How to make a chair from polypropylene pipes with your own hands: step-by-step manufacturing instructions

As a rule, after replacing or constructing a water supply system, plastic pipes and fittings often remain.Of course, such material is no longer suitable for reassembling communication networks, but it can be used to make various decorative crafts and practical things.

If you wish and have free time, you can make a chair from polypropylene pipes with your own hands - the assembly technology is very simple and can be done by any home craftsman. Do you want to collect original furniture, but don’t know where to start? We will help you realize your plans.

The article describes in detail three technologies for making various crafts. By following the instructions, you can assemble a children's high chair, a kitchen stool and a portable fisherman's chair with your own hands.

We bring to your attention an article about how to make a desk for a child with your own hands.

The content of the article:

Variety of plastic products

There is something attractive about furniture made from scrap materials. Thus, plastic pipes make it possible to produce structures of ideal geometric shapes. They will add zest to the interior of the room. In addition, the owner of such furniture will have an excellent chance to show off to his friends the masterpiece he created with his own hands.

Chairs made of plastic pipes have the following advantages:

- ease;

- compactness;

- strength;

- ease of manufacture.

And the most important thing is that you can build them with your own hands in a relatively short time. This will require a minimum set of tools and materials, and a little patience.

You need to start making a chair from polypropylene by choosing the design of the product and its design implementation. In this case, you need to start from the function that the furniture will perform.

Having decided on this, they begin to select the parameters of the product: the size of the future structure, its type (collapsible or solid), the method of connecting the parts. You need to draw a rough sketch of the future product in order to understand how much and what material will be needed for the work.

The design of PVC chairs is limited only by human imagination. To get ideas, you can look through interior design magazines or furniture catalogs. You don’t have to look only at plastic products; you can get ideas by looking at furniture made from any material.

Stools made of plastic pipes can be placed in the kitchen, country veranda, garage, and just in the yard - everywhere they will look stylish and original.

For trips to barbecue or fishing, you can build folding chairs that are convenient to store and transport when folded, and they do not take up much storage space.

You can make comfortable and bright chairs for children by covering a frame made of polypropylene pipes with brightly colored fabric.

The process of constructing a chair

Creating an original chair from plastic pipes is within the capabilities of any home craftsman or craftswoman. To work, you will need a minimum set of tools, which are likely to be found in every home and, of course, the remains of polypropylene pipes.

Step 1 - design of the future chair

At the first stage, you have to decide on the purpose of the chair and its design. If you decide to make a bright high chair for a child, you should definitely take into account the height of the little owner.

If you plan to use the stool in the kitchen or cottage, in order not to make a mistake with the size, be sure to measure the height of the existing furniture.

Those who have decided to try their hand at this creative and creative work for the first time may want to start by making the simplest design - a stool. This does not require a lot of skills and materials, and having coped with this task, you can begin to manufacture more complex structures.

For those who are already a little familiar with the technology of working with plastic pipes, you can try making a folding chair. When assembling such a homemade product, you need to take into account the weight of the owner so that the structure does not break during use.

In addition, folding chairs are used on various uneven surfaces (loose soil, sandy shore, slopes), so the structure must be stable.

Having decided on the homemade option, you can proceed to the next stage.

Step 2 - preparing tools and materials

Depending on what type of chair it was decided to assemble, the set of tools and materials may vary slightly.

But, basically, for work you will need:

- PVC pipes with a diameter from 25 to 32 mm - needed to create a structure frame;

- connection fittings – for connecting plastic parts together;

- soldering iron for plastic pipes - if you don’t have it, you can use a lighter;

- piece of thick plywood or thick fabric - depending on what type of chair was chosen;

- screws or self-tapping screws – to secure the seat (in the case of creating a stool);

- tape measure and pencil – to perform the necessary measurements;

- pipe cutters — this tool can replace a hacksaw or a regular knife.

In addition to this set of tools and materials, you may need threads for sewing fabric (it is better to take reinforced ones, since the chair bears increased loads). It is also better to choose dense fabric.

If, in the case of creating children's chairs, you can use ordinary calico, then for folding stools for adults, it is better to choose a more durable fabric - such as raincoat fabric or tarpaulin.

Step 3 - assembling the product

Having prepared all the necessary materials, made a drawing and all the necessary measurements, you can begin cutting pipes and assembling the structure.

To make it more clear, we will look at the process of making polypropylene chairs with our own hands using the example of the three most common designs.

Option No. 1 - kitchen stool

It will not be difficult to build a kitchen stool even for those who have never held a pipe soldering iron in their hands.

To build this homemade product you will need the following set of materials:

- polypropylene pipes with a diameter of 25 mm - the length will depend on the height of the product;

- connection fittings: crosspiece – 2 pcs, tees – 8 pcs, plugs – 8 pcs; it is better to take the latter without thread;

- piece of plywood or a board suitable in size for the seat of a chair;

- self-tapping screws to secure the seat;

- varnish or paint suitable shade.

Having prepared all the necessary materials and armed with a set of tools, you can begin making a kitchen stool.

Work progress:

- The basis of the chair is the crosspiece. To make it, you need to connect a cross, 4 pieces of pipe and 4 tees. The length of the pipe must be taken with a margin, taking into account the distance for soldering the parts. In size, the cross should be slightly smaller than the size of the seat

- The next step is to make the frame of the stool. To do this, using polypropylene pipes of the required length, we connect both crosses together. The presence of plugs allows you to adjust the height of the product if there were inaccuracies in the calculations

- The seat of the stool can be made from a piece of plywood or board, having previously sanded it. Having decided on the size, the seat of the desired shape is cut out using a jigsaw, and then sanded around the perimeter. To attach to the frame, 4 holes are drilled for self-tapping screws so that they coincide with the frame

- At the last stage, we screw the seat to the frame using self-tapping screws and check the stability of the chair. If desired, the product can be varnished or painted in a color suitable for the interior.

As a rule, the standard size of a chair seat is 35*35 or 30*30 cm. For cutting, it is better to use a jigsaw, but if you don’t have one on the farm, a regular hacksaw will do.

The edges of the seat should be sanded with a sander or regular coarse sandpaper. This is done with special care so that there are no uneven cuts left that could cause injury or a splinter.

The parts are connected using a special soldering iron for pipes. If it is not there, you can try to connect the parts by heating them with a lighter. It’s better to buy a soldering iron, especially since such a thing is not very expensive.

The presence of plugs for the legs makes it easy to adjust the height of the stool. So, if the product turns out to be too low, the plugs can be soldered on, thereby increasing the height. If the height is chosen correctly, the plugs are cut slightly to length.

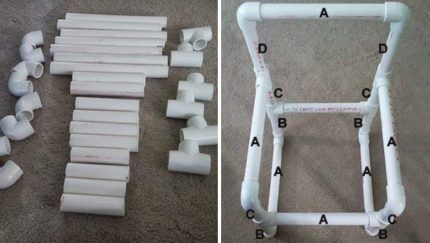

Option No. 2 – children’s chair with a backrest

This homemade product will definitely appeal to the little prankster. Moreover, there are many, many ideas for children’s high chairs.In this material we will figure out how to make a chair with a seat from stretched fabric.

To make a highchair you will need to prepare the following materials and tools:

- PP pipe 3 m long, with a diameter of at least 13 mm;

- pipe angles suitable diameter in the amount of 8 pieces;

- PVC tees - 6 pieces are enough;

- scissors pipe cutting machine or hacksaw;

- glue for polypropylene pipes or soldering iron;

- piece of cloth bright colors of the required size.

Having prepared everything you need, you can start cutting pipes. So, for a child seat you will need to cut 2 pieces of pipe 15 cm each, 7 - 25 cm each, 4 - 10 cm each and another 4 pieces 10 cm each.

Next, you can begin assembling the structure. Looking at the figure presented above, we connect the corresponding sections of pipes with tees and angles. First we assemble the backrest, and then the seat, after which we check the structure for stability.

You should not immediately solder or glue the parts - if a mistake is made, it will not be possible to correct it. If everything is in order with stability, you can attach a piece of fabric for sitting.

To do this, you need to sew a rectangle of suitable size, leaving holes for the crossbars. We disassemble the homemade product and stretch the fabric onto the corresponding crossbars. Now you can connect the structural parts together by soldering or using glue.

As you can see, there is nothing complicated in assembling a child seat from PVC parts. In addition, using the same principle, you can build a chair for adults, but, taking into account the weight of an adult, you need to take larger diameter pipes.

Option No. 3 – folding fishing chair

If you can’t imagine your life without fishing, or one of your relatives or friends likes to fish, then this homemade product will come in handy.

To build a folding fishing chair you will need: PVC pipes, a small piece of dense fabric, reinforced thread, fittings of the appropriate size, a drill or screwdriver, glue for plastic.

Self-construction of a folding stool for fishing will cost several times less than purchasing it in a specialized store. A minimum of materials are required, and they are not very expensive.

Another nice thing is that you can build such a homemade product in literally a couple of hours. Or you can involve your household members in the process - then things will go faster.

We have prepared a series of articles devoted to creating various crafts from plastic pipes. Interesting photo ideas will inspire you to make decorative and practical things, and the proposed instructions will help you realize your wildest idea.

We advise you to read:

- DIY crafts from propylene pipes: homemade options for home

- Screen made of plastic pipes: types of partitions + step-by-step manufacturing instructions

- PVC pipe hanger: popular options + step-by-step instructions

Conclusions and useful video on the topic

You can learn how to independently build a chair with a back from PVC pipes from the following video:

The process of constructing a folding fishing chair:

How to build a folding stool from polypropylene pipes with your own hands:

As you can see, there is nothing complicated in the process of creating PP pipe chairs. All necessary materials and tools can be purchased in the store at affordable prices. In addition, furniture made by yourself will not only be a source of pride in front of friends and relatives, but also a wonderful addition to the interior.

Do you have experience making a chair or other piece of furniture from polypropylene pipes? Please tell readers about your build method. Comment on the post, participate in discussions and add photos of your homemade products.The feedback block is located below.

Indeed, a useful thing can come out of scrap materials. I still have a lot of pipes left after replacing the water supply. I wanted to throw it away, but my hand didn’t rise; I still paid the money. A good chair will always come in handy around the house. I got 2 pieces, made them foldable, like fishing ones, sewed the fabric together for extra strength, and left them in the garage. They came out good, but still don’t buy them.

Very informative selection of photographs and descriptions. In general, I collect materials that show ideas for creating pieces of furniture from consumables that seem not intended for this purpose. I make custom inexpensive tables, chairs, and benches for my neighbors in the country whenever they need it. Everyone in the area already knows that if you need something inexpensive and fast, it’s me)))

Chairs made from plastic pipes should be a very practical thing. You can wash it, they are not afraid of water, you can take it apart and put it back together... It’s a very cool idea, I’ll definitely use it.

Nonsense!!! Folding fisherman - instructions: 4 x 40cm, 4 x 20cm. How will one frame fit into another? the video is nothing, it doesn’t show how much to cut, how to glue with a soldering iron, how to frame one into another, these are the most important details