Types and purposes of expansion joints for pipelines: characteristics and installation features

Heating networks are long-distance pipe lines that are subject to severe loads both from the outside and from the inside. Therefore, it is difficult to maintain them in technically sound condition. To solve some problems, special elements called compensators are installed in the network. Numerous types of expansion joints for pipelines, presented in a wide range on the market, prevent emergency situations.

The content of the article:

What are compensators used for?

It is necessary to understand that heating networks are pipe systems through which thermal energy carriers move. More often it is hot water, less often saturated steam. Therefore, such highways are subject to two main loads and two minor ones. But even small significance often leads to major accidents.

Main problems:

- temperature changes;

- pressure changes.

Under the influence of these two loads, the pipes either expand or contract. Such movements often lead to deformations, and over time to an increase in overloads. The end result is the destruction of the entire system or section, which is equally unpleasant and economically costly.

Two minor loads:

- vibration of pipes from work pumping units;

- own vibration of the highway itself.

If these two components coincide in amplitude, destruction of the pipe structure will quickly occur, especially at the joints of its elements.

To avoid this, compensators are installed in the pipeline.These are a kind of elastic structures (devices) that dampen not only vibration, but also the consequences of expansion and contraction of pipes. In essence, they compensate for the loads acting on the pipeline.

Under the influence of changing temperatures and pressure, pipes not only expand or contract in the transverse plane. There is such a thing as linear expansion of materials. It occurs constantly in the design of heating network pipelines.

This is a serious load that pipes can only withstand with the help of expansion joints. If they are not installed, then first of all, welds and joints of sections that have been carried out will begin to fail. couplings.

Therefore, today the installation of different types of heat compensators in pipelines of heating networks is a mandatory operation that is not discussed. This is the only way to ensure efficient and long-term operation of pipe heating systems.

What are the dangers of pipe expansion?

A list of what can happen to a pipeline if one of the types of compensators is not installed in it:

- bending of the line, which will negatively affect the speed of movement of hot water, and the supports installed under the pipes will also suffer;

- break in sections at the junction of highway elements;

- the appearance of leaks (this reduces the efficiency of the heating main).

This makes the system short-lived and leads to the need for constant repair work, which affects the cost of the services provided.

Types of devices for compensation

Compensators offered by manufacturers are divided into several types. The classification is based on different parameters. Before making a choice, it is necessary to study what parameters the heating network pipeline will have.Or more precisely, what material the installed pipes were made of. In this case, the system overload must be calculated at the design stage.

Omental

This type was the very first to be created. Although today such fuses are justified. This is especially true for the cost of the product. The stuffing box compensator showed excellent performance. With its help, you can compensate for expansion of the pipeline along its entire length.

But this type also has a number of disadvantages:

- leaks quickly appear at the installation site;

- repairs are not easy;

- does not withstand angular loads well;

- not able to withstand loads from chemically active liquids.

But this type has one big advantage - the longer the pipeline, the more efficiently the compensator works. That is, the reliability of compensation depends directly on the length of the line.

Structurally, these are two shells made of heat-resistant steel with different diameters. During assembly, one is inserted into the other, and a special sealing material is laid between them. During linear expansion, the inner shell moves inside the outer shell. Both elements are attached to the two connecting ends of the pipes.

The compensator can withstand pressures up to 2.5 MPa and temperatures up to +300°C.

Another disadvantage is that it is constantly necessary to tighten the connecting element - the hydraulic axle. Therefore, in the places where the compensator is located, a well is built in which preventive and repair work is carried out.

Rubber

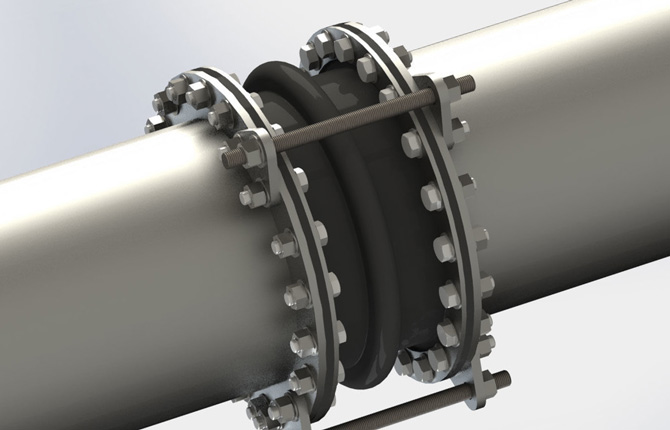

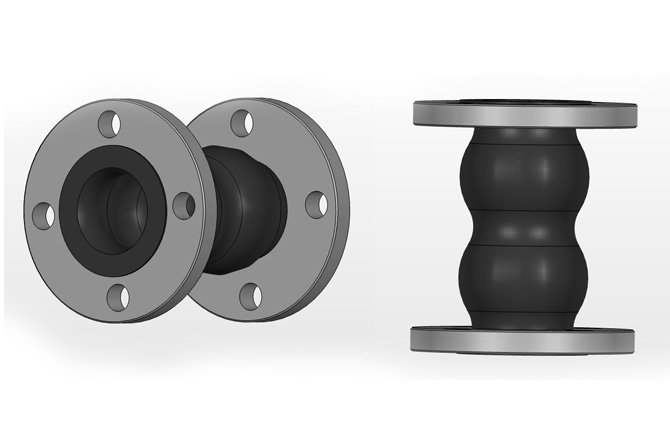

This type is considered universal because it can be installed on heating mains made of steel or polypropylene pipes. Essentially, these are the same two steel shells made in the form of thick flanges. A rubber insert is mounted between them.It acts as a compensator.

This device has many significant advantages:

- easily withstands axial and lateral loads;

- copes well with vacuum, which often forms in different sections of heating mains;

- shows high resistance to aggressive environments;

- has a high cyclicity of “expansion-compression”;

- has a service life of 20 years.

Withstands pressure up to 2.5 MPa, temperature up to +200°C. The reason for the appearance of the rubber look was the poor performance of the U-shaped model, which did not cope well with angular loads.

Fabric

This type is considered special because it was developed not for heating mains, but for gas pipelines. But over time, it began to be used in other pipe systems:

- heating;

- hot water supply;

- networks operated in cold weather;

- pipelines with aggressive liquids and gases.

The biggest advantage of a fabric compensator is its ability to withstand significant temperature changes. In addition, it has increased protection against ultraviolet rays.

Bellows

This type of compensator for pipelines got its name due to its shape. It consists of two corrugations made of two-layer separate steel, inserted into each other. In this case, the thickness of the inner wall is much greater than the thickness of the outer one.

Such design features make it possible to constantly maintain the required technical and operational characteristics of the device.

Lens

This type of compensator is special. It is installed in different areas depending on the material from which the pipeline is made.

- Steel pipes. Installation is carried out either in purge areas or near a pumping unit that operates in the hot water supply system.

- Propylene. They are used on main highways, but with the condition that they are not long.

The device has good characteristics:

- copes well with axial and angular loads;

- works great at high temperatures;

- has high rigidity.

The only negative is that it works unstably, especially under conditions of constant increased complex loads.

The lens compensator is assembled from steel lenses, which are formed by stamping. The technology allows us to produce lenses of any diameter. After which they are simply connected to each other by electric welding. Usually the design contains from one to four lenses, but there are types with a large number of elements, as shown in the photo below.

The connection to the pipeline is made by welding or flanges. Their cross-sectional shape can be round or rectangular.

Other types of compensators

This category includes models installed at heating main turns. It is difficult to take into account the various factors affecting pipelines and their connections. Therefore, two types of compensators are installed in such areas:

- radial;

- U-shaped.

To install the second one, you need to fulfill one requirement. It is based on a box, which is placed on the turning section of the highway. Its width is chosen so that changes in the shape and size of the pipes do not create obstacles to extending the route.

Type of compensator for polypropylene pipeline

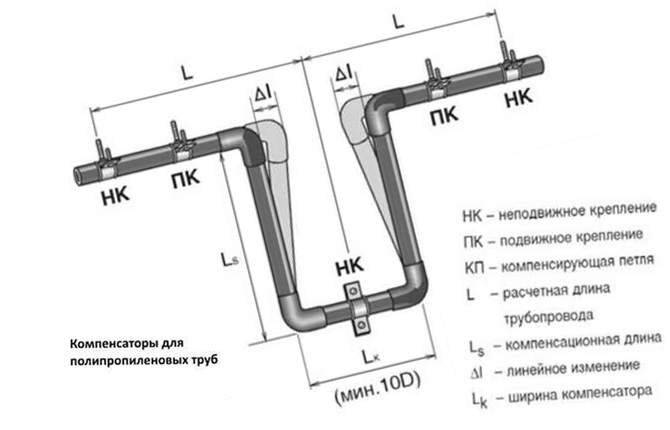

This is the simplest device, which is made from the same pipe as the entire pipe system. The form used is a loop, which provides maximum compensation for the linear expansion of polypropylene pipes.

Such a protective device easily copes not only with pipe movements and changes in their sizes, but also with water hammer, which are often found in pipe structures.

U-shaped expansion joints are also often used in polypropylene structures. They are easy to make from the same pipes. But there are certain nuances that relate to the method of fastening sections of the device:

- in the middle of the structure a rigid, or fixed, fastening is used;

- at the points of connection to the pipeline - sliding or movable fastening.

In the photo below, the design features of the compensator are clearly visible.

It is important to correctly calculate the parameters of the compensating device. Here the ratios of the lengths of different sections of the compensator itself are taken into account. Main positions:

- The optimal ratio of the width of the device to its reach (length) is 1:1.5.

- The ratio of the projection to the total volume of the device is 1:4.

- The tension in the backrests is no more than 1.1 MPa.

- The temperature of the liquid flowing inside is no more than +200°C.

- The pressure inside the pipeline is no more than 1.6 MPa.

Additional recommendations:

- The U-shaped compensator can only be installed on horizontal sections;

- complete symmetry is required - the shoulders are located at the same distances;

- the device should not be exposed to external loads: wind, shocks, etc.;

- The design uses standard smooth plastic bends.

Another type suitable for polypropylene pipes is the so-called Kozlov mechanism. It is used in heating and hot water supply systems, where pipes with a diameter of no more than 63 mm are installed. Therefore, manufacturers offer devices that can withstand temperatures of no more than +100°C and pressures of 1.6 MPa.

This compensator is included in the category of bellows models. Purely structurally, this is a bellows made of two-layer steel 1.5 mm thick. The compensator is enclosed in a polypropylene pipe that acts as a casing. Couplings are installed at the ends, with the help of which the structure is welded to the pipeline.

Features of installation of compensating devices

Any installation operations on sections of heating mains are carried out strictly according to the design. This document specifies exactly where the expansion joints will be installed. You cannot change them without permission. Any additions or deviations from the project will lead to irreparable consequences.

The connection of expansion joints to pipelines is carried out by welding or flanges. When using polypropylene products - soldering or welding.

Before fastening, the joints between the ends of the pipes and expansion joints are aligned along the same axis. Even the smallest shift cannot be allowed. It will lead to an increase in lateral loads precisely at the incorrectly installed joint.

All work is carried out during pipeline installation. There are some requirements:

- a support must be installed under the stuffing box;

- suspended support structures cannot be installed under the bellows type;

- installation is carried out only in horizontal and vertical sections;

- the compensator itself is installed on a horizontal section of the pipeline so that its arrow on the body indicates the movement of the coolant;

- if installation is carried out on a vertical section, then installation is carried out with the arrow pointing downwards, regardless of the direction of movement of hot water.

Compensating devices cannot be repaired. They can only be replaced with new ones.

Compensators play an important role in the efficient operation of heating pipelines of various types and purposes.Today, without them, not a single pipe line through which liquids and gases move under high pressure and at elevated temperatures is in operation.

If you liked the article, bookmark it and share it with friends on social networks. If you have any questions, we are ready to listen to them in your comments.

We also recommend watching a selection of videos that will reinforce your knowledge and answer any remaining questions.

Bellows expansion joints - types.

The Kozlov compensator is an elegant solution for heating and water supply.

Sources:

- https://trubanet.ru/truby-dlya-otopleniya/kompensatory-dlya-polipropilenovykh-trub-silfonnye-p-obraznye-kompensator-kozlova.html

- https://m-strana.ru/articles/kompensatory-dlya-truboprovodov

- https://iseptick.ru/truby-i-fitingi/polipropilenovye-truby/kompensatory-dlya-truboprovodov.html

The question is: is a compensator needed in heating if a pipe with a diameter of 32 mm is used?

It all depends on the water temperature. If it is no more than 70-80 degrees, then there is no need to install anything. If the temperature reaches the boiling point, then it is better to install.