Ventilation of corrugated sheet roofing: recommendations for design and installation

If your house is just under construction, then it’s time to think about quality roofing.Perhaps you are planning to choose a hard surface like profiled sheets? In order for the ventilation of a corrugated sheet roof to be properly organized, you should follow the recommendations and avoid mistakes. Redoing anything will be technically problematic.

The covering on the roof can deteriorate or even collapse due to external factors. It would be nice to think about protection from uncomfortable temperatures, moisture accumulation, penetration, and other unpleasant things that threaten your roof. If you do not make the right decisions about the air exchange on the roof, then in the worst case, the load-bearing system in the attic will suffer. In general, there is nothing complicated.

In our article you can familiarize yourself with the design of a roofing pie for roofing made of corrugated sheets. You will receive advice from which you will create a set of optimal solutions.

The content of the article:

Ventilation in corrugated sheet roofing

Roof ventilation is a significant stage of roofing work, along with insulation and waterproofing. The roof will not be in danger of destruction only if the conditions in the attic and on the roof itself are normal.

Houses need ventilation outlets, which are made on the roof. The condition of the roof depends on local ventilation. The growing demand for housing with an attic has led to the fact that local air exchange under the roof and in it is organized more carefully.

Profiled sheet (corrugated sheet, corrugated sheet) is a facing material for roofs and walls, made from galvanized steel by cold rolling. In the process, sheet blanks are made wavy: with square, trapezoidal and other shapes. The material eventually becomes stronger.

Corrugated roofing should be protected from:

- moisture;

- icing;

- elevated temperatures.

Ice forms due to heated air in the roof. The lower layers melt, but quickly harden if it's frosty outside. For corrugated sheeting, ice on the outside is not a problem, but ice will gradually fill the gutters.

Icing also forms inside - from condensate. Warm air escapes through the cake, enters the cold flow of the roof ventilation gap and turns into moisture. In summer, the corrugated sheet protects well from rain, but it overheats if there is poor ventilation underneath it.

Proper air exchange in corrugated roofing

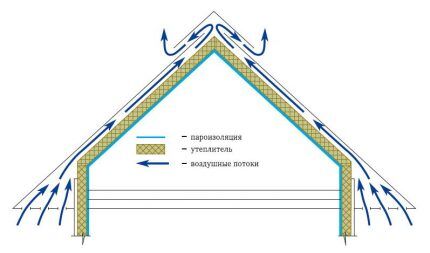

Ventilating the roof is easy. The air enters from the eaves overhangs and rises to the top - the ridge (ridge). It leaves through cracks near the ridge or special removers.

The air gap is made by lathing: it separates the corrugated sheet and waterproofing (waterproofing). The sheathing leaves gaps between the waterproofing and the transverse slats - due to vertically oriented slats - counter slats.

These gaps become channels for natural ventilation. There is also a gap between the insulation and the waterproofing, but not always.In the ridge, protection from moisture is provided only through compaction; waterproofing is not laid there.

Sometimes the sheathing is made continuous, and not thinned out, that is, without crossed slats. Then they take moisture-resistant plywood boards about 1 cm thick and lay them on the rafters, but with the addition of transverse strips between them. These slats are selected up to 10 cm in height if placed on edge. This provides additional protection from moisture.

If we talk only about the insulating layers, then keep in mind that the waterproofing is the topmost one, below that is the thermal insulation and insulation, and below it is the vapor barrier.

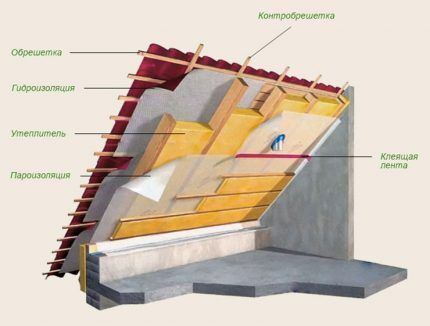

Full diagram of a standard roofing pie made of corrugated sheets:

- At the very bottom there is a continuous hem.

- Above lies the base of the roof - the rafters. Between her rafters lay sections of insulation. Beneath them is a thin vapor barrier layer. Install a vapor barrier before laying the thermal insulation and before connecting the sheathing to the rafters.

- Even higher is the first air layer or waterproofing immediately.

- Next comes the sheathing and the main ventilation gap.

- The corrugated sheet is located above this air gap.

Lay waterproofing sheets perpendicular to the slope. Make several adjacent strips with an overlap of 10-15 cm and cover it with adhesive tape.

Move from the overhangs to the ridge. Lay waterproofing sheets with small hanging waves between the planks. Allow 1-2 cm vertically for each.

Sometimes waterproofing is organized in two layers: under a row of counter-battens and above it, or on top of the entire sheathing. Ventilation will not become worse, and moisture will pose less of a threat to the roof and attic. Waterproofing is then placed on the insulation.

Canopies and roof sections above terraces/verandas do not require organized air exchange. For a roof with a very steep slope, minimal ventilation is enough, but for large areas made of corrugated sheets, ventilation outlets are needed - aerators.

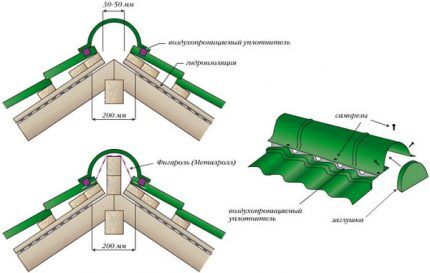

When the profiled sheets are laid, free space is left in place of the ridge. This is how natural ventilation is established. This method also reduces the temperature, because on hot days the metal heats up quickly.

The corrugated sheeting has grooves, which, in combination with ventilated ridges, makes air exchange at the top of the roof more efficient. Grooves leave gaps between the sheet and the ridge, and also at the bottom of the overhangs. The holes at the level of the waves should be sealed, and those below should be covered with a net so that less snow gets in. It will be worse if the gaps are filled with leaves and dirt: air exchange may then stop.

Previously, the holes were reduced with sealants, by about 2/3 of the height. I had to move from place to place and wait for the next layer to polymerize. Now the gaps from the waves of material are closed with relief seals for corrugated sheets. They are made from foam materials.

Don't worry about ventilation - thanks to the structure of the seals, even the closed part will allow some air to pass through. In addition to uniforms, universal tape is suitable for sealing. You can secure it in the right places.

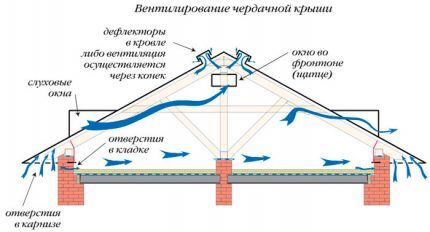

In houses with an attic, the roof is ventilated based on the safety of the structure, air exchange in the room and its temperature conditions. At the attic level, the air itself moves actively; cold air displaces warm air above.

Ventilation is also designed to protect against moisture. Condensation will not get into the lower part of the roof if there are waterproofing and vapor barrier membranes in its path. Many ventilation slots are added to the design to allow liquids to evaporate.

Installation of roof aerators

Aerators are also called fungi. They are used to enhance air exchange and remove moisture/steam. The devices are connected to ventilation gaps directly or through the roof. Aerators can be solid or point.

Continuous type devices improve ventilation throughout the entire roof structure. They have sponge filters and cover the entire length of the ridge. The devices are often called ridge devices, just like the point variety. Due to their structural features, solid solid aerators cannot be combined with corrugated sheets.

Point aerators are installed on individual parts of roofs: pitched and ridge.

Point slope devices are installed:

- on areas of the roof that get very hot - in as many quantities as possible, if the entire roof is like this;

- on slopes of a large area;

- in areas of roofs with complex patterns and curves.

Ideally, pitched aerators are installed on the highest places of the roof, right under the ridge. If there is a valley on the roof, then the devices are mounted no lower than the imaginary lines between the tops of these funnels.

Place at least one point aerator per 60-100 m² of roof. Mount the two units in relative proximity on parts of the roof where more moisture is expected. As a guide, use the compass rose for the area. The slopes will receive more rain from the side where the wind blows more often.

If possible, install aerators at the same time as the roof. When installing them, select the joint lines between the thermal insulation: insulation mats partially absorb liquids. If the vapor barrier layer is damaged, moisture enters the insulation from the house. Secure with dowels or anchors. The ventilated space under the ridge must be protected from leakage, and for this you will need sealing tape or sealant.

Find suitable elements for your aerator. Start with the installation area under the corrugated sheet wave. Do not replace it with Master Flash, because it will be difficult to bend it to the terrain. Insert the capsule into the mounting pad and put the adapter on it. Then attach the corrugated pipe, but do not use the aluminum one.

If you have to dodge obstacles in the attic, the channel will need to be bent. Aluminum is not good for this. This part will be under the roof. Equip the external one with a deflector.

Ridge point aerators have a flattened shape, and they are mounted on the ridge itself or just below.In general, slopes bring more benefits, and in some cases are irreplaceable. A ridge aerator will not cope with air exchange in a slope that is elongated in height.

The situation will be the same if the entire roof consists of many bends and transitions. The air stagnates in these forms for a long time. Aerators for structurally complex roofs are planned simultaneously with the roof. Then you will need to monitor whether the installation site is collapsing.

Ventilation between waterproofing and insulation

Make a ventilation gap between the insulation and the waterproofing. This is how the vent is expanded in the eaves of the slope - at the level of the bottom of the sheathing, if you look into the thickness of the roofing pie. Make a gap from the vent to the top edge of the waterproofing.

After removing the waterproofing from the insulation, it will protect just as well from liquids from above, and moisture from the thermal insulation will begin to leave faster. The waterproofing film must also absorb moisture, but an air layer does the job better. The air from the gap will escape through ridge ventilation.

The gap between the insulation and the waterproofing film/membrane is separated by stretched fishing lines. The hydraulic protection is raised by at least 5 cm. The fishing lines are attached to the wood using a construction stapler.

A gap must be made if a film acts as a waterproofing barrier. In the case of a membrane, everything is almost the same: most products are not suitable for installation directly on the insulation. You can create a gap, even if it is not necessary, but remember that ventilation between the corrugated sheet and the membrane is more important.

Other nuances in the arrangement of ventilation

Air exchange largely depends on the design of the upper and lower edges of the roof. We are talking about a ridge at the very top and a vent at the edge of the slope. For a corrugated roof, strong natural ventilation in the channel is important, where outside air rises, interacts with the inside air and goes outside.

Organize ventilation below:

- Take the ventilation mesh tape and cover the vent. Secure with self-tapping screws. If you want, make holes in the soffits for more active air flow. The net is a necessary measure to protect against foreign objects, birds and insects.

- Install the curtain rod and maintain an interval of at least 3 cm in width to the vent. Do not lower its lower end more than 10 cm from the vent. The vent itself may be hidden.

- Cut polypropylene tubes across the entire width of the free interval. Secure the cornice strip with large self-tapping screws.

Then place gutter - on special holders and below the level of the cornice strip.

The main element for air exhaust is the ridge at the top of the roof. The shape of the ridge can be very different, often has branches, but the main branch falls on the upper half a meter.

A seal or a more breathable ventilation tape is fixed in the space between the tops of the slopes.

The bars are attached to the tops of the roofing sheets, and then the ridge cap is installed on top. The boards are taken 5 cm thick and laid two side by side, in increments of 40 cm or more. Form triangles upward. On both slopes, long wide boards are nailed perpendicular to the bars.

They will become the basis for the ridge cap.The latter is made with stiffening ribs, but relatively flexible in the center. Reinforcements will prevent the edges of the ridge from moving and deforming.

On both sides of the ridge, vents are left between the bars, which are then protected with a ventilation mesh. To prevent the wood from being noticeable, cut metal strips to match the color of the mesh are screwed onto it.

The open ends of the ridge are closed with plugs. Flat is suitable for straight skates, and those inclined at the hips are covered with conical ones.

Shed roofs with corrugated sheeting are equipped so that air moves without obstacles and passes through. Overhangs are also equipped with ventilated soffits.

If you are not going to heat the attic, you can install it there attic windows for ventilation. In this case, excess moisture will not appear in the roof. In a heated attic, you can maintain a slight draft from slightly open windows.

Conclusions and useful video on the topic

Nuances of roof ventilation and experimental assembly of the roofing pie:

Ridge seal for protection against snow and cold:

The condition of the cold attic six years after installing the corrugated sheets, and is it possible to install waterproofing without counter-battens:

You have learned what an air exchange system under a corrugated sheet roof is. Now consider the climate in your area, the expected roof load and the type of roof you plan to use. Add aerators to enhance moisture removal. Make the air gap as wide as possible.

Take care of the passage of aerators and general ventilation through the roof, and plan the corrugated sheet covering only after this. Don't forget about air exchange in the ridge. Control the construction of your roof so that everything turns out perfect the first time.

Write comments and ask questions about roof ventilation made from profiled sheets. Share your experience with other readers if you had to do ventilation on the roof of your house. The contact form is located below the article.