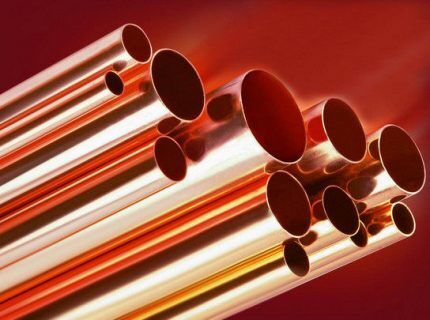

Installation of copper heating pipes: features of the technology for performing the work

Despite the appearance on the market of inexpensive and practical materials, copper pipes are still successfully used for assembling internal wiring of heating circuits.But copper is an expensive material, so the installation of copper heating pipes should be carried out after carefully studying the rules and regulations.

The efficiency of the finished system depends on both the quality of the equipment and the skill of making connections.

Let's look together at the features of copper heating pipelines and their installation technology.

The content of the article:

Differences between copper pipelines for heating

Copper has a whole range of positive qualities that make it stand out from other materials. If the construction project allows the use of such expensive elements, then a kit should be purchased for the internal wiring of the heating system copper pipes and fittings in the quantity included in the estimate.

Pros of copper pipelines:

- the ability of metal to expand makes it easy to withstand high temperatures of the coolant, sudden temperature changes and even freezing of water;

- for the same reason, copper perfectly withstands pressure drops in the network, as well as possible water hammer;

- the reddish metal is resistant to hard water containing foreign impurities - lime, chlorine, etc.;

- the material does not have ideal smoothness of the inner walls, however, the low degree of roughness protects against the formation of limescale and creates little resistance to the movement of the coolant;

- copper is known for resisting the development of pathogenic bacteria and mold formation;

- the combination of strength and softness allows you to create pipelines of various designs;

- in some cases, heating wiring serves a decorative function, although safer copper cold water or gas pipeline circuits are recommended for room decoration.

To prevent foreign inclusions from depositing on the pipes and reducing functionality, special requirements are imposed on the coolant: the water must be clean and filtered.

But copper pipes also have their disadvantages, the main one of which is high cost. If we take for comparison two meter-long pipes with a diameter of 26 mm made of metal-plastic and copper, then the first will cost 147 rubles, and the second – 486 rubles. It turns out that copper wiring will be more than 3 times more expensive.

Copper is selective in relation to other metals, so fittings should be selected carefully. Aluminum, duralumin or steel parts cause an electrochemical reaction and rapid corrosion.

Therefore, they usually use either “native” copper connecting elements, or brass, bronze, chrome-plated or nickel-plated. Tin or PIC solder is used only during the soldering process.

Regulatory requirements for pipes

If you are completely satisfied with copper as a material and the cost of the products does not bother you, you need to check the compliance of all components of the system with state standards.

Documents regulating the installation of wiring will also be useful - STO NP "AVOK" 6.3.1–2007 “Pipelines made of copper pipes...” and SP 40–108–2004 "Design and installation...". Requirements for product range, coolant composition, pipe characteristics.

Data from tables and graphs will help when choosing solders. Material about anti-corrosion protection, repair work and calculation methods may be useful.

Installation technologies and rules

First, let's look at the general rules regarding the installation of copper pipelines. As you know, metal is an excellent conductor. To provide protection from stray currents, as well as reduce the risk of corrosion, you can use products in a polymer shell.

In private practice it is quite rare, but in industry the assembly of pipelines made of steel and copper is still used. In this case, it is recommended to use steel for risers, and copper for wiring, that is, steel products should be in the first position in terms of coolant current. Magnesium connectors are required.

There are several ways to connect products, the choice of each of them depends on the specific situation:

- capillary soldering with solder;

- compression fittings;

- pressed fittings;

- threaded installation.

The last method is practically not used because it has lost its relevance. Soldering and crimping differ in the degree of labor intensity, execution technique, and the presence of different tools, but are equally in demand. Let's look at three popular pipeline construction technologies.

How to connect pipes using capillary soldering?

Soldering takes more time, but the connections made are durable and tight. The best option for solving everyday problems is to use soft solder. The operating temperature does not exceed 250 °C.

The use of hard solder increases strength, but the work will require expensive equipment and special conditions, since the soldering process takes place at a temperature of more than 700 ° C.

With the help of soldering, permanent connections are created, which are made either using the socket method or using fittings.With socket technology, one end of the pipe must be expanded so that when the elements are joined, a gap of 0.2-0.3 mm wide is formed between their walls.

It is filled with solder, after which a sealed connection is created. But let’s take a closer look at soldering with fittings, the most popular among installers.

Materials and tools for work

It is necessary to prepare copper pipes and fittings, but not the first type that comes across, but those specially designed for soldering.

Tools for performing the work:

- gas-burner – enough propane;

- pipe expander (calibrator);

- pipe cutter, since metal shears deform the shape of the pipe;

- chamfer;

- equipment for cleaning and polishing (fine sandpaper, brushes, rags).

When choosing solder, it is better to choose the option with a tin base. In addition to tin, the solder may contain bismuth or silver. This type is good because its melting point is much lower than that of copper products.

You can read more about solders for soldering copper pipes in this material.

During the soldering process, the solder will take on a liquid state and will be able to hermetically fill the connection gap, while the copper elements will not react to high temperatures.

For ease of installation work, you can use special fittings for low-temperature soldering.They differ in that at the ends they have a narrow groove filled with solder.

Low-temperature (soft) soldering is typical for household work, while high-temperature (hard) soldering is used in production. The rigid type is also used when connecting pipes of air conditioning systems and refrigeration units.

Description of the soldering process

Copper is a malleable material, it is not difficult to work with it, but if you have no experience, it is better to first practice on unnecessary sections of pipes.

The connection must be allowed to cool and then thoroughly rinse the joint with clean water. If leftover solder is not removed, it will cause corrosion over time. It is not recommended to speed up the cooling process with cold air or water; under natural conditions, the connection cools within 7-10 minutes.

We also recommend that you read the step-by-step instructions for soldering copper pipes. Read more - read Further.

Taking Precautions

Soldering, unlike crimping connection methods, is a dangerous activity that requires the use of protective equipment. In addition to work clothes made of thick material, you must wear gloves, as well as glasses with special glasses or plastic.

Some types of solders contain fluorine and cadmium, and when the flux is heated, harmful compounds are also released, so it is necessary to keep the window open during operation.

Installation instructions using fittings

There are two types of compression fittings - the so-called compression and compression. They create completely different connections, so before starting work you need to decide what kind of connections you would like to see: permanent or conditionally detachable.

Press fittings are similar to solder fittings, but have shallow recesses at the edges with sealing gaskets. Using special press pliers, which have a set of nozzles for different diameters, crimping is carried out.

As a result, it creates a sealed, permanent connection that cannot be repaired, and in the event of an accident can only be replaced.

Pressing creates a strong, reliable connection of parts, while maintaining the geometry of the pipes and does not deform the connecting elements. There is a nuance of pressing “soft” copper products: before the operation, a support sleeve is inserted into the pipe, which resists deformation of the pliable material

The pressing process is simple and does not take much time. The tools required are a standard set for cutting and processing pipes, as well as press pliers with the required attachment.

Pressing is considered a reliable method. If you plan to thermally insulate copper pipes, you can use insulating tubes, which are easy to put on even on curved structures. After pressing, the finished heating network can be masked in grooves, covered with decorative cladding and filled with screed.

The second type of fittings is compression. They differ in design and installation process.

The crimping procedure is as follows:

- a nut is loosely placed on the prepared end of the pipe;

- then the collet is put on;

- last of all, the fitting body is put on until it stops;

- the nut is screwed manually along the thread, while simultaneously pressing the split ring;

- The connection is tightened with an adjustable or sized wrench.

During the compression crimping process, the cutting ring tightly grips the pipe, creating a strong and airtight connection. The nut may become loose over time, so pipelines with this type of installation must be regularly maintained.

The connections are conditionally detachable, since they can be disassembled, however, if necessary, the fragment with the clamped ring will have to be removed and a new fitting installed.

Conclusions and useful video on the topic

Depending on the location of the pipeline, the diameter of the products and installation conditions, you can choose one method or another. Useful tips for using them are presented in the following videos.

Recommendations for pressing small and large diameter pipes:

How soldering is done:

Overview of all types of fittings:

Soldering nuances - practical application:

Every pipe connection method has its own characteristics that must be taken into account at the design stage. Crimping technologies seem simpler, while soldering requires experience and professional skill.

If assembling a pipeline yourself seems difficult, we recommend inviting a specialist to help you and, under his guidance, installing a heating network from copper pipes.

If you have the necessary experience and knowledge in installing copper pipelines, please share it with our readers. Perhaps you know some installation subtleties that we did not mention in this article? Please leave your comments in the block below.

Copper heating pipes are a beautiful luxury. Very expensive material and quite high cost of installation work. If you assemble a system using compression fittings, you will need to use expensive tools that not everyone can offer you for rent.

Regarding the service life, the installation suppliers themselves will not give you a 100-year guarantee, as written in the article.We must remember that copper heating pipes are not compatible with aluminum radiators, and cast iron and steel cannot be connected directly to copper.

It is also advisable not to drain the system frequently, which is difficult to control in a high-rise building. Also, the copper walls are easily and quickly erased, especially at “turns,” by impurities in the coolant.

If you install a copper heating system in your own home, you can easily comply with all the restrictions, but this is difficult to achieve in apartment buildings - in these cases, other materials are preferable.

Good luck.

Probably, someone can afford heating pipes made of silver, you never know the rich eccentrics? I would like to note one more nuance. In the pictures we see new, beautiful pipes. After some time, they will turn black, become covered with a layer of oxide, and they will have to be periodically polished to a shine. Who needs this and why? By the way, this will probably be interesting to lovers of vintage style.