How to assemble a sink drain: instructions for installing a drain with overflow

The sink drain, like any other plumbing equipment, is vulnerable to breakdowns and often the home handyman is faced with the question of replacing the device.Its installation is a simple procedure, for which there is no point in inviting a professional plumber.

Let’s take a closer look at how a sink drain works and what nuances to consider when choosing a device. We will also describe the step-by-step technology for assembling and installing the drainage device.

The content of the article:

Purpose and design features

A sink drain in a bathroom or kitchen with an overflow is a curved structure, the key purpose of which is to redirect excess water into the drain, thereby preventing the sink bowl from overflowing.

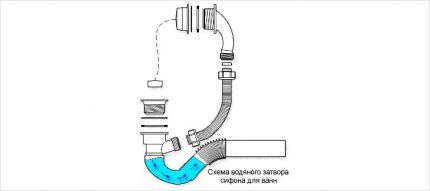

Device bath drain system almost identical to the design intended for the sink.

Structurally, the overflow drain for a sink or sink consists of the following elements:

- siphon with water seal – is a “U”-shaped element that performs a dual task: it prevents the emission of foul odor from the sewer and protects the drain pipe located below from clogging.

- a drain pipe – made of corrugated or rigid plastic pipe and designed to redirect wastewater into the sewerage system.

The main secret of the functionality of the siphon is in its design. Due to the bending, the water does not completely leave the pipe. The formed water seal acts as a barrier to the penetration of sewer “ambre” into the drain hole.

Such designs are convenient because if they become clogged, they can be easily removed and cleaned mechanically or chemically.

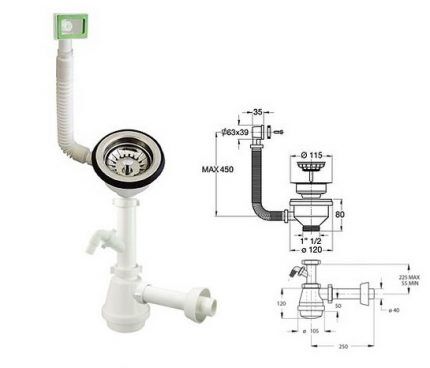

Do you want to install a more durable device that is less prone to clogging? In this case, it is better to purchase a design in the form of an overflow drain for the sink. It differs from traditional models in that it is equipped with an additional tube.

This device connects the hole made in the upper side of the side of the bowl with the elements of the drainage system located in front of the siphon. Thanks to this, the overflow drains liquid from the sink, thereby preventing the bowl from overflowing.

From the outside, the drain hole is covered by a grill. It performs a protective function, trapping small debris and hair, thereby protecting the system from clogging.

Main types of drain devices

There are several types of drain systems. One of the most common options is a design in which the drain is secured with a large locking nut.This method of fastening can be found even in the bathrooms of houses built more than two decades ago.

Classification by device principle

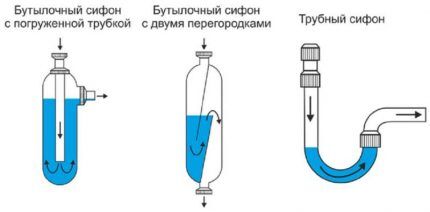

Drain siphon systems used when connecting sinks come in three types: flask-shaped, elbow and combined.

They differ according to the type of construction:

- Bottle or flask-shaped. The main structural elements are two cylinders immersed in each other. A tee is installed inside the flask of the device, distributing the liquid and forming a hydraulic barrier.

- Pipe. The main element of the double-turn design is the “S” or “U”-shaped bend of the pipe, which forms a hydraulic barrier.

- Mixed type devices. In addition to the structural elements of the bottle structure, supplemented by two partitions, they are equipped with a corrugated hose.

In bottle-type devices, the waste, entering the siphon, moves down through an internal pipe of smaller diameter. Having reached the bottom, the wastewater rises through the cavity between the inner and outer cylinders and is discharged into the sewer pipe.

Bottle siphons are advantageous in that even with rare use of the plumbing fixture water seal in the sewer system does not dry out for quite a long time. This effect is achieved due to the fact that the outlet from the siphon is located approximately in the middle of the flask.

Many owners prefer bottle siphons for the reason that, if necessary, they can always connect several drains. To do this, the structure only needs to be equipped with an additional element.

Siphons of mixed type have proven themselves to work well. The corrugated siphon, used when arranging a mixed-type drain structure, is a modified version of a conventional curved tube.

Unlike analogues of bottle and pipe versions, among the combined options there are no models with sockets, and therefore they cannot be connected to overflow systems and household appliances.

Division by material of manufacture

Available for sale sink drains Depending on the material of manufacture, there are two types: those made of polymers and those made of metal alloys.

Polymer products are famous for their low price and ease of installation. Structures equipped with a corrugated pipe can be conveniently adjusted in length.

But the service life of PVC structures is relatively short. And the sealing properties of the assembled structures leave much to be desired. Therefore, all joining elements must be equipped with rubber gaskets during assembly.

In terms of reliability and durability, metal elements of drain systems are more beneficial. The models made of non-ferrous metals: brass and bronze are most in demand in everyday use.The harness made from such materials often has a chrome coating, due to which it acquires a rather presentable appearance.

To prevent the accumulation of dirt deposits on the inner surface of the walls during the manufacturing process, manufacturers coat metal products with a protective film of chromium.

Installation of metal structures does not present any particular difficulties. A hitch can only arise at the stage if you need to shorten the outlet pipe.

Siphons for non-standard equipment

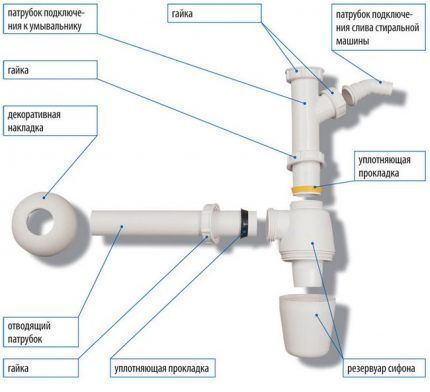

For non-standard models of double “pair” sinks, siphons equipped with two outlets are used. Such siphon devices are connected to the drains of both sinks, and a little lower along the flow of waste water they are combined into a common flask.

Do you need to connect a sink located on an open shelf to communications? Then choose a model that offers hidden installation. Yes, the price will be somewhat more expensive than traditional options, but it will allow you to completely hide unesthetic elements of communications.

Drain systems of such designs will not be difficult to hide in a niche, covered with a decorative screen. But it is worth remembering that if the bend of the outlet pipe is too short, there is a high risk of an unpleasant sewer “aroma” appearing.

Technology for installing a drain with overflow

There is nothing difficult about installing an overflow drain on your own. Each device usually comes with instructions. It contains information about the order in which the structure should be assembled.

The simplest path will be taken by an independent craftsman who installs a sink with an overflow channel provided in the design of the sink:

Step 1. Preparation of necessary materials and tools

With all the variety of models of drainage equipment siphon installation technology almost identical.Therefore, even if your plumbing fixture had a drain system installed, for example, a bottle type, you can easily replace it with the same combined option.

The standard siphon package includes the following elements:

- device body;

- outlet pipe;

- decorative cover for drain;

- plastic and rubber cuffs;

- connecting nuts and screws;

- rubber flat gaskets.

To better understand the sequence in which you need to assemble the structure, lay out all the elements of the siphon on a table or on the floor.

It will be impossible to install the system without a set of necessary tools.

To work you will need:

- flat screwdriver;

- adjustable wrench;

- FUM tape;

- sealant;

- container for collecting water;

- cotton fabric.

If during the work you need to cut pipes and corrugation to the required size, prepare a tape measure and a hacksaw in advance. To sand the edges of the pipe, use sandpaper.

Step #2. Removing the old siphon

To remove an old siphon device, you need to unscrew the screw installed in the center in the grate located in the drain hole.

Often the drain grate screw and nut “stick” to each other during operation.If you can’t unscrew them, then first dismantle the lower part of the siphon, leaving the upper pipe intact. By rotating this part you will help free the stuck nut and screw.

From the moment you dismantle the old siphon until you start connecting the new equipment, it is better to “clog” the sewer pipe with a rag or plug of the appropriate size.

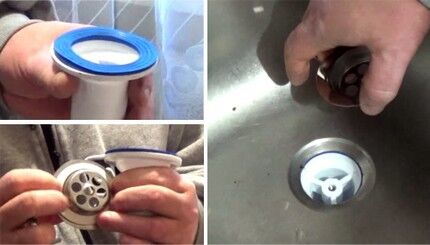

Step #3. Assembly of structural elements

When installing a pipe drain system, the structure can be assembled during the installation process, sequentially “stringing” all the elements. If you have to work with a flask-shaped system, before assembling such a drain for the sink, it is necessary to carry out a number of preparatory work.

First of all, the device is placed under the bowl and preliminary fitting is performed to ensure that the dimensions match. After this, check the reliability of the lower plug.

To do this, unscrew the plug along the thread and inspect whether there are chips or other flaws in the rubber seal. This step should not be neglected, since the lower plug constantly takes on the pressure of the system.

If burrs are found on the surface, they can be cut off with a sharp knife. If not removed, they may damage the O-ring during installation.

Having ensured the quality of the installed gaskets and threaded connections, proceed to assembling the flask.

The work is carried out in several stages:

- Putting a rubber gasket on the threads of the device, screw the bottom.

- A gasket is placed on the ends of the spout tube, and a tightening nut is placed on top.

- By inserting the end of the spout tube into the hole in the upper part of the siphon body, fix it in a given position by tightening the nut.

- Having equipped the device cover with a rubber gasket, the drain is screwed to the body with a nut.

To increase the reliability of the connection, the ring gasket inserted into the groove must be coated with a sealing compound. They should also cover the lower part of the threaded connection.

After this, the sink is installed in its seat and the installation of the drainage device begins.

Step #4. Overflow assembly features

When dealing with models equipped with overflows, before assembling this element, you need to determine the height of the tube. This parameter must correspond to the depth of the bowl. If everything matches, the tube is connected at a given height to the main pipe.

If the overflow tube is a prefabricated structure, then its height can be easily adjusted using the principle of telescopic extension. The corrugated pipe is simply stretched to the required length and bent in the right place.

When fixing the overflow tube to the sink, do not forget to place the included rubber gasket between the surfaces. The connection point of the outlet with the overflow pipe is secured with a clamping nut. To avoid damaging the connection, tighten the nut by hand without applying much effort.

Step #5.Installation of a drain device

Before connecting the assembled structure to the waste system, the surface of the sink in the area of the drain hole is thoroughly degreased and cleaned. During the installation process, the first step is to combine a protective grille equipped with 5-6 divisions with the drain hole of the bowl.

The upper end of the outlet pipe is equipped with a rubber gasket and connected to the hole in the sink. Pressing the upper side of the pipe tightly against the drain, fix it using a D6 mm screw inserted into the protective grill.

The thread into which it must be buried is pressed into the body of the pipe itself. When tightening the screw with a flathead screwdriver, it is important to achieve as tight a seal as possible while avoiding rotation of the flange and gasket.

The lower end of the pipe is chamfered. This is necessary in order to ensure free insertion of the end of the pipe into the siphon cavity.

A plastic coupling nut is “strung” onto the outlet pipe, placing it with the thread downwards, and a conical gasket, placing the wide side towards the nut. Then they connect it to the outlet pipe, not forgetting to seal the connection.

To connect the outlet pipe to the sewer pipe, the diameter of which is traditionally 50 mm, an installation rubber collar is used.

To ensure that it tightly covers the pipe, thereby preventing the spread of sewer “odors,” a product is used whose internal diameter is slightly smaller than the outer diameter of the outlet pipe.

Tip: if the diameter of the outlet does not match the size of the sewer pipe, use a ready-made plastic adapter.

The corrugated siphon is extremely easy to connect. It is equipped with two rigid pipes at both ends. To connect it, you just need to attach it to the outlet pipe, then stretch it a little and give it the desired bend. After this, remove the second pipe to the sewer.

Step #6. System health check

At the final stage, all that remains is to check the tightness of the connections and the functionality of the system. To do this, the area of the floor under the siphon is covered with a piece of cotton napkin or a paper sheet. Some craftsmen place a container under the siphon for this purpose.

Open the tap and watch as the water goes into the drain hole and, passing through the siphon, falls into the sewer.

If there are no leaks at the joints and no drops appear on the napkin, the work has been done efficiently. If any are found, tighten the nuts more tightly, and the connection is additionally sealed.

Technology for installing branched siphons, allowing connect washing machines to the general drain, there is practically no difference. The only difference is that flexible hoses coming from household appliances are additionally screwed to the outlets of the structure.

For those who are planning to install and connect a new sink to the sewer system, we recommend that you read the article Installing a bathroom sink: installation instructions for modern models

Conclusions and useful video on the topic

Video review on how to properly assemble a siphon:

Sink installation and drain connection:

Modern sink drain models are not that difficult to install. The main thing is to correctly select the model that is optimally suited for specific conditions, and strictly adhere to the installation instructions.

We invite everyone interested in installing a sink drain to leave comments and ask questions. Please share your personal experience with plumbing connections. The contact form is located in the lower block.

The sink drain had to be installed more than once. It gets clogged from time to time, mostly in kitchen sinks. There is a lot of grease and similar contaminants where dishes are washed. To clean the drain under the kitchen sink you need to disassemble, clean and put it back together. Also, drain components sometimes break, and then you have to replace them. It’s easy to change, you just need to tighten all the connections that are on the threads properly, but don’t overtighten them so they don’t burst!

A couple of months ago I had to replace the sink and cabinet in the bathroom. Since the work is troublesome, I need to dismantle the old sink and install a new one with the dimensions for the cabinet, I decided to call a professional. When it came to installing the siphon, the master rejected the one I purchased in the store and recommended a siphon whose drain pipe was smooth, without bends, and not corrugated. He explained that this option involves a lesser degree of contamination of the tube walls. Is it so?

I didn't understand one thing. The sink overflows through its internal cavity. Why does this cavity have two holes at the bottom? The drain hole was closed with a plug and the overflow occurred on the floor.