Exhaust hood in a chicken coop: the best ways to arrange a ventilation system in a poultry house

Raising chickens is a troublesome business, so you need to try to ensure that it has maximum returns.Good productivity of poultry, along with other measures, is ensured by exhaust hood in the chicken coop. Without the supply of clean air, the health of chickens is at risk, therefore, egg production decreases.

We suggest that you familiarize yourself with the methods and options for arranging ventilation in a poultry house. Here are the regulatory requirements for the construction of closed pavilions for domestic birds. Taking into account our recommendations, you can provide laying hens with a regular supply of fresh air.

We supplemented the detailed description of ventilation technologies with visual diagrams, photo collections, a video presentation of a system proven in practice, and a video manual.

The content of the article:

The role of ventilation in creating a poultry house microclimate

In the chicken coop, as in any poultry house, there are ammonia vapors dispersed throughout the room. If fresh air does not come from outside and harmful fumes reach a high concentration, its inhabitants begin to get sick, and in some cases this becomes the cause of death.

Birds do not tolerate high temperatures well, so a system that allows air to circulate is simply vital for them.

Without ventilation, it is difficult to control air humidity. Birds feel equally bad in both overly humid and dry rooms.

This problem becomes especially urgent in winter, when the entire livestock is constantly in a confined space. Carbon dioxide and water vapor accumulate in the air, plus toxic ammonia released by droppings. Rotting litter and food scattered on it are a good basis for the proliferation of harmful microorganisms.

Just opening the door is not the answer. This method of providing fresh air can create another problem - frostbite on the ridges. Sudden temperature changes and drafts are also dangerous for laying hens. Therefore, having a competent scheme for general ventilation in a chicken coop in winter is a matter of extreme necessity.

Existing ventilation methods

There are 3 ways to ventilate a room where poultry is kept:

- natural;

- mechanical;

- combined.

The first is the least expensive and is used when there are a small number of chickens. It is simple ventilation, but it must also be arranged according to certain rules. Before you decide to make such ventilation in the chicken coop with your own hands, you need to take into account all the points while designing the bird house.

The second method of ventilation is more effective, but simple to implement. If there are more than 20 birds on the farm, you should choose this option.

Mechanical ventilation can be supply, exhaust or combined, i.e. supply and exhaust. It is carried out on large farms. The feasibility of using a mechanical system in a home poultry house is determined by the size of the flock - the room should be designed for a hundred or more chickens.

In a combined mechanical system, either the exhaust air mass is removed naturally, and fresh air is injected mechanically, or vice versa.

Standard methods of organizing and types of ventilation described here. We invite you to familiarize yourself with the operating principle of typical options and the general rules for designing systems.

Four basic system requirements

The chicken coop ventilation system will work effectively only if the basic requirements for this room are met:

- Constantly providing the poultry house with clean air.

- No drafts, because the inhabitants of the chicken coop are very sensitive to them.

In addition, to avoid immediate contamination of the air that replaces the dirty air mass removed by the exhaust hood, it is necessary:

- Regular removal of droppings, spoiled food and dirty water.

- Periodic destruction of small rodents. In addition to disturbing birds, their presence also serves as a source of additional air pollution.

To make sure ventilation is in place and functioning properly, go into the coop and stay there for a while. If you do not feel short of breath and do not get a headache, then the test is passed. Otherwise, something will have to be corrected.

Chicken coop ventilation options

When arranging ventilation for a home chicken coop, you can do it yourself.

It is important to do everything correctly to ensure comfortable conditions:

- The temperature in the cold season is not lower than 16⁰ for adults and 28⁰ for chickens.

- Humidity from 60 to 80%.

- Air flow speed is 0.8 m/s maximum in summer and no more than 0.5 m/s in winter. If these indicators are exceeded, there will be drafts inside the room.

The ventilation scheme, both in the chicken coop and in other buildings, is built on the same principle. Based on the area of the premises and the number of birds. When determining the performance of the system, the following point is taken as a basis: for every m² of area there should be 5 chickens.

To solve the issue of ventilation, you need to decide on its type.The next step is drawing up a detailed diagram, then purchasing materials. Then all that remains is to follow the technology and carry out the necessary work.

Organization of natural air exchange

It is based on air parameters: temperature, pressure, wind speed. This type of ventilation can be either unregulated or organized. Unorganized ventilation occurs through leaky doors and windows; air infiltration occurs through walls and ceilings.

For organized air circulation (aeration), you need to provide a small window, placing it in the ceiling above the perch or directly above the doorway. To control draft, the window is made in the form of a window.

When the door is open, it will supply the house with fresh air, and exhaust air will escape through the window. This method is good for the warm season. In winter, the effect of such ventilation is insignificant. It is unprofitable because a lot of heat is lost. You will have to spend a lot of money to maintain the optimal temperature inside the poultry house.

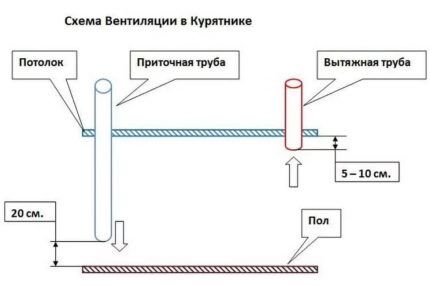

The most primitive circulation or open system, suitable for a room of about 9 m², consists of 2 sewer or ventilation plastic pipes, 2 m long, 200 mm cross-section and 90⁰ elbow. One of the pipes will act as a hood. It is mounted above the perch at ceiling level or slightly lower.

It should rise 1-15 m above the roof. To do this, make a hole of the appropriate size, insert a pipe and elbow, and fill the cracks with foam.

On the opposite side, install a second pipe using the same method, placing it 0.5 m below the level of the first, 20-25 centimeters should remain to the floor. In order not to provoke drafts, the supply pipe is located away from the perch.

Installation carried out in accordance with regulatory requirements requires the opposite end of the pipe to extend 0.3 m beyond the roof.

Valves must be installed on pipes. To prevent dust and precipitation from entering the room through the pipes, their ends are made L-shaped or umbrellas are installed. You can purchase and install special attachments - deflectors. Under the influence of wind, they increase the rarefaction of air in the pipe. The outside of the pipes is puttied and painted. This will protect against the formation of cracks in the future.

The most efficient air circulation is provided by pipes with a circular cross-section. It is better to insulate products made of plastic and metal, otherwise condensation will appear on the inner walls in winter. If it freezes, after some time it can completely block the ventilation passage.

To securely fix plastic air ducts they are installed near the rafters, in some cases additionally secured with staples. Sometimes, instead of pipes, channels are made from boards. In this case, you need to pay special attention to their sealing.

At very low temperatures, the air duct dampers are closed, and if they are not installed, the openings are protected from wind flow using rags. In summer, the air ducts are opened completely.

There is another simple way to ventilate a small chicken coop:

- They construct a box from boards with a cross-section of 200 x 200 mm square. Install the structure vertically.

- Divide the inner part of the channel in half.

- Close the top of the box.

- The outer surface of the canal is sealed and painted.

- Drill holes in the sides.

The part of the channel located on the leeward side will provide air supply to the chicken coop. The exhaust air will escape through the second half of the duct.

If the area of the chicken coop is large, it has more solid ventilation, operating on the supply and exhaust principle. To do this, preliminary calculations are made and an individual project is created. It is important to choose the correct cross-section of pipes so that air flows do not create drafts.

For ventilation pipes, you can purchase ready-made check valves both round and rectangular in cross-section. Their design includes a body of the appropriate cross-section and a damper. Round valves are made from galvanized sheet metal, and rectangular valves are made from sheet aluminum.

Valves with a damper, the position of which is manually adjusted, are marked with the letter P. If the model is controlled using an electric or pneumatic drive, then the designation contains the letter E or P, respectively. A standard round valve can be used with a pipe diameter of 250 mm or more. The feasibility of their use is determined by the scale of the poultry house.

Mechanical system design

The task of mechanical hood is to provide optimal operation regardless of the weather.On a small scale, its use does not always justify the costs associated with paying for electricity. It is impossible to recoup costs if chickens are raised only for the needs of the family.

This type of ventilation is similar to the supply and exhaust method, but here a slightly improved technology is used, which consists in the use of fans. In some cases, the system is controlled manually, in others there are special control panels.

The mechanical ventilation scheme for use in winter contains two pipes and duct fan, the location of which depends on the type of circulation. To ensure supply ventilation, it is placed in the supply pipe. When installing an effective exhaust fan, the fan must be located in the exhaust pipe.

The installation process is almost the same as when installing supply and exhaust ventilation:

- Install 2 pipes.

- Drill holes for condensate outlet at the end of the exhaust pipe.

- Lay the electrical wiring to the fan installation site.

- Install the switch. There can be 2 options: a switch that turns on the light and the hood at the same time, or a 2-key type of switch that allows you to control the lighting and the hood separately.

- Install the fan.

In a simplified version of mechanical retraction of household axial fan placed in the wall on the ceiling or in a window vent. The last option is the simplest. The fan is tried on, a rectangle made of OSB or plywood is cut to the size of the glass.

Mark and cut out an opening for the fan, then insert the element into the frame and secure it with screws. The fan itself is inserted into the resulting hole. The method of securing the latter depends on its design.

Connect the fan included in the system to the electrical network. It is better to lay the wiring outside the chicken coop, because... conditions inside are not entirely suitable for this. It is important to carefully insulate the electrical wiring.

Such ventilation does not have to be left in working condition for a long time. It can work for only 2-3 hours a day and this will be enough for effective ventilation.

For ease of control, sensors are installed. At a certain humidity and temperature, they turn the ventilation on and off. Sometimes the pipes are located in the attic, and the fan is in the ceiling.

Making a deflector for a ventilation riser

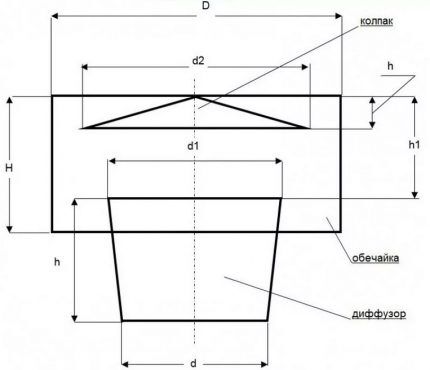

It is installed on a ventilation riser rising above the roof. The deflector works as follows: it cuts the wind directed in its direction, which leads to a decrease in pressure inside the device and increased draft in the exhaust duct.

Making your own wind turbine is inexpensive, but the effect is impressive. Install it on the roof. Before you start making it, you need to calculate the dimensions.

To calculate the height, the diameter of the ventilation pipe is multiplied by 1.7. By multiplying the diameter by 1.8, you get the width of the hood, and by multiplying this parameter by 1.3, you find out the required width of the diffuser.

Having calculated the dimensions, they are applied to cardboard and patterns are cut out. Next, the development of the cap, sketches of the diffuser blanks, cylinder and racks are transferred to a metal sheet or plastic. Using scissors, cut out all the parts and connect them using a special gun. All that remains is to install and secure the deflector.

You can also make a rotary valve yourself. To do this, a frame is welded from the corners. Holes are drilled on opposite sides of the frame and the axle is threaded through them. Bushings are made from pipe sections and welded.

A locking plate is made from a steel sheet according to the dimensions of the pipe. It is inserted into the frame and fixed to the axis by welding. To control the damper, a wooden handle is attached to the axis. To prevent the damper from closing spontaneously, a limiter is provided.

The disadvantage of such a ventilation system is the very fact of the presence of pipes in the room. From their surface, as well as from the perch, you will have to periodically scrape off droppings.

Conclusions and useful video on the topic

Presentation of a homemade ventilation system in a poultry house with a visual demonstration of the design:

Together with the author of the video, you can make ventilation in the chicken coop yourself:

Any task can be mastered if you carefully follow the instructions. Make a hood in your own chicken coop with your own hands and your birds will feel much better.

Would you like to talk about how you built ventilation in your own chicken coop? Do you know the nuances of its structure that are not mentioned in the article? Please write comments in the block below, ask questions about controversial and unclear points.

To circulate air, I usually open the window at noon, when the temperature is warmest. My husband did not make an additional hole. An hour is usually enough, after that I start cleaning there. It's easy to breathe. By the way, the window is made from the side of the bathhouse, air flows in, but does not blow out much. And rodents not only spoil the air with their presence, but also spoil food and sometimes eat eggs. I set traps with glue for them. It’s very convenient: even if a bird steps on it or tries, it won’t get poisoned, but a mouse can’t get out of it on its own.

Opening the window once a day is clearly not enough for normal ventilation. In winter, this method is generally not applicable, let in the cold.

A hood in a chicken coop is definitely necessary. Since childhood, I remember the aroma of the room where our family raised chickens. There is still that smell))) But during my childhood, there was no talk of any special hoods in private farms, so they ventilated in the most accessible and banal way - they opened the doors and let the draft carry out all the odors. For poultry, a draft is detrimental, so it happened that chickens periodically got sick. I’m glad that at least now we don’t have to subject the bird to such tests of endurance. I made a ventilation system for the poultry house - and everyone is happy.

In my small chicken coop with natural ventilation (50mm pipe), condensation constantly accumulates on the windows and in the corner, the sawdust is also slightly damp. I will try forced with a fan.

First, try to calculate the volume of required air exchange for your chicken coop, and based on this, select the diameter of the pipes. They are placed on opposite walls, one at the bottom, the other at the top. If you do it right, you can easily do without forced ventilation.