Stone sink: advantages and disadvantages of natural stone, comparison with alternative options, installation nuances

Bathroom equipment should be functional, durable and aesthetically pleasing. Natural stone products meet these requirements.What is attractive about the material, what advantages and disadvantages does it have?

In our article, a stone sink is presented in a variety of popular options among users. Products from different species used in the manufacture of plumbing fixtures for many centuries are described in detail. Installation instructions and useful recommendations are provided.

The content of the article:

Features of products made from natural materials

Plumbing fixtures made from natural stone are distinguished by the fact that they are carved from large pieces or combined from several parts. The materials used are soapstone, marble, onyx, basalt, granite, sandstone, travertine and other ornamental minerals that have the necessary strength and can be machined.

Sawing, milling, grinding and polishing are used to give shape.

To reduce the porosity of the outer layer, additional processing is used that does not disrupt the structure of the material and the unique pattern. This provides protection from water penetrating through the pores and household pollutants dissolved in it.

This sink is functional and easy to use.In addition, it will be an excellent indicator of taste and wealth. The aesthetics of the material is expressed not only in the design form of the products, but also in the expressiveness of the pattern and the richness of the color of natural stone.

Some solutions require monotony, others require multicolor or a pronounced pattern of spots, veins, layers and inclusions. Marble, malachite, onyx, jasper have a rich palette; travertine, jade and sandstone provide the most delicate shades.

Onyx sinks are highly polished; plain stones combine perfectly with reliefs. For richly textured pieces, simple shapes and neutral surroundings are preferred. Let's take a closer look at the most popular materials.

Granite

Its relatively low cost makes it the most popular material. Granite comes in different colors. It may be dominated by pink shades, pink-red or gray. Durable, resistant to moisture and chemicals, granite sinks are durable and easy to maintain.

Marble

A product made of material worthy of palace halls will decorate the bathroom. Marble, with its beautiful cool tones, is stunning and brings comfort and harmony to a room.

The material is durable, does not form cracks, does not delaminate, and can withstand severe loads. Its distinctive feature is the complete absence of hygroscopicity; it does not require special care, only standard sanitary actions.

Onyx

The striped fibrous structure of the material looks expensive and luxurious.A variety of shades - from light yellow to dark brown - allows you to create unique designs. Onyx can be completely opaque or translucent with a glass-like shine. Low porosity results in high water repellency.

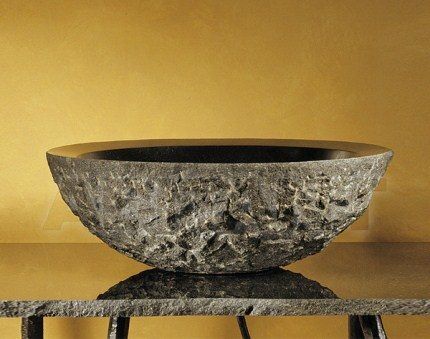

Basalt

A commonly found rock used in the production of exclusive shells. The products are strong and durable, in black, gray and greenish-black shades. Basalt is heavy and at the same time practical, easily processed stone. Resistant to water and chemicals, absorbs sound.

Travertine

A beautiful, light and dark shade, pliable stone with a patterned texture. Strong, lightweight and durable products of various shapes are made from it. The disadvantage is the porosity of the structure, which requires careful care of the products.

A stone sink will be appropriate in any interior style. The combination of a unique pattern, magical energy and design solutions will create a special world in your bathroom.

Production of stone sinks

Stone products are always exclusive; their production is a complex process, which results in real works of art.

Initially, a part is separated from the rock and processed on machines. Subsequent operations are performed manually, as they require special care and meticulous finishing.

Advantages and disadvantages of products

The advantages of sinks made from natural materials include:

- durability;

- greater strength;

- the ability to maintain original novelty;

- high functionality;

- environmental safety;

- temperature stability;

- richness of texture;

- presentableness.

Sinks made of natural stone are individual in shape, size, texture and weight. It is impossible to make similar products from it.

The most common shape is arbitrary, dictated by the outlines of the stone piece, as well as round, square, oval, rectangular or cone-shaped. Complex structures are usually made to order; they can be in the form of a monolith or a figured bowl.

The disadvantage is the large weight of the products, which complicates installation and transportation. Some types of natural stone do not tolerate direct contact with acids and alkalis, which requires more careful care. The main disadvantage is the high price range of the products.

If the disadvantages outweigh the advantages, it is worth considering an alternative option, for example, artificial stone products created on the basis of stone chips with a polymer binder.

Differences between natural stone and artificial

Compared to stone sinks, products made from chips and polymer components are cheaper, but have the same properties, and sometimes even superior. For example, an artificial analogue is able to withstand heavy objects falling on it, but a natural one is not always able to do so.

Externally, washbasins made of artificial stone are difficult to distinguish from natural products, but they are still inferior in quality, as they contain chemicals. If the smoothness of the surface and appearance is damaged, the product can be restored, which is an advantage. They are easily polished and re-impregnated to form a protective layer.

Thanks to the plasticity of the working solution, it is possible to create sinks of various shapes from artificial stone using casting technology. Processing of such products is simpler, cheaper and more technologically advanced. Sinks can be assembled from several parts using a special glue, the strength of which is very high, and the adhesive seams are invisible.

Plumbing made from stone chips

Artificial stone refers to materials such as porcelain stoneware, granitek, silgranite, fragranite and others, which differ in the percentage of the main component, the presence of metal chips, glass and other additives.

The composition of artificial sinks is constantly being improved by manufacturers, which helps to increase the strength and increase the service life of products.

The properties of the material allow you to diversify the design. More and more buyers prefer plumbing products of unusual shapes and colors. In addition to extraordinary options, the assortment includes many classic models, corner sinks, mini-format plumbing fixtures.

The technology for manufacturing artificial stone sinks of medium and low price categories assumes the following composition:

- stone chips – 80%;

- acrylic resin – about 15%;

- coloring pigment – 5%.

Stone chips or aluminum hydroxide in shells make the material more fragile. If the amount of crumbs is below 80%, the products are of poor quality.

Why are artificial products attractive?

In addition to the low price, sinks made of artificial material have many other advantages:

- Attractive appearance.

- A variety of textures and shades that imitate all kinds of materials with a glossy or matte surface.

- Over the course of 10 years of active use, the products are able to maintain their color unchanged.

- Convenient operation.

- Resistance to damage due to mechanical stress.

- Resistance to critical temperatures and thermal expansion.

- Ease and convenience of care.

- Durability of the working surface.

- Hygienic safety, absence of mucous plaque.

- High strength and reliability.

- Possibility of eliminating defects. Potholes and scratches are removed with sandpaper, loose pieces are glued with acrylic glue.

Among the disadvantages, it is worth noting the sensitivity of the surface to very high temperatures, the appearance of cracks and chips when heavy objects fall on the sink. The appearance of products can be spoiled by abrasive substances used for maintenance.

The relatively high price, which exceeds the cost of products made from other materials, also does not suit buyers.

Installation of stone sinks in the bathroom

The installation methods for stone sinks also differ. Products are installed or built into sanitary countertops, which are made from the same stone as the sink, or from a different material. Most often, wood is used for these purposes.

Most common installation methods

It is considered convenient, practical, requiring minimal care drop-in sink. From the outside it is covered by a table top. To install and connect such products, the skills of a novice master are sufficient. This type of sink is installed in a pre-cut hole in the countertop.

The sides of the product are located on the same level with the working surface or rise above it. The countertop hides connections, pipes and drain device, so the design looks neat and aesthetically pleasing.When choosing a cabinet for a sink, it is necessary to take into account the dimensions of its surface, which must be commensurate.

The semi-recessed bowl is partially embedded, the rest protrudes beyond the countertop. It can be deepened completely or along the sides.

Most often among stone sinks they are made in the form overhead type models. In this case, the product rests on a rigid base.

In addition to mortise, semi-recessed and overhead models, there are monolithic (integrated) sinks that form a single whole with the countertop. Due to the absence of joining seams, they are reliable and highly hygienic. The heaviness of such structures and the associated difficulties are their only drawback.

To attach mortise sinks, special fasteners are used, which can be included in the package or selected individually. Sometimes only sealant is used for fixation, which complicates the dismantling process if necessary.

Useful tips for installation and operation

In order for the sink to serve for a long time, you must adhere to the rules of installation and subsequent operation:

- The support must be strong and distribute the weight evenly. The best option is a special forged stand or a tabletop reinforced with a metal frame.

- It is necessary to ensure water drainage and drainage of the sink.

- When installing the drain, you should not create stress in the material; you must be careful when tightening the threaded connections.

- It is necessary to choose a location for the sink that prevents various heavy objects from falling on it.

During operation, it is necessary to take into account that excess moisture can harm the product, and natural or artificial coloring substances can change its color.

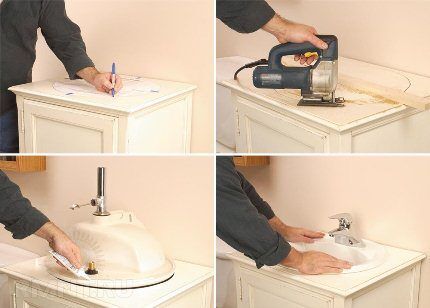

Instructions for installing a washbasin on a countertop

To install a sink on a countertop you will need:

- jigsaw;

- electric drill;

- cutting machine;

- pliers;

- diamond disc;

- screwdriver;

- clamps;

- screwdriver;

- roulette,

- pencil, ruler;

- fasteners;

- brush or spatula;

- sealants;

- clean rags.

Attach the template to the countertop for the future hole for the sink, make markings. Cut it out using a jigsaw and drill. Clean the cut and treat it with sealant.

For processing, you can use epoxy resin or silicone. For countertops made of wood or plastic, an alcohol-based sealant is suitable. It is applied with a spatula or brush, the excess is removed.

If additional fixation is unavoidable, holes are made in the countertop for future fastening. The fasteners are installed on the sink, the bolts are inserted into the slots of the countertop, which is attached to the base. On the reverse side, a gasket is made or silicone is applied along the contour of the sink.

The plumbing fixture is neatly placed in the countertop and pressed to the surface using clamps. The fasteners are secured in the slots and the sink is fixed.To avoid damaging the tabletop, do not over-tighten the bolts.

Conclusions and useful video on the topic

From time immemorial, natural stone and its substitutes have been used to improve human housing. Even more interesting information is in useful videos.

Video #1. What is the difference between artificial stone:

Video #2. Original models of stone sinks:

Video #3. Installing a sink on a countertop:

The market for plumbing products is so diverse that every buyer will be able to purchase products that suit his own taste and capabilities.

The owner of an expensive sink made of natural or crushed stone should take care of professional installation. This will provide additional guarantees of high-quality installation.

Please write comments in the block below. Tell us about your impressions and attitude towards plumbing fixtures made of natural or artificial stone. Share useful and interesting information on the topic of the article, post photos, ask questions.

Friends in a country house had a simply stunning sink made of natural stone, the cost was fabulous. Well, but it surpasses many materials in strength. I myself would not risk spending so much money on a sink, especially since natural stone requires a certain design, otherwise even the most expensive sink will look out of place and even funny.

I think the only advantage of such a sink is its appearance. But this design in itself is inconvenient. It takes up a lot of space, unlike sinks built into a cabinet - it is placed on the cabinet, and there is still space around it that you do not use.It also turns out to be higher than standard sinks.

Such models are appropriate in designer kitchens with a lot of free space.

Agree. A stone sink is terribly impractical. This solution is either for some thematic place - a museum or a hotel, for example. Or for people who really have nowhere to put their money.