What to do if the drain tank does not hold water: causes and solutions for breakdowns

Any breakdown of the toilet is a real stress for the owners, as it is associated with unexpected expenses, unpleasant emotions and loss of time. If the drain tank does not hold water, and you don’t know what to do in such a situation, then read our tips.

We will tell you how to determine the cause of the problem. We'll show you how to fix the problem yourself step by step. The article we have proposed describes in detail the types of damage that can cause the container to stop holding water, and ways to solve the problems.

The content of the article:

Features of the tank

The mechanism for draining water from the tank is of two types. In the first, all the water is drained when you press a button or when you lift the handle up. The first option provides two buttons for rational use of water. When you press one of them, the water is partially drained, and using the second you can remove all the water from the tank.

If the flush works normally, then water flows into the toilet bowl quickly and without delay with a characteristic sound. If problems arise, the flow of water either does not stop and the walls of the toilet are constantly wet, or the water overflows from the tank.

This kind of breakdown can cause flooding of the toilet room, or provoke the formation of limescale on the walls of the toilet and, undoubtedly, lead to high water consumption due to its constant supply. Another sign of a malfunction may be the appearance of condensation on the cold water pipe that leads to the toilet.

To avoid further problems and fix the leak, it is important to find out cause of leak and determine in which part of the tank the breakdown occurred and check all the parts. To do this, you need to turn off the water in the riser, then clean the tank and study the design.

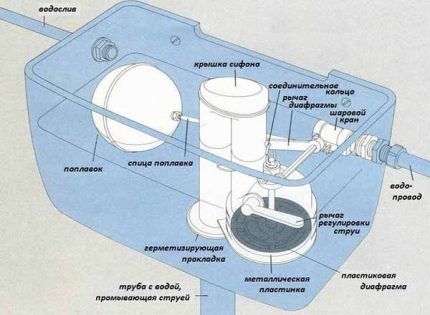

Flush design device

If previously the tank body was made of cast iron, today ceramics, earthenware or special plastic are used. All the main elements of the tank are connected to each other.

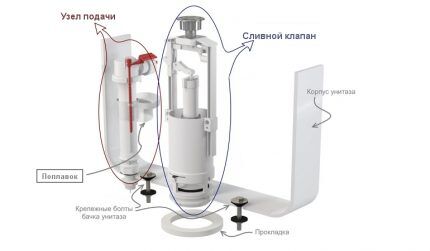

There are only three key mechanisms: inlet, adjustable float, flush and overflow systems:

- Inlet or filling valve stops the flow of water into the tank after it is filled. The required water level is “measured” by the float.

- Lock or drain mechanism. This is the flapper/valve that opens during flushing.

Modern models have buttons for this. They can be single or double to adjust the amount of water flushed. Old Soviet toilets use a chain, lever or rope that is attached to a lever with a bulb. These elements are connected by traction. And the pear is at the bottom of the tank.

Regulates the operation of the locking mechanism and controls the level of collected water toilet float, the design of which depends on the option of supplying water to the tank (bottom or side).

There are several types of floats, but each one has air inside:

- The first, hollow, is made of rubber. It is located at the bottom of the reservoir and functions as a rocker arm.

- The second, plastic, glass-like float. Located at the top of the tank. When the tank is filled with water, it rises up and works almost silently. The latter type is used only in older models; the first type is installed in modern toilets.

The overflow system protects the entire toilet room from flooding if the filling mechanism does not work for some reason. When more than normal water enters the tank, it is cistern fittings flushes it down the toilet. If you find a leak, then do not panic, but remove the toilet lid and figure out what the problem is.

Causes of tank leakage

To find out the exact location of the breakdown, you need to carefully inspect the fittings. Move from checking one part to another until you eliminate the cause of the leak. Prepare the toilet for use. You need to turn off the water using a shut-off valve. It is mounted on the water pipe leading to the toilet.

If there is no such valve, then shut off the water on the pipe leaving the drain. Then remove the cap from the tank. To do this, remove the button or lever. Sometimes it is enough to gently pull the cap and disconnect it from the shut-off valve.

If the button is decorated with a ring, you need to unscrew the system from it counterclockwise. Or pry it with a sharp object and remove it. It’s easy to remove the double button: you need to press on the small, then on the large halves of the mechanism and twist, without removing the pressure, counterclockwise.

Reason No. 1 - breakdown of key valve components

After opening the tank, start checking filling valve. To do this, lift the float lever. If after this water continues to flow into the tank, then the mechanism can no longer hold it. There can be several reasons for the breakdown: either the rubber gasket has worn out, or there is debris under the valve itself, or the valve itself is broken.

Let's move on to troubleshooting:

- turn off the water and rinse;

- then remove the shut-off valve itself;

- thoroughly clean it and the drain hole, wipe and dry;

- inspect the rubber gasket;

- if it becomes unusable, then replace it;

- When completed, you can install the mechanism in place.

If after these manipulations water still flows, then you need to replace the shut-off valve with a new one. Before purchasing, take an old part and try to find a copy or analogue.

To replace it, you should:

- Use a wrench or an adjustable wrench to unscrew the part connecting the valve to the water supply.

- Then remove the float lever, nuts and pull out the lever itself.

- Dry the nuts and lever, if necessary, clean them with sandpaper.

- Install the new valve and all parts in place.

Check your work. Very often the cause of a leak is the float. Let's look at the most common cases.

The float has become depressurized. Because of this, the system cannot stop the flow of incoming water in time, which will subsequently overflow and end up on the floor. This happens if an empty plastic float is used in the toilet for a long time.

Over time, it may wear off and water will begin to flow into it.The ideal option is to install a new element. If this is not possible, then we offer two temporary measures. You can wrap the float in thick cellophane or polyethylene. Or seal the holes with plastic.

To do this you need:

- Turn off the water and rinse, then remove the float, tighten the bolt and wipe it dry.

- Afterwards, cover the crack with plastic (waterproof) or wrap it with polyethylene.

- Dry again, replace the float and check operation.

In any case, try to achieve maximum tightness. Then you will have one to two months to find a new part. In some tanks, the float is connected to a plastic holder. To adjust it, unscrew the nut holding it. Then move it to the desired position and fix everything again.

Float is not set correctly. During prolonged use, the fastening of the mechanism weakens and it becomes loose. To solve the problem, set the float to the correct position and thus the water level will decrease. The material of the holder will tell you how to repair it.

The pin holding the rocker arm may also break. It can be replaced with thick wire. Simply unscrew the old part and install a new one in its place.

Broken float lever due to long-term use. In most cases, it simply bends. Therefore, it must be carefully unbent and fixed in a strictly horizontal position. This part should be located 20 mm from the valve through which water enters the tank.

Siphon membrane fell into disrepair. This part is used in modern toilet models. Unfortunately, it cannot be repaired, but only replaced with a new one. Before purchasing, also check the siphon itself. It may be worthwhile to completely replace the entire mechanism.

The replacement is quite simple:

- drain all the water from the tank;

- turn off the water supply to prevent the tank from filling up again;

- Unscrew the nuts that secure the drain hose using a wrench;

- then do the same with the siphon mount. It is located at the bottom of the tank;

- dismantle the siphon and replace the old membrane with a new one. They must be completely identical;

- Install all parts and nuts in their places.

If the fill valve and float are in order, then the cause of the leak may be a broken drain system or its elements. Most often, the bulb and gasket become unusable.

Rubber bulb failure can provoke a continuous flow of water of varying intensity. The pear is an element of the Soviet-era tank drain system with a side control lever. It should be carefully inspected for damage.

For example, the loss of elasticity of a pear occurs due to constant contact of rubber with hard water. Therefore, the rubber becomes hard and the position of the part on the saddle changes. As a result, cracks are formed that allow water to pass through.

There are two ways to solve the problem.The first one is suitable if you are encountering such a problem for the first time. You can simply make the bulb heavier by placing old nuts or something heavy in it. The second method is to replace the old pear with a new one if the old one has become unusable.

Plaque on the saddle. The pear is located on the saddle. The problem may be the formation of plaque due to hard water and rust settling on the saddle itself. Use sandpaper to remove sediment. If a gap has formed between the saddle and the bulb, you just need to tighten the nuts using a socket wrench.

The gasket in the drain mechanism has become unusable. This can be seen if the plumbing fixture without delay water flows. The only thing that will help is replacing it with a new part. To do this, you need to turn off the water, rinse, unscrew the bolts, lift the tank and replace the old gasket with a new one. After that, install everything in place.

If it has fallen into disrepair drainage system (a device at the bottom of a tank with a diameter of 20 mm), then water will continuously flow into the tank and ultimately flood the toilet. How to check?

Carry out a test: turn off the water, turn on the flush and at the same time press the overflow valve. If the leak stops, then the fixing nuts have loosened. You just need to tighten them a little and check their operation by opening water access to the toilet.

If the problem persists, then you need to drain the tank again and try to completely unscrew the nuts holding the drainage system pipes.If it works, then wind the sealant onto the dried threads of the overflow valve so that it can be installed in the hole at the bottom of the tank.

If not, then pour silicone glue or paint into the gap between the pipe and the bottom of the tank. Leave to dry and check the result. If it is unsatisfactory, then tank repair will require other actions.

Reason No. 2 - damage to the toilet body

A leak may start due to damage to the walls of the tank or problems with its attachment to the toilet. Or if the connecting collar/gasket or seal is worn out. This can be seen visually, or using a paper towel. The paper must be attached to the attachment point. Where it gets wet is where the problem is.

Replacing the cuff or purchasing a special clamp can correct the situation. As a temporary measure, the seal can be secured with construction tape or liquid silicone.

A leak can be caused by the hose connecting the tank and the toilet bowl. If it starts to leak at the attachment point, then we change the gasket, and if it drips from the corrugation itself, then it should be replaced with a new one.

Weak fastening of the tank may be the result of haste or miscalculations by the installers. To correct the situation, you just need to tighten the bolts using an adjustable wrench. In this situation, the main thing is not to overtighten or break the thread. Then you will definitely have to completely replace the toilet.

Cracks on the walls of the tank most often appear due to wear of the fittings or if something heavy has fallen on the toilet. A quick repair can be made using a special ceramic adhesive. You need to understand that this is only a temporary measure and after a while you will have to completely change cistern.

To protect the tank from damage in the future, regularly inspect the fittings and clean them from time to time. Monitor the condition of the toilet sink and check the flexible water hose for leaks.

If you find a puddle on the floor next to the toilet, do not rush to panic. It is possible that this is just condensation formed on the flush tank. It is written about how to deal with this problem in the next article, the contents of which we highly recommend that you familiarize yourself with.

Conclusions and useful video on the topic

The author talks in detail about the structure of the drain tank and shows with an example how to repair the shut-off and overflow valves. Also from the video you can learn about the causes of the breakdown and how to fix it:

The master shows how to eliminate a tank leak using improvised means. It is shown how to adjust the drain valve and install an additional part:

The author offers his own method of repairing a float. He shows in detail how to find out the cause of the leak and repair the fittings:

As you can see, there are no complex elements among the components of the tank. Therefore, if desired, everyone can handle the repairs. The main thing is not to rush and outline a preliminary work plan.

But if you are not confident in your abilities or were unable to fix the problem on your own, then you should contact a plumber.

Would you like to tell us how you corrected the situation with a tank that did not hold water with your own hands? Do you have information about technological subtleties that may be useful to site visitors? Please write comments in the block below, ask questions, post photos on the topic of the article.

I ran into a different problem. Water filled the tank very slowly, and the pressure was clearly not enough to flush the toilet clean. I went through the entire drain mechanism myself. Everything turned out to be simpler than I expected. The water supplied to our homes contains a lot of invisible debris. As a result, the plastic filter became clogged. After thorough cleaning the problem was resolved. However, over time you will have to repeat this procedure.

I once got to the point of flooding this way. The only lucky thing is that the neighbors have waterproof ceilings. When I called a mechanic, it turned out that the problem was in the gasket. So, I also had to pay for a new gasket, and I bought it myself, quickly running to the right store. Now I try to carefully monitor the water pressure.

This is the second time we have bought a float with a valve for a small toilet and none of them hold water!!! It will probably cost less to call a professional!