Comparative review of ventilation and air conditioning systems

Decreased work efficiency, a constant feeling of weakness in the body, increased nervousness, and a regular desire to take a nap are often the result of insufficient air exchange.However, proper ventilation and air conditioning can help prevent these problems.

Moreover, it will not be possible to limit ourselves to the natural system; it has a number of disadvantages. It is necessary to select the optimal mechanical type of air exchange and mixing, analyzing the pros and cons of each method.

Let's try together to understand how different ventilation systems work and in what cases one or another type is used.

The content of the article:

Why is ventilation necessary?

Air renewal helps prevent diseases of the cardiovascular and central nervous systems, increased sweating, deterioration of attention, and chronic diseases in people with weak immunity.

The standard ventilation system allows:

- reduce the concentration of dust and other small particles in the air;

- choose a comfortable temperature for work;

- remove exhaust gases and aggressive components that cause allergies.

Of course, you can open the windows, but then dust and dirty air will enter the room. And in the cold season, heating costs will increase. Also, drafts have a negative impact on human health.

Air conditioning process

Even in the warm season, it is problematic to carry out a simple air exchange without the use of special devices. Therefore, it is advisable to use additional equipment.

In summer the air is humidified and warm. Air conditioning will ensure that it cleans and sets a lower temperature. For example, split systems, industrial air conditioners and chiller-fan coil.

But in the cold season the air is frosty and less humid. Naturally, don't forget about filtering. However, it is still necessary to heat and humidify the air, which it successfully copes with heater, ensuring the temperature rises to a comfortable level.

This process is often achieved through mixing: cold flows are combined with warm ones. The air is cooled in special chambers due to the ingress of small drops of water.

There are also rooms that require a special approach to organizing ventilation. For example, in gyms with swimming pools, water constantly evaporates, increasing the humidity level.

Designed to solve such problems dehumidifiers. The disadvantage of the latter is the lack of ventilation. The air remains in the room, but the moisture level decreases. Therefore, the oxygen concentration drops, which negatively affects people’s well-being.

Mechanical method of air evacuation

Natural ventilation often does not fulfill its direct functions. Therefore, the need to use an artificial system becomes urgent. Its main difference is that it works with coercion.

The mechanical type of ventilation is used not only in industrial production, but also in residential premises.Its action is based on the operation of electric motors, air heaters, fans and filters.

Key advantages of an artificial system over a natural one:

- Efficiency. Transferring almost any volume of air over significant distances indoors.

- Weather independent. Flawless performance of direct functions by the system at any time of the year.

- Additional features. Adjusting temperature and humidity levels, cleaning the air from dust and other small particles.

Mechanical ventilation is divided into ducted and non-ducted. During the first, the air passes through special elongated paths.

In ductless systems, fans are placed in a special design. They provide an influx of fresh air masses.

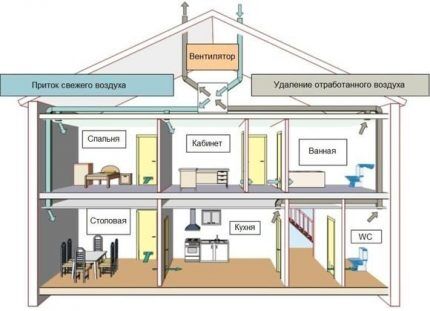

Depending on the type of mechanical ventilation, systems are divided into supply, exhaust and supply and exhaust.

Description of the supply system

The main task of this type of ventilation is to provide fresh air into the room. In order for the equipment to optimally perform its functions, complex models are equipped with additional elements that are responsible for cleaning and moistening.

The main disadvantage is the lack of air intake. Therefore, the room cannot be 100% filled with renewed air masses.

Operating principle and design structure

The standard system includes a fan that is mounted in the transom of the window. It provides a flow of fresh air into the room. In the latter, the concentration of gases increases. Therefore, there is no space left for the exhaust air and it leaves the room through special exhaust openings.

The key component of the system is the supply fan.Its main parameters are power, air supply efficiency and pressure in the working area. The requirements for the technical characteristics of the fan directly depend on the length and complexity of the channels.

In addition to this device, the system consists of the following elements:

- gratings;

- valves;

- air ducts;

- distributors;

- filters;

- heaters.

Filters are responsible for removing mechanical particles from the air that arrives: dust, insects, debris, etc. They can provide coarse, fine and very fine cleaning. Depending on the characteristics of the work, they are divided into electrostatic, dry and wet.

Heaters or calorifiers are responsible for increasing the temperature of the incoming air. They come in water and electric types. The first ones work on the basis of the home heating system. The power source of the latter is the electrical network.

As for additional elements, they could be:

- elements that reduce noise levels;

- dehumidifiers;

- recuperators;

- humidifiers;

- means of automation of system operation;

- and others.

The air receiver must be located in a clean place that is protected from dust. A supply chamber should be located near this structural element.

Where is this method used?

The mechanical type of inflow organization is used for both residential and industrial facilities. Responsible for the whole premises or only for a separate part of it, for example, a workplace in production. Ensures air enters at optimal temperature.

It also creates special clean areas, even if there are elevated levels of toxic substances in other rooms. Can be combined with exhaust and natural ventilation systems.

Read more about how to properly arrange a supply ventilation system in this material.

Characteristics of exhaust ventilation

An exhaust system is the opposite of a supply system. Its task is to remove polluted air from the room. There are holistic and collective types.

Structure and principle of operation

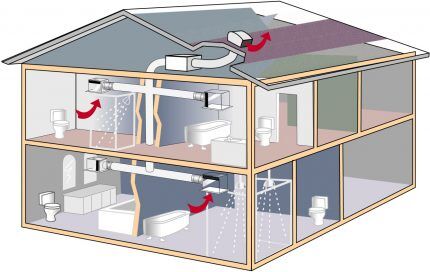

Evacuation-type ventilation is popular for furnishing apartments. Provides exhaust or heated air outlet. Exhaust grilles or valves for ventilation usually located in the upper part of the room. Fresh air is supplied through special connectors directly from the external environment or through neighboring rooms.

The system can be located at a certain distance or completely block the source of pollution. If the point of release of toxic substances can be limited, then local ventilation will be effective, and if not, general ventilation.

The fan plays a key role here. It is its power that determines the efficiency of the entire system. There are low pressure (air flow speed up to 50 m/s), medium - up to 80 m/s and high pressure (up to 200 m/s) exhaust devices.

The main elements of this type of ventilation are as follows:

- Fume hoods. They are distinguished by the greatest effectiveness. Remove excessively humid and warm air, heavy gases and dust.

- Blowjobs. Eliminate the maximum amount of harmful substances, taking in a minimum of air. Do not interfere with the employee’s performance of duties.

- Exhaust hoods. Designed to remove substances that rise upward. There are types whose work is based on natural or forced traction.

- Exhaust panels. Effective for removing dust and hot harmful gases.Relevant for workplaces where parts are welded.

- Onboard suctions. Used when working with large or bulky objects that are held vertically using metal cords or other means. They have a small diameter (less than 100 mm) and are located away from the work object.

The exhaust system is designed primarily to evacuate exhaust air. Considering the above design elements, they are effective for local ventilation.

Nuances of using the system

This type of exhaust ventilation is suitable for rooms with low concentrations of harmful substances. Moreover, the latter can arrive at different levels, as a whole and in separate streams.

This system is relevant for warehouses, supermarkets, sports facilities, health centers and residential premises. Used in industrial premises where the release of toxic substances cannot be avoided. Optimally combined with natural and forced ventilation. It can act both locally and provide general removal of waste materials.

When choosing, you need to analyze the characteristics of the exhaust air. If the latter contains a lot of aggressive substances, then it is advisable to choose the option with an anti-corrosion coating.

The essence of supply and exhaust ventilation

This type of indoor air mass renewal is considered one of the most optimal. It allows you to combine the advantages of supply and exhaust systems.

The key design task is to balance the volumes of incoming and exhaust air.If the first predominates, then the pressure in the room increases due to the high concentration of gases; with an increase in the amount of evacuated air, it decreases.

Supply and exhaust ventilation has two types. The first is mixing, when clean air enters the room through special structural elements, mixes with existing gases and exits through special valves.

Another type is embossed ventilation. The system is installed at floor level. The elementary laws of physics work here - the exhaust air has a high temperature, therefore it is displaced by the gases that enter. It comes out through gratings located on the ceiling of the room.

But fresh air enters the lower part of the room, where it moves slowly. Therefore, in the work area, in the part of the room where the residents are located, comfortable conditions for rest and work are created.

For displacement ventilation to be effective, the fresh air must be at a lower temperature than that already in the building. For residential premises the difference is 1-3 °C, for plants, factories and other facilities with special requirements - 1-5 °C.

This type of ventilation has both advantages and disadvantages. The advantages include the possibility of use in industrial buildings, which are characterized by the release of toxic substances and elevated temperatures, and high operating efficiency.

But the disadvantages include the following:

- the need for relatively large areas for supply diffusers;

- increase in the surrounding area;

- reduction in the efficiency of the system as a result of excess objects entering the supply diffusers;

- increasing vertical temperature gradient.

The latter is the difference between the gas temperatures in the working area and under the ceiling.

If you want to opt for a displacement ventilation and air conditioning system, then analyze the placement and power of the heating equipment. These characteristics affect the combination of air flows in the room.

For example, incoming air that should go directly into the work area may be blocked by warm gases from radiators or space heaters. The result is ventilation not by displacement, but by mixing.

The mixing process involves introducing air into the room in one or more ways. But the exhaust gases come out in one stream.

The key parameter for mixing ventilation is ejection. This is a combination of any kind of environment, when one of them influences and directs the other. In a specific case, this is the ability of diffusers to harmoniously combine air streams.

Ejection determines the features of the ventilation system. For example, mixing is provided by jet-type diffusers with a high index value. And displacement is characterized by devices with a low injection rate.

To minimize the number of drafts if the difference between the temperature of the incoming air and the air in the room deviates from the norm, diffusers must have a large value.

The speed of movement of air masses and air temperature are also important. To ensure maximum comfort, gases must move no faster than 0.18 m/s and have a temperature of 20 to 22 °C.

Particularly dangerous for human health and well-being is an excess of the first and a decrease in the second indicator. Then it’s difficult to just be in the room, let alone do any productive activity.

When designing ventilation, the influence of physical obstacles must be taken into account. The latter include lamps placed on the ceiling, tiers, ceilings, columns, etc.

Auditoriums are non-standard rooms that are distinguished by a large working area, a large number of listeners and a high ceiling. Accordingly, the approach to ventilation is quite specific.

A popular method is to supply fresh air directly under the seats of the listeners. It is believed that incoming gases will heat up, rise to the ceiling and be removed from the room.

However, practice shows that this approach is incorrect - gases behave in the same way as liquids. First, the air collects in the lower part of the audience and only then rises.

Even reasoned calculations and computer modeling do not guarantee the most accurate prediction of the direction of air movement. However, it is necessary to take into account the number and location of diffusers relative to each other, the placement of heating elements, obstacles and other factors.

Most studies regarding diffuser placement show that agitation ventilation deserves an arbitrary assessment.For example, it is effective to place air exhaust holes at the entrance to the room from the rear desks.

But if you place taps in other parts of the audience, then in most cases you will not be able to get the desired effect. And proper exchange allows you to prevent the formation of a strip of warm and exhaust air.

We also recommend reading another article, where we described in more detail the principle of operation of supply and exhaust ventilation. More details - go to link.

How does local ventilation work?

If air purposefully enters certain areas of the room or is removed from there, then such ventilation qualifies as local. The latter is divided into supply and exhaust.

Local supply ventilation requires much lower costs when used than general ventilation. Popular in industrial areas that require rapid gas renewal. Allows you to reduce moisture and temperature.

Local exhaust design is also used in industry. Relevant for removing toxic substances and reducing temperature in a certain small part of the room. We talked in more detail about ventilation of industrial premises in this article.

Allows you to prevent the consequences of the mentioned and other negative factors. It has a positive effect on the work comfort of employees, since harmful substances leave the premises almost immediately after formation.

If work associated with the release of toxic substances is carried out over the entire or larger area of the premises, then local ventilation will not be effective. However, it is still advisable to use it opposite the places with the highest emissions.

Conclusions and useful video on the topic

Video about local ventilation in a room with technological equipment:

The video explains the features and relevance of designing a ventilation system, its equipment options and installation nuances:

The video demonstrates the operating features of a standard ventilation system:

Each ventilation system has its own characteristics. When choosing, you need to take into account many factors: from the specific use of the room to the presence of obstacles to air flow. However, a careful approach will allow you to settle on the optimal ventilation system.

After studying the material, do you still have questions about the topic of the article? Or can you add valuable information to the above? Please leave your comments, ask questions, and share your experience in the block below the article.

This is not the first generation of both developers and their immediate clientele asking the same question. Ventilation or air conditioning? The traditional opposition is cheap vs additional protection from humidity (if you have a swimming pool or sauna) and even more so from harmful substances (although here it depends on the situation - just as a banal hood can help, an air conditioner may not cope with an artificial climate). My personal choice was very simple - there are two allergy sufferers in the family, so we weren’t limited to a hood. But there will still be no general laws here - the specifics of the development will still remain the main factor.

The question “Ventilation or air conditioning,” Efim, does not exist - one complements the other. Re-read the section “Air conditioning process”. By the way, on the site there is an article “Air conditioning with fresh air supply» – in the section “Supply channel models” “hybrid models” are described.

The market already offers ventilation equipment for apartment formats, operating in parallel with air conditioning. This means a program that stops the operation of the air conditioner while the air is being updated with ventilation. The screenshot shows the characteristics of such a gadget, which, by the way, solves the problems of allergy sufferers.