping clean water from the well. Our website also has rating of submersible pumps for a well. We recommend that you familiarize yourself with it.

How to choose the right model?

To choose the right pump, you should pay attention to the digital markings of the various models. After the name of the pump there are usually two numbers characterizing its operation. The first indicator indicates the maximum possible water flow in one minute, which can be obtained at the outlet if there is no resistance to the flow of water.

The second indicator describes the maximum pressure that the pump can provide in the system if all water intake points are blocked (the so-called “deadlock” pump operation situation). Thus, a pump marked 60/52 supplies upward 60 liters of water per minute and can produce a pressure of 52 m (which corresponds to 5.2 atmospheres) if all the taps in the system are closed and other consumers are turned off.

Of course, this is data for an ideal situation, which almost never arises. The pump can be selected using parameters for the limiting operating mode, but the so-called “operating point” must be taken into account. To calculate it, you need to divide the limit indicator by two, i.e. take 50% of the maximum.

The following information will help you navigate when choosing a pump based on its limit values:

- For wells and wells with low or medium flow rate, i.e. with a nominal water flow of about 2-3 cubic meters. m/hour, it is recommended to use a pump with a maximum water flow of 60 l/min; this is usually enough to service 3-4 points of consumption.

- If the flow rate of the structure exceeds the average (corresponds to the nominal water flow rate within 3-4 cubic meters per hour), you should pay attention to the “Vodojet” with a maximum flow rate of 115 l/min.

- For high flow rates (nominal flow rate 4-6 cubic meters per hour), it is recommended to purchase a unit that provides trouble-free consumption of 150 liters of water per minute.

The maximum pump pressure is selected depending on information about the static water level in the well or well. (It is calculated as the distance from the water surface in a calm state to the bottom of the water intake.)

Here are some helpful guidelines for specific numbers:

- pumps with a head of 30-32 m are recommended for structures with a dynamic level of up to 5 m;

- models providing a pressure of 45-52 m will allow you to lift water from a depth of no more than 25 m;

- pumps with pressure ratings within 60-75 m are intended for structures with a statistical level of 25-45 m;

- devices with a pressure of 92-115 m are used for exceptionally deep wells; the statistical level of such structures can be 45-60 m.

Thus, knowing the characteristics of your structure, you can immediately navigate the features of the Vodomet pump model for your system.

Features of device operation

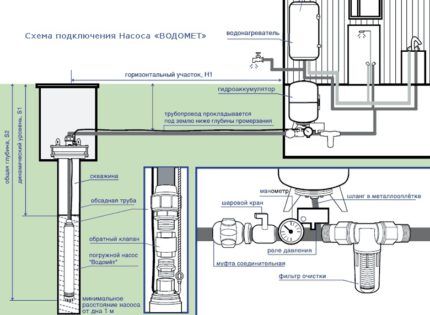

Typically, the Vodomet pump is not equipped with a check valve. But this element is extremely important for the effective operation of the device. The check valve is mounted on the outlet pipe of the pump so that after the pump is turned off, water does not flow out of the water supply system back into the well or borehole.

A check valve is especially necessary in automated autonomous water supply systems so that normal pressure is maintained in them. A check valve installed near the deep water pump has an additional function - it protects the water supply system from water hammer.

At installing a check valve The following point should be taken into account: if the distance between the surface of the water and the check valve exceeds seven meters, voids may still form in the water supply. In this case, each time the pump is turned on, a water hammer will be observed.

You should also not install a check valve directly at the outlet of the pump, even if the shallow immersion depth allows this to be done, taking into account the previous recommendation.Such a close location of the valve can cause the formation of an air lock not in the plumbing system, but in the pump itself.

As a result, the flow of water into the device will stop, causing a dangerous “dry running” situation. If the immersion depth of the pump is less than one meter, it is recommended to install a check valve at a distance of one to seven meters from the pump. It only makes sense to refuse to install a check valve if the pump is periodically removed to the surface.

For example, if the unit is used only for watering or filling storage tanks, and not for a full autonomous water supply, installing a check valve is not necessary. However, the operation of such a system should be treated with increased attention.

A hose filled with water has an impressive weight. When turning off pumping equipment that is not equipped with a check valve, it will operate on the principle of a vacuum cleaner. If at this time it lies on the ground, then there is a high probability of the pump clogging.

If such a dangerous situation arises, you should immediately turn off the pump manually. Such cases often cause the pump to become clogged with foreign particles, causing premature equipment repair or its final failure.

Conclusions and useful video on the topic

An interesting review of the Vodomet 55/50A pump can be seen in the following video:

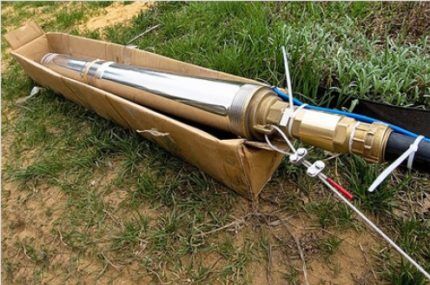

Here you can see a realistic review of the unpacking of the powerful borehole pump “Vodomet 115/75”:

Gilex Vodomet pumps are a reliable and relatively inexpensive option for a well or well. It is only important to choose the right model and ensure appropriate operating conditions.

Looking for a pump for a well? Or do you have experience using Vodomet pumps from Gilex and can you give valuable advice or share the nuances of how this equipment works? Please leave your comments and ask questions in the block below the article.

Gilex is currently a leader in the production of submersible pumps and is successfully resisting the onslaught of Chinese products - this is a fact. There you can even order a single pump and they will make it for you, it will be expensive, but they will do it.

A distinctive feature of the pumps is their high service life and operation in any conditions. But they are very afraid of power surges, so take it or connect it to an existing stabilizer, and your pump will last a long time.

I used Gilex Water Jet to pump water in a well. It took a long time to pump - almost two years passed before the water could be used for drinking. Before this, they only watered the garden and used it for technical needs. All this time the pump worked without any complaints. So, I completely agree with the reasons for popularity listed in the material - a reliable, productive pump at a reasonable price.