Plastic boxes for hoods: overview of types + installation rules

Forced ventilation systems are present in almost every apartment or private house.They consist of an air intake device and an exhaust duct, which can be made of various materials.

The plastic hood box has become widespread - an affordable and durable element that can be installed independently.

In order for the assembled system to work effectively, it is necessary to correctly calculate the cross-section of the channels, design and select the components of the air duct. Equally important is to carry out proper installation.

We propose to deal with all these questions in order. We have supplemented the step-by-step instructions for installing a plastic exhaust ventilation duct with visual photographs.

The content of the article:

Duct Selection Options

For the normal functioning of the ventilation system using a hood, it is necessary to correctly calculate the parameters of the air duct. In most cases, plastic boxes of standard shapes and sizes can be selected for household purposes.

Calculation of the optimal cross-section of the ventilation duct

The main parameter of the ventilation duct is its internal section. The speed of flow through the channel depends on it and on the exhaust power. The cross section is selected based on the maximum volume of air passed through.

There are no regulatory documents regulating the speed for household plastic air ducts, so they focus on practical tested values of 3-7 meters per second.

The cross-sectional area of the duct is taken to be equal to or slightly larger than that of the exhaust air duct branch pipe, the size of which is indicated in the device passport.

If it is not planned to regularly turn on the maximum mode, then in this case a proportional reduction in the cross-section of the ventilation duct relative to the size of the outlet opening is permissible.

So, if S – cross-sectional area of the exhaust air duct pipe, N – volume of air passed through at maximum device mode, M – the volume of air passed through under the planned mode, then the required cross-sectional area of the duct is calculated using the formula:

P = S*(M/N)

Insufficient cross-section of the box leads to significant air speeds and increasing friction force.

This is fraught with the following negative effects:

- the load on the ventilation mechanisms of the hood increases, which leads to a decrease in the operating life of the device and additional energy costs;

- due to an increase in resistance, a decrease in maximum performance occurs, which reduces air circulation in the room;

- as a result of aerodynamic effects in the ventilation duct, the noise level during operation increases;

- there is an increase in air pressure from the inside on the system elements, as well as vibrations, which requires more reliable fastening and sealing.

If the cross-section of the duct is larger than necessary, this will not negatively affect the functioning of the forced ventilation system, but will lead to unnecessary financial costs.

In addition, ventilation ducts and other large components are more difficult to install and integrate into the design of premises.

Consideration of shape and size

Plastic boxes for ventilation are round or rectangular in shape. A circle has the smallest perimeter compared to other geometric shapes with the same area.

Therefore, from the standpoint of minimizing the resistance of the inner surface of the duct to the movement of the air flow generated by the hood, a round channel shape is preferable.

The most common types on sale for household purposes are round ones. plastic boxes following diameters:

- 80 mm, cross-sectional area 50.3 sq. cm;

- 100 mm, cross-sectional area 78.5 sq. cm;

- 125 mm, cross-sectional area 122.7 sq. cm;

- 150 mm, cross-sectional area 176.7 sq. cm.

Rectangular ventilation ducts are easier to fit into the interior of the room. They can be placed in niches above kitchen cabinets, above a suspended or suspended ceiling.

The most common boxes are the following sizes:

- 110 x 55 mm, cross-sectional area 60.5 sq. cm;

- 120 x 60 mm, cross-sectional area 72 sq. cm;

- 204 x 60 mm, cross-sectional area 122.4 sq. cm.

If necessary, larger ventilation system elements can be found.These are plastic boxes for household purposes, round in shape with a diameter of 200 mm, rectangular - from 220x90 mm.

However, before making a choice in favor of non-standard sizes, you need to make sure that you can purchase all the elements necessary for arranging an exhaust duct of the required geometry.

Plastic shaped elements

Ventilation systems from the hood to the shaft have different geometries and topologies due to individual approaches to kitchen layout. Therefore, special elements are provided to implement almost any configuration of a plastic box.

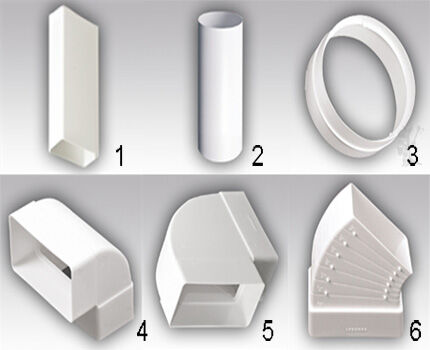

Ventilation ducts are straight air duct elements of rectangular or round shape. Their standard length is 0.35; 0.5; 1; 1.5 and 2 meters, however, you can cut off a piece of the required size yourself using a hacksaw or grinder.

If you need to get a straight section more than two meters long, then it is mounted using several fragments of standard length using special connectors for plastic channels.

In this case, there is no increase in the length of the section due to the size of the connector.

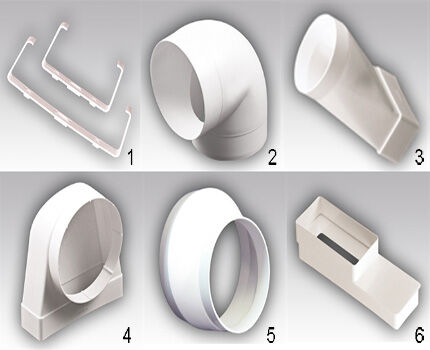

Another necessary element is an elbow, with which the air duct is rotated at an angle of 90 or 45 degrees. For rectangular boxes, elements for changing direction horizontally and vertically are distinguished.

To turn at angles not multiples of 45 degrees, use the so-called multi-angle elbow. Depending on the required angle, one side of the connector is cut off.

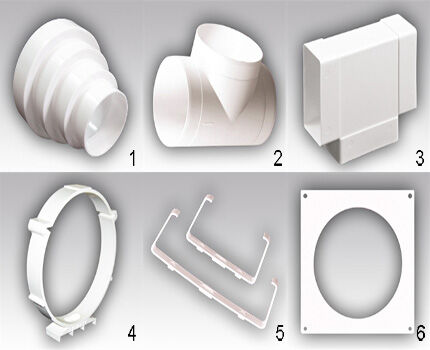

To change the shape of the box from round to rectangular (or vice versa), special adapters are used.

Their use, as a rule, is due to the difference in the shape of the ventilation ducts with the outlet hood funnel or the hole in the overhead grille. They can be either straight or angular in shape.

The most common transition options on sale are:

- from a diameter of 100 mm to a size of 110x55 mm;

- from a diameter of 100 mm to a size of 120x60 mm;

- from a diameter of 125 mm to a size of 204x60 mm.

If it is necessary to switch to another size of a plastic box without changing its shape, then reducers are used. For round options, there is a special universal adapter that can be used to connect all standard sizes.

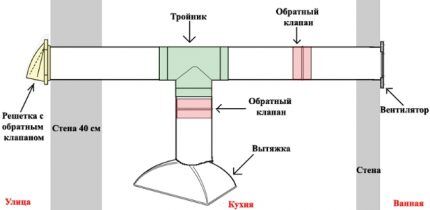

For structures with complex topology, tees are provided, with the help of which air flows from several hoods, for example from the kitchen and from the bathroom, can be connected towards the exit.

They can be rectangular, round, or combined shapes.

The elements of the box are fastened to the wall using holders. Since plastic structures are lighter than metal ones, their installation is not a difficult task.

These factory-made parts are inexpensive and fit well into the interior of the room, so the use of home-made structures is impractical.

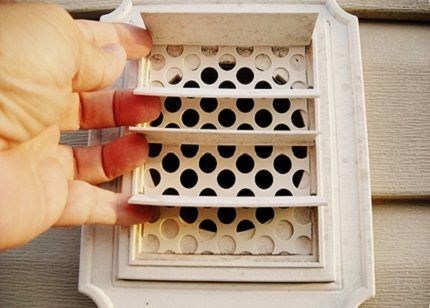

The wall trim or grille is attached over the hole in the wall leading into the ventilation shaft or to the street. The grille, if necessary, may contain additional slots for natural ventilation.

In this case, it is necessary to provide protection against the penetration of the air flow generated by the hood through these openings back into the room.

To prevent the occurrence of reverse draft when the hood is not working, a check valve is used. It can be integrated into the plastic duct connector, or its function can be performed by the louvers of the ventilation grille.

In the absence of such a device, air may enter the room from the street or from a ventilation shaft.

Design and installation features

Installation of a plastic box for ventilation from kitchen hood can be done independently without the involvement of specialists. In this case, it is necessary to take into account some simple features of the design and installation of such systems.

The installation of a plastic system includes a number of traditional stages that must be completed both by an independent craftsman who decides to build a box with his own hands, and by a hired worker.

Stage #1 - choosing the geometry of the ventilation system

A wide variety of structural elements allows you to implement almost any geometry of a plastic ventilation duct.

To maintain the functionality of the air passage system at the proper level when designing the air duct, the following rules must be observed:

- Box length. If possible, you need to minimize the length of the box.The optimal distance from the hood outlet to the ventilation grille is considered to be less than 3 meters.

- Fewer elements. It is advisable not to use a large number of elements that change the direction of air movement. Curves, tapers and various transitions create additional aerodynamic drag.

- Minimum turns. It is necessary to minimize the number of elbows with the box rotated 90 degrees. They create the greatest resistance to flow, generate noise and accumulate deposits in the form of grease and dust adhered to it.

If the box is placed near a heating riser or other heat source, it is necessary to prevent the plastic from heating to a temperature above 50 degrees Celsius.

To do this, you need to either bypass the hot object or lay thermal insulation between it and the air duct.

The easiest way to use foam as an insulating material is because it has low thermal conductivity. In addition, it will not create noise when the box vibrates.

Stage #2 - installation of check valve and grille

A necessary element of the ventilation system is check valve, whose role is difficult to overestimate.

If the duct goes only from the hood to the shaft and does not have branches to other sources of air intake, then the valve is installed at the end of the air duct. An alternative is to use grilles with check valvepreventing air return.

If there are several sources of air intake into the ventilation system, a check valve is installed near the connection of each branch with the main air duct and another one near the grille.

If it is necessary to support natural ventilation when the hood is turned off, there are three solutions:

- separate the exits for forced and natural ventilation, and they should not go into the same ventilation shaft;

- install a tee “exhaust hood – grille – check valve” near the outlet;

- use a ventilation grille with slots for natural air movement and protection against reverse draft.

Birds or rodents living in the ventilation shaft sometimes get inside the duct. Once caught in the bends of a plastic box, they may die, causing decomposition products to enter the room.

To prevent such a development of events, the grate leading to the street or to the mine is often equipped with special protection that is insurmountable to animals.

Detailed information about the types and selection of ventilation grilles is presented in this article.

Stage #3 - fastening and placement of the air duct

Sections of the plastic air duct from the hood to the ventilation grill can be secured in different ways, depending on their position relative to the cabinets, walls and ceiling.

In any case, installation is not difficult and can be done independently.

However, it is necessary to approach this procedure responsibly, in order to avoid noise from vibrations, as well as sagging or other deformations of the box with its possible subsequent depressurization.

If the box is located inside cabinets, then it is secured to the rear wall of the cabinet using clamps. The places where the air duct passes through the walls are also fixed using foam or polystyrene foam inserts.

These materials do not produce noise when in contact with vibrating elements of the system.

If part of the air duct is located above the cabinets, the easiest way is to fix it to the cabinets using holders and short-length wood screws. The plastic box in this position does not create any significant lateral pressure.

When attaching the air duct to a wall or ceiling, it is recommended to place the holders every 1 meter. Fixation occurs using special clamps, which can be purchased to match the shape and size of the box being purchased.

The weight of the entire plastic structure is small, so its fastening is quite simple.

If the plastic box is closed with a suspended or suspended ceiling, then it is necessary to check the reliability of its fixation when the hood is operating at maximum power. In other cases, the fastening can easily be strengthened after identifying weak points.

Sometimes, during operation of the ventilation system, a rattling or knocking noise may occur caused by the contact of the vibrating elements of the plastic box with solid objects, such as a cabinet, wall, etc.

In this case, instead of additional fastening, it is enough to lay foam rubber or polystyrene between them.

Stage #4 - ensuring the tightness of the structure

Elements in the ventilation system, made of plastic parts, do not have a seal. The dimensions of the joints are well adjusted, but after some time due to deformation, the density of some joints may decrease.

In the event of a leak in the joints of structural elements, air from the ventilation system may leak out. In this case, odors and moist air spread through the rooms through which the air duct passes.

In addition, when air passes through the cracks, significant noise sometimes occurs.

To prevent depressurization of a plastic ventilation duct, there are two solutions:

- Sealant. Coat the joints of the structure with a special silicone or acrylic sealant. It is applied in a thin layer to the edge of the element before its insertion into the system.

- Scotch. Wrap the joints with self-adhesive tape. This method can be used after installation of the system if depressurization areas are detected.

The first method is more reliable, however, serious problems may arise if it is necessary to disassemble the ventilation duct for repair, cleaning or changing its geometry.

Over time, the sealant holds the structural elements together so strongly that in some cases it is necessary to sacrifice one of the parts to begin disassembling the system.

The external sealing method, on the contrary, makes it easy to disassemble the plastic box. However, this method affects the appearance of the structure, so it is practically not used if it is located in plain sight.

Conclusions and useful video on the topic

Installation of a kitchen box, eliminating gaps in the joints of structural elements using silicone sealant and self-tapping screws. Preventing vibration using foam in the following video:

Installation of a plastic air duct for a kitchen hood. Fastening the elements to each other, fixing them to the ceiling using holders:

Operation of a check valve for the functioning of natural ventilation using the example of a tee “exhaust - grille - natural ventilation”:

The information we have presented on the selection, design methods and main components of plastic ventilation ducts will help you build a reliable box for kitchen ventilation with your own hands. The main thing is not to rush and carefully seal each joint of the ventilation duct.

We invite everyone interested in the issue of calculation, arrangement of air ducts and installation of plastic exhaust ducts to leave comments and ask questions. The contact form is located in the lower block.

My personal opinion: for an apartment, plastic ventilation is the best option. Firstly, if it is not covered by bedside tables, then white plastic channels look much more aesthetically pleasing than corrugated or metal. If desired, it can be disassembled and washed without any problems; I doubt that such a trick will work for you with corrugation. Well, the metal in the apartment just looks disgusting, and it can also be washed without any problems, well, it looks terrible!

As for me, in a home kitchen all these industrial exhaust ducts do not look very aesthetically pleasing. When we carried out the hood, my wife and I argued for a long time.

She wanted some kind of secret hood. Of course, I’m not against it either, but it was unrealistic to do this without special designs. We got out of the situation by ordering taller kitchen cabinets, and the pipeline from the hood is almost invisible from human height.

Hello. This was my first time encountering the installation of a range hood. A new kitchen set with a fully built-in hood will be delivered very soon. The description states that the diameter of the outlet on the hood is 120 mm. And then I had a problem: how to connect the ventilation duct to the hood itself, if stores only have ducts with a diameter of 100 mm, 125 mm, and 150 mm? Round boxes with a diameter of 120 mm are not on sale anywhere.

There are no round channels.But there is an adapter (round bend connector, reducer - called differently) with steps from 100 to 160, including that same 120. It is cut off at the required step and that’s it. It is sold in many places, but it sells out quickly - you need to ask and order.

I read the article and still don’t understand how to calculate the minimum cross-section of a rectangular box. After all, the option of connecting both 55#110 and 60#120mm to a 120 mm pipe is the same to implement, and judging by the recommendations of the authors

I need to get a bigger box