Scissors for cutting polypropylene pipes: overview of types + instructions for use

Polypropylene is a material that has taken first place in modern plumbing.Many plumbing parts are now made from polypropylene, including pipes and fittings. In this regard, logical questions arise. For example, what tool should I use to cut PP pipes?

We will talk about how best to cut polymer blanks for pipeline assembly. The article we presented describes in detail how to use scissors for cutting polypropylene pipes in practice. The recommendations we give will help you ideally cut pipes with different diameters and wall thicknesses.

The content of the article:

Review of polypropylene pipe cutters

Before starting the review, it is worth clarifying: scissor cutters can cut pipes of small diameters (usually 15-32 mm). Scissors are generally classified as hand tools.

Pipe cutters are used for cutting products with large diameters (32 mm or more). There are manual and electric pipe cutters.

Cutting tools in everyday life are used in pipeline assembly heating systems and water supply in country houses. They will be needed to carry out repairs and modernize existing circuits in city apartments.

Craftsmen who make interesting products will need cutters crafts made from PP pipes, who collects greenhouses and landscaping sites.

All cutting tools are conventionally divided into types, depending on their design:

- scissors;

- telescopes;

- guillotines.

Scissor cutters are precision hand tools. The characteristic “precision” literally means precise. Indeed, precision scissors give an accurate, even cut thanks to the sharp steel blade.

As a rule, such structures are built on the basis of a ratcheting mechanism, which allows you to operate with one hand without much effort. The disadvantage of scissors is that the blades move at a certain angle relative to the pipe surface and result in an ovality defect.

The telescopic tool is structurally designed in the form of a bracket, on the front side of which there are 1 or 2 pairs of metal rollers.

On the back side of the bracket there is a cutting disk mounted on a movable rod. The plastic pipe is inserted between the rollers and the disc cutter, after which cutting is performed using the method of smoothly supporting the cutter and rotating the tool around the axis of the pipe.

Guillotine models are structurally similar to scissors, but in this case the distinctive feature is the exclusively direct stepwise feed of the wedge knife onto the pipe body.

There is a uniform distribution of the load, which gives a better quality cut (eliminates ovality defects after cutting).

There are manual guillotine models and automatic ones, for example, operating from a small-sized battery-powered engine.

Decide on the best pipe cutter model For cutting a polymer pipe, the useful tips outlined in our recommended article will help.

Examples of pipe cutter models

The brand of pipe cutter is chosen based on its purpose and technical characteristics. Sometimes in selection cutting tool They are guided by their own experience and liking for the products of a particular company.

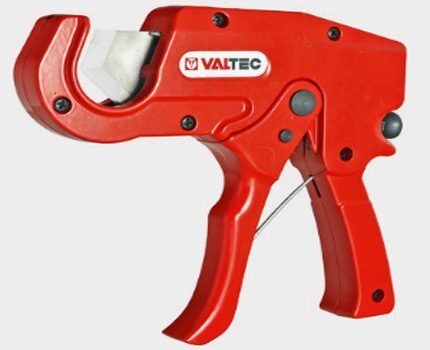

VALTEC

Among the rich variety of cutting tools, we can highlight products from the Italian company Valtec, in particular, the VT m.397 model.

A pipe cutter for metal-plastic and polymer pipes with a diameter of up to 32 mm is available for manual use. Provides high quality cutting at right angles using a guillotine mechanism.

The tool is designed to work with pipes made of polyethylene (including the PEX and PERT series), polypropylene, polybutene, and metal polymer.

I-TECH

Another quite successful example of a pipe cutter (primarily in terms of price) is a product under the “I-TECH” brand. Chinese telescopic cutter, which can process polypropylene metal-plastic pipes up to a diameter of 63 mm. By the way, the same company produces scissors for cutting small plastic pipes.

The design of the I-TECH telescope is equipped with a thin, sharp disk cutter made of alloy steel. Under conditions of moderate productivity, the service life of the cutter will be at least 3 years.

KRAFTOOL

Polypropylene pipe shears from the German company KRAFTOOL, but in Chinese design, are sold on the market under the EXPERT brand. Allows you to cut sleeves up to a diameter of 42 mm.

The cutter is made of alloy steel. The body of the scissors is made of duralumin, which explains the light weight of the tool and fairly high strength.

The perfect ratcheting mechanism ensures ease of operation and requires little physical effort from the user.

MILWAUKEE

Cordless pipe cutters are quickly gaining popularity. As an example of such technology, we can note the product MILWAUKEE C12 PPC-0 from American manufacturers.

Automatic shears work with PEX plastic pipes with a diameter of 12-50 mm. The energy source is a 12-volt battery, allowing you to perform up to 200 cuts on one charge.

You will find valuable tips on choosing the optimal pipe cutter for polypropylene pipes in the next article, the contents of which we advise you to familiarize yourself with.

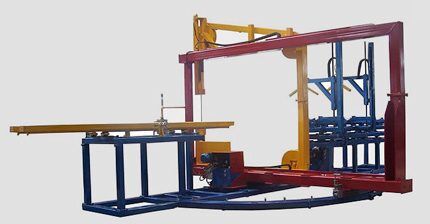

Plastic pipe cutting machines

Professional activities where work is carried out with polypropylene pipes already involves the use of machines. Such equipment is mainly intended for cutting large diameter plastic pipes from 63 to 1600 mm.The machines not only help you perform cutting, but also allow you to do it at different angles.

BADA pipe cutting machines

Among specific examples of machine equipment, we can note, for example, BADA band saws:

- SJC 315;

- SYH 500;

- SJC 1600.

Model 315 works with products with a diameter of up to 315 mm, cutting workpieces at almost any desired angle (0 - 67.5º). With specifics cutting pipes at an angle Using a hand tool, you will familiarize yourself with the article, which we recommend reading.

Among other things, such scissors for cutting plastic pipes can also process tees, crosses, bends, etc.

Band saws SYH 500 and SJC 1600

The SYH 500 radius band saw allows you to work with pipes with a diameter of 63 to 500 mm, process bases and cut at angles, at speeds from 0 to 250 m/min. The SJC 1600 model cuts hoses up to a diameter of 1600 mm at different angles (0-67.5º) at speeds up to 250 m/min.

Equipment for professional use - working with plastic pipes - is a stationary type device. The equipment usually requires power from a three-phase network (380 V).

The weight of the machines reaches several tons, and they are structurally composed of several separate modules. The processing functionality of BADA band saws goes beyond just cutting.

Pipe cutter Exact PipeCut P400

Finnish manufacturers made something similar, but much lighter and not so large, giving the name to their own invention - Exact PipeCut P400. As the name of the machine implies, it is capable of cutting any type of plastic pipe up to a diameter of 400 mm and does this in one pass.

In addition to cutting, the Exact PipeCut P400 supports chamfering at an angle of 3.9º - 15.7º as a separate function. The kit includes two supports for installing pipes - single and double. The Finnish machine can easily be used in the domestic sphere, since it operates on a 220 V network, and its weight is only 6 kg.

Polymer pipe cutters: instructions for use

Of course, scissors for cutting plastic pipes, depending on the design features, come with their own instructions. Regardless of the type of tool and the working conditions, it is recommended to strictly follow the instructions. This approach will protect the user from industrial accidents and help maintain the service life of the tool.

You should always remember: instructions are written with the aim of conveying to the user all the intricacies of working with the tool.

How to use a pipe cutter with rollers?

The user manual for a pipe cutter with rollers usually mentions the following sequence of actions:

- Using a marker, mark the cutting line on the surface of the pipe.

- Unscrew the stop screw to the point where the pipe fits freely into the bracket mouth.

- By rotating the stop screw clockwise, press the disk mechanism with slight force against the pipe wall.

- Rotate the cutter around the pipe axis 360º (the operation can be repeated).

Then repeat steps 3 and 4 until the pipe is completely cut.

It should be emphasized: it is unacceptable to press the cutter disk excessively against the pipe. This action can cause the appearance of microcracks at the cutting point, which will have a negative impact on the quality of work.

The nuances of using scissors for PP pipes

The instructions for cutting a pipe with hand scissors mention the following user actions:

- Use a marker to mark the cutting line on the pipe.

- Place the blade-base of the scissors on the marked line.

- Check the accuracy of the blade installation through a special slot.

- Using little force, gently squeeze the handles of the tool.

Cutting is performed using approximately the same scheme using guillotine shears, with the only difference being that in this case the tool handles must be squeezed several times to achieve complete cutting.

Plus, the guillotine design has a mechanism for returning the cutter blade. Therefore, before each new use, by pressing the return button, the cutter is set to its original state.Typically, maintenance should be performed after 450-500 cuts.

Maintenance consists of actions aimed at cleaning and lubricating all working parts of the mechanism. The tool body is carefully opened, cleaned and the rubbing parts are lubricated with machine oil.

According to the instructions, the tool should be stored in the packaging in which it was purchased. It is prohibited to use a pipe cutter to work with pipes made of materials other than polymer.

If the time has come to replace the knife on the guillotine, it must be dismantled, sharpened or replaced.

The procedure for removing the blade is as follows:

- Place the knife in a position where the heads of the fastening screws are visible in the holes on the body.

- Use a Phillips screwdriver to loosen the mounting screws.

- Remove the blade from the holder body.

Install the sharpened or new cutting element in the reverse order.

Other instruction requirements

Relevant for people who use cutting tools for domestic purposes. Each instruction contains information warning that cutting polypropylene pipes manually and using cutters is considered full-fledged plumbing work.

In fact, work with pipe cutters of various types should be performed only by qualified personnel (at least a 4-5 category plumber), trained and with the appropriate certificates.

Actions with the tool performed by unqualified persons, without permits and certificates, can result in an accident and damage to the tool.Therefore, in such cases, cutter manufacturers decline any responsibility and leave no chance of compensation for damage.

About how to choose tool for cutting metal-plastic pipes, you will learn from the article devoted to this important issue.

Conclusions and useful video on the topic

Some tips on choosing scissors are in the following video:

Pipe cutters for polymer pipes are useful and popular tools designed to greatly facilitate plumbing installation work. Thanks to the variety of designs and models, it has become possible to process pipes of different diameters and any wall thickness.

Scissors and cutters easily cut not only ordinary pipes, but also metal-plastic products. The need for such a tool cannot be overestimated.

Tell us about how you cut plastic pipes with your own hands. Share with site visitors technological subtleties that will be useful when performing this work. Please leave comments in the block below, post photos on the topic, and ask questions.

During my practice I have already ruined about 8 scissors. And not because I’m crooked, or because I buy cheap scissors. At first I bought expensive ones, but they break down just like the ones we have now – after a year or two they are thrown away. Now I take Turkish ones, they normally last the allotted time. I work with small diameters, up to a maximum of 40mm, so I don’t need all these machines, and they’re unnecessary expenses.

For a long time I generally made do with a regular hacksaw. If the pipe is narrow, then you can easily make an even cut and sand the frayed edges.

When I started working with thicker pipes, I bought cutters.Not everything is going smoothly with them; some do not master the declared diameter and begin to mow, and fail within a few months. You'll have to splurge on I-TECH or KRAFTOOL.