Installing a hood in the kitchen with your own hands: detailed step-by-step installation instructions

An exhaust hood is a device that purifies the air in an apartment from the odors of food being cooked on the stove, the smallest particles of fat and gas combustion products. It is believed that installing a hood in the kitchen improves the microclimate of the living space, ensures normal air exchange, and is part of the supply and exhaust ventilation.

To install a household appliance, you do not need to hire a specialist: thanks to detailed instructions, diagrams and accessories, you can install it yourself. However, this requires basic tool skills and a small amount of knowledge.

In the article, we tried to outline all the intricacies of the installation process - we listed the main installation requirements, and also prepared a step-by-step master class on attaching the hood and connecting it to the air duct and electrical network.

The content of the article:

Rules for installing exhaust devices

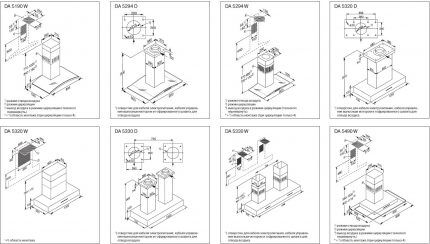

Installation depends not only on external conditions, but also on the features of the device itself: type, shape, size, weight, purpose, set of functions.

Some hoods are built into furniture modules, others are hung in the middle of the kitchen - above the “island”, others are simply installed on wall mounts.

All home hoods can be divided into 2 categories:

- devices with air ducts, through which exhaust air is discharged into the ventilation shaft;

- circulation type devices, purifying the air using filters.

The former have greater productivity, but are more difficult to install; the latter are easily mounted on the wall, but they clean the air efficiently only until the filters become clogged. But there is a third option - combined, combining the capabilities of both categories.

Today it is easy to get confused in the range of exhaust devices. In hardware stores you can find everything from the simplest "visors" with carbon filters to expensive “island” units designed for installation in spacious rooms.

Even a quick inspection of the devices makes it clear that they are installed differently.What do you need to consider when installing a domestic kitchen hood yourself?

If you leave aside the technical nuances of the equipment and focus only on installation, then the following rules will come in handy:

- the device must be compact, suitable in design and size to fit into the interior;

- Before installation, you need to prepare the place: check the strength of the load-bearing wall or select a furniture module;

- if a gas pipe runs nearby, you need to consider installing it on a bracket or choose a more expensive option - moving the pipeline;

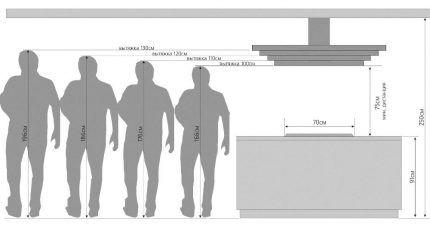

- according to the requirements, the device is mounted at a certain height: 65-75 cm for electric stoves, 75-85 for gas stoves (except for some models that can be installed lower);

- the installation of air ducts is planned in advance - the dimensions of the boxes or exhaust pipes, number of turns, “route” of passage.

Even when choosing equipment and hood installation height take into account such nuances as the size of the hob and the height of the person who will do the cooking.

Ideally, the hood screen should be slightly wider than the stove, no matter whether it is gas or electric, but you need to remember that when gas burns, combustion products are released, so it is better to purchase a more powerful unit.

Main stages of hood installation

Island appliances are less common, and it is recommended to hire at least two workers for their installation. Therefore, let’s look at how to properly install a simpler model hood in the kitchen with your own hands – built-in or wall-mounted.

Connecting the equipment to the electrical network and the air duct is carried out according to the same principles, but installation is carried out differently: built-in is integrated into the cabinet, wall-mounted is attached to the wall.

Step #1 - preparing the tool and installation location

Expect the greatest difficulties from the preparation, since you will have to either drill into the main wall for dowels, or cut mounting holes in the cabinet.

The procedures for direct installation of the hood body are carried out easily, by assembling and tightening self-tapping screws or screws.

So, for work you will need:

- laser level;

- tape measure and marker for marking;

- for a concrete wall - a hammer drill or impact drill, for a wooden wall - a screwdriver;

- set of keys and screwdrivers;

- for processing cabinets and plastic boxes - a hacksaw, a jigsaw, a router, and sandpaper.

The air duct usually has a prefabricated structure, so a sealant, preferably silicone, will also come in handy. We recommend that you carry out all work wearing protective gloves, and when drilling concrete walls, wear special glasses.

If installation is carried out on a wall, check its strength. Usually the wall near which the slab is installed is load-bearing, so there is no doubt about its reliability.

However, the cladding may fall off during operation if it is a tile, a decorative screen made of plastic or a laminated board, which, by the way, is not recommended to be placed near a gas hob.

For a built-in model, prepare a cabinet - remove the bottom plane, make a hole at the top to lead the air duct outside. Reinstall it in the same way as the adjacent cabinets.

If the air duct will be “hidden” behind mezzanines or built into a suspended ceiling, this should also be taken into account in advance. For this reason, the installation of suspended structures is usually postponed until last; the ceilings are installed after the kitchen has been installed.

Step #2 - unpacking and checking the contents

To make sure that the installation process goes smoothly, you need to remove the hood from the packaging and carefully inspect all its parts.

Sometimes it is one large housing with niches for filters and a short outlet, sometimes it is a complex prefabricated structure with a large screen or dome.

Pay special attention to the control panel and decorative parts - scratches and small dents are sometimes the result of an impact and indicate possible breakdowns.

The electrical wire and plug must be hermetically sealed with insulation.

Check for filters - not all models come with them. However, circulation and combination hoods usually have a starter kit. It includes an anti-fat element - a metal mesh, as well as carbon filters – 1-2 pieces.

If everything is in order and you don’t need to buy additional parts for installation, you can start marking.

Step #3 - marking work

Any household appliance will work with 100% efficiency if it is installed correctly, so first take a level, tape measure, pencil or marker and draw two perpendicular lines on the wall.

The first is the vertical, going from the stove to the installation site, which centers the hood and the stove, and the second is the horizontal of the working surface of the exhaust device.

The hood screen and the hob must be positioned strictly one above the other, parallel. The offset is not only wrong due to safety or functionality reasons, but also from an aesthetic point of view.

Next, you need to look at the instructions and, according to the installation diagram, indicate where to attach the bracket or other device for hanging to the wall.

If the hood is built into a cabinet, then you just need to take its body, attach it to the walls of the cabinet and also mark the mounting locations.

This is where the marking work ends. If you plan to install an air duct, we recommend that you outline the laying route and the possibility of fixing pipes or ducts to the wall (cabinet) in advance.

Step #4 - attaching the hood to the surface

The processes for wall mounting and cabinet mounting are different, so we'll look at both.

Installing a Tilt Wall Model

The installation process of an inclined wall hood is one of the simplest.

The procedure is as follows:

- We fix the template on the wall with tape so that the horizontal lines on the paper and on the wall, as well as the center line, coincide in height.

- Use a drill to drill holes in the wall using the template. Usually their diameter is 10 mm, but it is better to check the instructions. Depth – at least 50 mm. If the wall is tiled, first use special drills so as not to break the tile.

- We remove the template from the wall and insert 10 mm dowels into the holes.

- We screw screws into the holes so that there is a small distance between the cap and the wall for hanging the device.

- Take the hood housing, remove and set aside the filters. On the inside of the case we find mounting holes shaped like a keyhole - we hang the hood on the wall using them.

If only circulation operation of the device is planned, the installation ends here.

To connect the air duct, you need to install a false pipe.

First we install the air duct, and then the false pipe. To attach it, two special holes are used on the inside of the hood and two self-tapping screws screwed into the wall.

When all the hood elements are installed, all that remains is to insert the filters, and you can proceed to the next steps - further installation of the air duct and connection to the power supply.

Installation of a built-in hood

The built-in hood is mounted differently:

- Using a level, check whether the cabinet is installed evenly relative to the hob.

- We remove the bottom panel of the cabinet - the shelf to which it will be attached, and fix the template with tape.

- Using a pencil or an awl, we mark 4 mounting holes according to the template - they will be located in the corners, as well as the center of the large hole intended for the air duct.

- We measure the radius with a compass, using the same template, and draw a circle so that we can then cut out the hole.

- We take a drill, install a 5 mm drill and drill holes for self-tapping screws in the marked places, and then use a jigsaw, clearly in a circle, for the air duct.

- We put an adapter on the hood to connect to a ventilation duct or pipe.

- If the cabinet is small, we immediately fix the shelf to the hood, and then fix everything together into a module; if it is large, first install the “bottom” of the cabinet in place, and then the hood.

- We mount the cabinet on the wall.

The final stage is installing filters and connecting to the power supply. The installation of the air duct can be done immediately or later.

A cabinet with a hood is not purely technical, that is, it can be used for long-term storage products, dishes or kitchen utensils.

Step #5 - Installing the Air Duct

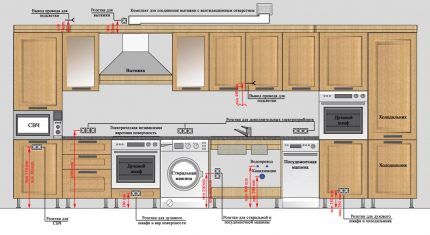

Air duct is a channel for removing vapors and combustion products to the outside. One end of it is connected to the hood adapter, the other - to a hole leading into the ventilation shaft or made in the wall of the house.

The second option is only suitable for private houses.

It is not difficult to select parts of the required sizes, make calculations and draw up a diagram. But it is important to take into account one point: do not tightly block the ventilation hole with the duct from the hood, otherwise the natural ventilation of the room will be disrupted.

There are two ways to maintain supply and exhaust air exchange:

- install double grille, one half of which remains open, and the second is a hole for connecting a pipe;

- equip the outlet with a valve, which can be opened/closed if necessary.

The good thing about the grille is that it is always open and does not require additional actions.

Some factory models of grilles are equipped with a pipe that makes it easier to connect a pipe or duct.

The advantage is that you can choose a model according to certain sizes or shape of the hole.

If you are concerned about the aesthetic side of the issue, you can choose a model with check valve, which is installed from the shaft side.

Plastic boxes are used as air ducts, corrugated pipes, special ventilation pipes with fittings.

How to connect them together and fix them on walls, ceilings or cabinets depends only on the type of channels and installation conditions.

Before installation, it is advisable to stretch the corrugated pipe - put it on the pipe, and then stretch it as far as possible towards the ventilation hole. Many depressions and protrusions can cause the air duct to quickly become clogged with grease and soot.

Step #6 - connecting to the power grid

Household hoods cannot be compared in power to washing machines or air conditioners, so a regular outlet is enough to connect the device. It is better to install it next to the device, to the right or to the left.

If the hood is built into a cabinet, then the socket is placed under it.

When installing an electrical point, you need to remember two nuances: high humidity and mandatory grounding. The first is easy to do by purchasing an electrical installation with protection class from IP44 and higher. Problems may arise with the second, especially if the high-rise building is old.

We do not recommend performing any actions yourself; be sure to invite an electrician. He will find a way out of the situation, and at the same time install the missing circuit breakers on household appliances.

After installing the hood and connecting it to the power supply, you need to test it by first installing the filters.

Conclusions and useful video on the topic

Built-in model - detailed instructions:

Video tutorial on installing a “slider”:

How to install and connect the dome model:

An example of installing a plastic air duct:

Installing a hood is one of those household chores that you can do yourself, without the involvement of specialists. The main installation guide is always the manufacturer's instructions; the rest depends only on specific conditions.

However, in case of any deviations from the manufacturer’s recommendations, remember the requirements for the installation and operation of electrical appliances, ventilation, and hobs.

Do you have anything to add, or do you have questions about installing and connecting a kitchen hood? You can leave comments on the publication, participate in discussions and share your own experience in performing installation work. The contact form is located in the lower block.

I also installed a hood in the kitchen myself, and I realized that there was nothing complicated about it. Correctly noted about the wiring, it’s better not to risk it and hire an electrician.

There is nothing complicated if the standard ventilation system in your apartment building is working properly. But if there are problems, then sometimes you have to separate it through your own channel so that there is no reverse blowing.

Good advice was given regarding wiring and grounding, I agree. However, for some reason many people ignore the last point, considering it optional. It is clear that in Soviet high-rise buildings a number of problems quite often arise with the installation of grounding. Here it is worth remembering that the humidity will constantly increase under the hood during cooking, so automatic machines and grounding are simply necessary.