Acrylic or cast iron bathtub - which is better? Comparative review

Modern man is spoiled by comfort and cannot imagine his existence without the so-called “benefits of civilization.”The bathroom, equipped with the latest technology, is far from the last place on their list.

At the same time, it is important to understand what material the plumbing fixtures are made of, because not only the appearance, but also the ease of use depends on this. A wide selection of offers can confuse consumers, don’t you agree? In order not to be disappointed in your purchase, you should know about the pros and cons of each model.

We suggest you figure out what is better - an acrylic or cast iron bathtub, which option should be preferred and why. In the article, we described in detail the characteristics, features of the operation of different hot tubs and their care. A comparative assessment of the parameters will help you make an informed choice.

The content of the article:

All about cast iron baths

For the manufacture of sanitary equipment, only high-quality alloy is used. Cast iron is cast in sand molds. After the workpiece has cooled, it is cleaned and coated with enamel.

For this purpose, a special powder is used, which, under the influence of high temperature, turns into an enamel coating. The walls of bathtubs from Russian manufacturers are up to 1 cm wide, which, accordingly, increases their weight.

Leading European manufacturers produce products with a wall thickness of up to 5 mm, while their strength is not inferior to their domestic counterparts. The composition of the enamel also differs.

Russian products are often coated with a composition containing zirconium, while European ones are coated with a mixture of titanium.

The latter option gives a more durable and smooth coating.The length of bathtubs from different manufacturers is approximately the same. The peculiarities of the technological process do not allow the production of products longer than 1.9 m.

Why choose such products

Cast iron baths have a number of significant advantages.

We list the main ones:

- High strength. The metal from which they are made is rigid and holds its shape well. The bottom of the bowl does not sag under any circumstances; it does not require additional supports besides the legs. Even if two people with a lot of weight take the bath, the bowl will not change its position and will not become deformed.

- Low thermal conductivity. Thanks to this, hot water in a bathtub made of this alloy does not cool down for a long time. On average, it takes 8-10 minutes for its temperature to drop by one degree. Therefore, there is enough time to soak in the foam without having to add hot water.

- Aesthetic appeal. Cast iron bathtubs are coated with a special anti-corrosion coating, which helps the bowl maintain its original appearance for a long time.

- Resistance to temperature changes. The enamel is applied in an even, smooth layer; the substances included in its composition make it insensitive to sudden temperature changes.

- Good noise absorption. Thanks to this, you can draw water into the bowl almost silently, which is impossible, for example, for steel products.

With proper care of a cast iron bathtub, the service life of plumbing fixtures is much longer than that of equipment made from other materials and is at least 50 years.

It cannot be said that manufacturers produce cast iron bathtubs of various shapes. Due to the characteristics of the material, this is extremely difficult to do, but the products are equipped with functional additions: handles, hydromassage, etc.

Despite the many advantages, plumbing fixtures also have disadvantages. First of all, this is, of course, a large mass. The bathtub weighs on average 120 kg.

It is clear that installation “alone” is impossible here. Moreover, such a product is difficult to transport and lift to any floor above the first. You have to use the services of movers, which entails additional costs.

Another disadvantage is the fairly high cost of cast iron bathtubs, especially if they are made by a well-known company. Buying a cheap product of unknown origin is quite dangerous, because in this case its quality is not guaranteed.

Features of caring for cast iron baths

Replacing a cast iron bathtub and enamel restoration - a labor-intensive and costly process. Therefore, it is worth taking care of the new product, then it will last a very long time. Caring for an enamel bathtub is quite simple. First of all, it should be washed after each bath.

Particles of grease and soap flakes collect on the enamel; if they are not removed immediately, they will dry out and turn into difficult-to-remove dirt. Therefore, you should take a soft sponge soaked in a mild detergent solution and treat the bowl.

If you don’t have time for this, you should rinse the bathtub with hot water from the shower head.It is strictly not recommended to use powders or abrasives to clean equipment. They will scratch the enamel, which will begin to deteriorate.

Compositions with acids corrode the enamel surface of the bathtub. It loses its smoothness and becomes like sandpaper. Contaminants easily stick to such a surface and are very difficult to remove from it.

To deal with stains that appear on the enamel, you should use special products. The coating of the bowl must be protected from chipping. They can appear from objects falling from a height into the bathtub: glass vials, shower head, etc.

There is no need to place metal buckets or basins inside the container: they can damage the enamel. For the same reason, when bathing pets, especially large dogs, a rubber mat should be placed on the bottom.

More information about methods and means for caring for cast iron bathtubs is written in this article.

Signs of a high quality product

The store usually offers a large range of cast iron bathtubs.

A quality product can be easily recognized by several features:

- perfectly smooth inner surface;

- uniformly colored enamel without stains or inclusions;

- absence of defects such as chips and gouges on the outer surface of the product.

It is good that the bathtub comes with a drain and all the necessary elements: legs, handrails, etc. It is desirable that the legs can be adjusted in height. This will make the product easier to install.

Acrylic bathtub: what the owner needs to know

Under the name acrylic bathtub, two completely different types of plumbing fixtures are sold in stores.Their main difference lies in the material from which they are made. By and large, the properties of finished products depend on its characteristics.

The first type of bathtub is made from pure or, as it is also called, cast acrylic, the second - from co-extruded acrylic.

Before the polymerization procedure, various components are added to polymethyl methacrylate or PMMA to improve the properties of the future product. Thanks to this, the composite acquires durable color, plasticity, maintainability and hygiene.

In addition, additives can be added to plumbing acrylic to prevent the proliferation and growth of bacteria on the walls of the bowl.

Despite the fact that PMMA is used in the manufacturing process of both types of baths, the results are different.

Products made from cast acrylic are produced as follows. First, high quality material is made. To do this, the liquid compound is poured into sealed glass molds and sent to a steam oven for polymerization. The result is a high-quality sheet of solid material with a thickness of about 8 mm.

The resulting sheet is heated, then vacuum-stretched to the desired size and shaped. A reinforcing layer is applied to the back side of the acrylic blank: a mixture of fiberglass and polyester resin.

Then all excess is cut off from the almost finished bowl, and all the necessary holes are drilled. The workpiece is mounted on a load-bearing frame assembled under its structure and polished.

Products made of two-layer plastic are made differently.In addition to PMMA, they also contain acrylonetrile butadiene styrene or ABS, which is an elastic plastic.

During the production process, melts of both compositions are simultaneously squeezed out through the nozzles of the apparatus and combined with each other. After hardening, a plastic structure is obtained, which has a glossy acrylic surface on one side and an impact-resistant ABS base on the other.

Pros and cons of acrylic products

The undoubted advantages of acrylic bathtubs include their low weight, up to only 40 kg. Such products are easy to transport and do not create additional load on the floors. Equipment installation is also greatly simplified. If desired, it can be performed by one person.

The products have sufficient strength, however, this applies to devices made of cast acrylic. They are able to withstand even strong impacts with minimal losses.

Among the acrylic models, you can easily choose a product for any interior style. The number of colors is also practically unlimited. The pigment is introduced into acrylic before polymerization, which allows you to obtain a durable color that does not change over time.

Acrylic bathtubs have low thermal conductivity. The water collected in them retains its temperature for a very long time. It will take about 30-40 minutes to cool by one degree, so periodically adding warm water while taking a bath will not be necessary.

In addition, despite its smoothness, acrylic has anti-slip properties, which makes water procedures safe.

The composite absorbs sound quite well, so the owner of the bathtub does not have to listen to drumming while pouring water into the bowl.

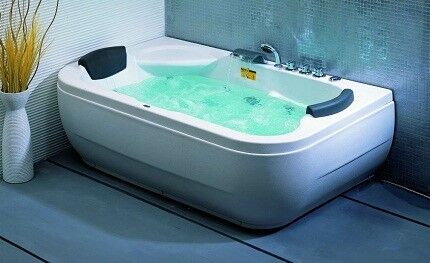

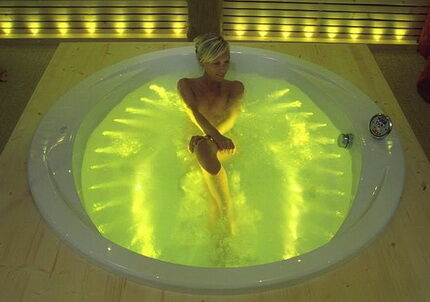

Acrylic products are multifunctional. The ease of processing the material makes it possible to install in them all kinds of nozzles and nozzles for hydromassage, handrails of various shapes and configurations, lighting, an automatic overflow system and much more.

One of the main advantages of acrylic bathtubs is their repairability. Small cracks, scratches or chips can be restored very quickly and simply using special compounds that can be easily purchased at any hardware store.

An acrylic bathtub that has lost its attractive appearance can also be restored. There are two acceptable methods - you can insert it inside acrylic liner or use filling method.

Both methods are quite effective and will help extend the life of your favorite bathtub. It must be admitted that all the above-described advantages are inherent for the most part in products made from cast acrylic.

Models made of two-layer plastic are coated with PMMA only on the inside and the layer of this coating is very thin. ABS, which, in fact, makes up approximately 80% of such a bowl, absorbs moisture and breaks down quite quickly.

The disadvantage of acrylic bathtubs is their sensitivity to high temperatures. PMMA melts at a temperature of 160°C, so when hot water is poured, the plastic softens a little and may become deformed.For this reason, manufacturers recommend pouring cold water into the bath first and diluting it with hot water.

The composite is sensitive to alcohol-containing substances. Under no circumstances should they fall on the surface of such a bath.

Another disadvantage is the fragility of acrylic products. A strong impact, especially if an object falls from a height, can destroy the plastic. At the same time, serious deformations cannot always be restored and the bathtub has to be replaced with a new one. Under the weight of a large person, acrylic can “play” and bend, which is not very pleasant during the bathing process.

The disadvantages include the high cost of high-quality injection molded products.

How to care for acrylic equipment

Contrary to popular belief, caring for acrylic products is quite simple. Especially if you follow certain rules.

Rule #1. The acrylic surface should be washed after each use or at least rinsed with hot water. Contaminants frozen on the acrylic surface turn into difficult-to-remove stains.

Rule #2. To clean products, you can only use special products or solutions of mild detergents. All cleaning compounds with abrasives are the enemies of acrylic. They scratch the gloss and over time turn a shiny bathtub into a matte one.

Rule #3. Taboo on chlorine-containing products and solvents. When trying to disinfect a bowl with one of these compounds, you can only achieve a sharp clouding of the coating. If you use the drug a second time, the acrylic bowl will be covered with a network of small pores.

All solvents, including acetone, also affect it.At first it becomes cloudy, if the composition is not washed off immediately; with prolonged contact, it simply corrodes the surface of the bowl. Ammonia and formaldehyde have a similar effect on acrylic. They should not be allowed to come into contact with the bathtub.

Rule #4. If rust stains or lime deposits appear on the surface, you should not use traditional methods; you should only use special products for acrylic.

On our website there is a series of articles devoted to the care of acrylic plumbing fixtures, we recommend that you read:

- Caring for an acrylic bathtub at home: useful tips

- Choosing cleaning products for acrylic bathtubs: a comparative review

How to “recognize” quality acrylic

When it comes to choosing an acrylic bathtub high quality, you need to understand that most often only the injection molded version is meant. Double-layer plastic almost never falls under this definition. Therefore, the first thing to do is to determine the composition of the model you like.

It's very easy to do. On the cut side of the bathtub, cast acrylic will have two layers, co-extruded acrylic will have three.

In addition, there must be:

- Smooth surface - any roughness indicates low quality.

- Structural strength — when pressed, the bath should not “play.”

- Same material thickness on all surfaces of the product - checked with a flashlight.

- Fairly simple form - an overly complex configuration often reduces the strength of the product.

It is worth paying attention to the thickness of the sides. For quality products they cannot be thinner than 4 mm. Often they are even wider – about 6 mm.Low-quality bathtubs have sides that range from 2 to 4 mm wide.

Comparing acrylic and cast iron: important characteristics

And yet, when choosing a bath, should you prefer acrylic or cast iron? To completely dispel all possible doubts, let’s compare both options in several important parameters.

Durability and strength

When comparing these indicators, cast iron definitely wins. It does not corrode and is highly resistant to any mechanical stress. The maximum that threatens him in this sense is a chip of the enamel. If desired, such damage can be restored by restoring the enamel layer.

Cast iron holds its shape very well, does not sag and serves the owner for decades.

Acrylic is inferior in many ways. Its service life depends entirely on the quality of the product and how it was made. Double-layer bathtubs rarely last more than 5-7 years; for cast bathtubs, this period is certainly longer. But still it is not as long as cast iron: only 10-15 years.

The strength of acrylic products is low. Even the best bathtubs can sag under the weight of a person, which creates some discomfort and a feeling of instability.

Appearance and design features

In this area, acrylic products simply have no competitors. Their production technology allows us to fulfill any design ideas. Baths can have various shapes, even the most whimsical.

The ease of processing plastic allows you to make a large number of holes for installing additional equipment, which makes it possible to equip acrylic bowls with any functionality.

There are no restrictions in choosing the colors of products. Cast iron bathtubs cannot boast of such variety. Heavy metal does not require the use of designer refinements in processing.

The range of cast iron products is very small, and the number of shapes is also small. Only the legs of the structure and, possibly, the handrails are decorated. There is also no variety of colors - all the devices are mostly white.

Installation features

Everyone knows that installation of a cast iron bath is quite complex, which is due to its weight - any model weighs more than 100 kg. To this you need to add the mass of the person bathing and the water collected in the bowl.

The result will be more than 220-250 kg, which can be considered a serious load on the floors. Concrete, undoubtedly, will withstand it, but structures made of wood, for example, will need to be further strengthened. However, this is where the difficulties with installing a cast iron bathtub end.

It is quite difficult to deliver it to the installation site, especially if it is on one of the upper floors. Due to its massiveness, it is very stable and all the installer needs to do is level it in height. Why are there adjustable legs?

We must admit that installing acrylic products is also quite difficult. The main difficulty here lies in the mandatory presence of a metal frame, which is necessary to strengthen the bowl. For each model, the design is developed specifically. Bathtubs are equipped with frames at the factory.

During installation, you must first correctly assemble the frame and connect it to the bowl. Many people think that such a design will not be enough to make an acrylic bathtub stable.

In this case, a homemade frame is additionally used or a brick cushion is assembled as a base. All this certainly makes it difficult installation of acrylic product.

But otherwise it is quite simple, considering that the weight of the frame and the bathtub itself is small. If desired, any home master can cope with such work alone.

Cost and additional expenses

It must be admitted that the price of quality products made of cast iron and acrylic differs slightly. In both cases, you can purchase the simplest model for relatively little money, but all additional elements will significantly increase this amount.

The price is determined depending on the brand, design and quality. Each buyer determines the acceptable ratio of these characteristics for himself.

It is important to understand that there is no point in buying something that is too cheap and obviously of poor quality. The funds spent on its purchase and installation can be considered wasted, because it will not last long.

Additional costs include the cost of purchasing special cleaning products to care for the bathroom. These will definitely be required for acrylic; cast iron products are less capricious in this regard.

Conclusions and useful video on the topic

Comparison of technical and practical qualities of sanitary ware for an informed choice of a bathtub from innovative acrylic or traditional cast iron:

Criteria for choosing a cast iron bowl:

How to choose a good acrylic bathtub correctly?

It is believed that acrylic bathtubs are ideal for multi-story buildings - they are easy to transport and easy to install. Among them, you can easily choose a model for the smallest bathroom. Cast iron bowls are better suited for a private home or cottage.

However, these are only recommendations from practitioners. Both options have disadvantages and advantages. The elegance of acrylic or the practicality of cast iron: the final choice is up to the buyer.

Are you looking for a practical, beautiful and durable bathtub? Or do you have experience using cast iron or acrylic plumbing fixtures? Please share with readers your impressions of using different types of bathtubs, ask questions and participate in discussions. The comment form is located below.

In my opinion, a cast iron bathtub is still better. With proper care, it will last much longer than acrylic. Yes, you will have to puff while installing it, because it is quite heavy, but you won’t have to change it every 5 years. I've had a cast iron bathtub in my house for forty years. I recently restored it using special paint. White now, like new. It will stand for many more years.

We have had a cast-iron bathtub installed at home for several years, and when the child appeared due to sleep problems, we often began to bathe our daughter in various herbs. After a few weeks, the bath began to take on a yellowish tint. I suffered a lot to bring it into proper shape and return it to white.I decided to temporarily install an acrylic liner without gluing, so as not to spoil the expensive cast-iron plumbing.

Modern enamels for cast iron bathtubs are made using titanium salts, which significantly increases the strength of the enamel. Now it can be washed with almost any chemical, rubbed with brushes, etc. But old-style bathtubs with enamel based on zirconium salts are more susceptible to corrosion - any scratch and there is a risk of rust.

So you definitely need to pay attention to this when purchasing. And the cast iron bathtub is more durable, so I prefer it.