Water heater for fresh air ventilation: types, design, review of models

To solve air exchange issues in private homes and industrial buildings, along with fans, devices are used that heat or cool the air that comes from the street. This helps improve the characteristics of the indoor microclimate and increase the level of comfort.

One of the economical and affordable devices is a water heater for fresh air ventilation, more familiar to residents of the northern regions. From our material you will learn about the operating principles and design features of equipment of this type. We will also talk in detail about several popular models of air heaters for ventilation.

The content of the article:

Types of water heaters for ventilation

Let us immediately note that devices used to heat air in ventilation and air heating systems can operate not only on water.

There are four types of heaters, differing in the method of heating the coolant:

- fire;

- water;

- steam;

- electric.

Water ones are the most popular due to their budget cost and minimal maintenance costs. The only difficulty concerns installation, which requires connecting water supply pipes.

For this reason, it is impossible to install the device in city apartments, but in large buildings (for example, in warehouses, garages, catering establishments) a system with proper heater piping is quite effective.

A distinctive feature of steam appliances is the high speed of reaching the required temperature. They are relevant for industrial enterprises, where it is easy to install and maintain steam pipelines; for private housing, their use is impractical.

If you need quick installation, uncomplicated by connecting communications, use models of electric heaters for supply ventilation. A protected power supply point is sufficient for their operation. There is no coolant as such at all, Heating elements serve as heating elements. Like any electrical appliances, they are unprofitable from a financial point of view.

Operating principle and design features

Universal devices operating on water are installed in places with a well-established heat supply system. A simple but quite effective design solution allows you to heat air in the range from + 70 ° C to + 100 ° C and is relevant for hangars, gyms, supermarkets, greenhouses, warehouses, large pavilions - that is, large premises that require additional heating.

If you have ever used a household heat heater, you will easily understand the principle of operation of a water device. It also heats the air, but the role of an electric spiral enclosed in a small housing is played by a set of metal tubes through which the heated coolant circulates.

The heating process is as follows:

- hot water, heated to the required temperature (on average from + 80 ° C to + 180 ° C), from the heating pipes enters a heat exchanger consisting of small aluminum, steel, bimetallic or copper tubes;

- the tubes heat the air passing through the device;

- The built-in fan distributes heated air throughout the room and stimulates its movement in the opposite direction - towards the device.

There is no need to specially heat the water, since it is part of the heating system, so significant cost savings occur.

The design of a standard water heater is a hybrid of a heat exchanger, fan and convector. It is effective for heating large industrial premises, and, when choosing the right piping, also for cottages with a well-established ventilation system.

Pros and cons of using

If the enterprise has its own heat supply system, the use of heaters for the supply air ventilation of industrial premises is the most cost-effective.

Advantages of devices connected to a centralized system:

- simple installation, no different in complexity from installing heating pipes;

- rapid heating of a large room;

- safety of operation of all components;

- possibility of adjusting the flow of heated air;

- strict industrial design.

But the main advantage is the absence of regular financial investments - payment occurs only when purchasing new equipment.

The main disadvantage is considered to be the impossibility of using water models in everyday life, especially in urban housing. An alternative is to use electrical appliances.

Another nuance concerns negative temperatures: the equipment must be installed in rooms where the minimum threshold does not fall below 0 °C.

Application of water equipment

The heater is an active supply ventilation unit and has its own installation, operation and maintenance features. Wiring diagrams and installation instructions will help you understand the connection and operation of the device.

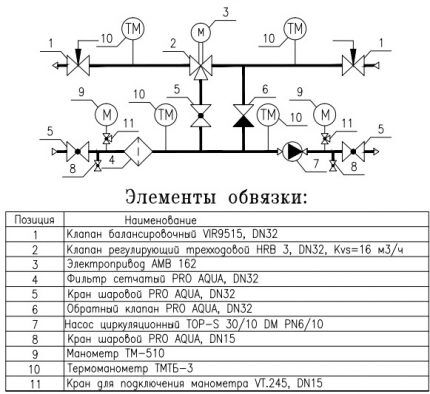

Diagrams of strapping units

The location of the units depends on the installation location, air exchange pattern and technical characteristics of the equipment. Several installation options are possible, among which the most popular is mixing recirculated air with supply air.

A closed system, which involves only recirculation of air masses indoors, is used less frequently.

More opportunities for installing the device arise if natural ventilation is well established. The heater can be connected to the heating system directly at the air intake point, which is usually located in the basement.

In the presence of forced ventilation The heating device can be installed in any convenient place.

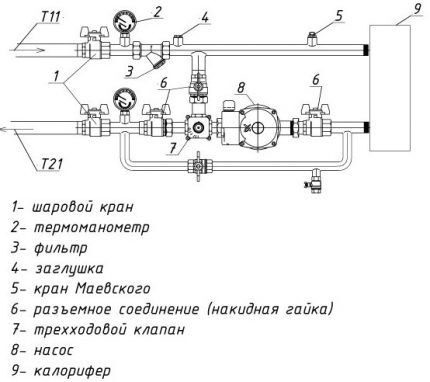

The demand for air exchange systems has led to the fact that some enterprises began to produce ready-made models of piping units in various designs.

These are kits designed for assembly and include the following parts:

- balancing and check valves;

- pumps;

- bypasses, ball valves;

- two-three way valves;

- pressure gauges;

- cleaning filters.

An example of complex production of components is the products of the Integration company (St. Petersburg).

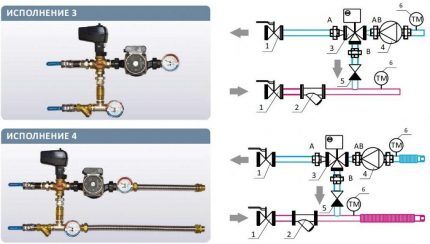

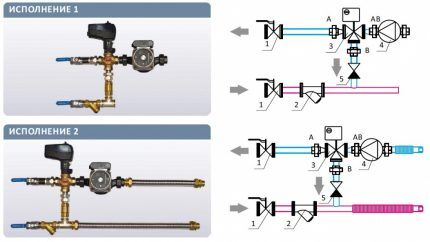

Based on technical installation conditions and user needs, there are several common combinations of arrangement of parts in assemblies.

The following diagrams demonstrate four popular designs:

In versions 1 and 3, the units are connected in a rigid way, in versions 2 and 4 - using flexible metal hoses.

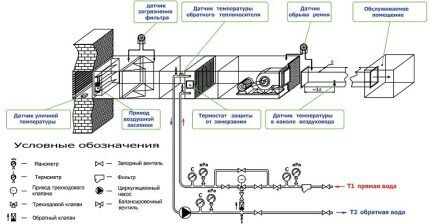

Adjusting the heating process

To regulate the thermal power of air heating devices, mixing units with three way valve. Thanks to the mixing principle, you can significantly reduce the cost of heating a room.

A three-way valve allows you to reduce the temperature of the coolant by mixing into the hot water entering the heater a certain amount of cooled liquid discharged from the heat exchanger.

Installation circulation pump increases the efficiency of the system. It is preferable to install it at the outlet, since chilled water (or an alternative - glycol solution) extends the life of the device.

There are several important operating conditions for mixing equipment:

- maximum proximity to the heater;

- accessibility for maintenance;

- filtered coolant without chemical inclusions;

- the air temperature in the room is above 0 °C.

Technical characteristics of devices may vary, but on average the recommended coolant temperature is from + 2 °C to + 150 °C. To regularly monitor the indicators, it is recommended to install two thermomanometers near the heat exchanger.

The three-way valve is adjusted using an actuator and a controller. Measuring instruments allow you to set the required temperature and change the pressure as accurately as possible.

Installation and connection features

A team of specialists is invited to install air heaters in production workshops or other industrial facilities. You can connect household devices yourself if you strictly follow the instructions and have the skills to work with electrical and heating appliances.

For those who have furnished their home with their own hands heating system, installation of an air heating unit will seem like child's play.

Household models are small in volume and relatively light in weight, but before hanging them on a wall (or ceiling), you should check the strength of the base. Concrete and brick walls are considered the strongest, wooden walls are moderately suitable, and plasterboard walls are the weakest.

First of all, a metal frame is attached - a bracket with holes for fixing the body. Some manufacturers call the frame a mounting bracket.

Suspend the heater body and alternately connect pipes with a set of shut-off valves or a mixing unit, which can be partially installed before installing the device.

Insertion into the heating system is carried out in two ways: by using connecting fittings (couplings with gaskets) or by welding metal pipes. The second method is considered the most reliable, but it is not possible with a flexible connection.

One of the weakest areas is the heat exchanger pipes, which need to be ensured stability. If there is a risk of changing the position of the device, it is better to replace rigid tubes with flexible elements. In any case, the load on the pipes should be avoided. To ensure the insulation of the system and prevent leaks, the joints are treated with sealant.

Before the testing process, it is necessary to remove air from the channels, check the operation of valves and blind guides.

Operating rules and repair possibilities

To ensure that the equipment works flawlessly and fully performs its functions, the following rules should be taken into account:

- monitor the air composition in the room (compliance requirements can be found in GOST 12.1.005-88);

- carry out installation strictly according to the instructions and based on the manufacturer’s recommendations;

- do not increase the coolant temperature above + 190 °C;

- comply with pressure standards - about 1.2 MPa;

- after cooling the room, heat up gradually, at about 30 °C per hour;

- Make sure that the air temperature does not fall below 0 °C, otherwise the heat exchanger tubes will burst.

If the heater is installed in a room with high humidity, the degree of dust and moisture protection must be IP66 or higher.

We do not recommend making repairs yourself, since one breakdown most often leads to the next, and in the end you will simply have to replace some parts. It is better to contact a service center and entrust the work to professionals. In addition, before purchasing, do not ignore heater power calculation, otherwise there is a chance of wasting money.

Brief overview of modern models

To get an impression of the brands and models of water heaters, let’s look at several devices from different manufacturers.

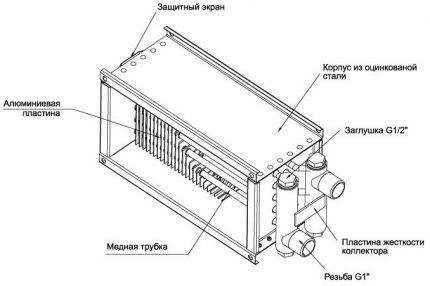

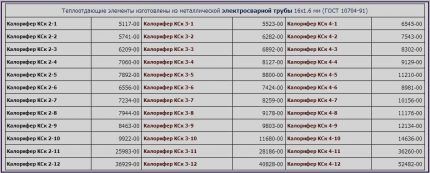

No. 1 - KSK air heaters

Heaters KSK-3, produced at the company T.S.T.

Specifications:

- coolant temperature at the inlet (outlet) - +150 °C (+70 °C);

- inlet air temperature - from -20 °C;

- working pressure - 1.2 MPa;

- maximum temperature - +190 °C;

- service life - 11 years;

- working resource - 13,200 hours.

External parts are made of carbon steel, heating elements are made of aluminum.

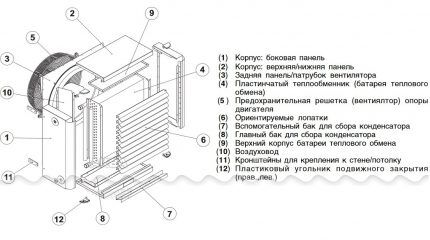

No. 2 - Volcano fan heaters

The Volcano mini water fan heater is a compact device from the Polish brand Volcano, characterized by practicality and ergonomic design. The air flow direction is adjusted using controlled blinds.

Specifications:

- power within the limits - 3-20 kW;

- maximum productivity - 2000 m³/h;

- heat exchanger type - double row;

- protection class - IP 44;

- maximum coolant temperature - 120 °C;

- maximum working pressure - 1.6 MPa;

- internal volume of the heat exchanger - 1.12 l;

- guide blinds.

Volcano water fan heaters are designed to heat the air in domestic and industrial premises using water coolant.

No. 3 - Galletti AREO air heaters

Galletti AREO heater made in Italy.

The models are equipped with a fan, a copper-aluminum heat exchanger and a drainage tray.

Specifications:

- power in heating mode - from 8 kW to 130 kW;

- power in cooling mode - from 3 kW to 40 kW;

- water temperature - + 7°C +95 °C;

- air temperature - from 10°C to + 40°C;

- working pressure - 10 bar;

- number of fan speeds - 2/3;

- electrical safety class - IP 55;

- motor protection.

In addition to the devices of the listed brands, on the market of heaters and water air heaters you can find models of the following brands: Teplomash, 2VV, Fraccaro, Yahtec, Tecnoclima, Kroll, Pakole, Innovent, Remko, Zilon.

Conclusions and useful video on the topic

Review of the Volcano brand water heater:

Details about the technical characteristics of the Ballu BHP-W-60 model:

Simple design and easy-to-do-it-yourself installation are the reasons why water heaters are chosen. The correct choice of device and proper installation of the piping will increase the efficiency of ventilation and improve the heating system of industrial and residential premises.

Do you have any questions about the topic of this article? Or maybe you found some shortcomings in our material or want to supplement it with interesting information? Please write your comments in the block below.

I prefer a water heater to air heating not only to save energy. Our old units with metal incandescent coils dried out the air and worsened all its indicators, burning everything that fell on them from the atmosphere, filling the room with a burning smell. For some time I used an oil radiator; it no longer burned oxygen, but was uneconomical and quickly consumed electricity.