What is a quaril bath: types, advantages and disadvantages, installation nuances, leading manufacturers

The main disadvantage of acrylic products is their instability and instability of the position of the bowl.Without a reliable frame, polymer baths cannot be used, because... there is a high risk of capsizing. Attempts to correct the situation while preserving the advantages of acrylic led to the emergence of a modified material - quarry.

A new product on the plumbing market, the quaril bathtub differs from its predecessor in optimized density and hardness. This expanded the installation options and ensured the safety of hygiene procedures. We will tell you everything about choosing sanitary ware from Kvaril, and introduce you to the leading models and manufacturers on the market.

The content of the article:

Quaril: characteristics of the composite material

Quaril is an innovative composite material created for the purpose of restoring acrylic products. In practice, the synthetic composition has proven its strength and versatility, and enterprising Europeans have expanded the scope of its application. Today, sanitary equipment is made from quaril, in particular, shower trays and bathtubs.

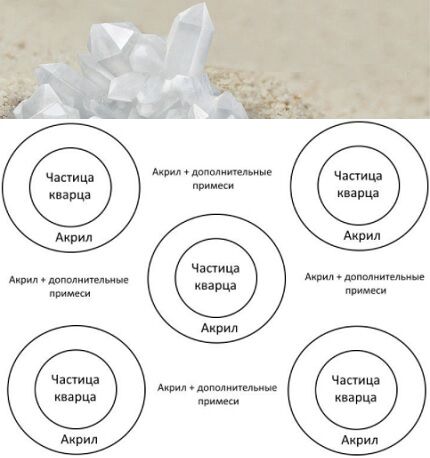

The main components of Kvaril: quartz sand, acrylic resins and patented additives. The quartz component in the material provides strength, wear resistance and rigidity of the finished products. Acrylic resins make up about 60% of the total mass. Polymers are responsible for flexibility with ductility during the processing stage.

Additives give quaril a uniform rich color, anti-slip properties, shine and smoothness. The composite complies with European safety and environmental standards, the material has been tested and approved for the manufacture of sanitary equipment.

The thickness of the bowl walls varies in the range of 0.8-1.8 cm, the bottom of the bath – up to 2.5 cm. The plasticity of the composite melted before polymerization allows you to give the bath various shapes: smooth or strict geometric lines.

Advantages of modified acrylic plumbing fixtures

The quarryl bathtub not only absorbed the advantages of its acrylic predecessor, but also got rid of some of its disadvantages. Composite baths have many advantages.

Low thermal conductivity. Water in a composite container cools slowly - the indicator is comparable to the properties cast iron bathtubs. The coating heats up quickly and retains heat, maintaining a comfortable temperature for water treatments.

Variety of performance styles. Quaril sanitary ware is impressive in the possible shapes and colors.

Wear resistance. The hardness of quaril is comparable to artificial stone.Due to the formation of strong structural bonds in all directions, resistance increases: deep scratches do not remain on it, and the coating made from it is difficult to break or break.

Thanks to its excellent characteristics and large thickness, the bathtub can last a long time, maintaining its attractive original appearance. Kvaril is not afraid of corrosive processes; the material tolerates the effects of hot water at temperatures standard for hygienic procedures and treatment with household chemicals.

Injury safety. The inner surface of the bowl is absolutely smooth, without any roughness. At the same time, the walls and bottom of the tank are not slippery.

Lightness of design. The weight of a standard size model is significantly less than its cast iron counterpart. However, in comparison with an acrylic bowl, quaril specimens are somewhat inferior. Low weight facilitates transportation and installation work.

Good sound insulation. This property, like the previous one, was inherited by composite bowls from their polymer counterparts.

Variability of installation. Installation of quarry plumbing is carried out using support frame or without it. The method depends on the design features and configuration of the bowl, as well as on the design idea.

Easy to care for. Due to the absence of joints, smooth lines and smoothness, dirt is practically not retained on the surface of the sanitary container. To prevent the appearance of deposits, the bathtub should be rinsed with water after bathing and periodically treated with cleaning agents.

You can connect hydromassage options to the quaril bowl, install practical stands, comfortable headrests and other devices for comfortable use.

Negative aspects of quaryl capacity

Plumbing fixtures, which are almost ideal from the point of view of operation, decorativeness and manufacturability, also have some disadvantages.

The disadvantages of quaril baths include:

- high cost;

- fear of extremely high temperatures;

- demanding of cleaning products;

- limited availability of products.

Price. The quarry bath is a new product on the sanitary equipment market. The high cost is due to scarce supply - the number of companies working with quaril is limited.

In terms of price, quaril bowls are superior even to cast iron bathtubs, but are inferior to expensive exclusive models made of natural stone.

Thermophobia. Like acrylic, composite material can become deformed when exposed to high temperatures for long periods of time. The downside is quite relative, since the likelihood of filling the bathtub with boiling water is low. Quaril tolerates standard bathing temperatures (35-40°C) without problems.

Gentle care. Despite the ease of maintenance, care must be taken when cleaning a polymer product. Excessive force when removing stains with abrasive cleaning agents will reduce the original gloss of the surface and make it rough.

Limited availability of plumbing products. Production has been established using a unique technology shower trays and bath bowls. When arranging a combined bathroom, it can be problematic to choose a harmonious trio “bathtub-toilet-sink”, where all the elements correspond to the same style.

The strength of quaril can also be called a relative disadvantage. Compared to cast iron and steel, composite products are inferior, but compared to acrylic, the modified polymer is more resistant to mechanical stress.

The quaryl tank can be damaged maliciously when hit with a heavy object. In everyday life, under typical operating conditions, the risk of deformation and chipping is very low.

Variety of models

Quaril products are classified according to three main characteristics: the method of installation, the characteristics of the enamel coating and the shape of the bowl. The choice of a specific model depends on the dimensional capabilities of the room and the personal preferences of the user.

Types of baths by placement method

All types of composite bathtubs, based on installation technology, are divided into two groups: built-in and free-standing.

Built-in models. Standard installation option - the bowl is installed on a frame or on legs and closed decorative screen.

Features of built-in options:

- compact placement – wall-mounted models occupy a minimum area, saving usable space in the bathroom;

- practicality is the place between functional decorative screen and a bowl is used to store shower accessories and household chemicals;

- the price of built-in modifications is lower than the cost of “stand-alone” models, but their installation is more labor-intensive and requires additional financial investments for the arrangement of the podium, frame or underground communications supply.

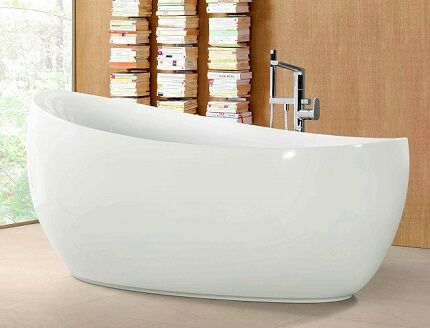

Bathroom free installation. Free-standing bowls look elegant and exclusive. However, it is appropriate to place such plumbing fixtures in a spacious room. Free-standing baths are an expensive option.

Technological solutions for bath surfaces

The leader in the production of quaril sanitary ware, Villeroy&Boch, has developed two coating processing technologies:

- ActiveCare. Ceramic antibacterial enamel with positive silver ions. The synthetic surface prevents the growth of bacteria - reducing the need to disinfect the bathtub.

- Ceramic Plus. Particularly smooth polished coating, which minimizes the deposition of dust and the accumulation of contaminants on the surface.

Micropores present in traditional plumbing products are smoothed out as much as possible - it is difficult for foreign particles to gain a foothold on the coating. Thanks to Ceramic Plus technology, cleaning your bathtub becomes much easier.

Bowl shapes and sizes

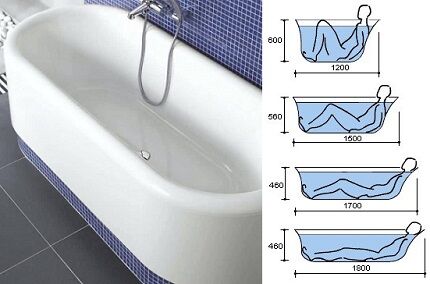

The choice of bath dimensions depends on the size of the room and the height of the household. The standard length of a sanitary container is 170 cm, depth is 50 cm, which is comparable to sizes of bathtubs made of cast iron and acrylic. If you need to replace old plumbing, then a similar quaril option can be selected.

The shape of a composite bathtub largely determines its location.

Quaril bowls are produced in the following configurations:

- rectangular;

- oval;

- round;

- triangular.

Rectangular bowls. Universal models – available in full-size and seated models. Installed in the corners of the bathroom or along the wall.

Oval. The smooth lines of the sanitary container add peace and harmony to the space of the room. Oval bowls allow you to implement various conceptual interior ideas.

The hemispherical type looks harmonious in luxurious oriental, traditional classic, sophisticated Japanese, natural Scandinavian or seasoned minimalist style.

Features of oval composite bathtubs:

- overpriced compared to rectangular plumbing fixtures;

- models with an oblong configuration are quite spacious, but their installation will require more space than for mounting a container of the “correct” shape;

- the bowl looks better in a spacious room - where the beauty of the “oval” can be admired from different angles.

Round. Bathtubs require a lot of free space to accommodate them. The diameter can vary between 150-210 cm.By individual order it is possible to produce a bowl designed for two.

Round bathtubs are considered the best option for installation and equipment hydromassage equipment. Such plumbing fixtures are usually installed for relaxing procedures in SPA salons and private cottages.

Triangular. This group usually includes corner bathtubs and models of regular triangular shape.

Quaril views adjacent to two adjacent walls have a number of advantages:

- space saving - taking a place in the corner frees up space for installing a spacious pencil case, washing machine or washbasin; a corner bowl of compact dimensions is an excellent option for combined bathrooms of small dimensions;

- the ability to combine a full bath with a shower;

- variety of design solutions - right- and left-handed models, symmetrical and asymmetrical bathtubs.

A corner bathtub is similar in capacity to a round shape, so they are also often used for arranging hydromassage equipment.

Installation technology for quaril plumbing

The sequence of installation work is almost identical to the installation of bathtubs made of other materials. One of the important features of the quaril tank is the absence of an overflow or drain hole.This complicates the installation somewhat, but allows you to independently determine the location of the communications connection.

Installation of a built-in bathtub

The first stage, regardless of the placement method, is marking and preparing holes for drainage. Even at the planning stage, you should decide on the location of the bathtub, the point of supply to the sewer system, the placement of the mixer, handrails, nozzles and other equipment.

Following actions:

- Place the bowl on a cleaned base.

- Adjust the horizontal position of the container by twisting and adjusting the height of the support legs.

- Install the faucet and install taps into the side of the bathtub or adjacent wall. An alternative option is to install the floor mixer separately from the bowl.

- Connect the siphon, connect the drainage system to the sewer pipe.

- Assess the quality of sealing of joints at joints. Fill the bowl with water and leave for a couple of hours. In case of leaks, eliminate the gaps.

- Install a decorative screen. If necessary, cover the front panel with finishing material.

The final stage is sealing the joints between the wall and the bathroom. One of the advantages of quaril models is their precise geometric shapes. Therefore, the seam between the edge of the plumbing and the tile will be minimal, provided the wall is even.

Placing a Freestanding Bowl

A separate bathtub is the absolute dominant feature of the room’s interior. To install it, it is advisable to choose a place so that the distance from the walls of the container to surrounding objects is at least 50 cm.It is important to adhere to an asymmetrical or axial interior composition.

A special feature of installing a free-standing type is the need to lay water supply and sewer pipes deep into the floor. There is not enough space under the bowl siphon connections and communication systems, as when installing traditional wall-mounted plumbing. Grooves are prepared in the floor screed and pipes are laid in the channels.

Sequence of work:

- Lay the plumbing pipeline through the floor.

- Place the quaril bowl on supports, such as bars. Raising the bathtub will provide access to its base for connection work.

- After connecting the bowl to the communications, remove the stands and install it on hidden legs.

- Level the horizontal position of the bath.

- Test the tightness of the joints and install the front panels.

A rational way to install a quaril bathtub is to arrange a podium behind which all the plumbing equipment will be hidden. The solution will simplify repair work and effectively highlight the area where water treatments are performed.

Overview of composite plumbing manufacturers

The undoubted leader in the manufacture of composite bathtubs is the German manufacturer of sanitary equipment, dishes and household accessories - Villeroy&Boch. The company is a pioneer in the production of quaril baths.

Decisive advantages of Villeroy&Boch quarry:

- high-precision casting technology allows for the implementation of unique design solutions;

- the material is excellent for flush-mounted hydromassage systems;

- resistance to UV radiation;

- impact resistance of the bowl – wall thickness 8-18 mm;

- smooth coating with slip resistance.

Bestsellers: free-standing spherical bathtubs, oval, rectangular and corner options.

In addition to Villeroy&Boch, composite plumbing products are produced by the following companies:

- Jacob Delafon (France);

- PAA (Latvia).

Jacob Delafon. A French company with a rich history and reputation as a high-quality manufacturer. The main specialization is the production of exquisite sanitary ware and bathroom furniture. Jacob Delafon offers a wide range of sanitaryware made from acrylic, cast iron and artificial stone.

Jacob Delafon composite bathtubs are equipped with an antibacterial BioCote coating - the material contains silver ions. Side and front panels are provided for decoration.

P.A.A. Leading manufacturer of sanitary products in the Baltic countries with an export network covering Eastern and Western Europe. Among the diverse assortment, there is a line of bathtubs made of GRP composite.

PAA plumbing is a successful combination of ergonomics, functionality and artistic value.

Conclusions and useful video on the topic

The video review shows several options for placing a quaril bowl and ways to harmoniously combine plumbing with the design of the bathroom:

The cost of innovative plumbing fixtures is high, and it is represented exclusively by European brands that guarantee the reliability and durability of their products. Quaril products have already occupied a certain niche in the group of goods, and will soon become more in demand due to a gradual reduction in price.

Please write comments in the block below. Share useful information on the topic of the article. Ask questions about unclear and controversial issues, post photographs.

How quickly everything changes: not long ago I was looking for a new bathtub and didn’t see quaril ones on sale, but now they suddenly appeared everywhere. I myself prefer cast iron; I’ve never been attracted to acrylic bathtubs, but if Kvaril’s characteristics are not inferior to cast iron, being lightweight, and even so varied in design, then you should definitely take a closer look at it.

I haven’t earned enough money for a quaril bath yet) But I had the pleasure of seeing one at my friends’ house in a private house. What can I say - cool thing. I don't even know what else to add. A completely different level of quality of life, a different level of the space surrounding you at home. Friends chose a free-standing floor bowl. There were no problems with laying pipes and water outlets. The secret is that the bathtub was changed in parallel with a major overhaul of the entire bathroom. When the new subfloor was poured, all the pipes were laid at once and they hardened and fixed at the same time along with the screed. I didn't have to cut or gouge out anything.I made a note for myself that this is the most competent and optimal option. The only caveat is that you should not save on pipes laid under the tiles. Take the best ones. If it leaks, it won’t seem like much, especially if the house is connected to a centralized water supply.

Essentially, a quarryl bathtub is an improved version of an acrylic one. I’ll say for myself that it’s not at all easy to care for it, many cleaning products can damage the surface, and prolonged exposure to hot water can cause it to become deformed!

Although it does retain its ideal appearance longer. And the main disadvantage is the price. She is inappropriately tall. It’s easier to buy regular acrylic every year, and you’ll still have an advantage.