How to lay pipes using the puncture method: technical rules and expert advice

If underground communications cross a road or railway, dismantling such objects can be extremely difficult, and often completely impossible. Laying pipes using the puncture method will help solve the problem. This method is much simpler and cheaper to implement.

For those who want to know how pipes are laid in the ground without disturbing ground coverings, demolishing buildings, or moving mobile objects, we will reveal the specifics of the technology. Here you will learn what equipment is used during the work and how punctures are carried out.

In addition to the title method, we described alternative options for laying pipes in the ground using trenchless technology, attached diagrams, photo collections and video materials.

The content of the article:

What is the puncture method?

The puncture method is a technology in which it is possible to obtain a hole without developing and excavating soil by compacting it.

This method is suitable for laying steel structures. The diameter can vary between 100-500 mm, the length of the hole is 30-50 m. Piercing under the road is one of the most popular methods of trenchless installation of communications.

In this way, underground branches of water supply and sewerage are arranged and brought to the site main gas.

A controlled puncture is used for laying:

- communications made of metal and plastic;

- cases into which gas and water pipes are then laid;

- cases for power, telephone cables, etc.

A puncture is used not only in cases where it is necessary to safely cross a highway or railway tracks.

The method is suitable for laying holes in a well (provided that the diameter of this well is at least one and a half meters), the basement of a house, if necessary, running wires under some relatively small object, etc.

Most often, controlled puncture is performed in thick clay soil under various roads, for example, under a highway or railway track. For this purpose, a pump-jacking pressure unit is used, for example, such as an installation Ditch Witch P80.

In addition, you will need a set of expanders, rods, heads and other tools with which drilling work is performed.

Be sure to use a hydraulic station. The necessary force is provided by a hydraulic cylinder; the acceptable power of the unit is about 36 tons. The operation of the station must be ensured by an internal combustion engine. Wireless location equipment is used to monitor the progress of work in the soil.

As an example, we can consider the operating procedure of the location device Eclipse. A probe is placed in the drill head, which transmits information about the progress of drilling operations.

The information is sent to the locator. Here the data is analyzed, as a result of which the exact location of the drilling tool in the soil thickness, the angle of inclination of the drill head, and the compliance of its movement with the previously drawn up work plan are determined. At the same time, the battery condition of the probe from which the information is received is monitored.

The drill head is designed in such a way that part of its surface is beveled. This improves productivity, but affects the quality of work.

Due to the bevel, when moving through the soil, the position of the head will constantly deviate from the vector of influence. The operator must constantly adjust the trajectory of the head, checking the location results.

In order for the tool to move strictly in a straight line, it must be rotated at a constant speed. The first stage of the puncture begins in the starting pit, and is completed in the receiving pit. Here, instead of a drilling head, a conical expander is attached to the installation.

This device passes the resulting horizontal well in the opposite direction, which allows it to expand and compact the walls.

After this, a pipe of the required diameter or a case for laying communications is inserted into the resulting long hole. Depending on the situation, you can lay not one, but several pipes. Further actions are to lay these communications and connect them to the general system.

During the preparatory work, it is also necessary to consider the storage location of the pipes, which should be located near the drilling site.

Typically, a platform for pipes is provided next to the starting pit. The dimensions of the storage area depend on the length of the pipes, which can reach six meters. It is advisable that pipes selected for laying were stored horizontally. This will simplify installation and reduce the likelihood of damage to the structure.

In addition, it is necessary to provide access roads to the starting pit in order to freely deliver materials and equipment necessary for the work.

First, a preliminary survey of the work site is carried out on the ground. In this case, specialists use design documentation, based on which, as well as on the results of the analysis of the object, a plan for performing the puncture is drawn up.

If it is necessary to puncture under an object experiencing serious traffic loads (tram tracks, highways, railways, subways, etc.), the pipes are laid in special cases.

Such a case should have a diameter that exceeds the dimensions of the pipes by about 15-20 cm. First, the case is placed, then the pipes are installed in it, and the space between these communications is filled with a solution, for which you can use an inexpensive cement M-100. The cases reduce the load on underground communications and reduce the risk of damage.

Hydro-, vibration puncture and punching

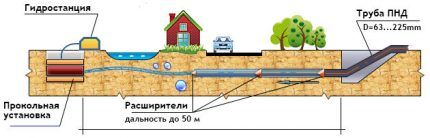

There are hydro- and vibration punctures. In the first case, a water jet is used as a tool for pushing the soil, which shoots out from a special tip under high pressure.

This method is especially effective on cohesive sandy soils that are easily eroded by jets.It allows you to make a hole with a diameter of about 50 cm in a minimum amount of time. But the maximum length of a well with hydraulic puncture is 30 m.

Vibration puncture, as the name implies, is carried out using vibration. The device for performing a puncture uses shock-vibration-pressing installations with exciters of longitudinally directed vibrations.

Static indentation is combined with the impact of a vibratory hammer on the ground. The method is used on water-saturated and low-moisture sandy soils both for laying pipes and for removing them. The diameter of the well can reach 50 cm, and its length – 60 m.

The pushing method is carried out using jacks, just like puncture. But in this case, the pipe is directed into the ground with its open end. As the structure moves forward, a dense plug of soil forms in the pipe, which is then removed.

To perform this type of work, from two to eight powerful (200-400 tons) hydraulic jacks are used, the operation of which requires the installation of a thrust wall with a frame and a cap.

During a shift, such a device can penetrate up to 10 meters of soil, and the total length of the well usually does not exceed 80 meters. If it is necessary to lay a longer route, it is divided into separate sections of no more than 80 meters.

This method also requires the construction of an initial and finishing pit, in which the necessary hydraulics are installed.

Drilling of each section is carried out twice: in the forward direction and then in the opposite direction.The operation of the mechanisms and the quality of pressing are monitored by the operator who is in the pit.

Technically, this method is more complicated than a regular puncture, but it can be used on almost any soil. The diameter of the structure can reach 172 cm. The sampling of the core formed inside the pipe can be done manually or by mechanized means.

Advantages of the puncture method

The demand for the puncture method is explained by its significant advantages compared to other options for performing work of this type. For example, a puncture is available at any time of the year; high or low temperatures of the outside air and soil do not matter much.

The operation of the installation does not require the use of bentonite solution, the supply of water or drilling fluid to the well. This is a compact and powerful unit that is equipped with a reliable electrical safety system. It is not difficult to deliver it to the site and install it. At the same time, its compact dimensions do not prevent the device from working with high power levels.

The work time is also shorter than when using other methods. Even if there is an increased level of groundwater in the area where the puncture is being made, there is no need to take measures to drain water from the area.

During the passage of the expansion cone, the trench walls are also compacted, so additional work in this regard is not required.

Performing punctures on different objects

The complexity and speed of this type of work largely depends on the conditions, i.e. depending on the terrain and characteristics of the object under which the puncture is performed. Drilling under a railroad track usually requires quite a bit of paperwork. First you need to coordinate drilling with a number of railway services.

In Russia, you need to contact the divisions of ECh, ShCh, RCS NODG, PCh and other services of JSC Russian Railways. It is mandatory to draw up contracts for technical supervision, as well as for the installation of insurance packages. All executive documentation must be agreed upon and provided to the railway authorities.

A package of documents is transferred to the distance at the end of the cycle of pipe laying work. In cities, a puncture under the road is in great demand when laying new communications, especially in places with historical attractions.

The method allows not only to maintain normal traffic on the roads, but also to prevent the destruction of the ancient pavement when it is necessary to lay pipes under such areas.

Restoring such an object can be difficult and sometimes impossible. In cottage villages, laying communications using the puncture method allows all work to be completed with minimal damage to already completed objects: roads, fences, etc.

Evaluating Alternatives

In addition to the guided puncture method, there are other options communication devices in the soil thickness without making trenches. Sometimes the alternative may be more acceptable than a puncture, it all depends on the specific situation.

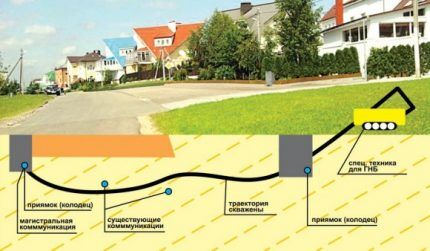

Horizontal directional drilling, which is also called inclined directional, is used for laying pressure and non-pressure pipelines. Drilling using this method is performed from the surface of the earth. The diameter of the hole should be 30-50% larger than the size of the pipes that are supposed to be laid in it.

The hole is not expanded immediately, but in several stages. In this case, a bentonite solution is used, which is mixed with loosened soil and facilitates its removal from the trunk. In addition, this working fluid is used to cool the drilling tool, and later it forms a layer on the walls of the shaft that protects them from destruction.

A sludge pump is used to pump out the spent bentonite solution. After pumping out, the unnecessary solution must be taken to a landfill for further disposal. If the work is done correctly, the result is a clean well with strong walls.

Drilling rigs for this type of work have different characteristics, such as torque and traction. The length of the pipes that will be laid in the soil thickness, which can reach 1000 meters, depends on this.

The permissible pipe diameter is 120 cm. Both metal and plastic pipes can be laid using horizontal directional drilling.

Drilling is carried out along a pre-calculated trajectory, the movement of the drilling tool is controlled using a location system. The drilling angle can vary between 26-34 degrees.

Another important indicator when using HDD is the bending of the rods, which can be 6-12%, depending on their type. Another popular method of trenchless pipe laying is auger drilling. To perform this, a special hydraulic installation is used that acts as a jack.

First, the starting and finishing pits are made. The depth of each of them should be one meter deeper than the level of the pipeline. A hydraulic installation is lowered into the starting pit, which rotates the auger and pushing pipes. As a result, part of the soil is removed and a well for the pipe is obtained.

Then pipes, cases, etc. are installed inside. The maximum laying length is usually only 100 meters, but the diameter of communications can reach 172 cm, the figures largely depend on the type of soil on which drilling is carried out.

To control the work during auger drilling, a laser is used, which ensures the correct angle of inclination of the drill, and also allows you to track the direction of drilling with high accuracy. After the auger reaches the finishing pit, it is removed from the resulting well in the reverse order.

Microtunneling is a high-precision method of trenchless laying of communications, which is carried out using a special tunneling shield.

A high-power jacking station is used to move the device. It affects the column of reinforced concrete pipes that are connected to the shield. Gradually, the length of the well increases, so the length of the column is increased by increasing reinforced concrete structures.

This method also requires the preliminary preparation of two pits, the distance between them can vary between 50-500 meters. The jacking installation must be lowered into the starting pit to a depth that corresponds to the level of the communications. If the well length exceeds 200 meters, an intermediate jacking station is usually used.

The tunneling shield loosens the soil, which is washed away with water or bentonite solution supplied through the supply lines. The waste liquid, mixed with soil particles, moves into the sump through drain lines. After the tunneling shield enters the finishing pit, the work can be considered completed.

The equipment is disassembled and removed. The microtunneling method can be used to install not only reinforced concrete, but also steel pipes. To monitor the correctness of the work, a navigation system is used, consisting of a laser, a target and a measuring wheel.

For long sections (more than 200 m), an electronic laser system equipped with a hydrostatic level is considered effective, which provides accurate information about the depth of pipe installation, regardless of the air temperature inside the structure.

Subtleties of choosing the appropriate method

The method of laying communications using horizontal drilling is chosen at the design stage of a specific process. If trenchless pipe laying is carried out as part of the construction of a facility, for example, a residential building, then the work may become part of the overall construction project.

When designing, the following information is taken into account:

- the length of communications that need to be laid using a trenchless method;

- diameter of the case or pipe;

- the material from which the communications are made;

- the depth to which the pipes must be laid;

- type of pipeline (pressure or non-pressure);

- the ability to install starting and finishing pits of suitable depth;

- access roads to the work site;

- the presence of a sufficiently spacious area for storing materials, equipment, etc.;

- groundwater level;

- other geological features of the site;

- a plan for the location of communications already available on the site.

During the construction process, it is sometimes necessary to change an already drawn up project. This may be due to a desire to cut costs by using e.g. plastic pipes instead of steel. In addition, the plan for the location of underground communications at the site is not always sufficiently accurate.

When performing work, such unaccounted for pipes or cables may be discovered. All these points may require changes in the project, and this may affect the decision on the drilling method.

If the depth of laying communications is small, there is a danger of subsidence of the top layer of soil, especially if bentonite solution was used during drilling. In such cases, it is better to give preference to horizontal auger drilling.

Very often, the drilling method is determined by what kind of equipment is available to the organization carrying out the order.

For example, if builders have jacks or an installation for horizontal directional drilling, then this will be preferred over the puncture method. Most often, such changes are dictated by considerations of economic benefit.

Conclusions and useful video on the topic

The operating process of the installation for performing a controlled puncture is clearly presented in the video:

Controlled puncture is a highly accurate and relatively inexpensive way to lay communications under a road or other object. At the same time, it is important to correctly design all the work and strictly follow the technology.

Would you like to report interesting facts related to pipe laying using puncture technology? Did you have any questions while reading the information provided? Please write comments in the block below the text of the article.

Good afternoon, colleagues. However, we need your services; we need to lay a cable under a street in St. Petersburg, the length is 45-50 m. We are looking for a reliable contractor.

Hello. Unfortunately, you are unlikely to find a contractor here; we cannot make such recommendations, and trusting consumer reviews on the Internet is not always advisable.

We advise you to turn to natural sources, find a company using an advertisement and ask them for the address of at least one property from the portfolio. Don’t be lazy, go there and ask former clients (in general, this information is usually not given out, but many clients don’t mind recommending good workers and most often, the company has 2-3 such free addresses), and then decide whether to trust such performers or not .

The father-in-law lives in the village and has undertaken to supply gas to the house.The desire is good, but obstacles began almost immediately - the gas workers charged him a huge amount. As an alternative, they suggested either laying the pipe under the road yourself, then the amount would be reduced by about 5 times, or trying to get official permission from the administration to open up the asphalt and lay the pipe in an open way.

For now we are figuring out what will be best. Purely technically, there seems to be nothing complicated about a puncture under the road, and all this costs a lot of money. But it is unclear what permits and approvals are needed for this and from whom to collect them.

Hello. First of all, please read the following documents:

1. SNiP 2.07.01-89.

2. ODM 218.3.083-2016 Methodological recommendations on methods for trenchless laying of road culvert pipes.

3. TTC. “Laying utility networks across the carriageway of highways and railways.”

4. TTC. “Performance of work on closed (trenchless) laying of pipelines in steel protective casings (cases) under roads using the horizontal drilling method.”

5. SP 341.1325800.2017 “Underground utilities. Laying by horizontal directional drilling.” Please note that this set of rules does not apply to “the installation of new, reconstructed and overhauled pipelines and branches from them using the HDD method, the design of which is carried out in accordance with SP 36.13330, SP 125.13330.”

6. P. 12.35. Table 15 in SP 42.13330.2011 (photo in attachment).

7. SP 249.1325800.2016 “Underground communications. Design and construction using closed and open methods.”

You can also really go to the administration, since it is the owner of the road, and clarify all the facts, and in addition to this, get all the engineering details of the internal condition of the road and geological surveys. We are sure that they will definitely help you there. Usually they meet you halfway and don’t really need to “knock out” anything.

Also, look at TTC. Laying utility networks across the carriageway of highways and railways. TYPICAL TECHNOLOGICAL CARD. Technological map for laying utility networks across the carriageway of highways and railways." This is usually a regional document, but the requirements for materials and the procedure for the approval process are detailed here.

Something like this. There is a lot of documentation, and yet, it is preferable to go straight to the administration, they will tell you everything quickly and briefly.

Good afternoon, please tell me! We submitted an application to supply gas to the house, they gave us a contract - according to the contract there is a puncture, i.e. the pipe must go through a village road covered with rubble. The road is not paved, the length of the pipe from the main pipe to the house will be a maximum of 8 meters. How legal is it that we were charged with a puncture in the road? Thank you in advance.

Good day. The requirement is legal and justified if the road is on the balance sheet and included in the cadastre, no matter what it is strewn with.

Good afternoon, please tell me which method should be chosen and what equipment should be used if you need to lay a cold water pipe under a residential building about 30-40 meters long.

Dear friends! I am engaged in performing punctures using a hydraulic installation, using one of the methods described above. Not for advertising purposes, but rather to clarify the situation.

There is no need to be afraid of this method of laying communications. In general, this way of crossing a road, another obstacle, or an area of improvement is really much easier and cheaper! Well, just imagine the costs of restoring the excavation site, after which the soil will settle for another 3-4 years. It is especially critical for roads where holes and puddles with potholes form.

Also, when digging trenches, one must not forget that communications are not laid in the ground, but it is necessary to install a special cushion of sand, sand-gravel mixture, etc. under and above the pipe. This is a separate cost and labor-intensive process. When puncturing, the walls of the well are compacted with a force of 32-36 tons, and no additional materials or bedding are required! I consider the trench method to be a rudiment. Puncture is fast, technologically advanced, accurate and accurate!

The project provides for a closed method of laying a gas supply pipeline. The installers decided to carry out the installation in an open way, explaining that it was technically impossible to place the machines and mechanisms. Max. The length of the gasket is 10 meters. Can anyone tell me the overall dimensions of these installations? Or suggest a gasket, how much would it cost?

Hello. My neighbor had a gas pipe laid by piercing. Now they will make a gasket for me next to the one they made. How can I avoid accidentally getting on the laid pipe?

Is it possible to pierce rocks?

Hello.It is possible, but this requires special equipment and an experienced specialist.