How to make a heated floor under tiles: installation rules + installation guide

Installation of heated floors is possible in rooms with high ceilings.Most often they are installed in the bathroom, but heated floors under tiles can be installed throughout the entire area of the apartment.

There are several heating methods that must be chosen individually, depending on the height of the ceilings, the condition of the wiring and the water pressure in the apartment or country house. The most popular are heating mats, which are easy to install.

In this article we looked at the basic rules for laying infrared and cable heated floors. They also provided detailed instructions on how to set up a heating system under tiles using heating mats. The material is supplied with step-by-step photos and video recommendations from specialists in laying heated floors.

The content of the article:

Types of heated floors

Before you start choosing a floor heating system, you need to consider that they have limitations. Despite the fact that heating systems can completely replace heating in an apartment, this cannot be done according to Russian legislation.

These restrictions are due to a number of reasons:

- In apartments it is only allowed to use electric heated floor, and the widespread use of such systems in the home leads to an increase in the load on the electrical network.

- A massive or partial transition to electric heating leads to an imbalance in the heat supply system in the house.

Since the floor will not be used as the main source of heat in the apartment, you can save on its installation. The saving lies in laying the heating cable or film only in those places that are free from furniture.

In a private home, the possibilities for using this technology are much wider. Depending on the available energy sources, you can choose an acceptable option between water and electric heating.

If the house is equipped with autonomous sources of electricity, such as wind generators or solar panels, undoubtedly, it is worth making a choice in favor of electric ones, i.e. cable or infrared heating systems.

If electricity is supplied through power lines, then using an electric heating option for a private home will be very expensive. In this case, it is better to opt for water heated floor. It will last about 35 years, after which it will require replacement.

Basic rules for installing heated floors

Despite the different heating principles, there are several basic principles for installing all types of heated floors under floor tiles.

The first general rule is to remove the old screed after directly dismantling the coating. This will allow you to gain a few centimeters of room height, which is especially important in apartments with low ceilings or if heating is installed in only one room.

For waterproofing, you can use special compounds such as liquid glass or bitumen. Particular attention should be paid to bathrooms. If moisture gets through the screed, this will lead to gradual destruction of the concrete. This is true for both private houses and apartments.

After waterproofing, you need to do thermal insulation. Its thickness is determined individually, depending on the height of the ceilings and the level of difference between the rooms. The thinner the insulation layer, the greater the heat loss.

Another rule is the need to reinforce the floor under the tiles.

For this, ready-made reinforced meshes with a wire thickness of no more than 6 mm are used.

Mixtures with a gypsum base cannot be used to pour floor screed under tiles. They are too fragile and not suitable for pressure. In addition to fragility, they do not have the properties necessary for adhesion to tile adhesive.

It is necessary to use leveling mixtures such as self-leveling floors. They give the best effect, since the surface is smooth and suitable for laying tiles with minimal consumption of adhesive solution.

Rules for laying cable heated floors

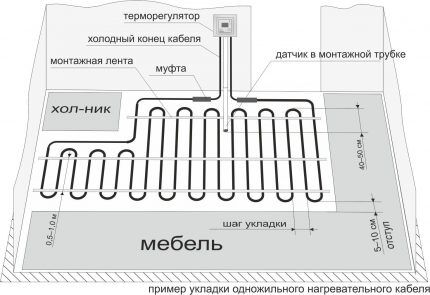

Before installing new equipment that will create a load on the wiring in an apartment or house, you need to make sure that the wiring can withstand it. First you need to make markings where the electric mats will be laid.

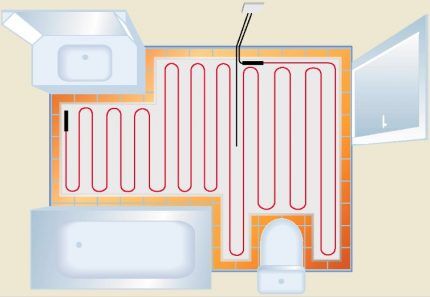

When planning an apartment, it is necessary to exclude the installation of permanently installed large furniture without legs, plumbing fixtures and household appliances in areas where they are located. This is because electricity creates a magnetic field that will interfere with household appliances.

When planning, it is also forbidden to install electric heating in the areas where water and gas pipes are located.

Determination of power, cable cross-section and wiring in the house

The minimum distance from each wall must be at least 10 cm. It is also necessary to exclude areas where furniture is installed. The area for installation of mats is calculated by subtracting from the total area the sum of square meters where installation will not take place.

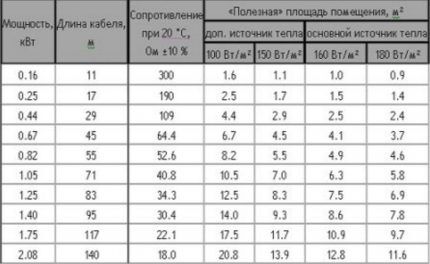

The resulting number must be multiplied by 140 W if the floor is not used as the main source of heat. If you plan to use only the floor for heating, then you need to multiply by 180 W.

Based on the data obtained, you can purchase cables or electric mats for heating the floor covering.

As for the wiring, it is necessary to calculate the total power of the devices that are used in the apartment. This information can be found in the instructions for the equipment, and it is also duplicated on the device body.

Aluminum is not suitable for wiring a house where you plan to install an underfloor heating system. This is because copper has better thermal conductivity. Using the table, you also need to determine the current strength and install the machines on the electricity meter.

If the wiring in the apartment does not meet the required specifications, it must be replaced before installing the heating cable or mats. If this is not done, then the electricity in the apartment will periodically be cut off, and then the sockets will begin to melt.

Ultimately, this will cause a short circuit and fire. This is dangerous and you should not skimp on safety, especially if the house or apartment is made of flammable materials. We recommend that you familiarize yourself with the wiring diagrams in the apartment and recommendations for installing it yourself. For this follow the link.

Installation of mats and installation of control system

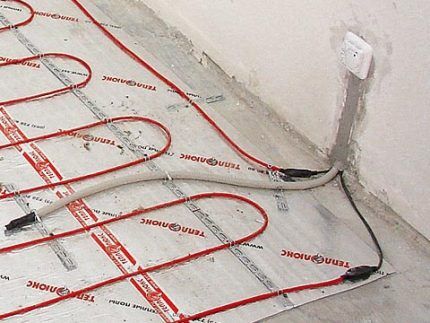

The process of installing electrical mats is simpler and faster than installing cables. It is enough to place them on the heating area, which was determined when drawing up the diagram.

This will ensure an even level of heating of the floor surface. It is not recommended to cut the cable during installation.

After laying the cable you need to install thermostat. It performs an important function - maintaining the specified temperature of the floor covering.

This allows you to reduce energy consumption, since the heating will periodically turn off when the set temperature is reached. If the temperature sensor detects a decrease in the user-specified mode, the heating will automatically turn on.

The hole should be located above 30 cm from the floor surface. A vertical channel is drilled down from the hole where the corrugation for the temperature sensor will be installed.

The opposite end of the corrugation should be located between the turns of the heating cable at an equal distance. If this rule is not followed, the sensor readings will be overestimated.

When connecting the heating cable to the control unit, you must follow the instructions from the equipment manufacturer. Before connecting, you need to check the resistance of the wires with a special device.

Rules for laying infrared heated floors

Despite the design differences infrared heated floor Installs just as easily as electric mats. But there is a difference between them. When connecting a film heater, parallel rather than serial connection is used.

From a design point of view, this is a more reliable method, since if one module fails, the rest will continue to function.

The film must be laid with a slight overlap, strictly following the markings. The modules are fastened together with masking tape. This is a temporary method of fastening, since after pouring the self-leveling floor there will be no need for fastening.

We discussed in more detail the features of film type heating in another article.

Installation guide for electric underfloor heating

The quality of the coating depends on the condition of the base on which it is to be laid. The work should begin by dismantling the old coating. Everything must be dismantled, including the old screed.

After removing the old coating, it is necessary to remove all small debris and dust. After this, you need to inspect the floor area and if there are cracks, they need to be repaired. When the floor surface is prepared, you can begin waterproofing and insulation.

Stage #1 - installation of insulation under the electric floor

Insulation must be laid on the prepared base. It is preferable to use cork sheets. They have sufficient density and do not sag under the weight of the screed, as happens with expanded polystyrene.

The use of low-density insulation will lead to the need to dismantle the finished floor due to depreciation of the material.

The insulation is attached to the surface by gluing it onto bitumen mastic. Through the use of this material, not only fixation of cork sheets is achieved, but also waterproofing.

The service life of heated floors also depends on the quality of gluing. After waiting 5-6 hours, you can proceed to pouring the screed. The thickness of the screed must be at least 3 cm.

When using a self-leveling floor, there is no need for regular leveling, as happens with self-mixed cement mortars. After work, you need to leave the surface until completely dry, approximately 3-4 days.

Stage #2 - laying heating mats

After the filling solution has hardened, you can begin installing the heated floor under the tiles. First, you need to outline with chalk the places where the mats will not be installed. This will help you navigate and not overuse material.

After installing the mats, you need to begin installing the control unit and temperature sensor. The control unit must be connected in strict accordance with the diagram and color markings of the wires provided by the manufacturer.

A special corrugation is laid down from the control unit where the temperature sensor will be installed. The end of the corrugation, which is located between the heating mats, must be tightly sealed.

When the installation of electronics is completed, you need to turn on the system and check its functionality. If there are no defects in the operation of the heating system, you can begin pouring the last layer of screed. The required fill level should be marked on the wall to make it easier to navigate.

The minimum thickness of the screed is 4 cm. When pouring the self-leveling floor, you need to ensure that the liquid is evenly distributed. A roller can be used to move excess solution.

After pouring, you need to wait a few days until it dries completely. At this time, you need to control the air temperature in the apartment. If the air is dry and hot, there is a risk of cracking the screed. You can start laying tiles only after the self-leveling floor has completely dried.

Stage #3 - cutting floor tiles

Manual is ideal for working with floor tiles. tile cutter. To work with it, you need to prepare the tiles in advance. The tiles are pre-soaked if specified by the manufacturer.

If there are no such recommendations, then just wipe the tiles with a damp cloth. This is necessary to clean the surface along which the cutting element of the tool will move.

This is done as needed, in places where the masonry approaches a wall or corner. If water supply or heating pipes come out of the floor, then it will be necessary to make shaped holes in the tiles.

A hand cutter is used for this. The holes made with it may have jagged edges. To eliminate the aesthetic defect, it is necessary to sand the edges with sandpaper.

Stage #4 - laying tiles on heated floors

It is necessary to begin work on tiling the floor with markings, which are largely determined by the type of masonry. The most common options for laying tiles are diagonal And straight.

Which method to choose depends on the interior design and geometric features of the room.

The tiles are placed on top of the adhesive solution and leveled. Periodically it is necessary to check whether there is any tilt. This is done using a building level.

The level should not be longer than 60 cm, since with a longer length the reading error increases. To maintain an equal distance between the tiles, you need to use plastic crosses.

Their standard size is 2 mm. If the tiles are large, you can use a larger size. The crosses that regulate the height are removed, and those that border the four tiles are not dismantled after laying, but are hidden when grouting the joints.

For grouting, special compounds are used, painted to match the coated surface. Grouting work can only be done after the adhesive solution has hardened.

Stage #5 - varnishing the finished tiled floor

To preserve the tiles in their original form, you need to take care of varnishing. This simple procedure will prevent the need to replace the tile covering.

Varnishing is especially important for matte tiles, which are often used for bathroom floors, as they do not slip.

When the first layer of varnish is applied, it is necessary to open the window in ventilation mode, and also close the door to the room. After complete drying, which occurs after 6-8 hours (depending on the composition of the varnish), it is necessary to repeat the procedure again.

Conclusions and useful video on the topic

How to mount the control unit:

How to install heated floors in rooms with little heat loss:

What happens if you don’t fix the insulation:

What to pay attention to when designing a house:

Correct installation of underfloor heating systems under the installation of floor ceramics will significantly extend its service life. You need to choose a company carefully -heating system manufacturer.

Most often, electronics fail, which can be easily replaced and continued use of heated floors. If the control unit breaks down, it will be difficult to get a new one if the manufacturer stops producing heating systems. Temperature sensors are easier to select since they are interchangeable in many models.

Have you installed heated floors under tiles in your home? What heating system did you use? How satisfied are you with the result and have you encountered any types of breakdowns? Share your experience in installing and operating heated floors - leave your comments under this article.

For a very long time I have been wanting heated floors for my kitchen and bathroom, and I have tiles here and there. But I can’t decide, it’s not fast and it’s not cheap. But the main thing that confuses me is the waterproofing. At first I also thought about bitumen mastic, but it is not recommended for use indoors, because at high temperatures it begins to release toxins.

The option with liquid glass is more interesting and seems to be more reliable. I would like to see a separate material for waterproofing, after all, this is very important, especially for the bathroom. Moreover, I have a shower stall there without a tray, just a floor with a slight slope towards the drain. In such conditions, is it even possible to make heated floors or is it too risky?

When buying an apartment and subsequent renovations, I installed a heated floor in my kitchen. First I had to change the aluminum wiring to copper.I managed to do everything myself with a friend, there were no problems with installation. I tried to remove the old screed as much as possible so that the finished floor would not be too high. However, after laying the tiles, the level still rose, I had to make a threshold to the kitchen, and cut off the door so that it could close. I cut the tiles with a grinder, but I couldn’t find a tile cutter. The only thing I didn’t know was about varnishing the tiled floor; I’ll have to look into this issue this weekend.